Experimental study of curvature effects on jet impingement heat transfer on concave surfaces

Zhou Ying,Lin Guiping,Bu Xueqin,*,Bi Lizhn,b,Wen Dongsheng,b

aSchool of Aeronautic Science and Engineering,Beihang University,Beijing 100191,ChinabSchool of Chemical and Process Engineering,University of Leeds,Leeds LS2 9JT,UK

Experimental study of curvature effects on jet impingement heat transfer on concave surfaces

Zhou Yinga,Lin Guipinga,Bu Xueqina,*,Bai Lizhana,b,Wen Dongshenga,b

aSchool of Aeronautic Science and Engineering,Beihang University,Beijing 100191,ChinabSchool of Chemical and Process Engineering,University of Leeds,Leeds LS2 9JT,UK

Anti-icing system;Concave surface;Curvature effect;Heat transfer;Jet impingement

Experimental study of the local and average heat transfer characteristics of a single round jet impinging on the concave surfaces was conducted in this work to gain in-depth knowledge of the curvature effects.The experiments were conducted by employing a piccolo tube with one single jet hole over a wide range of parameters:jet Reynolds number from 27000 to 130000,relative nozzle to surface distance from 3.3 to 30,and relative surface curvature from 0.005 to 0.030.Experimental results indicate that the surface curvature has opposite effects on heat transfer characteristics.On one hand,an increase of relative nozzle to surface distance(increasing jet diameter in fact)enhances the average heat transfer around the surface for the same curved surface.On the other hand,the average Nusselt number decreases as relative nozzle to surface distance increases for a fixed jet diameter.Finally,experimental data-based correlations of the average Nusselt number over the curved surface were obtained with consideration of surface curvature effect.This work contributes to a better understanding of the curvature effects on heat transfer of a round jet impingement on concave surfaces,which is of high importance to the design of the aircraft anti-icing system.

1.Introduction

Heat transfer associated with jet impingement on a flat or curved surface has been the subject of extensive investigation for decades because of its enhanced local heat exchange performance in a wide variety of applications such as glass tempering,metalannealing,and engine and turbine blades cooling.1,2Impinging jets are also used in the hot-air antiicing system of commercial aircraft where high-pressure hot air,bleeding from the engine,is ducted forward to a pipe with several small holes on it and impinges on the inner surface of the anti-icing cavity to heat the leading edge of wing.Since the anti-icing cavity is a curved surface,the effect of surface curvature should be taken into account when the jet impingement heat transfer performance is considered.

Many experiments were designed to study the heat transfer of impingement jets,with a focus on flat plates.The very early experimental work for the flat plate case were represented by Gardon3,Goldstein4,Hrycak5and Beltaos et al.6with varying impingement distance,Reynolds number and oblique angle.Many measurement techniques based on naphthalene sublimation technique7,temperature-sensitive liquid crystal8,9and thermal infrared camera10,11were adopted to measure and analyze the flow and heat transfer characteristics.

Metzger et al.12were probably the first to experimentally investigate the heat transfer characteristics of jets impinging on a concave cylindrical surface.The average heat transfer coefficient of single lines of circular jets was obtained with varied ratios of nozzle to surface distanceHand nozzle diameterdat the Reynolds range from 1150 to 5500.Results indicated that the maximum heat transfer could be obtained at the optimum relative nozzle to surfaceH/d=3–5,whose value decreased with increasing Reynolds number.Compared with the heat transfer performance on a flat plate,the stagnation point Nusselt number was higher on the concave cylindrical surface as reported by Hrycak.13Mayle et al.14also presented that the heat transferred to the boundary layer on the concave plate was greater than that on a flat plate.

Flow visualization facilities with smoke generation wire were applied by Gau and Chung15and Cornaro et al.16to visualize the flow structure of slot and round jet impinging on concave surfaces.The former result showed that the Nusselt number increased with increasing surface curvature for slot jet impingement on a concave surface,which was caused by the initiation of Taylor-Go¨rtler vortices along the surface.Similar observation was also obtained by Cornaro et al.16,who also found that the heat transfer rate on and around the stagnation point increased with increasing surface curvature.Lee et al.17experimentally investigated the local heat transfer from a long round jet impinging on a smaller relative curvature surface(d/D=0.034,0.056,0.089)with jet Reynolds number from 11000 to 50000.Similarly Yang et al.18investigated the concave effect but using a slot jet in the range 5920≤Rej-≤25500,with a fixed slot-width to diameter ratio of 0.033.Their conclusions were consistent and indicated that the surface curvature and generation of Taylor-Go¨rtler vortices were able to thin the boundary layer and enhance the heat transfer rates further in the downstream region apart from the stagnation point.

Since last decade,impinging jets have been applied to hotair anti-icing system of aircraft and much progress has been achieved.Brown et al.19experimentally investigated the heat transfer in an aircraft nacelle anti-icing system and a correlation of average Nusselt number on the impingement area was presented with consideration of the distance between the jet holes and the jet Reynolds number.Papadakis et al.20,21conducted experiments in the NASA Glenn Icing Research Tunnel for a range of external conditions representative of inflight icing.The effects of hot air mass flow and temperature,angle of attack,tunnel airspeed and piccolo jet circumferential placement were investigated.Imbriale et al.22used IR thermography to measure 3D surface heat transfer coefficients by a row of jets impinging on a concave surface,representing an airfoil leading edge,and the influences of jet inclination,jet pitch and Reynolds number were analyzed.A more recent study by Bu et al.23investigated the heat transfer characteristics of jet impingement on a variable-curvature concave surface of a wing’s leading edge experimentally.Parameters including jet Reynolds number,relative nozzle-to-surface distance and jet circumferential placement were considered for the effects on local Nusselt number distributions.

