Preparation of New Structure Energetic Composite of HNIW Implanted into Macroporous Fibosa

LI Ya-ru, REN Hui, JIAO Qing-jie

(State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing 100081, China)

1 Introduction

With the development of insensitive ammunition, ignition charges are required to have higher energy. Traditional charges are faced with new challenges and explosives with high energy density were hence introduced to the ignition system to improve the energy output[1]. Hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane(HNIW) has been widely investigated for its all respects especially explosion and combustion abilities since it was synthesized[2-6]. Relative documents showed HNIW would be a potential component of higher ignition charge[7]. As a new generation explosive, HNIW has higher energy density than other pyrotechnic charges[8-9], however, its thermal sensitivity is lower than other pyrotechnic charges. It is vital to improve the sensitivity of HNIW to heat to make it a perfect ignition charge. One way to achieve this is to combine HNIW with another material of more thermal sensitive, such as polymer.

Electrostatic spinning(ES) technique has become a mature technology for the preparation of micro/nano-scale fibers in recent years. The fibers fabricated by ES have been widely used in tissue engineering[10-11], battery[12-13], filter[14]. In the electrostatic spinning process, an electrically conducting polymer solution is charged when it flows through a fine nozzle connected to high voltage. The electric field between the nozzle and the ground receptor exerts electrostatic forces to stretch polymer solution into micro/nano-scale fibers[15]. Fibrosa with various pore structures and mechanical properties can be fabricated by adjusting the high voltage, viscosity of precursor solution, the receptor, and so on[16-19]. After the solvent evaporation, fibers remain on the receptor and form a macro porous fibrosa. The diameter, morphology and porosity of fiber will be determined by different synthesized parameters[20-22]. So it offers a new route to fabricate composite energetic materials. Polyacrylonitrile(PAN) is one of the materials easy to be electrospun, and carbon fibers prepared by PAN have good mechanical properties, therefore PAN has been widely used as electrospinning precursor[23-24]. We can use the fibers prepared by electrospinning as the matrix, then some high energy density compounds were coated or deposited on the surface of micor & nano-fibers. Besides, we noted that other researches have completed the fabrication of thermite fibers by means of electrospinning[25-27]. Previous researches focused on the thermite or nitrocellulose etc. Up to now, no published articles discussed explosive-contained composite energetic fibers. Consideration of electrostatic danger, the high voltage may trigger explosive reaction during electrospinning. We first obtained the fibrosa, followed by explosive implanted into the porous mats, energetic composites were resulted. In this work, PAN was chosen to be electrospun into fibrous mats as a matrix to strengthen the mechanical property and to improve the thermal sensitivity of mixed ignition charge.

2 Experiment Section

2.1 Materials and Instruments

The polyacrylonitrile(PAN), with average relative molecular mass of 102700, was acquired from Scientific Polymer Product Company(New York, USA).N,N-dimethylformamide(DMF) was produced by Sinopharm Chemcial Reagent Co., Ltd.(Shanghai, China). Acetone was produced by Beijing Reagent Company(Beijing, China). PAN, DMF and acetone were of analytical purity. HNIW (5-15 μm, 40% ε and 60%αcrystal form) was produced by Qingyang Liaoning Special Chemical Co., Ltd.(Liaoning, China) with chemical purity, higher than 99% .

A model RCT basic magnetic heated stirrer was obtained from IKA Company(Germany). A model BGG high voltage supply with +40 kV was supplied by Beijing Electro-mechanical Research Institute Supesvoltage Technique Company(Beijing, China). A model LSP02-1B constant flow pump was from Longer Precision Pump Co.,Ltd(Baoding, China).

Micromorphology was characterized by a Hitachi S4800 scanning electron microscope(Japan). Infrared spectra were recorded in KBr discs on a Bruker VERTEX70 infrared spectrometer(Germany) in the range of 4000-400 cm-1. Thermal behavior was studied on a STA449F3 differential scanning calorimeter(NET Co, Germany) at the rate of 5 ℃·min-1. A SIMD8 high-speed camera(Britain) was applied to record the ignition process with the sampling frequency of 250 fps.

2.2 Preparation of Fibrosa

PAN (8 g) was dissolved in DMF (92 mL) under agitation by magnetic heated stirrer at 60 ℃ for 6 h. The electrostatic spinning solution was loaded into a 20 mL syringe capped with blunt tipped needle. The positive lead of a high voltage supply was attached by an alligator clip to the blunt tipped needle. A 25 kV accelerating voltage was used in the electrostatic spinning process. A constantly-flow longer pump was used to meter the delivery of the PAN solution to the electric field, the delivery rate was set to 4 mL·h-1. The distance between needle and the receptor was 15 cm. After solvent evaporation, pure PAN fibrosa was obtained.

