Preparation of highly efficient antibacterial non-woven by facile plasma-induced graft polymerizing of DADMAC

Yujie SONG (宋俁潔) ,Jing YANG (楊景) ,Jiangzhou CUI (崔江舟) ,Benhua ZHAO (趙本華) ,Weimin YANG (楊衛(wèi)民) ,Haoyi LI (李好義),* and Ruixue WANG (王瑞雪),*

1 College of Mechanical and Electrical Engineering,Beijing University of Chemical Technology,Beijing 100029,People’s Republic of China

2 Shanxi Xinhua Chemical Defense Equipment Research Institute Co.,Ltd,Taiyuan 030008,People’s Republic of China

3 Beijing Spacecrafts Co.Ltd.,Beijing 100094,People’s Republic of China

Abstract The development of surface modification technology for temperature sensitive fibers has been a huge challenge.In this work,a novel technique based on cold plasma treatment was developed for the preparation of anti-bacterial polypropylene (PP) fibers.The results showed that plasma treatment introduced a rough surface and polar groups,which acted as the anchor point and initiators for diallyldimethyl ammonium chloride (DADMAC) graft-polymerization.The fabricated PP membranes presented a high bacterial sterilization rate,as well as excellent adhesion force and washing durability.After ultrasonic treatment for 30 min,the physical coating sample had lost anti-bacterial effect,while the plasma grafted sample still showed a sterilization rate of 91.67%.This work provided a clean and novel DADMAC grafting method and it is also applicable for anti-bacterial material fabrication.

Keywords: electrospinning,cold plasma,surface modification,DADMAC

1.Introduction

Microorganisms are ubiquitous in marine,soil,and humanassociated environments [1].The function of diverse ecosystems and biodiversity are significantly influenced by bacterial populations.However,microorganisms are also massive spreaders of deadly infectious diseases [2].Today,the demand for environmental-friendly antimicrobial fabrics and textiles is growing [3,4].With the outbreak of COVID-19,the demand for antibacterial nanofiber membranes increased dramatically.The fabrication of functional nanofiber membranes with excellent antibacterial properties is necessary.

There are many different techniques for fiber preparation,such as self-assembly [5],mechanical stretching [6],phase separation [7],template synthesis [8] and electrostatic spinning[9,10].Among these techniques,electrospinning is one of the most popular and commonly used techniques for the production of ultrathin fibers due to its unique and remarkable properties[11].Two synthesis routes including melt electrostatic spinning and solution electrostatic spinning have normally been applied for nanofiber preparation [12].Compared to solution electrospinning,melt electrospinning does not use toxic solvent,making it a green and safe technology.In addition,without solvent volatilization,nanofibers fabricated by melt electrospinning are uniform and smooth [13].In recent decades,melt electrospinning has been a research hotspot and employed extensively in the preparation of nanofibrous matrices [14,15].

In the textile industry,polypropylene (PP) fiber has been utilized widely and extensively due to its corrosion resistance,high strength and low cost [16].Usually,a variety of antimicrobial substances are applied to the substrate by physical or chemical methods,such as impregnation,grafting,sputtering and deposition [17,18].It is significant to note that antimicrobial fabrics need to be washed repeatedly in use,so it is important to ensure that the antimicrobial agent does not come off during the cleaning process.Traditional wet surface modification protocols are normally performed under harsh conditions with toxic reagents [19].In addition,due to the size effect,microscale and nanoscale materials often show sizedependent thermodynamic properties in comparison to bulk materials[20,21].It has been demonstrated that the melting point of nanoparticles is lower than that of bulk materials[22,23].This indicates that PP nanofibers are more sensitive to temperature compared to PP foils,which poses further challenges and increases the difficulty of surface modification.

Atmospheric pressure low-temperature plasma is a green and efficient technology for surface modification [24,25].Hidzir et al [26] applied a plasma-induced graft-polymerization technique to successfully integrate acrylic acid with polytetrafluoroethylene.High surface coverage and water uptake rate were achieved after plasma grafting.In most of the cases,alternating current(AC)power supply was used for plasma excitation,which suffers the problem of non-uniform discharge and high temperature in the filamentary discharge channel [27].This could induce irreversible damage in the modified fiber.Unlike AC discharge,nanosecond pulse discharge was generated in an overvoltage condition.Rather than heating the heavier particles,the electrical energy released during the discharge was primarily deposited at the powerful electrons [28].Thus,nanosecond pulsed discharge showed lower plasma gas temperature,improved discharge uniformity and reduced energy costs compared to AC condition [29].

Among excellent antibacterial materials,diallyldimethyl ammonium chloride (DADMAC) incorporates the benefits of ease of access,being environmentally friendly and low cost.According to the work of Pal et al [30],the U.S.Food and Drug Administration has approved DADMAC for water treatment.In this work,PP membranes were prepared by the melt electrospinning method.A high-voltage pulse generator was presented to produce a low-temperature and uniform plasma for low melting point PP nanofiber modification.Anti-bacterial PP membrane was fabricated with a subsequent heat induced radical graftpolymerization of DADMAC.Excellent antibacterial and washing durability properties were achieved.Also,DADMAC could be immobilized on the surface without use of cross-linking agents,reducing the use of toxic chemical reagents.This work presents a green,low-cost,safe and environmental-friendly way to prepare anti-bacterial ultrafine fibers.

2.Experiments

2.1.Materials

PP pellets with a melt flow index of 200 g min-1(Shanghai Eastone New Material Development Co.,Ltd,6250) were the raw materials used to produce electro-spun PP membranes.60 wt% DADMAC (Jiangsu Moore New Material Technology Co.,Ltd) was selected as the antibacterial agent to produce antibacterial membranes.The processes of the fabrication of electro-spun PP membrane and plasma surface modification are discussed in detail in sections 2.2 and 2.3.We produced four types of samples: physical coating samples,air plasma grafted samples,Ar plasma grafted samples,and Ar/O2plasma grafted samples,respectively.The physical coating samples did not undergo any plasma treatment steps.