All of above researches indicated an enhanced heat transfer performance of jet impingement on concave surfaces.However the confinement effect of concave surface,which could decrease the heat transfer effect,was seldom studied.When studying 3D temperature distribution of a concave semicylindrical surface impinged by round jets,Fenot24noticed that the confinement effect actually reduced heat transfer as the average Nusselt number for the flat plate was higher than that for the curved plate.It was believed that the confinement prevented ambient air from mixing with the jet air,and thereby increased the flow temperature.The range of Reynolds number was from 10000 to 23000,and the relative surface curvatured/D=0.10,0.15,0.20 andH/d=2–5.

O¨ztekin et al.25investigated the heat transfer characteristics of slot jet impingement on concave surface for jet Reynolds number from 3423 to 9485 and the dimensionless surface curvatureR/L=0.50,0.75 and 1.30,whereRwas the surface radius andLthe surface trace length.Results indicated that,compared with the flat plate,the average Nusselt number along the concave surface was larger whenR/L=0.75 and 1.30.The average Nusselt number increased with increasing dimensionless surface curvatureR/L,in other words,with decreasing relative surface curvatured/D.A slight increase in Nusslet number with decreasingd/Dwas also observed in Martin and wright’s experiment26with single row of round jets impingement on a cylindrical surface.This trend was more prevalent for larger nozzle to surface distances in the range of jet Reynolds number from 5000 to 20000,relative nozzle to nozzle spacing from 2 to 8,nozzle to surface distance from 2 to 8,andd/D=0.18,0.28.

As briefly reviewed above,although different studies have shown that surface curvature enhanced the heat transfer,detailed mechanism of heat transfer decay on a concave surface is still not well understood.This work conducted an extensive experimental study focusing on the curvature effect along the curved surface.By analyzing the stagnation point Nusselt number,and the average and local Nusselt number distributions in chordwise and spanwise directions,both the enhancement and confinement effects of the surface curvature were investigated.In addition,experimental data-based correlations of the average Nusselt number over the curved surface with consideration of the surface curvature effect were presented and experimentally verified.

2.Experimental apparatus

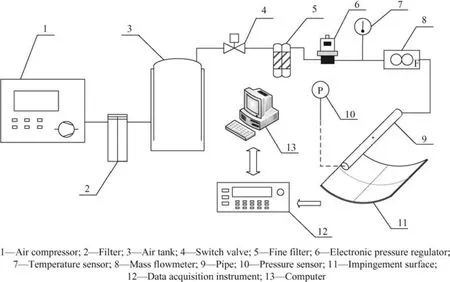

Fig.1 schematically shows the jet impinging system used in this investigation.The main elements of the experimental apparatus were a steel pipe with a round nozzle on it and an impingement surface.Both were mounted on independent brackets to keep the surface horizontal and the pipe vertically removable for different nozzle to surface distances.As indicated in Fig.1,the high pressure air from the air compressor became much cleaner and more stable after passing through the filter and air tank,and then went through the electronic pressure regulator where its pressure was adjusted to the desired value.The adjusted air flowed into the pipe from one side and injected into the center of the surface normally through the nozzle.The other side of the pipe was sealed and the pressure inside the pipe was measured by a pressure sensor.The mass flow through the nozzle was measured by a mass flowmeter.The steel pipe had an outer diameter of 20 mm with an inner diameter of 16 mm.Nozzles with diametersd=1,2,3 mm were used with the nozzle to surface distanceH=10,20,30 mm,respectively.

Fig.1 Schematic of experimental apparatus.

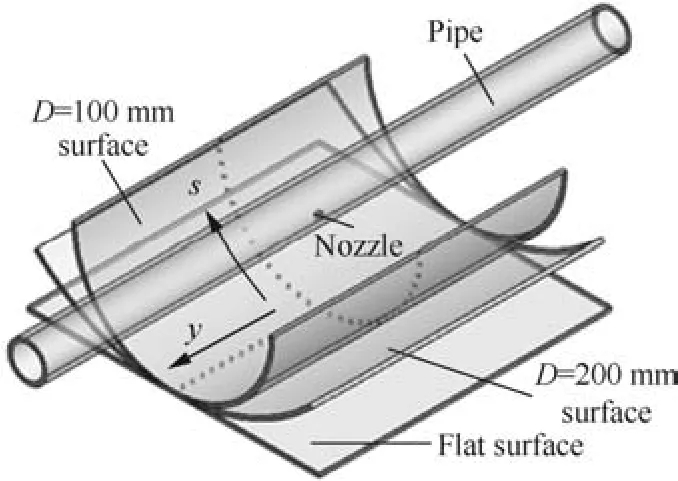

The impingement surfaces with different diameters ofD=100 mm,D=200 mm and a flat surface(regarded asD=1)manufactured from aluminum plates with a thickness of 2 mm were used in the experiments(Fig.2).All of these surfaces are kept square with a constant length ofL=150 mm.The relative curvatures can be calculated in Fenot’s way24:Cr=d/D=0.005–0.030,or in O¨ztekin’s way25:D/L=0.67,1.33.

