Prediction of Compressive and Shear Moduli of X-cor Sandwich Structures for Aeronautic Engineering

(張向陽(yáng)), (李勇), (李俊斐), n(范琳), gang(譚永剛), (肖軍)

College of Material Science and Technology, Nanjing University of Aeronautics and Astronautics,Nanjing 210016, P.R. China (Received 18 November 2014; revised 2 April 2015; accepted 12 May 2015)

Prediction of Compressive and Shear Moduli of X-cor Sandwich Structures for Aeronautic Engineering

ZhangXiangyang(張向陽(yáng)),LiYong(李勇)*,LiJunfei(李俊斐),FanLin(范琳),TanYonggang(譚永剛),XiaoJun(肖軍)

College of Material Science and Technology, Nanjing University of Aeronautics and Astronautics,Nanjing 210016, P.R. China (Received 18 November 2014; revised 2 April 2015; accepted 12 May 2015)

The so-called ″X(qián)-cor sandwich structure″ is a highly promising novel material as an alternative to honeycomb used in aircraft. Although much work has been conducted on the performance of the X-cor sandwich structure, the gap is still hardly bridged between experimental results and theoretical analyses. Therefore, a method has been innovated to establish semi-empirical formula for the prediction of compressive and shear moduli of X-cor sandwich structure composites, by combining theoretical analyses and experimental data. In addition, a prediction software was first developed based on the proposed method, of which the accuracy was verified through confirmatory experiments. This software can offer a direct reference or guide for engineers in structural designing.

X-cor sandwich structure; moduli prediction; compressive; shear

0 Introduction

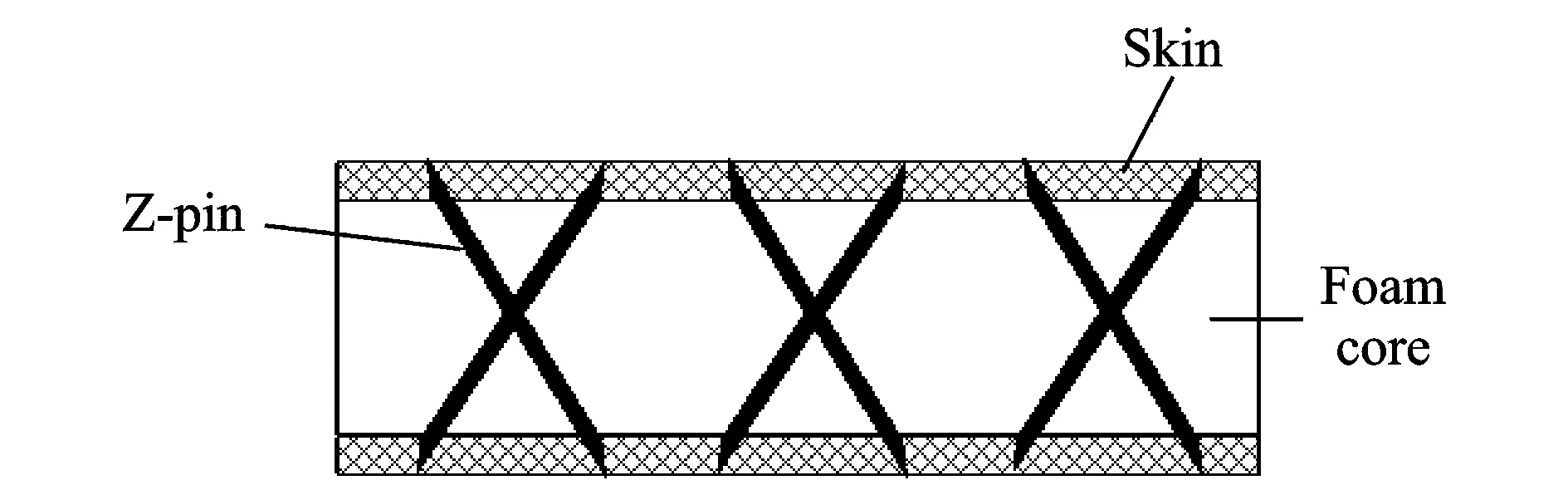

Considering the increasing demand of light materials in aerospace industries, more attentions have been drawn to the research and development of sandwich structure composites. However, the de-bonding problem between the core and the panel directly limits their applications in the main load-bearing structural components in aircraft. Recently, a novel technology, called Z-pin, has been reported to significantly improve the through-thickness properties of composite laminates, making it possible for composites to be used in structural components[1]. Fig. 1 illustrates the X-cor sandwich structure made up of embedded fibrous composite rods (pin) and the traditional sandwich structure. As shown, the tips are stitched into the uncured prepreg skins. By means of co-curing effect, the pins are bonded to the foam core and the skins simultaneously to improve the delamination resistance between the skins and the form core. Sikorsky Aircraft demonstrated that X-cor sandwich structures exhibited equivalent mechanical performance to 48 kg/m3biased glass honeycomb core while saving nearly 10% weight[2]. It was also reported that X-cor sandwich structure material was a potential alternative to the traditional honeycomb material thanks to their high specific strength and modulus.