2.2.Fabrication of electro-spun PP membrane

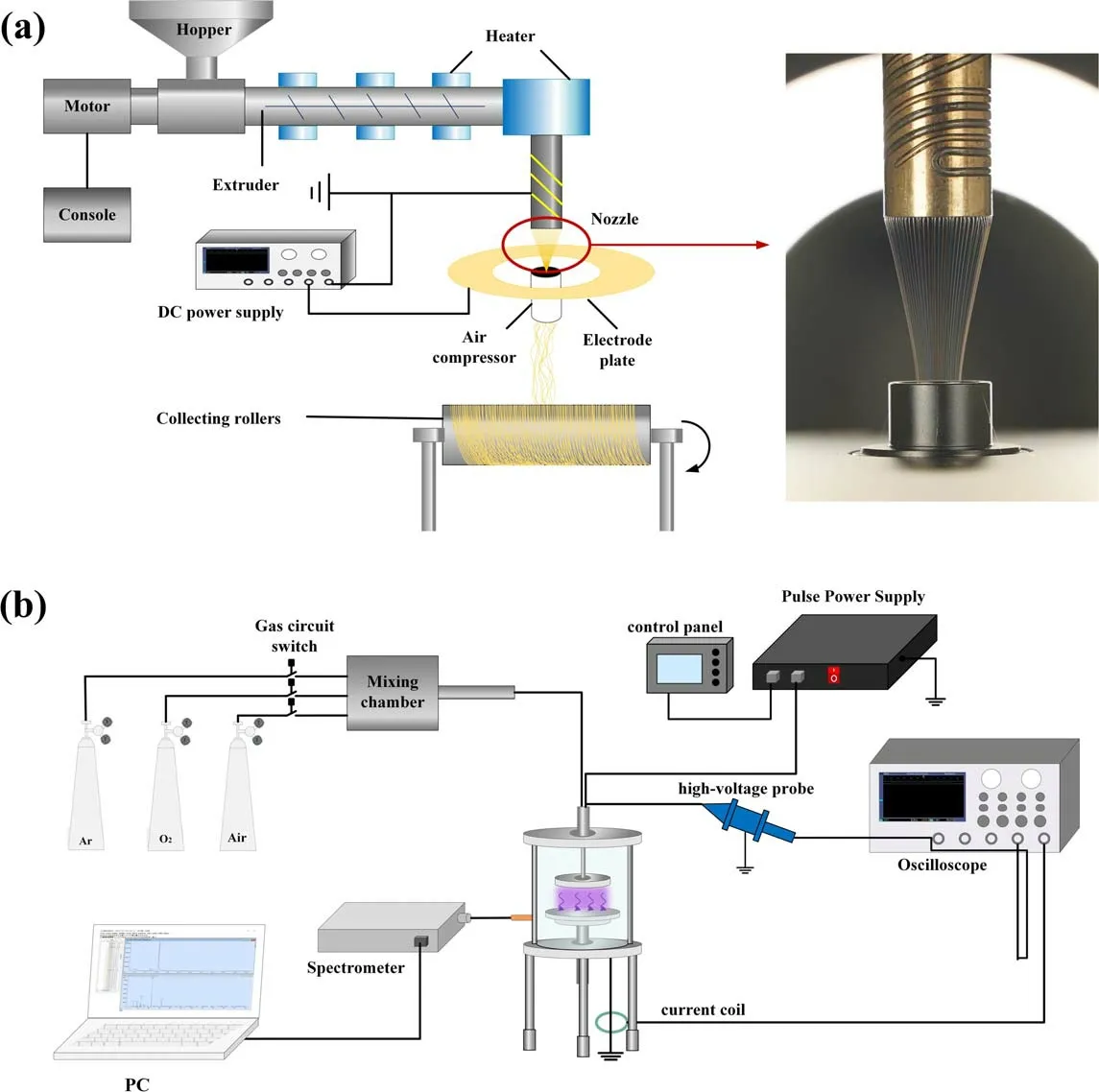

A schematic diagram of the self-designed apparatus for melt electrospinning is shown in figure 1(a).It mainly contained the following sections: high-voltage generator,console,motor,hopper,extruder,heater,nozzle,electrode plate,air compressor,and collecting rollers.Our team came up with the novel idea of a differential sprinkler after being inspired by waterfalls’ natural diversion.The basic idea is that on the bottom of the differential nozzle several Taylor cones can be generated by adjusting the breadth of supplied polymer melt on the differential nozzle’s surface.Multiple jets are then ejected when an electric field is strong enough.By using this device,the thickness of the polymer melt is reduced and the jet stream is uniformly controlled.In contrast to capillary needles,spinning efficiency is significantly improved.This work used PP non-woven fabric as the base membrane supporting material.PP pellets were put in the hopper and heated until melted,which passed via splitter plates and into the differential sprinkler.Numerous jets were generated by overcoming viscous forces and surface tension of melt under the combined effect of the forces of airflow-assisted traction,gravity,and electric field.The voltage of the high-voltage generator was set to be 45 kV,and the temperatures of the three heating zones including the differential sprinkler,splitter plate,and small screw extruder were set to be 250°C,230°C and 190°C,respectively.Additionally,the extruder speed was set to be 0.2 rotations per minute (r/min).PP membranes were generated at the spinning collecting roller after the jets crystallized into fibers in the air.

2.3.Cold plasma surface modification processes

The fabricated PP fiber membrane was further treated by an atmospheric dielectric barrier discharge(DBD)plasma to load antibacterial factors.Figure 1(b) shows the DBD surface modification diagram.The reaction chamber was equipped with two plane-parallel stainless-steel electrodes together with a quartz dielectric layer,following the specific details described in the literature by Wang et al[31].Three working gases were applied in this work,including pure argon(99.99%),a mixed gas of argon and oxygen(Ar:O2=1000:3)and air.Table 1 shows the discharge parameters of different working gases.The DBD plasma was generated by a highvoltage pulse generator (Xi’an Smart Maple Electronic Technology,HVP-22P,Xi’an,China) with adjustable pulse parameters.A current coil (Pearson,Model 6595,1 V A-1)and a high-voltage probe (Tektronix,P6015A,1000:1) were connected to an oscilloscope (Tektronix,DPO2024B,200 MHz) to monitor the current and discharge voltage,respectively.

Figure 1. Schematic diagram of (a) melt electrostatic spinning and (b) atmospheric-pressure plasma system.