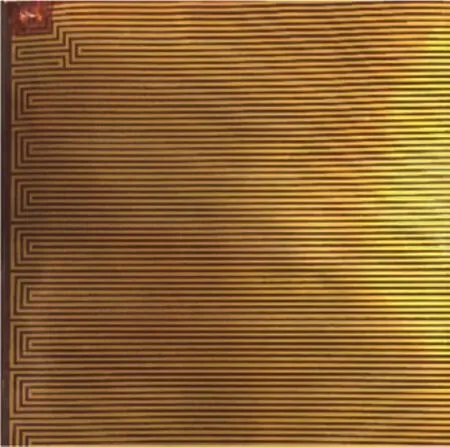

A thin film(0.02 mm thickness)electrical heater made of constantan provided a uniform heat flux on the opposite side of the jet impingement side of the plate.The high pressure jet impinges on the impingement surface as the coolant.This film was engraved as an electronic circuit with equidistant(2 mm width)constantan wires(Fig.3).Both ends of the film were connected to a DC power supply.In order to reduce the heat loss through the constantan film heater to the ambience,the rubber sponge which has high thermal resistance was employed to cover the film heater so that most of the heat would be conducted to the impingement surface,and the small heat loss was corrected in the preliminary test,as described subsequently.

57 type T thermocouples placement was indicated in Fig.2.The distance between two adjacent thermocouples was constant in both chordwise and spanwise directions.All thermocouple junctions were located in the blind holes on the aluminum plate with a distance of 0.5 mm away from the jet impingement surface and glued by the adhesives of good heat conduction and electrical insulation.The inlet temperature of the pipe and the environment temperature were also measured in the experiment.All the temperature data were acquired by three Agilent 34970A modules and stored in the computer.All the thermocouples were calibrated in the range of 20℃ to 80℃ before the experiment.

Fig.2 Test section and impingement plates.

Fig.3 Constantan film heater.

3.Data processing

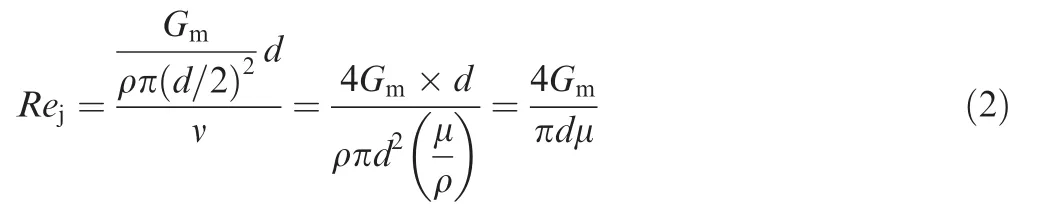

The general definition of Reynolds number is

where m is the kinematic viscosity of air,uthe air velocity which is proportional to the jet flow rate and inverse to the sectional area.

Thus,the jet Reynolds number can be defined as

whereGmis the jet flow rate,q the air density and l the dynamic viscosity of air.

The heater powerQof the constantan film is accurately determined by measuring both the voltage dropUacross and currentIthrough the film.

The heat fluxqin the heated areaAis calculated as

The local heat transfer coefficienthis defined in terms of the real convective heat flux and the difference between the surface temperatureTsand an appropriate reference temperatureTref.The jet inlet total temperature is employed as the reference temperature in the present experiment.

whereqlossis the total heat loss caused by radiation and conduction.

The average heat transfer coefficient is calculated from local heat transfer coefficient by area-weighted integral along lines of chordwise(s)and spanwise(y)directions respectively:

The local and average Nusselt numbers can be obtained as follows:

where k is the thermal conductivity of air.

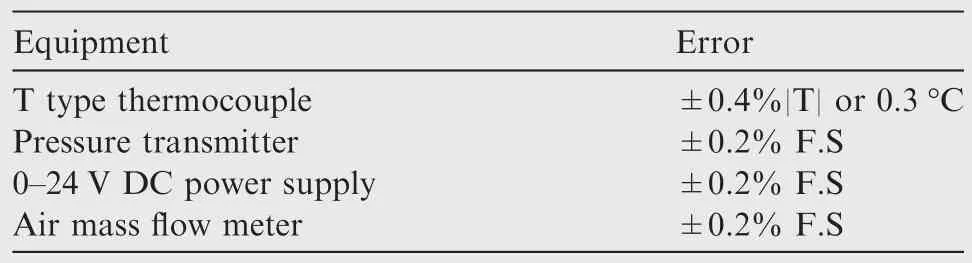

Table 1 presents the measurement uncertainties of the directly measured parameters,such as the temperature,pressure,voltage and flow rate.Based on the data in Table 1,the uncertainties ofhandNuwere all smaller than 4.3%.

Table 1 Uncertainties of measuring equipment.

