The effect of pulse voltage rise rate on the polypropylene surface hydrophilic modification by ns pulsed nitrogen DBD

Feng LIU(劉峰),Shuhao LI(李舒豪),Yulei ZHAO(趙昱雷),Shakeel AKRAM,Li ZHANG (張麗)and Zhi FANG (方志)

College of Electrical Engineering and Control Science,Nanjing Tech University,Nanjing 211816,People’s Republic of China

Abstract

Keywords: dielectric barrier discharge, pulse rise time, material surface modification,polypropylene, uniformity

1.Introduction

Due to its excellent chemical resistance, heat resistance,electrical insulation, and dielectric properties, polypropylene(PP)is a kind of high-molecular-weight polymer material that has a wide range of applications in the automotive,electronics and electrical appliance, construction, food industry, and other fields [1-3].However, the lack of polar groups in PP materials results in low hydrophilicity, which severely restricts their use in the fields of bonding, printing, and dyeing [4, 5].Therefore, the effort towards the expansion of the application of PP materials poses demands on the modification of their surface hydrophilic property.At present,PP surface modification methods mainly include ultraviolet irradiation [6], the wet chemical method [7], particle irradiation [8], and the low-temperature plasma method[9, 10].Low-temperature plasma surface modification technology makes a variety of physical and chemical changes on the material surface,such as etching and introducing polar groups, which can effectively improve the hydrophilicity of polymers and fibers.Jiang et al used plasma jet to enhance the surface wettability and adhesion properties of ultrahigh molecular weight polyethylene fibers [11].Samanta et al improved the water and oil absorbency of nylon, polyester fabrics, and cotton fabrics by glow plasma in Ar, He, air and O2[12].Teli et al treated silk fibers with He/N2plasma and found that the rate of dyeing in plasma treated silk was improved obviously [13, 14].Navaneetha et al adopted low pressure glow discharge to treat polyethylene (PE) film for improvement of adhesive properties [15].Resnik et al modified polyethylene (PET) with SF6or CF4at different pressures to the formation of the hydrophilic surface[16].The advantages of the low-temperature plasma method include easy operation, fast processing speed, low environmental pollution, and energy savings compared with other methods[17-19].Low-temperature plasma types that operate at atmospheric pressure include glow discharge, jet discharge,and dielectric barrier discharge (DBD).Among them, DBD has been extensively employed in the field of modifying PP surfaces because it can produce large-area,high-activity,lowtemperature plasma with a moderate energy density at atmospheric pressure [20-22].However, under atmospheric pressure,the pd(p and d are gas pressure and air gap spacing,respectively) value is quite high, the average free path of electrons is short, and frequent collisions between particles are easy to distort the original electric field.As a result,atmospheric DBD typically takes the form of a filament discharge, resulting in uneven surface modification and even material burning [23].

Large-scale homogeneous DBD discharge production under various operating conditions, including excitation source,working gas,electrode structure,and barrier material,has received a lot of attention [24-26].Pulse power supplies are frequently used to excite DBD due to the short duration and overvoltage breakdown of the pulse discharge, which is conducive to the generation of a uniform discharge.This is a result of the advancement of pulse power technology.Additionally,the pulse power supply has numerous adjustable parameters such as rise/fall time,pulse width,and frequency,which provides more options for optimizing the uniformity of the pulse DBD.Therefore, the investigations of variations of pulse power supply parameters of DBD attract much attention to improve discharge uniformity.Fan et al studied the effects of pulse rise time and pulse width on the discharge characteristics of atmospheric pressure ns pulsed nitrogen DBD and found that based on the volume memory effect,the discharge uniformity gradually deteriorates when the pulse rise time changes from 50 to 500 ns, while the discharge uniformity is hardly affected when adjusting pulse width time changes in the range of 0.1-1.5 μs [27].Xie et al studied the influence of pulse rise time on the discharge characteristics of pulsed DBD and found that when the pulse rise time is 50 ns,the discharge is relatively uniform.The discharge uniformity steadily deteriorates if the pulse rise time is increased to 400 ns [28].The research by Liu et al on the ns pulsed DBD mode conversion conditions demonstrated that the short pulse rise time produces overvoltage phenomenon, which makes it easier to transfer from non-uniform mode to uniform mode[29].Some experts and scholars have studied the application of pulsed DBD to polymer modification.Liu et al used bipolar ns pulsed power supply to drive DBD modified PET and the results showed that a large number of oxygencontaining polar groups were introduced into the film surface treated by uniform DBD, which had better surface properties[30].In order to introduce hydrophilic polar oxygencontaining functional groups and increase surface roughness,Samipour et al treated PET with oxygen DBD driven by a ns pulsed power source.As a result, the water contact angle(WCA) of the sample was significantly reduced [31].Yang et al used bipolar nanosecond pulsed air DBD to modify PP non-woven fabric.Compared to AC DBD, when the WCA decreases from 145° to 110°, the average energy cost of nanosecond pulsed DBD is only 1/20 of that of the former [32].