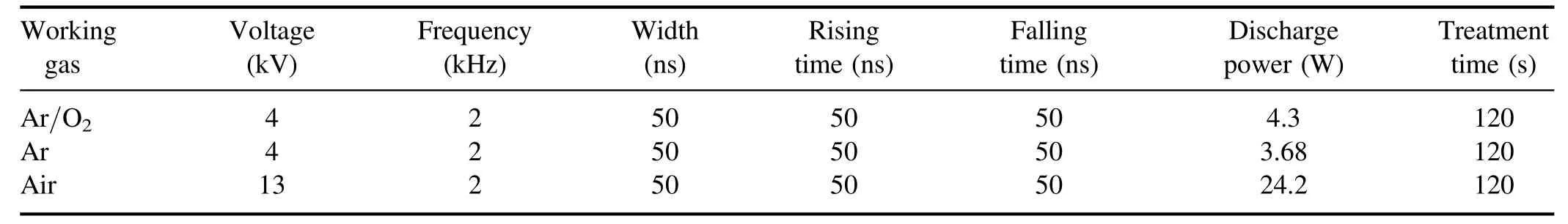

Table 1.The discharge parameters of different working gases.

The PP membrane was placed in the discharge chamber and treated both sides at room temperature and atmospheric pressure for a certain time.Before combining with antimicrobial agents,the membranes were kept in air for 30 min after plasma treatment.The aqueous solution containing 60 wt% DADMAC (Jiangsu Moore New Material Technology Co.,Ltd) was applied to the membrane surface in a vial.The sealed vial was placed in a water bath for 4 h at 80°C.After that,deionized water was used to clean the modified PP membranes in an ultrasonic bath for a certain time for subsequent testing.

2.4.Material characterization

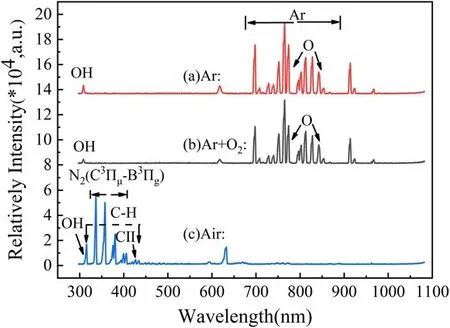

Figure 2.Discharge voltage and current waveforms of(a)Ar/O2 plasma,(c)Ar plasma and(e)air plasma and energy waveforms of(b)Ar/O2 plasma,(d) Ar plasma and (f) air plasma.

An optical spectrometer (FX2000+RD,Fuxiang,China) was used to monitor the optical emissions of the plasma.The surface morphology of samples was examined using scanning electron microscopy (SEM,TESCAN MAIA3).A contact angle goniometer (model: SL200KB,China) was used to measure the surface hydrophilicity of the PP membranes.A thermogravimetric analyzer (TGA Q50,Waters) was used to characterize the thermal stability in a nitrogen atmosphere heated at a rate of 10°C min-1from 30°C to 600°C.Uniaxial tensile tests of membranes were performed on a stretching machine (INSTRON-3365) to analyze the mechanical properties.X-ray photoelectron spectroscopy (XPS,Thermo Fisher,250XI,UK) and fourier transformed infrared spectroscopy(FTIR,Nicolet 6700,Thermo Fisher,USA) were used to monitor surface composition and the functional groups of the modified membranes.

The antimicrobial activity of the DADMAC modified PP film was tested under the guidance of AATCC Test Method 100.This is a typical test for antimicrobial textiles or foils.Escherichia coli was used as a gram-negative test bacterial strain.A 0.1 ml diluted bacteria suspension with a concentration of 1 × 105CFU ml-1was applied to PP membranes with dimensions of 25 × 25 mm2.After exposure for different times,the microbial cultures were diluted in sterile saline.The antibacterial rate was determined by the plate counting method.The following equation was used to compute the decrease in bacterial populations:

where A is the quantity of microbial colonies of the control group and B is the number of microbial colonies of modified membranes.Furthermore,the antibacterial and the washing durability of the initial and treated PP membrane were analyzed.

3.Results and discussion

3.1.Electrical and optical characterization of plasma discharge

To get a steady discharge during the plasma treatment procedure,the plasma discharge was carried out under optimal conditions.The discharge voltage and current waveforms and the energy waveforms of DBD plasma with different working gases are shown in figure 2.The stable working voltages for Ar/O2,Ar and air plasma were 4.4 kV,4.1 kV and 15 kV,respectively.The calculated average power for Ar/O2,Ar and air plasma were 4.3 W,3.68 W and 24.2 W,respectively.During the rise and fall times of the applied voltage,the positive and negative discharges were observed for all gases.Several small discharge current peaks were also observed after the negative current,due to the fluctuation of the applied voltage.For plasma with different gases,the discharge voltage changed,because different gases have different ionization energies or electron impact ionization cross sections[32].Air has the highest ionization energy (the ionization energies of N2and O2are 15.6 eV and 12.1 eV,respectively) [33],thus air presents the highest breakdown voltage compared to other two gases.

I remembered being a small girl at school picnics, watching other children and their mothers. It was often so painful that I had to turn away. It wasn’t until a kind and understanding young teacher took it upon herself to be my friend, and became a kind of surrogate mother to me, that I began to blossom. After that I grew faster, my grades were better and I felt alive inside.

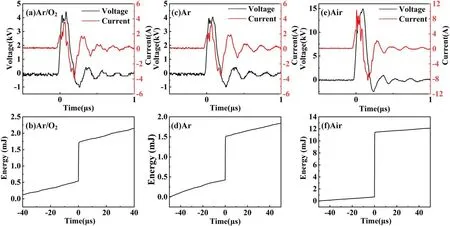

Figure 3. Optical emissions of air,Ar/O2 and Ar plasma.

The optical emission spectra(OES)of the Ar/O2,Ar and air plasma in the range of 300-1000 nm were monitored and are shown in figure 3.For Ar/O2and Ar plasma,the integrate time was 100 ms.The emissions at 306-309 nm and 700-1000 nm were OH (A2Σ+-Х2П) and Ar species [34].In the visible area at 777 nm and 844 nm,strong atomic oxygen emissions produced by processes of dissociative and direct excitation could be observed from the optical emission spectra of Ar and Ar/O2plasma.The appearance of OH species in Ar/O2and Ar plasma was because of metastable collisions of Ar/electron and water or air molecules in the environment [35].For air plasma,because of the low discharge intensity,the integrate time was increased to 500 ms.Strong N2second positive system N2(C3Пμ-B3Пg) at 330-420 nm (referring to as N2emission) and OH(A2Σ+-Х2П) emissions at 306-309 nm were observed.The data are assembled from studies by Bai et al[36].At the same time,C-H(C2Σ+-Х2П)emissions at 315.9 nm,CⅡemissions at 426.7 nm and C-H(A2Δ-Х2П)emissions at 432.9 nm were discovered.The appearance of these species provided evidence of PP chain breakup in the plasma discharge zone.The dissociation of PP was only observed in air plasma due to its high discharge energy.