Fig.1 Cross-section of X-cor sandwich structure

Marasco et al.[3]and Partridge et al.[4]conducted specific experiments to explore the effects of the pin-insertion angle (the angle between the axle of pins and the tangential direction) on the out-of-plane tensile, compressive and shear properties of X-cor sandwich structure materials. The results showed that with increasing the insertion angle, the modulus and the strength of both tensile and compressive results increased correspondingly, with the decrease of shear modulus and strength. Meanwhile, Mouritz et al.[5]proved that, the out-of-plane compressive strength and modulus went up as the density of inserted pins ascended.

Throughout reviews on X-cor sandwich structure materials, most of the work was accomplished by samples within specific parameters[6-10]. Meanwhile, most theoretical models built in literature have not been verified by large amount of tests. Considering the industrial applications, it is inconvenient to calculate the material constants by traditional theoretical models. Therefore, a common and convenient method is urgently in need. Aiming at this, the reinforcement of pins were homogenized over the whole volume of sandwich and the semi-empirical formula was built for prediction of X-cor sandwich structure properties by data fitting method. Then, the prediction software was developed to verify the practicability and versatility for the structural design of X-cor.

1 Analysis Model

The X-cor sandwich structure present outstanding improvement of the performance in through-thickness direction. In this section, the prediction of the out-of-plane compressive and shear modulus were presented, on account of the dispersion and complexity of the strength analysis. Two kinds of composites widely used in aircraft were discussed: CF/Epoxy with Rohacell?31IG form core, and CF/Bimaleimide (BMI) with Rohacell?51 WF foam core, to meet the demand of thermal property.

1.1 Compressive model

Fig.2 Single cell of the X-cor sandwich structure

As the X-cor truss plays a significant role in the load-bearing, the quotient of foam core could be left out of consideration to simplify the model. As shown in Fig. 2, a single cell of X-cor structure was selected including two pins inserted at ±θ.

Hao et al.[7]have regarded the pins as beam-column on Winkler elastic foundation and deduced the compressive strength and modulus. Given the pin′s axial compressive modulusEpinand the foam compressive modulusEf, the compressive modulus of the X-cor structureEXis presented as

(1)

whereθandVpinrepresent the pin insertion angle and the volume density of pins, respectively.

Ref.[11] demonstrated that traditional equation cannot match the experimental results well with the structure buckling and with the pin′s length discreteness. The deduced formula was modified by the stiffness discount coefficientM1caused by the structure buckling andM2caused by the pin′s length discreteness as

(2)

The design parameters, primarily determining the compressive modulus, are the insertion angle and the volume fraction. Ref.[10] proved that the influence of pin′s diameter and insertion density on the modulus is equivalent to that of the volume fraction. Not only Eq. (1) but also the modified model (Eq.2) indicate that the compressive modulus is proportional to sin4θ, as well asVpin. Therefore, numerous experimental results (Appendix A) of compressive module are analyzed utilizing the linear regression model in Matlab. The semi-empirical equations are deduced as

(3)

whereEeXandEbXrepresent the compressive moduli of CF/Epoxy and CF/BMI X-cor sandwich structure. Since the fitting was based on the experimental data tested on specimens of particular materials, including T300/FW125 epoxy and T300/NHZP-1 BMI for Z-pins, the predictor formula specifically verifies the structures made from such materials, and shear module prediction is brought about.

1.2 Shear model

Several models have been proposed for the shear property calculation of X-cor structure by now. In Ref.[12], X-cor structure was considered as the space truss frame. Utilizing the equivalent inclusion method, the shear modulusGXof X-cor is calculated by

(5)

whereEsis the tensile modulus of the pin,Gethe equivalent shear modulus which can be developed by the equivalent mingle method expressed by a complex matrix.

Shear stiffness is directly proportional to the volume rateVpin. If shear stiffness is evenly divided into each 1% volume rate pin,GXcan be concisely expressed as

(6)

wherekis the shear stiffness contribution of 1% volume rate pins, andG0the fitting constant. Referring to Eq. (5), it can be assumed thatkis a function of the insertion parameterγ,γ=sin2(2θ). Then the expression ofGXshould be

(7)

wherea,bandcare fitting constants. With the help of Matlab, the regressive fitting results of the shear modulus of Epoxy/CF and BMI/CF X-cor sandwich composite areGeXandGbX.

(9)

The assumption of Eq. (6) has attributed the whole structure stiffness to the pins′ insertion. Although non-considering stiffness of foam core can simplify the process, it leads to a divitation from the testing results, which will be discussed later. In addition,G0here is only a fitting constant without explicit physical meaning whose value and sign are meaningless.

1.3 Boundary conditions

The fitting equations derived above can predict the results precisely, only if the parameters are selected in proper range. Thereby, the boundary conditions for this prediction method as well as for the structure design discipline should be clear after all.