4.Experimental results and discussions

4.1.Preliminary test

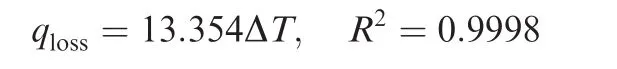

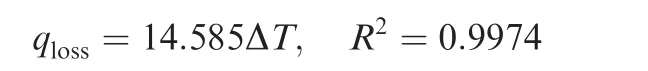

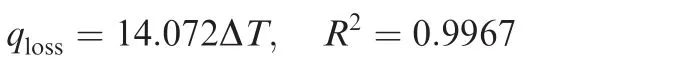

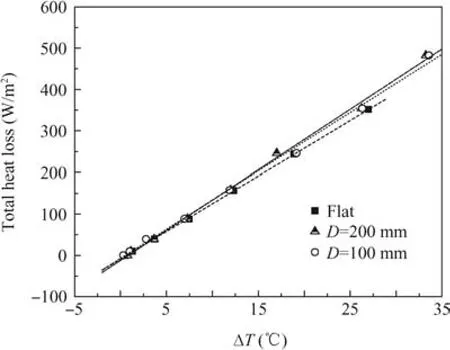

Preliminary tests were conducted to calibrate the heat loss and to minimize the experimental error.In the preliminary work,the plate was heated without cold jet impinging on the surface and the temperature data were recorded when the plate came to thermal equilibrium at a certain power applied to the heater.The total heat input is believed equal to the total heat loss caused by radiation and conduction.The total heat loss as a function of temperature difference DTbetween the surface and environment is shown in Fig.4.

It is indicated from Fig.4 that the linear correlativity between total heat loss and temperature difference is prominent.The dashed lines are linearly fit for the present experimentalresultsofdifferentplatesasdescribed in the following equations:

For flat plate:

ForD=200 mm plate:

ForD=100 mm plate:

whereR2is the coefficient of determination.

Thus,the corrected heat flux of the impingement surface can be deduced by subtracting the heat loss from the input total heat flux.All the results in this paper are corrected in the same way.

4.2.Effect of jet Reynolds number on Nusselt number

Fig.4 Total heat loss vs temperature difference between surface and environment.

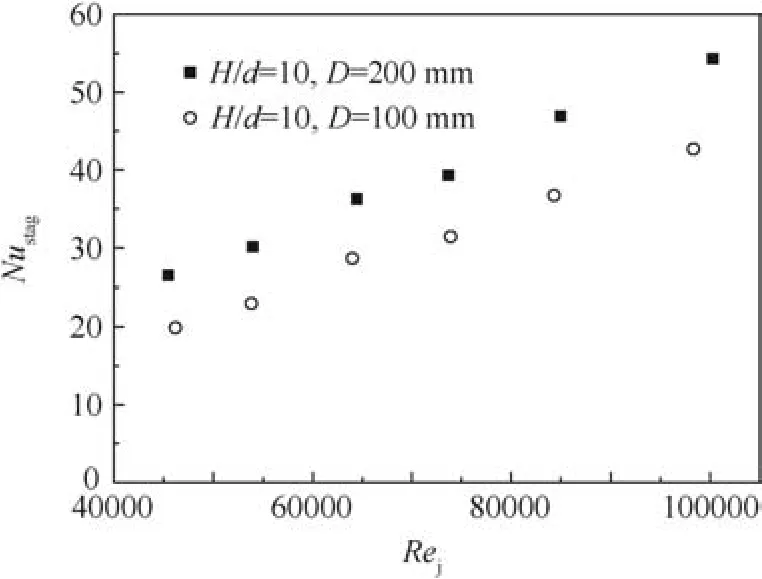

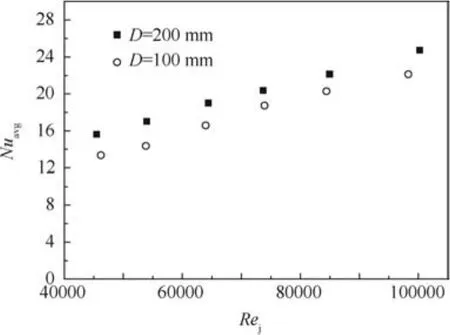

Fig.5 shows the influence of the jet Reynolds number on the Nusselt number at the stagnation pointNustagfor two concave surfaces at a fixed relative nozzle to surface distanceH/d=10.As shown in Fig.5,the stagnation point Nusselt numberNustagincreases with jet Reynolds numberRejfor both surfaces.It is mainly because the jet with larger Reynolds number brings more momentum and energy impinging on the stagnation point.Similar results were also shown by other researchers such as Yang et al.18and Lee et al.17However,in the wall jet region,high Reynolds number offers high velocity and turbulence intensity as a contribution of the generation of Taylor-Go¨rtler vortices,and thus enhances the heat transfer along the streamwise direction,which extends over the entire surface.Therefore,the average Nusselt numberNuavgover the whole surface also increases with increasing Reynolds number(Fig.6).In brief,the Reynolds number has a significant influence on heat transfer performance at both stagnation point and the entire impingement surface.

Fig.5 Influence of jet Reynolds number on Nustagfor H/d=10.