The temperature after plasma treatment was estimated by a thermocouple.A metal plate with good thermal conductivity was used as a substrate,and the temperature of the substrate was measured immediately after the discharge is completed.The temperatures were 31.9°C,26.3°C and 27.5°C after air,Ar and Ar/O2plasma treatment for 2 min,respectively.This result demonstrated that high-voltage pulsed discharge is an effective method to produce low-temperature and uniform discharge plasma.It can be applied for polymer surface modification without thermal damage to the surface.

3.2.The influence of plasma modification on PP fiber properties

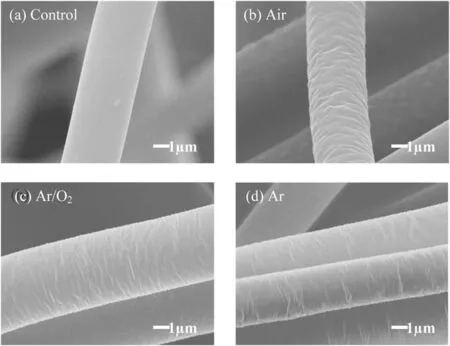

In the plasma discharge process,the weak boundary on the fiber surface is effectively removed by the bombardment and sputtering of massive particles in plasma,which is known as the etching effect [37].As plasma treatment time increased,the morphology of treated fibers and their surface roughness changed [38].Therefore,the plasma treatment time needs to be reasonably controlled according to fiber diameter.As shown in figure 4,the pristine fiber presented a smooth surface.After plasma treatment for 2 min,obvious winkles were observed for all three working gases due to plasma etching.In particular,air plasma presented a rougher fiber surface compared to the other two gases.The topography and roughness of PP fibers were modified due to energetic active species that can etch the surface and break the polymer chains [39].For Ar/O2and Ar plasma,the etching might be due to the bombardment of high-energy electrons and massive ions[37]or due to reactions with atomic oxygen [40,41].For air plasma,except for the etching effect from high-energy electrons bombardment,dissociation of PP chains in the plasma discharge zone was also observed (as confirmed by figure 3).This explains a rougher fiber surface with air plasma treatment compared to other two gases.

Figure 4.SEM images of (a) control,(b) air plasma treatment sample,(c) Ar/O2 plasma treatment sample and (d) Ar plasma treatment sample.

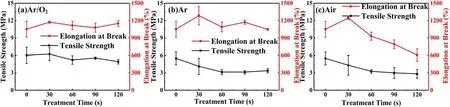

The increase of surface roughness had a detrimental impact on the mechanical characteristics of the fiber.The tensile strength of untreated PP membrane was 6.02 MPa and the elongation at breaking was 1051% (figure 5).Ar/O2and Ar plasma had little effect on the fiber mechanical properties.After Ar/O2and Ar plasma treatment for 30 s,60 s,90 s and 120 s,the elongation at breaking changed slightly.But for air plasma treatment,the value of elongation at breaking decreased rapidly as plasma treatment time increased.In addition,the overall trend of the tensile strength of Ar/O2,Ar and air plasma-treated samples showed a slow decrease with the increase of plasma treatment time.This result indicated that the mechanical properties of the micro-or nano-sized polymer fibers could be damaged to some extent due to the plasma etching effect,but it is controllable by choosing the right working gas or treatment time.

Figure 5.Tensile strength and elongation at break of(a)Ar/O2 plasma treatment sample,(b)Ar plasma treatment sample and(c)air plasma treatment sample.

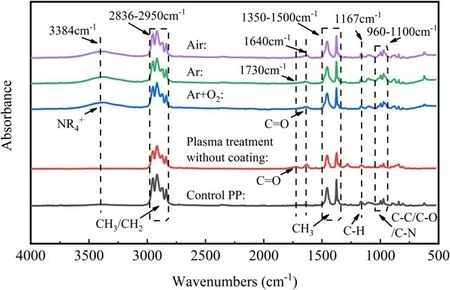

Figure 6.FTIR spectroscopy of (a) air plasma treatment sample,(b)Ar plasma treatment sample,(c)Ar/O2 plasma treatment sample,(d)plasma treatment without coating and (e) control PP.

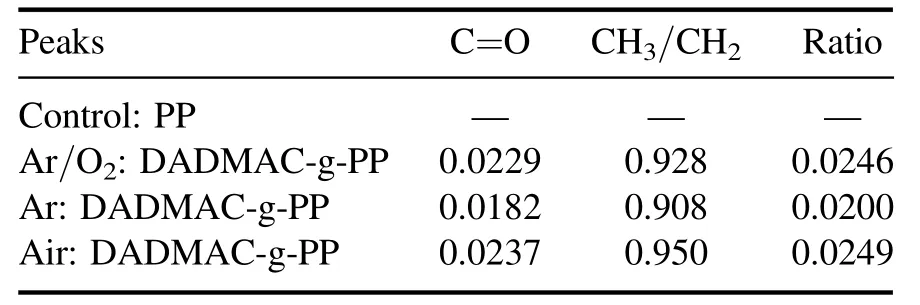

Table 2.Ratio of intensity of functional group peaks to intensity of the main PP group.

The composition and functional groups of the samples were investigated by FTIR,as shown in figure 6.The IR spectra are measured by the absorption spectra of the sample in a KBr plate.FTIR spectra for the control PP sample showed strong peaks at 2836-2950 cm-1,1350-1500 cm-1and 750-1250 cm-1corresponding to CH3and CH2stretching,CH3symmetrical bending,C-C stretching,C-H or CH3rocking in PP molecular chains,respectively [42].After plasma treatment,two new peaks at 1640 cm-1and 1730 cm-1appeared,confirming the existence of C=O stretching [43].A new peak appeared at 3250-3500 cm-1,corresponding to thegroup of DADMAC.In the meantime,the intensities of peaks at 960-1100 cm-1increased.This was ascribed to the C-N bond of DADMAC[44].These findings showed that DADMAC has been successfully integrated with PP membranes.Moreover,in the grafted samples,C=O stretching in the region of 1500-1750 cm-1can also be observed.The FTIR results confirmed that the observed functional group related to C=O served as starting points or the initiator for grafting-from polymerizations with DADMAC.The peaks appearing at 1640 cm-1and 1730 cm-1in plasma treatment without coating sample(only treated with plasma,without attachment of antimicrobial agents) demonstrated that the C=O bond present in the grafted sample was produced by plasma treatment,as PP and DADMAC themselves did not have C=O bonds.Table 2 compares the number of C=O groups by comparing the ratio of intensity of C=O group peaks to the intensity of the main PP group.Among them,the air plasmatreated DADMAC-g-PP samples shows the highest number of C=O bonds,indicating the best grafting effect.