The aforementioned findings demonstrate that by modifying the pulse parameters, the uniformity of DBD can be optimized, and pulsed DBD has a promising future in the field of material surface modification.The pulsed DBD belongs to the overvoltage breakdown,and the pulse rise time affects the discharge process, which is the key factor for the discharge uniformity.Although reasonable adjustment of the pulse rise time can improve DBD discharge uniformity,but it is still unclear how the corresponding synergistic relationship between the treatment uniformity of PP modification and the discharge uniformity interact is still unknown.

In this work, ns-pulsed nitrogen DBD plasma is generated at atmospheric pressure with different pulse rise times and used to treat PP material.The variation trend of discharge uniformity is quantitatively analyzed by digital image processing method,the electrical micro-parameters are analyzed by the DBD equivalent model method, and the plasma activity in the discharge process is characterized by parameters such as emission spectrum intensity, electron temperature (Te), and electron density (ne).The radial distribution and fixed-point distribution of the WCA are used as measures of the modification effect and the uniformity of the treatment.Simultaneously, the physical morphology and chemical composition of PP were compared before and after AFM and Fourier transform infrared (FTIR) treatment.

2.Experimental setup and methodology

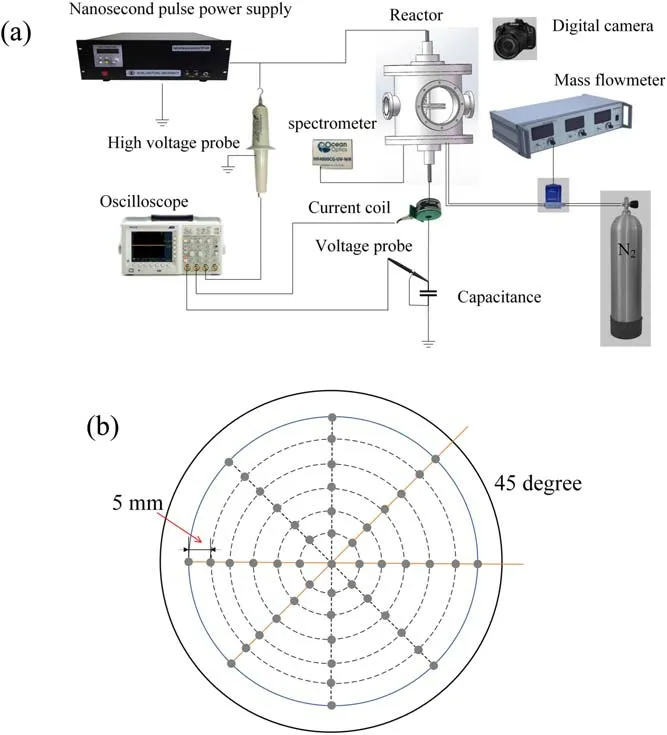

Figure 1.Experimental device and measurement system diagram(a)and a schematic diagram for PP sample WCA measurement (b).