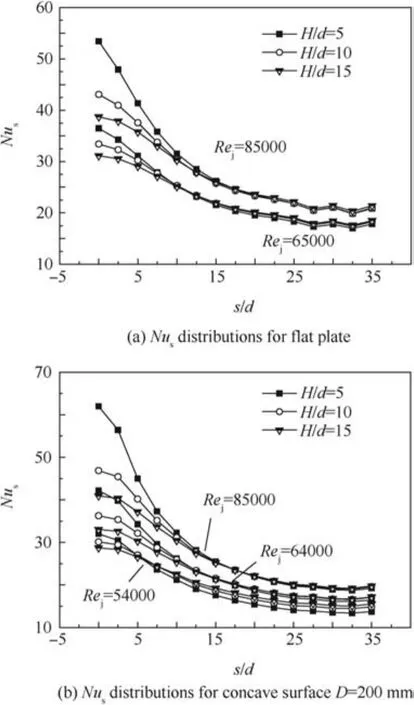

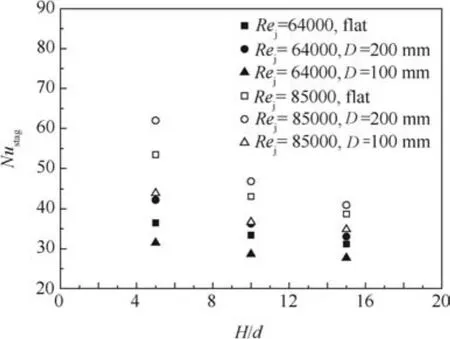

4.3.Effect of relative nozzle to surface distance on Nus

Fig.7 shows the distributions of local Nusselt numberNusfor flat and curved plates with different jet Reynolds numbers in the chordwise direction.Fig.8 shows the Nusselt number at the stagnation pointNustagfor varying relative nozzle to surface distanceH/d.As shown in Fig.7,the local Nusselt distributions of concave and flat plate indicate the same variation.The effect ofH/don heat transfer is mainly presented near the stagnation region ofs/d<12.5,whereas ats/d>12.5,little difference in Nusslet number can be observed.The maximum value in heat transfer distribution occurs at the stagnation point,and the stagnation point Nusselt number declines with increasingH/d(Fig.8).It is believed that the surrounding air entrained by the high speed jet before impinging on the surface would slow the arrival velocity at the stagnation point.ThusNustagdecreases with increasingH/d.In addition,this attenuation of the jet velocity is completed within a small range near the stagnation point,so the heat transfer is less affected byH/dfor a farther distance.

Fig.6 Influence of jet Reynolds number on Nuavg.

Fig.7 Local Nusselt number distributions for flat and curved plates in chordwise direction.

Fig.8 Nusselt number at stagnation point for varying H/d(d=2 mm).

4.4.Curvature effects

Heat transfer distributions affected by curvature along both chordwise and spanwise directions are investigated in this section for jet Reynolds numberRej=27000–130000,relative nozzle to surface distanceH/d=3.3–30,and relative surface curvatured/D=0.005–0.030.The relative surface curvatureCrwas calculated by the ratio of jet diameterdto the surface diameterD,and thus differentCrvalues could be obtained by varying surface diameterD,as well as the jet diameterd.

4.4.1.Curvature effects on a fixed surface

The average heat transfer performance varying with the change of relative surface curvature at different Reynolds numbers is shown in Fig.9 for a constant surface diameter ofD=200 mm.Because Reynolds number changes remarkably with the diameter of jet under the same inlet pressure condition,to figure out the effect ofCrat similar Reynolds number,more tests for jet diameters ofd=1.5 mm andd=2.5 mm were conducted.It can be inferred from the figure thatNuavgincreases with the increase ofCrat a given Reynolds number.

It is consistent with the results of many other studies that relativecurvatureenhancesaverageheattransfer18and increases local Nusselt number15as a consequence of the growing Taylor-Go¨rtler vortices along the streamwise direction.However,the authors believe that,for the same Reynolds number,the higherCrcaused by a larger jet diameter would lead to a larger flow rate according to Eq.(2).As it is proved by Bu et al.23that average heat transfer performance mainly depends on the flow rate,higherCrbrings better average heat transfer in this section.This point can also explain the results of Lee et al.27on the influence of jet diameters,in which they found the local Nusselt number increased with the increasing nozzle diameter near the stagnation point region when Reynolds number was constant.

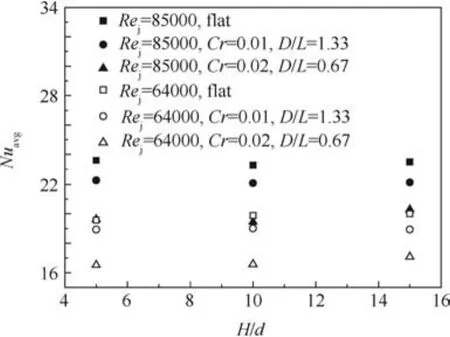

4.4.2.Curvature effects with changed surface diameters

Fig.10 presents average Nusselt number of curved and flat surfaces at differentH/dford=2 mm andRej=64000,85000.The relative curvatureCr=0.01 forD=200 mm surface andCr=0.02 forD=100 mm.The result shows that the average heat transfer performance is weaker for the curved plate than for the flat plate,andNuavgbecomes lower with increasingCr.The data are interesting since it is against the previous results obtained by Gau and Chung15and Yang et al.18As a new attempt,there is no similar investigation that can be a reference to explain this phenomenon.Unlike most researches in which differentCris obtained by altering the jet diameterd,the variedCrin this section is gained by different surface diametersDinstead,which is of high importance in the real aircraft wing anti-icing system as the surface curvature of airfoil changes constantly.