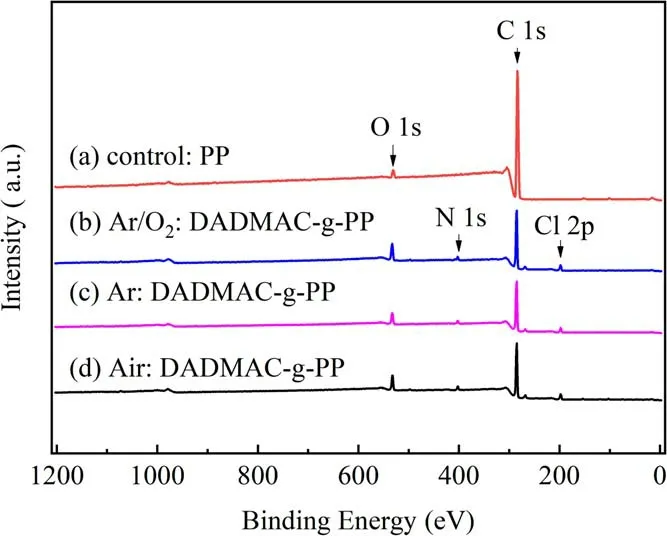

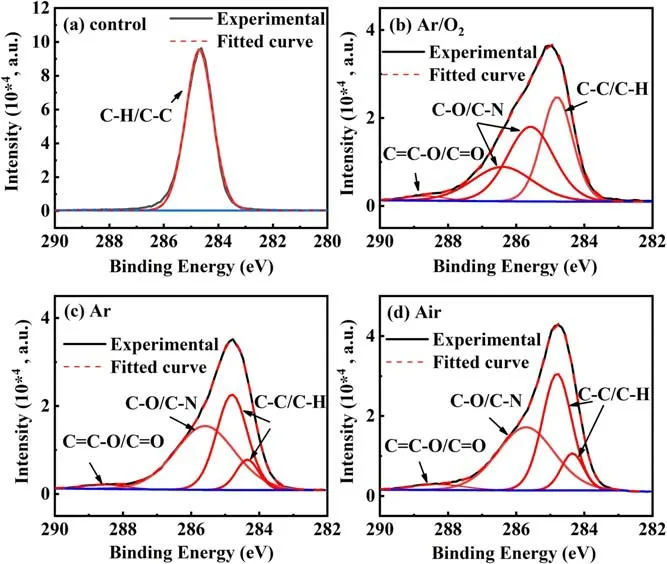

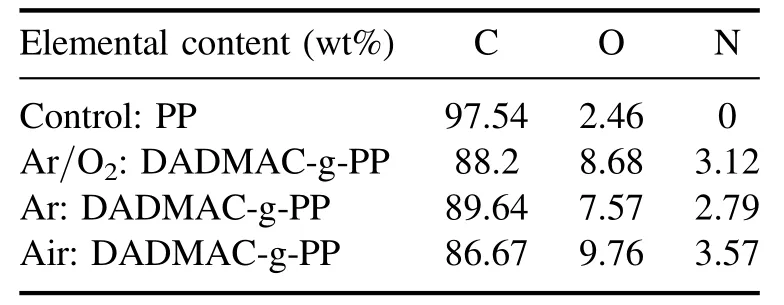

Figure 7.X-ray photoelectron spectroscopy of (a) control PP,(b)Ar/O2 plasma grafted sample,(c) Ar plasma grafted sample,(d) air plasma grafted sample.

XPS was used to further determine the chemical changes and composition of the PP membranes’ surface,as shown in figure 7.The peaks at 198 eV,285 eV,401 eV and 532 eV represent chlorine (Cl),carbon (C),nitrogen (N) and oxygen(O),respectively [45].Compared with the control PP,two new peaks of plasma treated samples at 198 eV and 401 eV were ascribed to Cl and N in the DADMAC,respectively.Table 3 shows the elemental content of different samples.For the DADMAC-g-PP samples,the content of oxygen elemental increased,and the content of carbon elemental decreased in contrast to the control PP.The result was a qualitative proof of the accumulation of polar oxygen-containing groups on all plasma modified membranes’ surface.The increase of oxygen content demonstrated that plasma discharge produced more oxygen-containing groups,which acted as binding points for grafting and initiators for DADMAC polymerization.Among all three treated samples,the air plasma treatment samples presented the highest oxygen and nitrogen content,indicating the highest amount of grafted DADMAC.To examine the chemical connections on the membrane surface in more detail,peak fittings of the C 1 s peak were performed,as shown in figure 8.For the control PP sample,there was only one peak at approximately 284.7 eV,corresponding to C-C/C-H bonds.In Ar/O2,air,the Ar plasma treatment of DADMAC-g-PP samples,new binding energies were observed at approximately 288.9 eV,286.5 and 285.6 eV,which can be attributed to O=C/O=C-O and CO/C-N respectively.In contrast to the control PP,peak areas at O=C/O=C-O,C-N/C-O and C-C/C-H of each treated sample changed remarkably.The existence of C=O/O=C-O and C-O/C-N bonds proved that there was successfully grafted DADMAC,which was consistent with FTIR results(figure 6).

Figure 8.C element peaks of (a) control,(b) Ar/O2 plasma grafted sample,(c)Ar plasma grafted sample,(d)air plasma grafted sample.

Table 3.The elemental content of different samples.

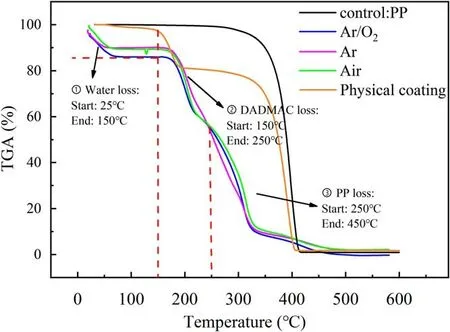

Figure 9.Thermogravimetric analysis of control,Ar/O2 plasma grafted sample,Ar plasma grafted sample,air plasma grafted sample and physical coating sample.