The schematic diagram of the experimental setup is shown in figure 1(a), which consists of a commercial ns pulsed power supply (Xi’an HV-2015), reactor, electrical and optical measurement system and air flow control system.In the experiment, the voltage amplitude was fixed at 12 kV, the frequency was fixed at 500 Hz, the pulse width was fixed at 1000 ns and the pulse fall time was 50 ns,while the pulse rise time was adjusted from 50 to 500 ns.The reactor was made of stainless steel with 200 mm diameter inside, which can be pumped to a vacuum (5 Pa) to maintain the gas component inside the reactor with a gas supply system.The parallel plate electrodes with a diameter of 50 mm were placed in the center of the reactor.The dielectric material was quartz glass with a diameter of 80 mm and a thickness of 2 mm, which was covered on the ground electrode plate.The air gap distance was fixed at 1.5 mm in the experiment.The applied voltage(Ut)and the total loop current(It)were measured by the high voltage probe (North Star PVM-5) and the current coil(Pearson Electronics Inc.2877) respectively.The measuring capacitance (CR) of 2.2 nF was connected to the discharge grounding terminal which can be used to calculate the electrical micro component of ns pulsed DBD, and the voltage of CRwas measured by the differential probe (LDP-6002).All voltage and current waveforms were recorded by a digital oscilloscope (Tek 3054).The optical emission spectroscopy was measured by a spectrometer (Ocean Optics HR4000CG).The discharge image was taken by a Canon EOS 6D SLR camera with an exposure time of 1/100 s.During the experiment, the reactor was maintained at a standard atmospheric pressure,and nitrogen(purity 99.999%)was used as the working gas.

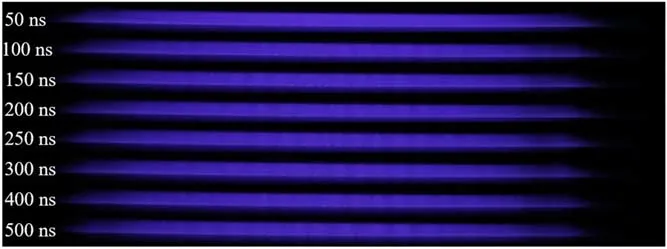

Figure 2.Discharge images of ns pulsed nitrogen DBD with different pulse rise times.

The PP sample with a diameter of 70 mm and a thickness of 1 mm was used.Before modification,the PP samples were cleaned.Firstly, the PP sample was soaked in ethyl alcohol for 10 min, then washed with ultrasonic cleaner containing deionized water for 15 min,and finally dried in a drying oven.A distilled water droplet with 2 μl on the surface of PP is used for WCA measurement.Figure 1(b) shows the points on circles with 5 mm distance for WCA measurement,which are used to study the modification effect and the WCA radial distribution (the averaged WCA value on each circle) of PP sample under different pulse rise times.

3.Results and discussion

3.1.Discharge uniformity

Discharge uniformity is an important factor affecting material surface modification.This section mainly studies the relationship between pulse rise time and nitrogen DBD discharge uniformity.Figure 2 shows ns pulsed nitrogen DBD discharge images with different pulse rise times(50-500 ns)taken from the side parallel to the electrode and the dielectric barrier layer.

Figure 2 depicts the general trend of discharge uniformity changing from uniform to non-uniform as the pulse rise time increases.At a shorter pulse rise time, 50 ns, there is no obvious discharge filament in the discharge space.As the pulse rise time increases from 100 to 500 ns, the weak discharge filaments gradually appear in the discharge space,which means that the discharge uniformity becomes worse.The reasons are that by decreasing pulse rise time, the large energy density can be injected in a short time, the discharge space reduction electric field strength(E/n)becomes stronger and more electron avalanche channels are generated and interact with each other, enhancing discharge uniformity.Although the transition of discharge state can be judged qualitatively by observing the discharge image with the naked eye, but it lacks a clear standard via this intuitive method,especially for the discrimination of light-emitting images with similar uniformity, where large errors often occur.In recent years,digital image processing technology has received more and more attention due to its high accuracy, convenient operation and wide application [33, 34].In this work, a gray value standard deviation (GVSD) method developed in our previous work [35] is applied to quantitatively analyze the variation of the ns pulsed DBD uniformity.At first, a horizontal line of 40 mm in the middle of the discharge gap is selected to calculate the gray values of the pixels xnon the line by graying processing and dividing the length of plasma.The averaged gray value xmis calculated with xn.Then the standardized pixel valuecan be obtained by formula (1)