2.3 Fabrication of Composites

Composites of HNIW and PAN fibrosa were fabricated by dipping the PAN fibrosa into acetone solution of HNIW with certain concentration. The content of HNIW in the composite could be adjusted by changing the amount of HNIW in acetone. After solvent was completely evaporated, composites dried in vacuum drying oven at 50 ℃ for 2 h were obtained.

2.4 Ignition Experiment

To judge the feasibility of composite as ignition charge, an ignition experiment was designed. Test material was cut into strips and then loosely filled into quartz tube to obtain enough oxygen. After that, electric igniter device was connected to the side of quartz tube with test materials to ensure the ignition head was fully contacted with materials. Moreover, to make sure the ignition head would not recoil the moment materials ignited, it should be deep enough into the tube. High-speed camera was employed to record and analyze the combustion process. To make a comparison, both pure PAN fibrosa and composite were ignited under the same condition.

3 Results and Discussions

3.1 Prediction of Optimal Proportion

The ingredient, proportion, thermodynamic state of energetic composites will influence its combustion reaction. In order to acquire the optimal proportion of the composites, it is necessary to have a thorough understanding on the reaction behavior of the composite with different proportions. Therefore, we conducted a serial of calculations both on the heat of formation and the adiabatic flame temperature(AFT) of the composites at different proportions according to principle of minimum free energy. The calculated results are shown in Fig.1. It can be learnt that both AFT and the heat of formation rise first and then fall with the mass ratio of PAN increasing. One should be noted that at the mass ratio of 3∶7, the heat of formation reaches the highest point which nearly the same to AFT, showing the advantage of that ratio over the rest. So we obtain the better stoichiometry used in following experiments.

Fig.1 Calculated heat of formation and adiabatic flame temperature (AFT) of composite at different ratio of PAN/HNIW

3.2 Characterization of Morphology

To observe the microstructure of composites, the morphologies of fibrosa, composites and combustion residue of PAN fibrosa and composite were investigated by scanning electron microscope(SEM). Their SEM images are shown in Fig.2.

a. electrostatic spinning fibre

b. composite of explosive and fibrosa

c. combustion residue of PAN fibrosa

d. combustion residue of composite

Fig.2 SEM images of samples

Fig.2a displays the electrostatic spinning fibers randomly distributed with smooth surface and an average diameter of 500 nm. The pore space between fibers is big enough to contain high mass loading. Fig.2b shows that HNIW particles uniformly adhere to the mat, which fully proves the feasibility of compound explosive and fibrosa together. And the structure of PAN fiber is very beneficial to be adhered by explosive.

PAN fibrosa and composite were separately ignited under the same condition, and the combustion residues of them were observed by SEM, as shown in Fig.2c and Fig.2d. During the ignition experiment, just small part of PAN fibrosa were fired due to no constant thermal source supplied. Fibers and carbides exist in the combustion residues according to Fig.2c, in accord with the experiment. In contrast, the composite with HNIW can be fully burnt. And compared with PAN fibrosa (see Fig.2c), there are more pores in combustion residue (see Fig.2d) of composite. Porous parts are speculated to be the combustion loss of HNIW.

3.3 FT-IRAnalysis

Fig.3 FT-IR spectra of four samples

3.4 Thermal Behavior

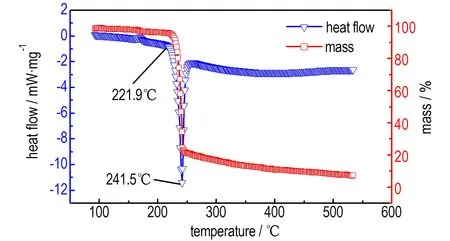

DSC/TG analysis is mainly used to analyze the reaction of energetic system under heat stimulus, and it is usually used to study the thermal decomposition of explosive. To know the thermal decomposition interaction between PAN fibrosa and HNIW, differential scanning calorimetry was used to analyze the thermal decomposition behaviors of PAN fibrosa, HNIW and their composite. Results are shown in Fig.4. In the thermal decomposition process, the starting point of decomposition for HNIW is 221.9 ℃ (see Fig.4b), while that for composite and PAN is 204.7 ℃(see Fig.4c) and 270 ℃(see Fig.4a), respectively. According to the above results, we can speculate that PAN makes the initial exothermic temperature of HNIW shifts