3.3.Characterization of adhesion force

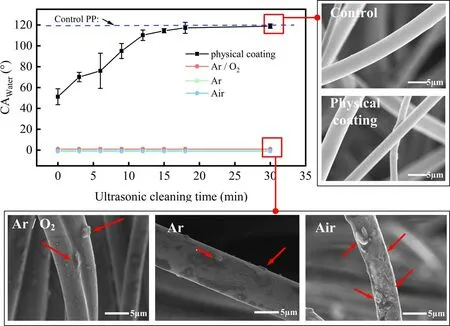

To verify the bonding force between PP fibers and DADMAC,the plasma fabricated PP membranes were cleaned in deionized water by an ultrasonic cleaner for different times,while the physical coating samples (without plasma treatment) were used as a control group.With the increase of ultrasonic cleaning time,the antibacterial agents on the membrane surface fall off to some extent,as shown in figure 10.For grafted samples (with air plasma treatment),there were still many particles attached to the surface after cleaning.However,for the physical coating samples,the attachments peeled off rapidly.With cleaning time increased to 12 min,there was no coating left on the PP film surface.The results of SEM indicated that plasma-induced graft polymerization presented an excellent adhesion force between the DADMAC coating and PP substrate.

The bonding intensity was further confirmed by water contact angle (WCA) measurement.Since PP is hydrophobic and the DADMAC coating is highly hydrophilic,the degree of hydrophilicity of samples should reflect the amount of DADMAC coating.The WCA of the pristine PP membrane was 119°,as shown in figure 11.The WCA decreased to 51.2°with a physical coating.With the increase of ultrasonic cleaning time,the WCA gradually increased,confirming a loss of DADMAC coating.After 12 min of ultrasonic cleaning,the WCA was close to the pristine PP membrane,indicating no coating left on the PP surface.By contrast,the grafted samples (after air,Ar or Ar/O2plasma treatment)presented high hydrophilicity with a WCA of 0°.With the ultrasonic cleaning time increased to 30 min,the grafted samples were still highly hydrophilic.This indicated that plasma treated samples (with all working gas) improved the adhesion between coating and PP substrate.In addition,different types of oxygen-containing groups (O=C-O,C-O,C=O,etc) produced on the surfaces during the plasma treatment can be monitored by FTIR and XPS examination.These functional groups were accountable for the change of the bonding intensity and hydrophilicity [46].

Figure 11.Water Contact Angle of control,Ar/O2 plasma grafted sample,Ar plasma grafted sample,air plasma grafted sample and physical coating sample.

3.4.Antibacterial properties

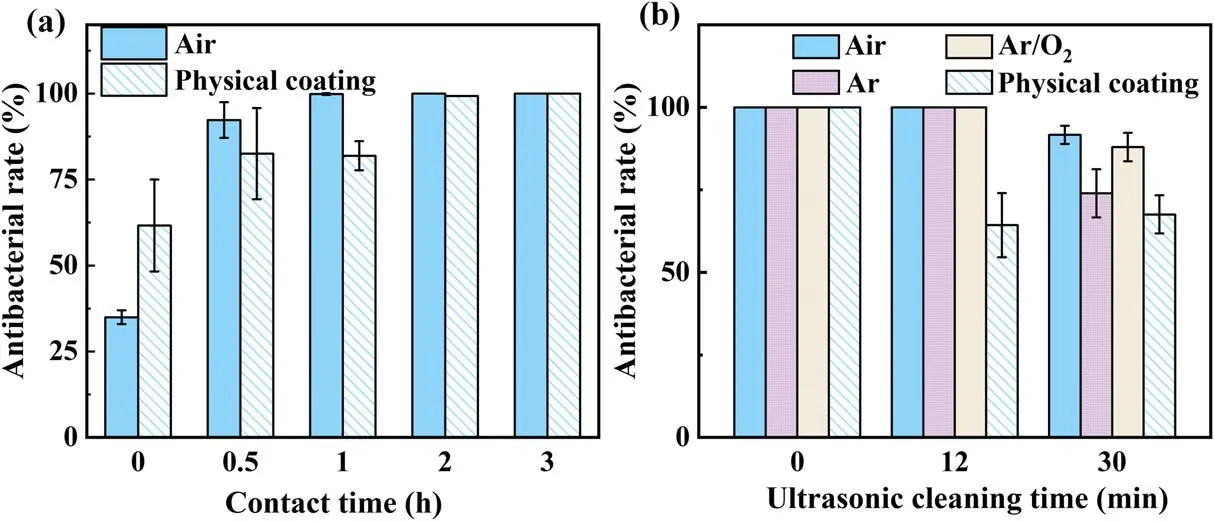

Figure 12.Variation of sterilization rate of(a)air plasma grafted samples and physical coating samples with contact time and(b)air plasma grafted samples,Ar plasma grafted samples,Ar/O2 plasma grafted samples and physical coating samples with ultrasonic cleaning time.