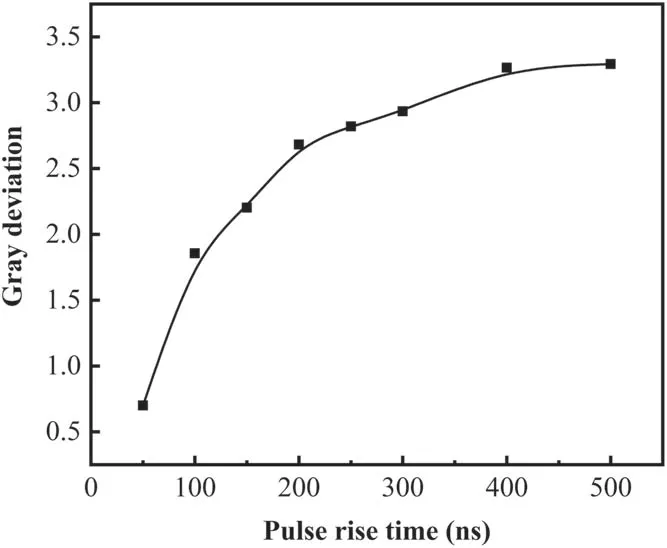

Figure 3.The gray value standard deviation of ns pulsed nitrogen DBD under different pulse rise times.

where v is the variance of pixel value.The gradient value ofcan be obtained by differentiation ofThe GVSD value is the standard deviation ofFigure 3 is the GVSD value change curve of ns pulsed nitrogen DBD images obtained under different pulse rise times, when the pulse rise time is 50 ns,the GVSD value is small(less than 1),with the increase of the pulse rise time(50-500 ns),the GVSD value gradually increases, which also shows that a shorter pulse rise time contributes to improve the discharge uniformity.

3.2.Electrical characteristics

According to the findings,discharge uniformity varies greatly depending on the pulse rise time.Since the pulse discharge belongs to overvoltage breakdown and has a short discharge time, the breakdown voltage and E/n at the beginning of the discharge are different under different pulse rise times.Therefore, to investigate the ignition and extinction process of the DBD and the effect of the pulse rise time on the DBD space electric field, discharge power and energy efficiency(η),it is necessary to carry out detailed separation calculation of each electrical parameter of DBD.Our previous work[35-37]estimated the Udby connecting a reference capacitor in series with ground electrode to separate the applied voltage and measured current, because the dielectric layer can be considered as a capacitor, the voltage on dielectric barrier(Ud) is proportional with the voltage on the reference capacitor (Ur).The amplification coefficient can be determined by making Ugnear zero when the discharge is extinguished.Then, Ugcan be obtained by subtracting the estimated Udfrom Ut.The conduction current(Ig)is obtained by subtracting displacement current(Id)from the total current It.Idis obtained by pumping the reactor to vacuum and distinguishing the discharge with the voltage applied [35].

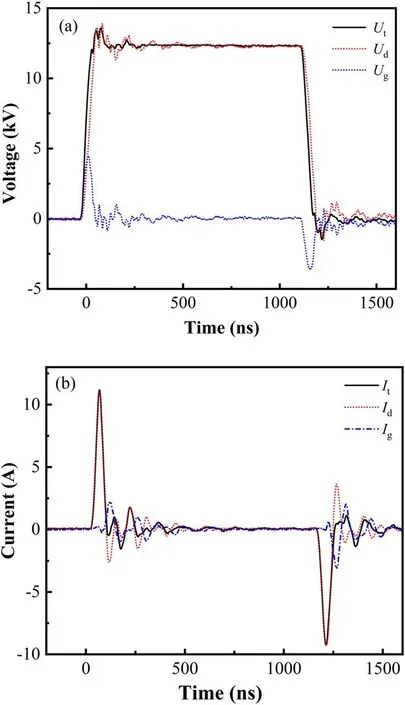

Figure 4.Waveforms of voltage separation(a)and current separation(b) with 50 ns pulse rise time.

Figure 4 shows waveforms of voltage and current separation under the pulse rise time of 50 ns.It can be seen from figures 4(a) and (b), when Utis applied to the air gap and dielectric plate,it generates three kinds of voltages Ut,Udand Ug, and the peak values of Ugand Utare different.The higher Ugincreases the electric field intensity across the gaps.When Ugreaches the breakdown voltage, air gas is broken down and Igappears.At this time, there is a large number of charges in the generated plasma, the air gap impedance decreases and Ugdrops from the peak value to 0, the discharge at pulse rise edge extinguished.Since Utapplies to the dielectric plate completely,Udand Utalmost coincide.At the falling edge of Ut, due to the accumulation of a large amount of charge produced by the previous discharge on the dielectric plate,Udstill maintains at a high voltage,and when the reverse pulse of Ugreaches the breakdown voltage,air gas breaks down again and the reverse current of Igappears.