(1) Insertion angle. Knowing that the pultruded pins are anisotropic materials whose axial stiffness is much better than that in the transverse direction, the pins embedded close to the vertical direction are prone to present better load-bearing property. As a result, the recommended design insertion angle of pins is 45°—90°.

(2) Volume rate of pins. The linear relationship between the stiffness and the volume rate is valid in a specific range. The volume fractions of pins are calculated as a function of the insertion intervals at the longitudinal and the latitudinal directions, as well as the diameter depicted as

(10)

whereDis the diameter of Z-pin,xandyare the insertion intervals in the longitudinal and the latitudinal directions, respectively. Based on the inspection of experimental data, on one hand, pins of diameter smaller than 0.4 mm can barely penetrate the rigid PMI foam core. On the other hand, pins of large diameters (≥1 mm) can lead to over-damaged skins, resulting in the declination of structural performance. Moreover, if the number of pins is surplus, pins would function as the defects rather than reinforcement. That is to say, if the space between two adjacent pins are very small (≤3 mm), the foam core will collapse and can hardly support the X-cor truss.

Summarily, the suitable pin insertion parameters should be set as insertion angle of 45°—90°, the diameter of 0.4—1 mm, and the insertion interval of 3—10 mm.

2 Software Development

2.1 Software programming

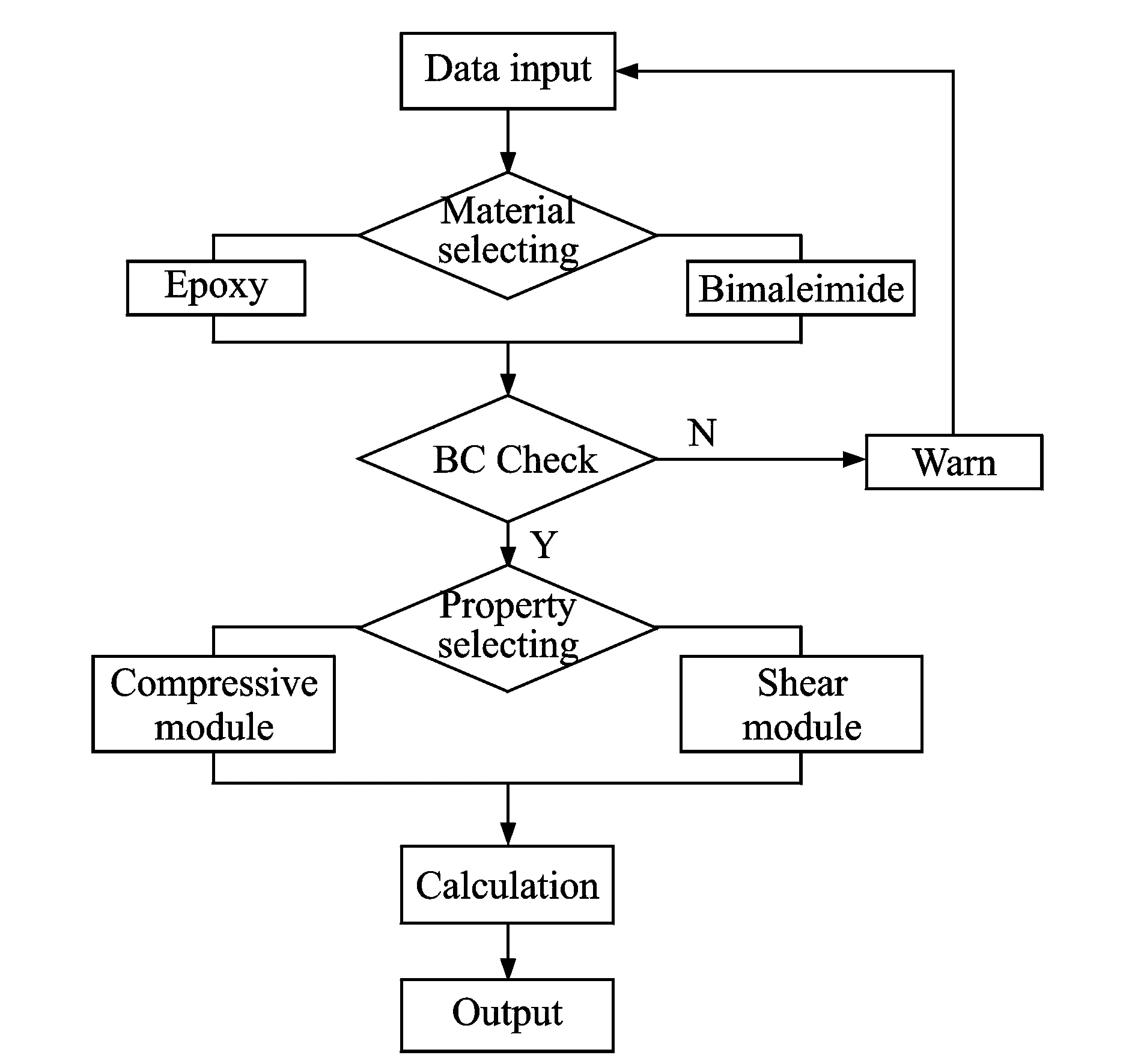

On the basis of the compressive and shear stiffness calculation of Eqs. (3, 4, 8, 9), the prediction software was programmed by VB 6.0. The algorithm process is briefly shown in Fig.3. With data input and material selected, the system checks whether the parameters satisfy the boundary conditions. If the answer is no, a warning window will appear to inform the users what should be noticed and corrected. Otherwise, the stiffness will be calculated, according to the choice of compressive modulus or the shear modulus. The limitation of the work is that the program database contains only two kinds of materials.

Fig.3 The algorithm of the prediction software

The software provids a clear and simple platform for the X-cor sandwich structural designers, especially for those without expertise. It is not necessary to explore the calculating models of X-cor sandwich structure engineering constants.

2.2 Prediction results

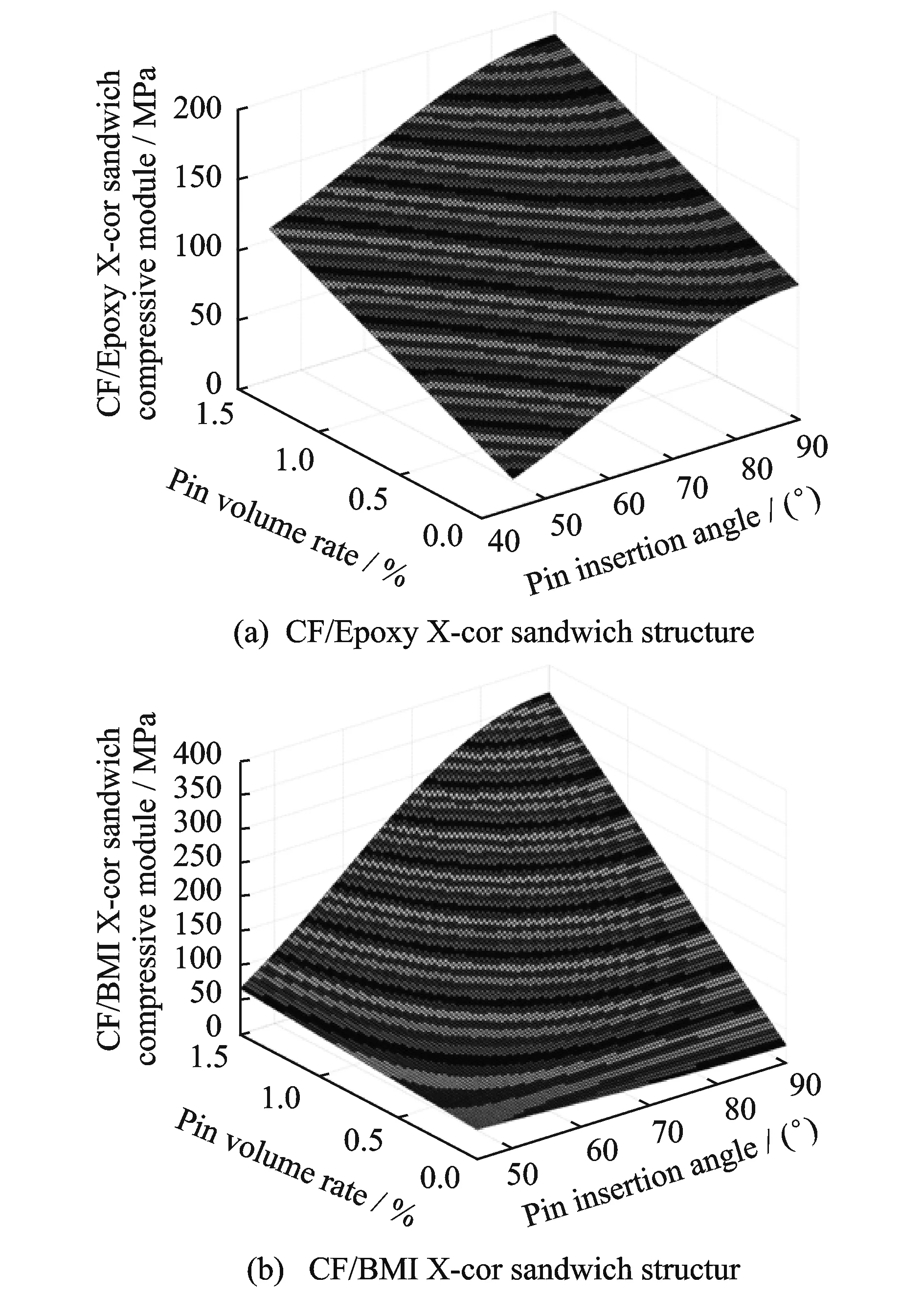

The curved surface of the compressive and shear prediction results are shown in Figs. 4, 5, when the insertion angle ranges from 45° to 90° and the volume rate is in common scale. In spite of the differences between the specific values of the CF/Epoxy and the CF/BMI X-cor sandwich structure properties, the dependency of their moduli on insertion angle and volume rate remains similar.