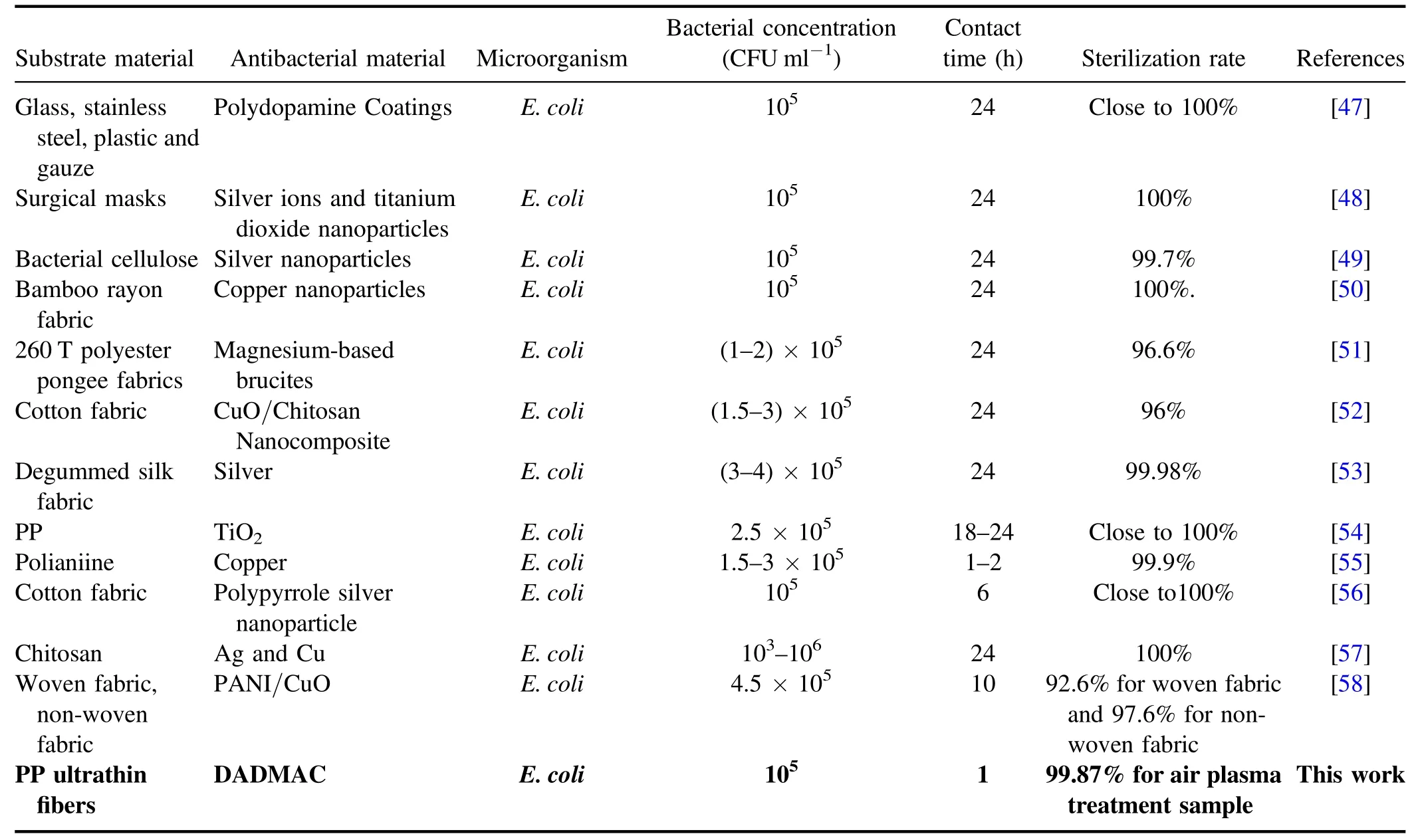

Table 4.Comparison of antibacterial properties of antibacterial materials in different references.

To confirm the germicidal ability of the modified membrane,the bactericidal performance of air plasma treated samples and physical coating samples at the same contact time was examined using the viable cell counting method.Variation of the sterilization rate of different samples with contact time is shown in figure 12(a).When the contact time reached 30 min,the sterilization rate of the air plasma treatment samples was 92.31%.At this time the sterilization rate of the physical coating samples was 82.53%.When the contact time reached 1 h,the sterilization rates of the air plasma treatment and physical coating samples were 99.87% and 81.93%,respectively.The above results showed that the sterilization effect was enhanced after plasma treatment.The reason for this phenomenon can be explained by the TGA results.After plasma treatment,the loading number of antimicrobial agents on the PP membrane increased.The loading of antimicrobial agents was the highest in the air plasma treated sample,and the lowest in the physical coating sample (figure 9).Therefore,under the same contact time,the sterilization rate of the plasma-grafted samples was higher than that of the physical coating samples because a larger number of antimicrobial agents were released.

Figure 13.The possible reaction mechanism:(a)the effect of plasma treatment(b)the free radical polymerization mechanism of DADMAC and (c) the mechanism of graft polymerization of DADMAC after plasma treatment.

To compare the washing durability of different samples,the antimicrobial properties of grafted and physical coating samples after ultrasonic washing for 0 min,12 min,and 30 min were tested,as shown in figure 12(b).All samples were exposed to bacterial suspensions for 4 h.As we can see from figure 12,without ultrasonic cleaning,both physical coating and plasma treated samples showed strong bactericidal properties.However,after 12 min ultrasonically cleaning,the sterilization rate of the physical coating samples decreased to 64.33%,indicating that the non-grafted and unreacted antibacterial agents were rinsed away.However,the plasma treated samples still presented strong bactericidal activity of 99.99%.For the physical coating samples,there was no bactericidal activity after 30 min of cleaning.However,the sterilization rates of grafted samples fabricated by plasma treatment of air,Ar and Ar/O2were 91.67%,87.97%and 73.95%,respectively.The reason for this phenomenon can be explained by the SEM and WCA results (figures 10 and 11).After plasma treatment,the adhesion force between the antimicrobial agents and PP membrane was improved.Under the same ultrasonic cleaning time,the number of antibacterial agents attached to the plasma-grafted samples was higher than that of the physical coating samples,therefore the sterilization effect of the plasma-grafted samples was better.The air plasma treated samples presented the best washing durability in all samples,which was consistent with the higher surface roughness,higher oxygen content and higher grafted DADMAC amount as shown in the previous sections.The antibacterial membrane fabricated in this work exhibited a high sterilization rate within a very short contact time (1 h) compared to other literature (table 4).