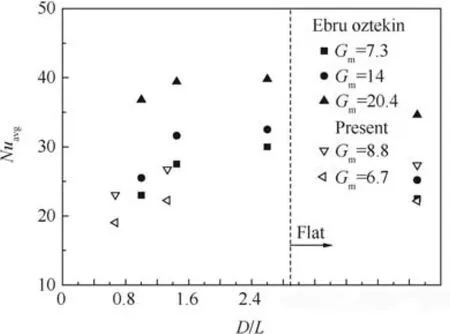

An appropriate explanation might be the experiment conducted by O¨ztekin et al.25using dimensionless surface curvatureD/Las defined in Section 2 to discuss the curvature effect of a slot jet flow.They found that the average heat transfer performance on the curved plate was stronger than that of theflatplateat1?D/L=2.6.Furthermore,theD/Lincreased both the local and average Nusselt numbers and the best heat transfer performance was obtained atD/L=2.6.In order to compare the present round jet impingement results with theirs,the average Nusselt numbers are recalculated on the equivalent impinging area(Fig.11).As the dimensionless surface curvaturesD/Lin the present work are 0.67 and 1.33,it appears plausible that the different heat transfer performance of the curved plates may be due to the nonreaching of the optimal dimensionless surface curvatureD/Lto get the best performance.

Fig.9 Average Nusselt numbers for varying Cr on a fixed surface of D=200 mm.

Fig.10 Average Nusselt number of flat and curved plate for d=2 mm.

Fig.11 Effect of D/L on average Nusselt number.

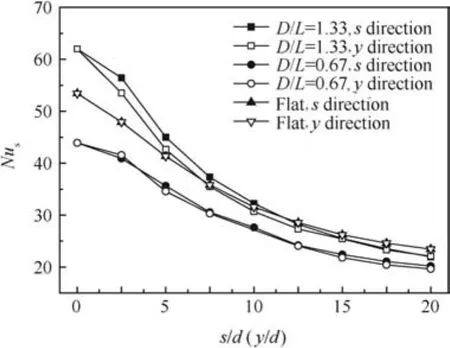

For a better understanding of the effects on different surfaces,the distributions of local Nusselt number in chordwisesand spanwiseydirection near the stagnation region are presented in Fig.12 forD/L=0.67,1.33 and flat surface.As shown in Fig.12,the increase ofD/Lenhances heat transfer at stagnation point asNustagofD/L=1.33 is larger than that of flat surface,whileNustagofD/L=0.67 is smaller.Another evidence ofD/L’s effect can be seen from the Nusselt distribution characteristics betweensandydirection.WhenD/L=1.33,the local Nusselt number insdirection is slightly higher than that inydirection at the same distance.However,whenD/L=0.67,the local Nusselt numbers are approximately equal in both directions.It is indicated that the curvature effect contributes to thinning the boundary layer and raising turbulent intensity insdirection for a largerD/L,while for a smallD/L,the curvature resists the jet flowing alongsdirection and reduces the heat transfer in this direction,where the local Nusselt number is supposed to be larger than that inydirection due to the thinner boundary layer caused by the curvature.

Fig.12 Nusselt number in s and y direction for Re=86000,d=2 mm.

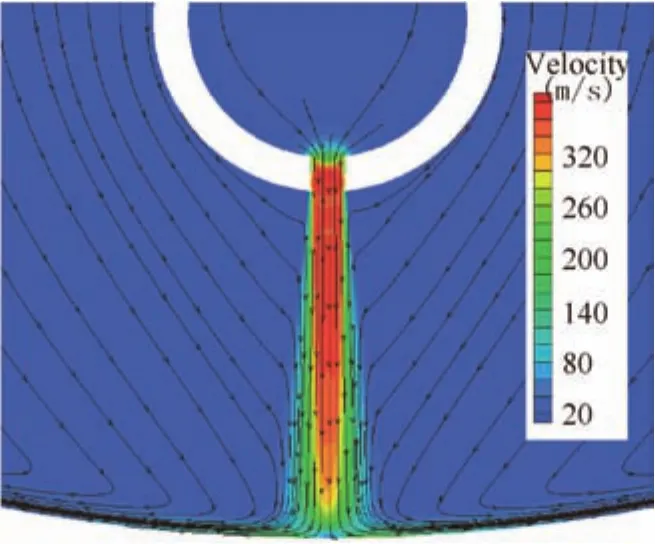

Fig.13 Streamlines in velocity profile of y=0 mm.

Fig.14 Velocity distributions along s and y direction.

A numerical simulation method is used to provide the important flow features along different directions.Fig.13 shows the streamlines in the velocity profile ofy=0,which indicate that the surrounding air is entrained by the jet.The flow velocity of the jet impinging onD=200 mm surface in the wall jet region is presented in Fig.14.The air velocity alongydirection is higher than that insdirection within a relatively large range near the stagnation point.It is indicated that the curvature confines the flow along chordwise direction,forcing part of the air to flow along the spanwise direction,and therefore reduces the heat transfer.

5.Experimental data-based correlation equations

5.1.Correlation equation for fixed surfaces

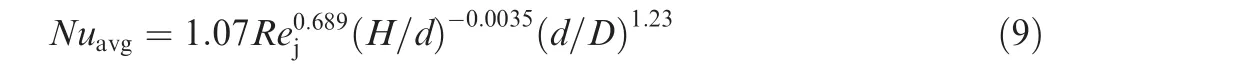

To compare with the previous results of other researchers,the correlation equations ofNuavgare given for each concave surface in terms ofRej,H/dand relative surface curvatured/D:

ForD=100 mm plate,

ForD=200 mm plate,

Nuavgvaries according to(Rej)0.689forD=100 mm and(Rej)0.633forD=200 mm,which approximately agrees with Gau and Chung’s15result of(Rej)0.68and Fenot’s24result of(Rej)0.72.The exponential values ofd/Dare much larger than those ofH/d,suggesting that changingH/dwould have much fewer influence onNuavgthan changingd/D.