Fig.4 Prediction results of X-cor sandwich compressive module

Fig.5 Prediction results of X-cor sandwich shear module

From the above results, several rules indicated are consistent with the research findings: (1) Along with the increase of insertion angle, the compressive modulus increases and the shear modulus decreases. When the pins are inserted at 45°, the enhancement of the compressive property is not obvious. In other extreme conditions, the pins can hardly improve the shear property of X-cor sandwich when inserted in the angle of 90°. Then, the pins insertion angle should be designed based on the loading environment. (2) Within specific limits, both the compressive and the shear modulus are proportional to the pins volume rate, which agrees well with the mixture theory of the composite modulus, despite that the slope differs when the pin insertion angle changes. However, to some extent, pin insertion is harmful to the skin and the form core of sandwich structure, then pins of high density will lead to the collapse of the skin material and the foam core.

3 Experiments and Results

3.1 Experiments

The compressive modulus was measured on the NEWSANS electronic universal testing machine, and the axial cross-head movement rate imposed on the specimen was set as 1 mm/min. Tests were designed referring to the standard test method GB 1453—87. The specimens for compression test were prepared in the size of 60 mm×60 mm×12.5 mm. The underlying half jig could adjust by itself to maintain the specimen horizontal by means of the semi-globular bottom, at a preload of about 200 N (Fig.6). As the load was ascending, a series of crackle sound could be heard. At last, the fractures in pins led to the overall failure of the specimen. During the experiments, the load-displacement curves were recorded so as to obtain the stress-stain relationship by taking the specimen dimension into consideration.

The shear test of the X-cor sandwich structure was conducted on the NEWSANS electronic universal testing machine with the constant loading rate of 1 mm/min, according to the standard test method GB 1455—88. As shown in Fig.7, two metal jigs ensured that the shearing stress was spread uniformly on the specimen. An extensometer sensing the shearing deformation was attached onto the specimen as well. To be clarified, the specimens were prepared in the size of 120 mm×60 mm×12.5 mm.

Regularly, the crack emergeds in the foam core at the very beginning. Nevertheless, the crack propagation was obstructed by pins later then. When the load ascended to the peak, the structure failed because of the pullout and rotation of pins.