4.Discussion

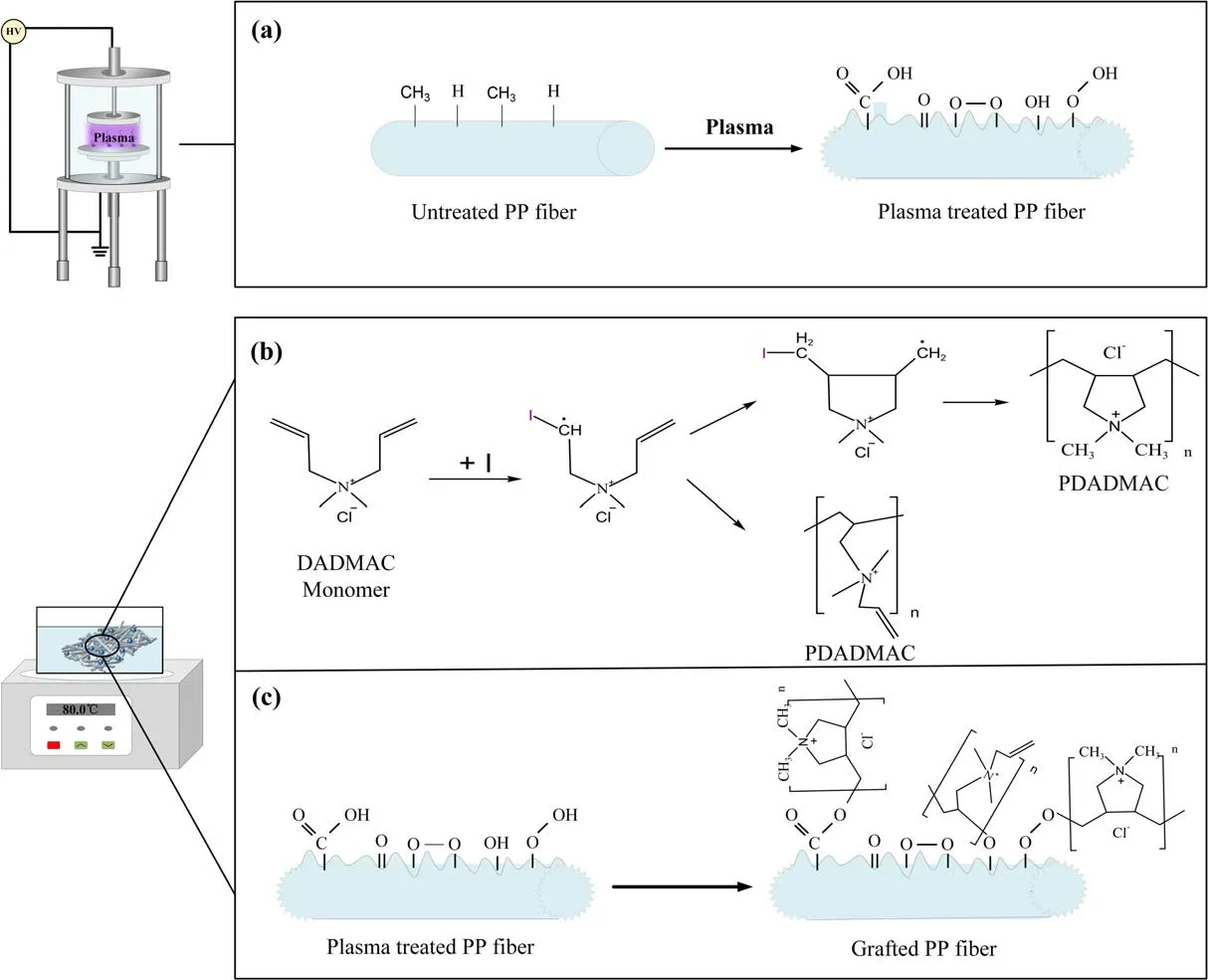

Plasma grafted DADAMC/PP membranes presented excellent anti-bacterial properties with a good adhesion force.Plasma treatment increased the PP roughness and also introduced polar groups.The increase of surface roughness was of benefit for DADMAC grafting by providing more binding sites.At the same time,the addition of the polar functional groups(such as O=C-O,C-O,C=O)after plasma treatment was responsible for the higher adhesion of the PP surface.Surface bound peroxides generated after plasma exposure can act as initiators for the graft polymerization of DADMAC after thermal homolysis.The carboxylic acid and hydroxyl groups on the PP fiber by plasma treatment act as starting points and react with DADMAC to form the ammonium salt.Electron-rich double bonds of DADMAC were attacked by initiators,and then the reaction was propagated by merging with other DADMAC units.When the reaction started,the polymerization may proceed with a ring-closure.This resulted in the formation of five-membered heterogeneous rings with ammonium cations [59].When two radicals unite,the polymerization is finished.The possible experimental mechanism is shown in figure 13.

In all three working gases,air plasma treatment possessed the roughest surface and the highest number of oxygen-containing groups that were able to graft more DADMAC (figure 9),presenting the best anti-bacterial properties and washing durability (figure 12).It is also important to mention that the increase of PP surface roughness had a negative effect on the fiber mechanical properties.As a result of the size effect,materials at the microscale and nanoscale exhibit size-dependent thermodynamic properties when compared to their bulk counterparts[20,21],and fibers of different diameters exhibit varying degrees of degradation in mechanical properties after plasma treatment.Therefore,the plasma treatment duration should be reasonably controlled according to factors such as fiber diameter,plasma discharge parameters,working gas type,grafting rate,and mechanical properties.Additionally,numerous investigations have indicated that for textiles or polymers a localized severe degradation may occur.In the gas phase,there is significant heavy particle heating,and this could result in surface heating.Direct surface damage by partial melting would then take place [60].However,in this paper,pulsed discharge uses the advantages of uniform and homogeneous energy as well as low-temperature gas;the average power released from the DBD plasma is comparatively gentle and no partial melting takes place in the PP membrane surface.It is an effective method and can be applied for polymer surface modification without thermal damage to the surface.

5.Conclusion

In this paper,anti-bacterial polypropylene (PP) membrane was fabricated by plasma activation followed by low-temperature induced radical graft-polymerization of diallyldimethyl ammonium chloride (DADMAC).Pulse plasma with a low discharge temperature increased surface roughness and introduced chemical groups on the PP surface without thermal damage.The successful grafting of DADMAC to the PP membrane,as well as the stabilization of the grafted layers,was validated by multiple tests.The fabricated membrane presented a high adhesion force and washing durability,compared to physical coating.In all three working gases,air plasma presented the best adhesion force,anti-bacterial property and washing durability.This procedure has the advantages of being fast,green,low cost,and can be easily scaled up to industrial applications.

Acknowledgments

This work was supported by National Natural Science Foundation of China (Nos.51877205 and 52011530191),Fundamental Research Funds for the Central Universities(No.buctrc201906) and Beijing Nova Program (No.2022015).

Plasma Science and Technology2023年11期

Plasma Science and Technology2023年11期

- Plasma Science and Technology的其它文章

- High-order field theory and a weak Euler-Lagrange-Barut equation for classical relativistic particle-field systems

- Design of new resonant magnetic perturbation coils on the J-TEXT tokamak

- Non-invasive optical characterization and estimation of Zn porosity in gas tungsten arc welding of Fe-Al joints using CR model and OES measurements

- A study of grid failure mode drivers and methods for accelerated life testing of a 30cm diameter ion thruster

- Research on degradation mechanism of trichlorobenzene and Hg0 by nonthermal plasma catalysis

- Ionization wave propagation and cathode sheath formation due to surface dielectricbarrier discharge sustained in pulsed mode