a. PAN

b. HNIW

c. PAN/HNIW

Fig.4 DSC and TG curves of samples

about 38 ℃ downwards. Besides, PAN enhances the exothermic quantity of HNIW, making the exothermic peak of HNIW shifts 19 ℃ downwards. The thermogravimetric analysis results reveal that the exothermic rate of composite is highest of all, which proves that the composite is more sensitive than HNIW. Based on the above analyses, the interaction process between PAN and HNIW includes three steps: first, reaching its decomposition point of HNIW and releasing heat, then, reaching its decomposition point of PAN by absorbing the decomposition heat of HNIW, finally, occurring the further thermal decomposition of HNIW by absorbing the exothermic quantity of PAN. In conclusion, the thermal decomposition of composite is the result of interaction of HNIW and PAN.

3.5 Combustion Properties

Fig.5 shows the ignition and combustion process of PAN fibosa recorded by a high-speed camera. The highest temperature of ignition head is about 300 ℃, but only few fibers contacted with ignition head are fired. Besides, fibosa flame is disappeared with ignition head dying out, indicating electrostatic spinning fibers can not burn constantly. Fig.6 shows the combustion process of composite recorded by a high-speed camera. According to combustion behavior, the whole process can be divided into four stages. First, composite contacted with ignition head is ignited by the combustion heat of ignition head (see Fig.6a). According to the record by camera, there is obvious flame which becomes lighter and longer. Second, the ignited part starts its long combustion process which moves to the near part (see Fig.6b). Material of this part can be totally burnt due to enough oxygen and heat supply. Then, due to the consumption of combustible and oxygen in the former stage, the combustion of this stage becomes weak and the flame becomes shorter and dimmer (see Fig.6c). The final combustion process is for the part inside the tube. Combustion of this stage is incomplete with no flame but tan smoke, due to lack of oxygen.

4 Conclusions

(1) Composite of PAN fibrosa and HNIW was successfully fabricated through the combination of electrostatic spinning method and self-assembly method. HNIW can physically imbed in PAN fibrosa and the composite showed a good uniformity, with no new organic groups appeared after imbed process.

(2) The addition of HNIW to PAN fibrosa efficiently increases combustion ability of PAN which can not burn constantly itself. The composite burnt process can be divided into four stages and it burnt more thoroughly than PAN itself under the same condition.

(3) The thermal decomposition of composite is a result of

c. 108 ms b. 140 ms c. 172 ms d. 316 ms

Fig.5 Ignition of PAN fibrosa

c. 160 ms b. 1520 ms c. 2400 ms d. 3040 ms

Fig.6 Ignition of PAN/HNIW composite

interaction of HNIW and PAN. DSC/TG demonstrated that composites had a higher thermal sensitivity than HNIW itself, which meets the demand of high ignition energy in narrow space. PAN makes the initial exothermic temperature of HNIW shifts about 38 ℃ downwards. This new composite have the potential application on ignition devices.

[1] YI Nai-rong, SHI Chun-hong, LU Qiao-li. A new HMX-containing high energetic ignition mixture[J].Initiators&Pyrotechnics, 2004, (3): 9-12.

[2] Elbeih A, Zeman S, Pachman J, et al. Heat of combustion and detonation characteristics of HNIW bonded by different plastic matrices[C]∥8th Asia-Pacific Conference on Combustion, Hyderabad, India, 2010: 295-300

[3] WANG Yu-ping, YANG Zong-wei, LI Hong-zhen. A novel cocrystal explosive of HNIW with good comprehensive properties[J].Propellants,Explosives,Pyrotechnics, 2014, 39(4): 590-596.

[4] YANG Zong-wei, LI Hong-zhen, HUANG Hui, et al. Preparation and performance of a HNIW/TNT cocrystal explosive[J].Propellants,Explosives,Pyrotechnics, 2013, 38(4): 495-501.

[5] CHEN Song-lin, LIU Jia-bin, WEI Shu-qiong, et al. Study on thermal decomposition kinetics of hexanitrohexaazaisowurtzitane[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2002, 10(1): 46-48.

[6] LIAO Su-ran, LUO Yun-jun, SUN Jie, et al. Preparation of WPU-g-SAN and its coating on HNIW[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2012, 20(2): 155-160.

[7] Elbeih A, Pachman J, Zeman S, et al. Detonation characteristics of plastic explosives based on attractive nitramines with polyisobutylene and poly(methyl methacrylate) binders[J].JournalofEnergeticMaterials, 2012, 30(4): 358-371.