3.2 Results and verification

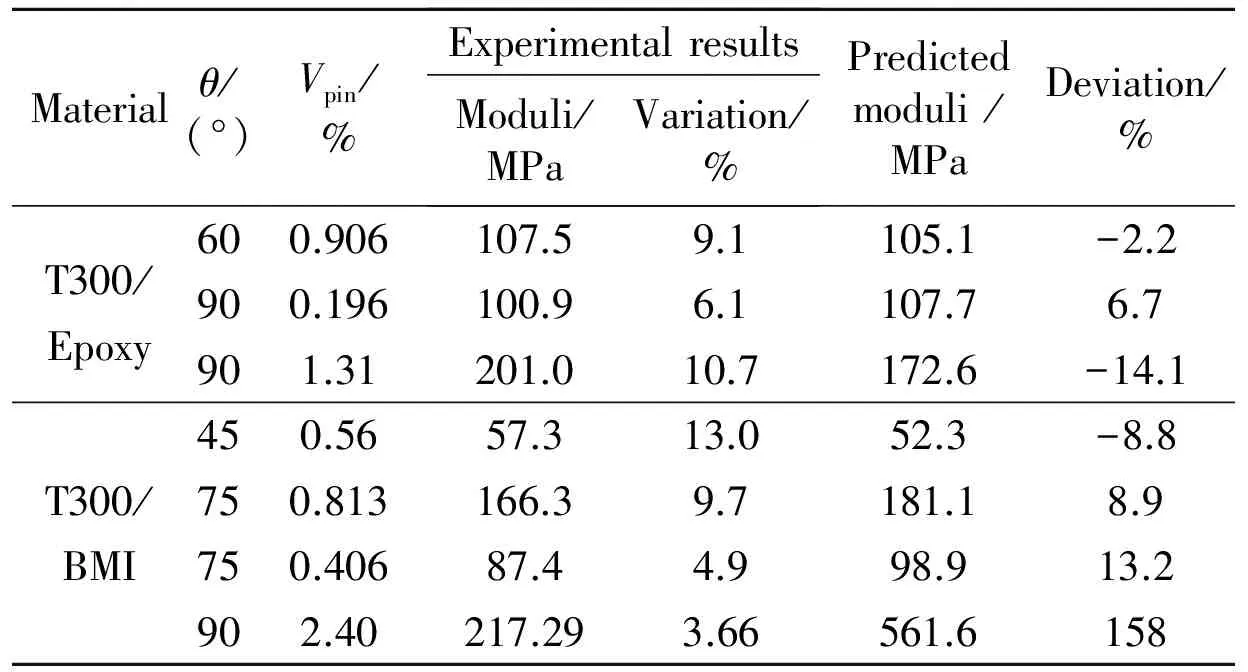

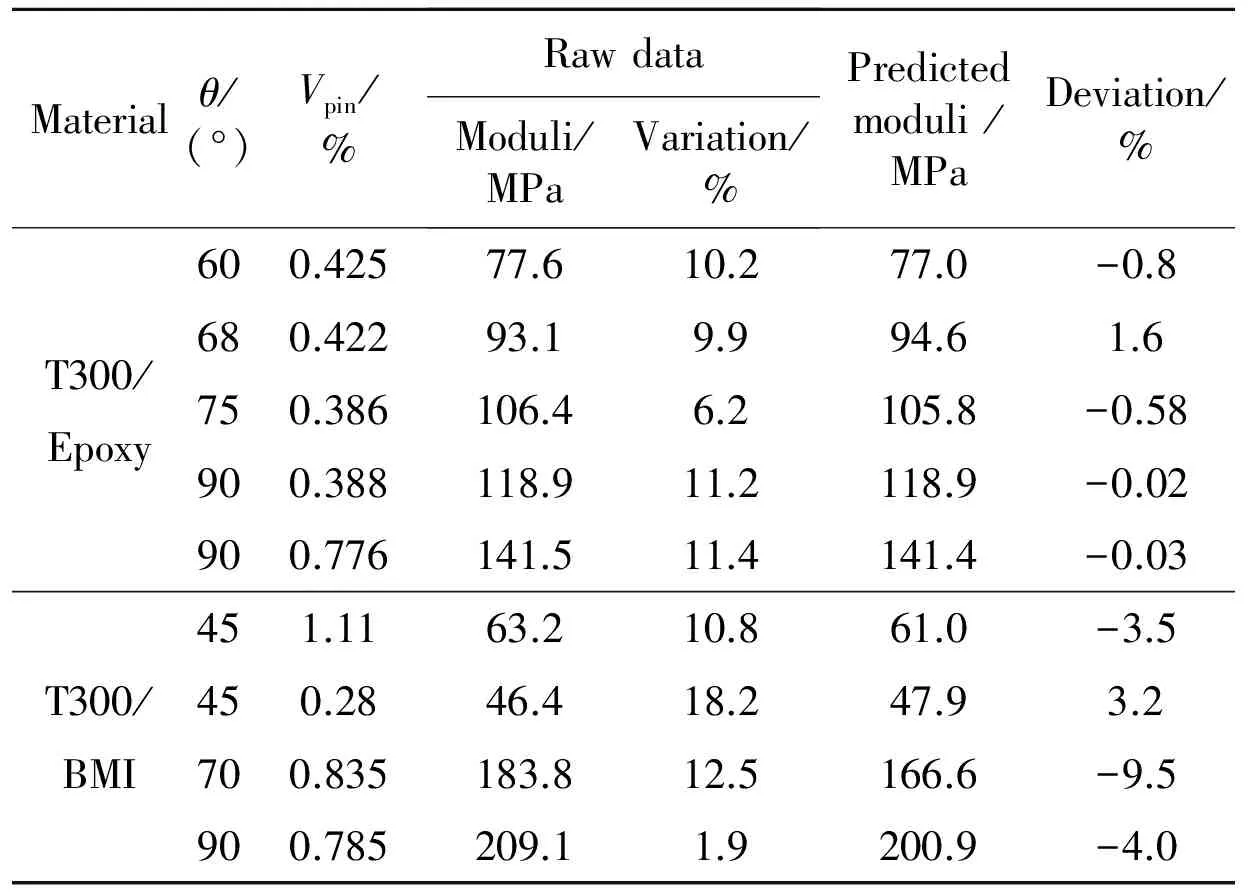

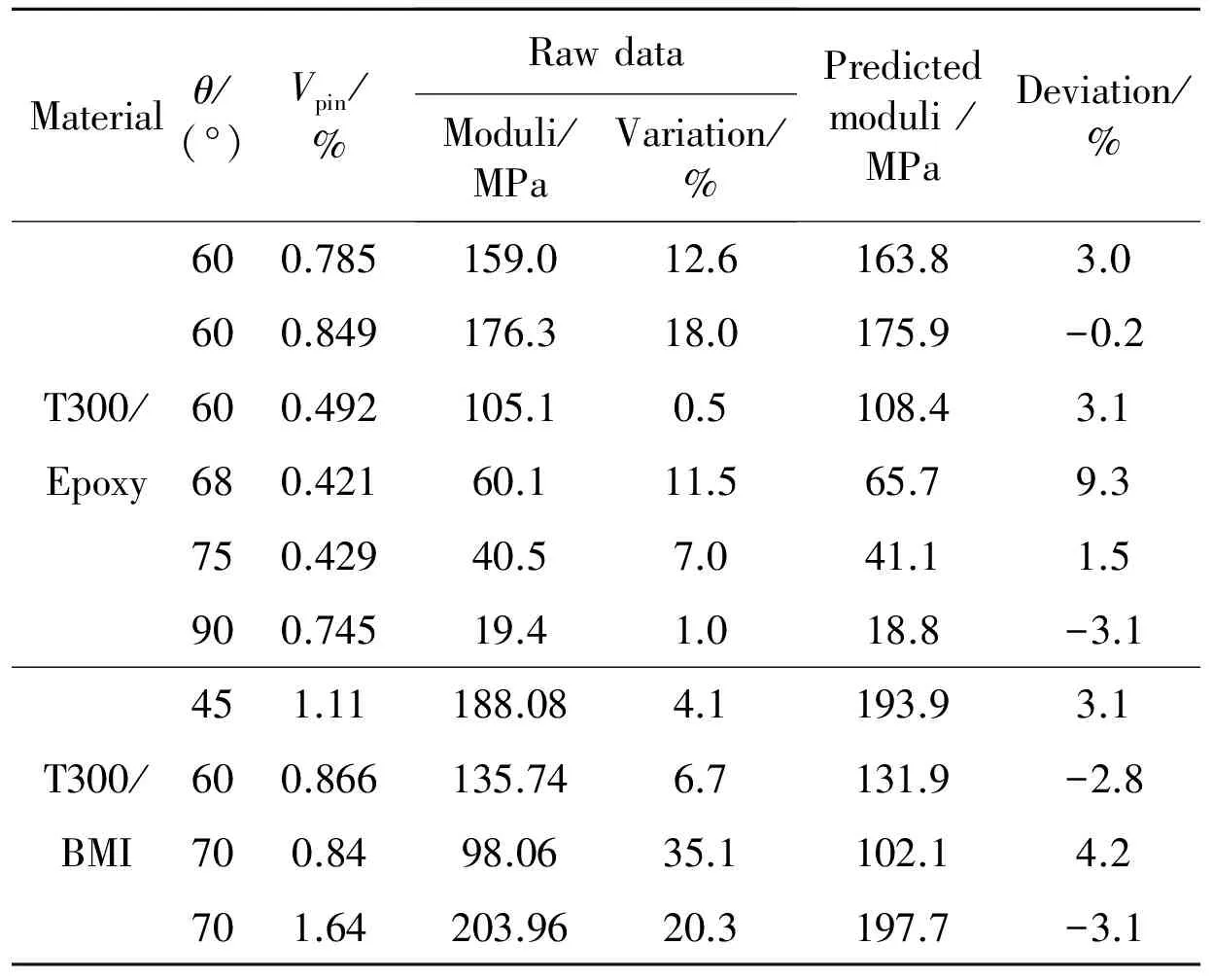

The compressive/shear stress were calculated by means of dividing the load by the dimension of each specimen. And the strain data were recorded by the extensometer. Given the stress-strain curves by the experiments mentioned above, the compressive and shear moduli of the X-cor sandwich specimen could be calculated. The experimental results and their contrast to the predicted outcome are listed in Tables 1—2.

Table 1 Experimental results of compressive moduli

The experimental verification were conducted for both epoxy and BMI systems within a wide range of pin diameter and density. And most of the deviations of the predicted data were less than 10%. It is well known that the properties of X-cor largely depend on the manufacturing process. Influencing factors, such as pin angle offset, pin/skin bonding conditions and pin length fluctuations, lead to a large variation of the muduli. Thus the deviation of confirmatory experiments (Tables 1, 2) had larger range than that of original data (Tables A1, A2). Similarly, the prediction of X-cor structure based on epoxy, with more stable manufacturing maturity, showed lower deviation and higher accuracy, compared to those on BMI matrix.

However, it is noticed that the predicted compressive modulus of T300/BMI X-cor was far more than the experimental results when the volume fraction was as high as 2.4%, which means the prediction was invalid at that point. The main reason lies in two aspects. One is the different failure mode. Densely inserted pins introduce serious damage to the foam core, which weakens the lateral support for pins under compression. In this case, the truss architecture of pins could destabilize as a whole and pins failed buckling rather than fracture. The other explanation comes from the length variation of pins. According to the theory of Shan[13], the contribution of pins to the compressive modulus is limited by statistical distribution of pin length. Acturally, only a certain amount of pins are active under compression even though a large amount are inserted. Thus, large density of pins is not recommended for compression load bearing X-cor structures.

4 Conclusions

In conclusion, the semi-empirical formulae for prediction of X-cor sandwich compressive and shear moduli are derived through the combination of experimental data and theoretical models. The data fitting method is innovatively employed for the mechanical properties prediction of X-cor structures based on the homogenization of pins.