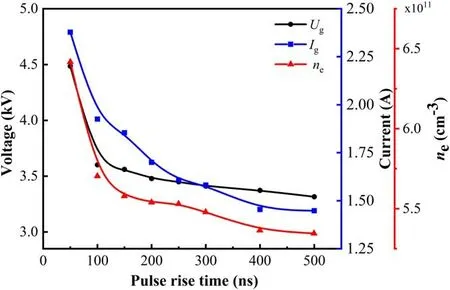

Figure 5.Variation curves of peak Ug and Ig,ne under different pulse rise times.

The variation curves of peak values of Ugand Igunder different pulse rise times are shown in figure 5.It is clear that as the pulse rise time increases from 50 to 100 ns, the peak value of Ugdrops rapidly from 4.48 to 3.60 kV.As the pulse rise time further increases to 500 ns, the peak value of Uggradually decreases to 3.31 kV and finally becomes flattened out.The peak value of Igdrops from 2.37 to 1.44 A with the pulse rise time increasing from 50 to 500 ns.Electron density(ne) is an important parameter to characterize plasma activity and DBD discharge intensity, which can be calculated by Ugand Ig.In this paper, the neis calculated by the method provided in our previous work [35, 38].With the calculated Ugand Ig, E/n can be obtained in formula (2), which can be used in BOLSIG+ code to calculate electron mobility and electron drift velocity Vdriftas shown in formulas (3)and(4).Then, necan be obtained, which is under the assumption of uniform discharge mode.In the filamentary discharge mode,newould be higher in filaments and be lower in space than the calculated value.From figure 5, we can conclude that the nedecreases gradually with pulse rise times (50-500 ns).The above result shows that nitrogen DBD has higher Ugand Igunder the shorter pulse rise time,which means that the higher energy density produced by ns pulsed power supply can be injected into the discharge space.More electrons are ionized by collision, resulting in neincreases and the discharge occupies all of space.That is because the discharge uniformity is better at a shorter pulse rise time

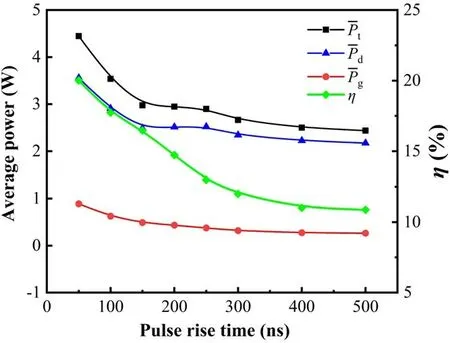

Figure 6.Variations of averaged power and energy efficiency under different pulse rise times.

The discharge power and energy efficiency are regarded as an important indicator to measure the DBD discharge intensity and the working efficiency of the plasma source.The instantaneous total power (Pt), instantaneous gap power (Pg)and instantaneous dielectric layer power (Pd) of ns pulsed power supply nitrogen DBD can be calculated by multiplying the instantaneous value of the corresponding voltage and current.The average total power,gap average poweraverage dielectric layer powerand η can be calculated by the average value of the corresponding Pt, Pg, Pdintegrals in complete cycle.The η is the ratio ofFigure 6 shows the variation trends ofand η of ns pulsed power supply DBD under different pulse rise times.The results reveal that as the increase of pulse rise time from 50 to 500 ns,all show downward trenddecreases from 4.44 to 2.43 W,Pgdecreases from 0.89 to 0.26 W anddecreases from 3.55 to 2.17 W.When the pulse rise time is less than 200 ns,theshow an obvious downward trendwith a slight decrease.When the pulse rise time is greater than 200 ns, the downward trend ofslows down andalmost remains unchanged.For η, as the pulse rise time increases,the η gradually decreases from 20%to 10.8%.The reasons are that the more energy is dissipated in the form of heat at the longer the pulse rise time,causing the energy used to generate high energy electrons to be less.It is worth to notice that the η is much lower than our previous reported values[37],which is because the treated PP material acts as a dielectric barrier and there is polarization effect between the quartz glass and PP film costing a lot of energy.

3.3.Optical emission spectra

The emission spectrum indicates the chemically active species and characteristics in the plasma, which plays an important role in studying the reaction mechanism of the plasma.In this section, the changes of the ns pulsed nitrogen DBD emission spectrum under different pulse rise times are recorded by the spectrometer.