[8] Simpson R L, Urtiev P A, Ornellas D L, et al. CL-20 performance exceeds that of HMX and its sensitivity is moderate[J].Propellants,Explosives,Pyrotechnics, 1997, 22(5): 249-255.

[9] Bazaki H, Kawabe S, Miya H, et al. Synthesis and sensitivity of hexanitrohexaaza-isowurtzitane(HNIW)[J].Propellants,Explosives,Pyrotechnics, 1998, 23(6): 333-336.

[10] Erben J, Pilarova K, Sanetrnik F, et al. The combination of melt blown and electrospinning for bone tissue engineering[J].MaterialsLetters, 2015, 143(15): 172-176.

[11] ZHU Wei, Masood F, O′Brien J, et al. Highly aligned nanocomposite scaffolds by electrospinning and electrospraying for neural tissue regeneration[J].Nanomedicine:Nanotechnology,BiologyandMedicine, 2015, 11(3): 693-704.

[12] Croce F, Focarete M L, Hassoun J, et al. A safe, high-rate and high-energy polymer lithium-ion battery based on gelled membranes prepared by electrospinning[J].Energy&EnvironmentalScience, 2011, 4(3): 921-927.

[13] LI Jia-xin, ZOU Ming-zhong, ZHAO Yi, et al. A simple integrated design and manufacture by electrospinning of stabilized lithium battery tin-based anodes[J].RSCAdvances, 2013, 3: 19251-19254.

[14] Chuang Y H, Hong G B, Chang C T. Study on particulates and volatile organic compounds removal with TiO2nonwoven filter prepared by electrospinning[J].JournaloftheAir&WasteManagementAssociation, 2014, 64(6): 738-742.

[15] WANG Ce, LU Xiao-Feng. Organic functional nano-materials-high voltage electrospinning technique and nanofibers[M]. Beijing: Science Press, 2011: 18.

[16] LI Dan, WANG Yu-liang, XIA You-nan. Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays[J].NanoLetters, 2003, 3(8): 1167-1171.

[17] WEN Shi-peng, LIU Li, ZHANG Li-feng. Hierarchical electrospun SiO2nanofibers containing SiO2nanoparticles with controllable surface-roughness and/or porosity[J].MaterialsLetters, 2010, 64(13): 1517-1520.

[18] Demir M M. Investigation on glassy skin formation of porous polystyrene fibers electrospun from DMF[J].ExpressPolymerLetters, 2010, 4(1): 2-8.

[19] Simonet M, Schneider O D, Neuenschwander P, et al. Ultraporous 3D polymer meshes by low-temperature electrospinning: use of ice crystals as a removable void template[J].PolymerEngineering&Science, 2007, 47(12):2020-2026.

[20] Lubasova D, Martinova L. Controlled morphology of porous polyvinyl butyral nanofibers[J].JournalofNanomaterials, 2011, 6(20):157-165.

[21] Thompson C J, Chase G G, Yarin A L, et al. Effects of parameters on nanofiber diameter determined from electrospinning model[J].Polymer, 2007, 48(23): 6913-6922.

[22] Nayani K, Katepalli H, Sharma C S, et al. Electrospinning combined with nonsolvent-induced phase separation to fabricate highly porous and hollow submicrometer polymer fibers[J].IndustrialEngineeringChemistryResearch, 2011, 51(4): 1761-1766.

[23] WANG Gang, PAN Chao, WANG Liu-ping, et al. Activated carbon nanofiber webs made by electrospinning for capacitive deionization[J].ElectrochimicaActa, 2012, 69(5): 65-70.

[24] Katepalli H, Bikshapathi M, Sharma C S, et al. Synthesis of hierarchical fabrics by electrospinning of PAN nanofibers on activated carbon microfibers for environmental remediation applications[J].ChemicalEngineeringJournal, 2011, 171(3): 1194-1200.

[25] YAN Shi, JIAN Guoqiang, Zachariah M R. Electrospun nanofiber-based thermite textiles and their reactive properties[J].ACSAppliedMaterials&Interfaces, 2012, 4(12): 6432-6435.

[26] XU Hong-mei, LI Rui, SHEN Jin-peng, et al. Preparation and characterisation of nanofibrous CuO/Al metastable intermolecular composite films[J].Micro&NanoLetters, 2012, 7(12): 1251-1255.

[27] Ji Y A, Kim W D, Kim S H. Synthesis of metal oxide porous nanowires and their applications into energetic materials[C]∥10th IEEE Conference on Nanotechnology (IEEE-NANO). Kintex, Korea, 2010: 422-425.