(1) The agreement between the predicted properties with the experimental results is demonstrated by confirmatory tests on X-cor sandwich structure with different insertion parameters. And the fitting method based on experiments is proved to be feasible for composite engineering constant prediction.

(2) The two crucial parameters determining the X-cor sandwich structure performance are the pins insertion angle and the volume rate. Both the compressive and shear moduli ascend with the increase of the pins volume rate. However, with the increase of pin density, the prediction model becomes ineffective for compressive modulus. Moreover, the density higher than 1.5% is not recommended for X-cor under compression considering the reinforcement efficiency. On the other hand, as the pins being inserted closer to theZ-direction, the compressive modulus keeps rising, while the shear modulus decreases.

(3) The prediction software provides a concise and visualized platform for structural designing. For curtain, its universality and practicability will greatly promote the X-cor structure′s engineering applications.

Appendix A: The original data and fitting deviations

Table A1 Raw data and deviations of compressive module fitting

Table A2 Raw data and deviations of shear module fitting

Acknowledgements

This work was supported by the Aviation Science Fund of China(Nos.2015ZE52049,2015ZE521049).

This research was based on the theoretical models built in the prior study. The authors are grateful to Hao Jijun, Du Long, etc.

[1] Mouritz A P. Review of z-pinned composite laminates[J]. Composites Part A: Applied Science and Manufacturing, 2007,38(12):2383-2397.

[2] Carstensen T, Cournoyer D, Kunkel E. X-CorTMadvanced sandwich core material[C]∥33rd International SAMPE Technical Conference. Seattle, WA, USA: Society for the Advancement of Material and Process, 2001:452-66.

[3] Marasco A I, Cartie D R, Partridge I K, et al. Mechanical properties balance in novel Z-pinned sandwich panels: Out-of-plane properties[J]. Composites Part A, 2006,37(2):295-302.

[4] Partridge I K, Cartie D R, Bonnington T. Manufacturing and performance of Z-pinned composite[M]. Boca Raton Florida, USA: CRC Press, 2003: 103-138.

[5] Mouritz A P. Compression properties of Z-pinned sandwich composite[J]. Material Science, 2006,41(17):5771-5774.

[6] Denis D C, Fleck N A. The effect of pin reinforcement upon the through-thickness compressive strength of foam-cored sandwich panels[J]. Composite Science Technology, 2003,63(16):2401-2409.

[7] Hao J J, Zhang Z G, Li M, et al. Compression property analysis of X-cor sandwich composites[J]. Acta Aeronautica et Astronautica Sinica, 2008,29(4):1079-1083. (in Chinese)

[8] Li Y, Xiao J, Tan Y G, et al. Study on compressive property of X-cor sandwich structure[J]. Acta Aeronautica et Astronautica Sinica, 2009,30(3):557-561. (in Chinese)

[9] Dang X D, Zhang H S, Wang X L, et al. Experimental study on mechanical properties of X-cor sandwich[J]. Material Review, 2011,25(5):54-58. (in Chinese)

[10]Dang X D, Tan Y G, Xiao J, et al. Finite element modeling analysis of compressive modulus about X-cor sandwich[J]. Journal of Materials Engineering, 2009(1):50-54. (in Chinese)

[11]Shan H Y, Xiao J, Shang W, et al. Experiment and analysis on compressive modulus of X-Cor sandwich[J]. Journal of Aerospace Power, 2012,27(4):782-788. (in Chinese)

[12]Du L, Jiao G Q, Huang T, et al. Shear property of X-Z-pinned reinforced foam core sandwich[J]. Acta Materiae Compositae Sinica, 2007,24(6):140-146. (in Chinese)

[13]Shan H Y, Xiao J, Li N, et al. Compressive properties of X-cor Sandwich[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2012,44(2):251-256. (in Chinese)

(Executive editor: Zhang Bei)

TB332 Document code:A Article ID:1005-1120(2015)06-0646-08

*Corresponding author: Li Yong, Professor, E-mail: lyong@nuaa.edu.cn.

How to cite this article: Zhang Xiangyang, Li Yong, Li Junfei, et al. Prediction of compressive and shear moduli of X-cor sandwich structures for aeronautic engineering[J]. Trans. Nanjing U. Aero. Astro., 2015,32(6):646-653. http://dx.doi.org/10.16356/j.1005-1120.2015.06.646

Transactions of Nanjing University of Aeronautics and Astronautics2015年6期

Transactions of Nanjing University of Aeronautics and Astronautics2015年6期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Modeling and Identification Approach for Tripod Machine Tools

- Three-Dimensional Planning of Arrival and Departure Route Network Based on Improved Ant-Colony Algorithm

- Three-Dimensional Reconstructed Finite Element Model for C/C Composites by Micro-CT

- Infrared Heating Technology for Automated Fiber Placement

- Effect of Tip-Blade Cutting on the Performance of Large Scale Axial Fan

- Mechanical Behavior of Bistable Bump Surface for Morphing Inlet