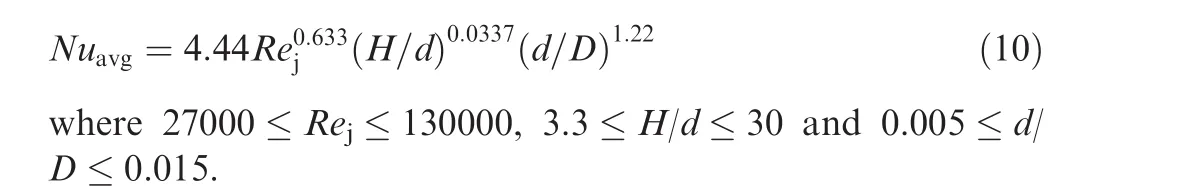

The calculated resultsNuavg,cof Eqs.(9)and(10)compared with the experimental dataNuavg,eare presented in Fig.15,which show a very good fitting with the experimental data.

5.2.Correlation equation for fixed jet diameter

Fig.15 Comparison between calculated results and experimental data for fixed surfaces.

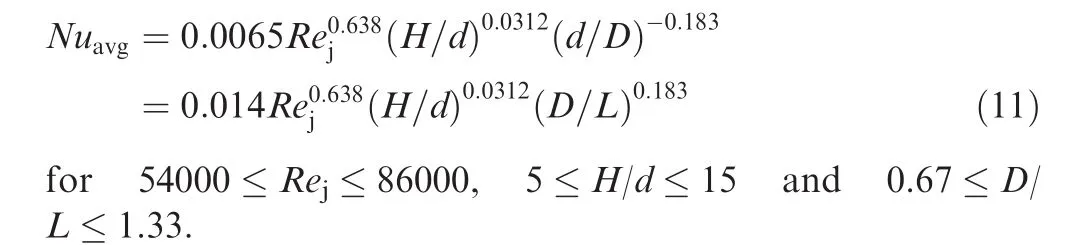

Based on the experimental results,the correlation equation of the average Nusselt numberNuavgin terms of jet Reynolds numberRej,relative nozzle to surface distanceH/d,and dimensionless surface curvatureD/Lfor a fixed diameterd=2 mm is obtained as follow:

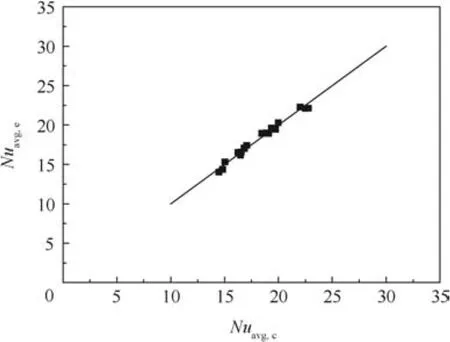

Fig.16 Comparison between calculated results and experimental data for d=2 mm.

The average Nusselt number increases with growing Reynolds number and increasing dimensionless surface curvatureD/L(i.e.,with decreasingd/D),which agrees with the results of O¨ztekin et al.25The calculated results of Eq.(11)compared with the experimental data are presented in Fig.16,which are in good agreement with the experimental data.

6.Conclusions

Extensive experimental study of the heat transfer performance of a round jet impingement on concave surfaces under constant heat fluxes were conducted in this work,where the effects of jet Reynolds numberRej,the relative nozzle to surface distanceH/dand the relative surface curvatured/Don local and average Nusselt number were investigated,and experimental data-based correlationNuavgequations were obtained.The major conclusions of the present study have been summarized as follows:

(1)Both stagnation point and average Nusselt numbers increased significantly with increasing jet Reynolds number,suggesting that increasing the inlet jet pressure or

flow rate is an effective way to enhance the heat transfer of an anti-icing system.

(3)Two opposite effectsof surfacecurvature on jet impingement heat transfer performance were observed.For a fixed surface diameter,the relative surface curvatured/Dincreased both stagnation point and average Nusselt numbers with increasing jet diameterd.In contrast,for a fixedd,the average Nusselt number declined with increasingd/D.TheNuavgincreased as the dimensionless surface curvatureD/Lincreased before reaching the maximum value for an optimalD/L.

(4)Under the same jet impingement condition(jet diameter and inlet pressure),the average Nusselt number over the entire surface was influenced more by the confinement effect than by the enhancement effect within the range of the present experiment,leading to a smallerNuavgfor the concave surfaces.

Further experiments of jet impingement on large surface diameters are planned to identify the optimumd/Dfor a givend,and to examine the practical anti-icing effect under different curvatures.

Acknowledgements

This work was supported by the National Natural Science Foundation of China(No.51206008)and the EU Marie Curie Actions-InternationalIncoming Fellowships (No.FP7-PEOPLE-2013-IIF-626576).

1.Zhang JZ,Xie H,Yang CF.Numerical study of flow and heat transfer characteristics of impingement/effusion cooling.Chin J Aeronaut2009;22(4):343–8.