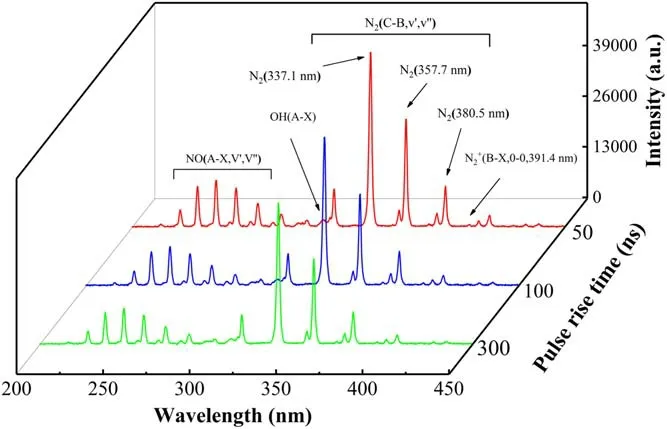

Figure 7.The emission spectra of ns pulsed nitrogen DBD under different pulse rise times.

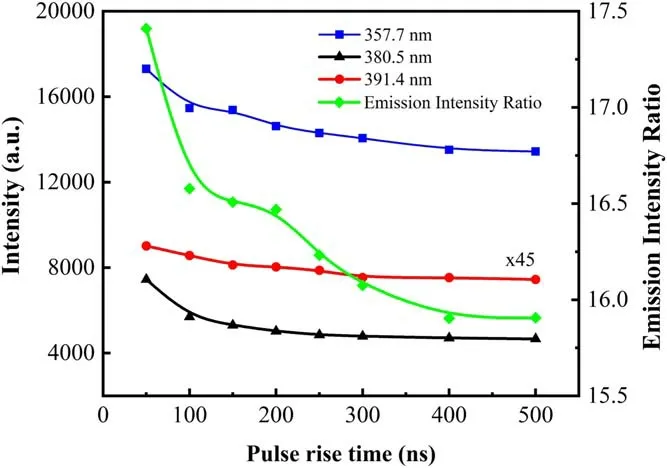

Figure 8.The optical emission intensities of N2 (357.7 nm), N2(380.5 nm), N+2 (391.4 nm), and the ratio of the emission intensities of N2 (380.5 nm) and N+2 (391.4 nm) of ns pulsed nitrogen DBD under different pulse rise times.

It can be seen from figure 7 that the emission spectra of atmospheric pressure ns pulsed nitrogen DBD mainly consist of the second positive band of nitrogen molecule N2(C3Πu→B3Πg) and NO γ spectral line.In addition, there are a small number of N2+(B2Σu+→X2Σg+)particles.Excited state N2(C3Πu→B3Πg), N+2(B2Σu+→X2Σg+) and metastable state N2*are produced by colliding between high-energy electrons and ground state molecule N2.Due to the presence of impurity water molecules and oxygen molecules, oxygen atoms that generate ground state molecules NO(X2Πu) are introduced to the reaction system.The ground state molecule NO(X2Πu) collides withand transitions to the ground state to generate the γ line of NO.The generated process of different excited-state particles is shown as reactions (5)-(8).Figure 8 shows the variation trend of the peak intensities of typical particles of nitrogen DBD under different pulse rise times, the typical optical line intensities decreased with the pulse rise times increasing, which can be considered as an indication of lower degree in ionization/plasma density at a larger pulse rise time.Please note that because the intensity of(391.4 nm) is very small compared with those of the other emission lines,the value of the intensity of(391.4 nm)in figure 8 is multiplied with 45.

During the discharge of pulsed DBD, a large number of processes such as electron excitation, ionization and chemical reaction occur.The analysis of plasma parameters (such as electron temperature) in the discharge process of DBD is very important to understand the physical and chemical processes of DBD.The electron temperature (Te) is a parameter used to characterize the electron energy in the plasma.In order to explore the effect of pulse rise time on the Tein DBD discharge, the intensity ratio of two particle spectral lines with the same element is measured to characterize the variation trend of electron temperature in plasma [38-40].The emission intensity I of gas molecules excited by electron collision can be given by formula(9)and the spectral intensity ratio with different excitation energy is shown in formula (10)

where Cλ,A and τ are the spectral response,Einstein coefficient and effective lifetime of the optical measurement system respectively,[N]is the number density of the ground state atom,and k is the excitation rate, which is determined by Te.Considering that the electron energy distribution follows Maxwell function, Tecan be characterized by the ratio of the emission intensity to the corresponding excitation rate.

Figure 8 shows the variation trend of the N2line intensity toline intensity ratio of under different pulse rise times.With the increase in pulse rise time, the intensity ratio ofemission spectrum decreases from 17.4 to 15.9, which indicates that Teis gradually decreasing.In addition,the ratio of the N2(380.5 nm) spectral line intensity and the 391.4 nmspectral line intensity can also characterize the discharge uniformity.Combined with the research results in section 3.1,the worse the discharge uniformity, the smaller the ratio of, that is the larger theratio.This is consistent with the result recorded in the literature [41] that in the atmospheric pressure ns pulsed air DBD,the larger theratio, the worse the discharge uniformity.The reason for the change of Teis that the increase in pulse rise time will lead to a decrease in E/n during primary discharge breakdown in a cycle, and the energy obtained by electrons from the electric field will be reduced, which will lead to the weakening of collision ionization between high-energy electrons and nitrogen molecules,and the decrease in electron number density and Te.

3.4.Measurement of WCA

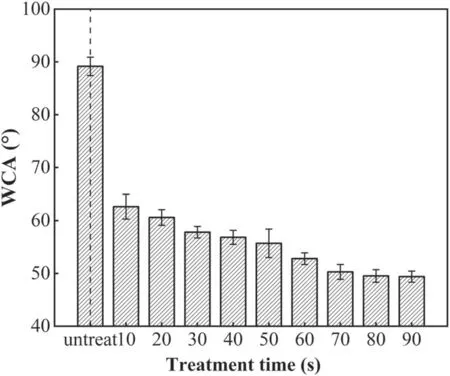

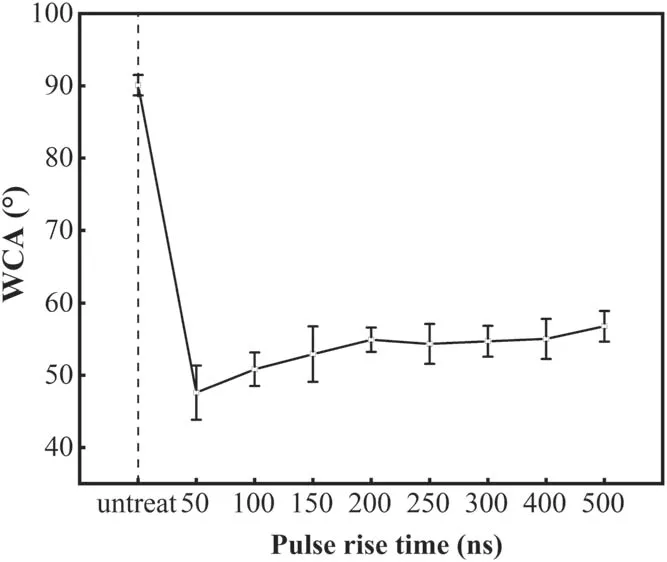

To study the modification effect of nitrogen DBD on PP surface under different pulse rise times, the WCA is used to characterize the effect of hydrophilic modification.Due to the aging effect of the plasma-modified PP material, the WCA is all measured immediately after DBD modification.Figure 9 shows the variation trend of WCA on PP surface with the ascending treatment time when pulse rise time is fixed at 50 ns.When the plasma treatment time is 10 s, the WCA of the PP sample drops sharply from the untreated 90° to about 65°, with increasing treatment time, the WCA of the sample decreases slowly, finally, reaches a saturated state of about 48° with a treatment time of 80 s.The variation of WCA on the PP film surface with different pulse rise times is shown in figure 10.The fixed processing time is 80 s, it is found that compared with untreated PP film, the WCA is significantly reduced to about 47° with the pulse rise time of 50 ns, and when the pulse rise time increases from 50 to 500 ns, the WCA of PP sample slowly increases from 47° to 55°.

Figure 9.The variation trend of WCA on PP surface with treatment time.

Figure 10.The variation trend of WCA under different pulse rise times.