2.Liu HY,Liu CL,Wu WM.Numerical investigation on the flow structures in a narrow confined channel with staggered jet array arrangement.Chin J Aeronaut2015;28(6):1616–28.

3.Gardon R,Cobonpue J.Heat transfer between a flat plate and jets of air impinging on it.International heat transfer conference;1961.p.454–60.

4.Goldstein RJ,Behbahani AI,Heppelmann K.Streamwise distribution of the recovery factor and the local heat transfer coefficient to an impinging circular air jet.Int J Heat Mass Transf1986;29(8):1227–35.

5.Hrycak P.Heat transfer from round impinging jets to a flat plate.Int J Heat Transf1983;26(12):1857–65.

6.Beltaos S.Oblique impingement of circular turbulent jets.J Hydraulic Res1976;14(1):17–36.

7.Sparrow EM,Lovell BJ.Heat transfer characteristics of an obliquely impinging circular.J Heat Transf ASME1980;102(2):202–9.

8.Goldstein RJ,Timmers JF.Visualization of heat transfer from arrays of impinging jets.Int J Heat Mass Transf1982;25(12):1857–68.

9.Goldstein RJ,Franchett ME.Heat transfer from a flat surface to an oblique impinging jet.J Heat Transf ASME1988;110(1):84–90.

10.Lytle D,Webb BW.Air jet impingement heat transfer at low nozzle-plate spacings.IntJHeatMassTransf1994;37(12):1687–97.

11.Attalla M,Salem M.Experimental investigation of heat transfer for a jet impinging obliquely on a flat surface.Exp Heat Transf2015;28(4):378–91.

12.Metzger DE,Yamashita T,Jenkins CW.Impingement cooling of concave surfaces with lines of circular air jets.J Eng Power1969;91(3):149–55.

13.Hrycak P.Heat transfer from a row of impinging jets to concave cylindrical surfaces.Int J Heat Mass Transf1981;24(3):407–19.

14.Mayle RE,Blair MF,Kopper FC.Turbulent boundary layer heat transfer on curved surfaces.J Heat Transf ASME1979;101(3):521–5.

15.Gau C,Chung CM.Surface curvature effect on slot-air-jet impingement cooling flow and heat transfer process.J Heat Transf ASME1991;113(4):858–64.

16.Cornaro C,Fleischer AS,Goldstein RJ.Flow visualization of a round jet impinging on cylindrical surfaces.Exp Therm Fluid Sci1999;20(2):66–78.

17.Lee DH,Chung YS,Won SY.The effect of concave surface curvature on heat transfer from a fully developed round impinging jet.Int J Heat Mass Transf1999;42(13):2489–97.

18.Yang G,Choi M,Lee JS.An experimental study of slot jet impingement cooling on concave surface:effects of nozzle configuration and curvature.IntJHeatMassTransf1999;42(12):2199–209.

19.Brown JM,Raghunathan S,Watterson JK,Linton AJ,Riordon D.Heat transfer correlation for anti-icing systems.J Aircraft2002;39(1):65–70.

20.Papadakis M,Wong SJ,Yeong HW,Wong SC.Icing tunnel experiments with a hot air anti-icing system.Reston:AIAA;2008.Report No.:AIAA-2008-0444.

21.Papadakis M,Wong SJ,Yeong HW,Wong SC.Icing tests of a wing model with a hot-air ice protection system.Reston:AIAA;2010.Report No.:AIAA-2010-7833.

22.Imbriale M,Ianiro A,Meola C,Cardone G.Convective heat transfer by a row of jets impinging on a concave surface.Int J Therm Sci2014;75(1):153–63.

23.Bu XQ,Peng L,Lin GP,Bai LZ.Experimental study of jet impingement heat transfer on a variable-curvature concave surface in a wing leading edge.Int J Heat Mass Transf2015;90(1):92–101.

24.Fenot M,Dorignac E,Vullierme JJ.An experimental study on hot round jets impinging a concave surface.Int J Heat Fluid Flow2008;29(4):945–56.

26.Martin EL,Wright LM,Crites DC.Impingement heat transfer enhancement on a cylindrical,leading edge model with varying jet temperatures.J Turbomach2012;135(3):323–34.

27.Lee DH,Song J,Jo MC.The effects of nozzle diameter on impinging jet heat transfer and fluid flow.J Heat Transf2004;126(4):554–7.

27 June 2016;revised 20 October 2016;accepted 21 December 2016

Available online 21 February 2017

*Corresponding author.

E-mail address:buxueqin@buaa.edu.cn(X.Bu).

Peer review under responsibility of Editorial Committee of CJA.

CHINESE JOURNAL OF AERONAUTICS2017年2期

CHINESE JOURNAL OF AERONAUTICS2017年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- High-temperature tribological behaviors of a Cr-Si co-alloyed layer on TA15 alloy

- Analysis and control of the compaction force in the composite prepreg tape winding process for rocket motor nozzles

- Impact of lubricant traction coefficient on cage’s dynamic characteristics in high-speed angular contact ball bearing

- Variable stiffness design of redundantly actuated planar rotational parallel mechanisms

- Adaptive formation control of quadrotor unmanned aerial vehicles with bounded control thrust

- Constrained adaptive neural network control of an MIMO aeroelastic system with input nonlinearities