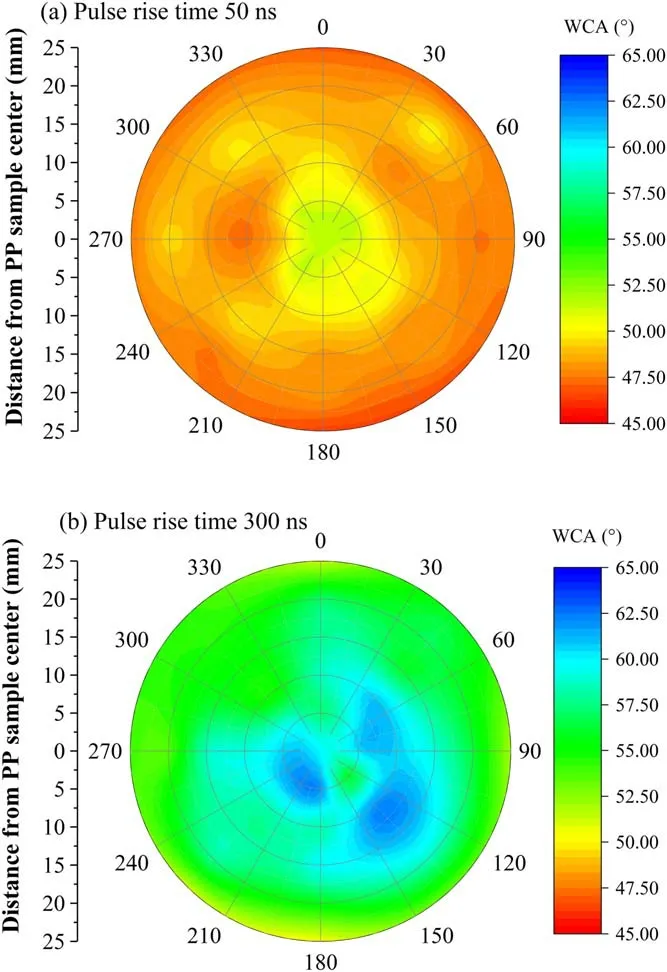

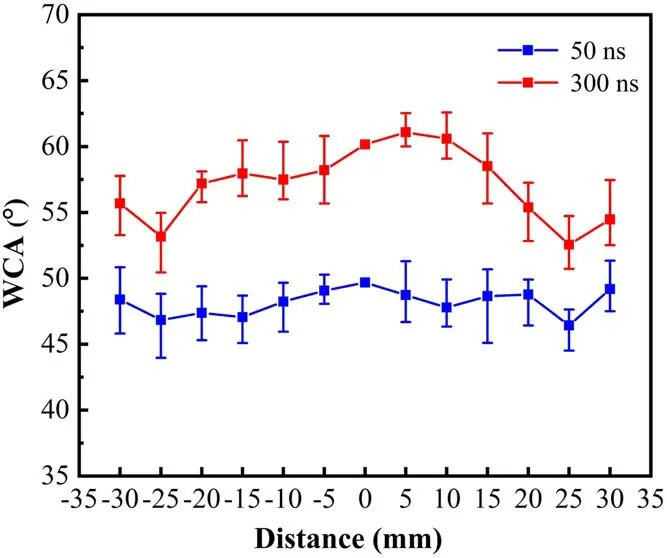

In order to determine the hydrophilic modification effect at different positions under different pulse rise times, the WCA was measured at the fixed position on the sample surface.Figures 11(a) and (b) depict the fixed-point distribution of WCA on the PP surface for pulse rise times of 50 and 300 ns, respectively.It can be found that after 80 s of plasma treatment under the pulse rise time of 50 ns, the WCA value is mainly in the range of 46°-50°, while under the pulse rise time of 300 ns,the WCA is mainly in the range of 50°-60°.Figure 12 shows the radial distribution of WCA on the PP surface,when the pulse rise time is 50 ns,the WCA deviation at the radial position is 3° which is better than the WCA deviation of 8°under a pulse rise time of 300 ns.Due to the uneven electric field generated at the electrode edge, the plasma activity is significantly higher than that in other places, and WCA at the corresponding position could even reach about 46°.The above results show that when the rise time is short,the WCA on the surface of PP sample is smaller,and the distribution uniformity of WCA is better.The reasons are that the shorter pulse rise time generates the stronger space E/n, the discharge uniformity, Teand neare significantly improved,which speeds up the physicochemical reaction rate between plasma and sample surface, as a result, the plasma generated in the discharge space can fully contact and react with PP samples, resulting in better treatment uniformity.

Figure 11.The fixed-point distributions of WCA of samples treated under pulse rise times of 50 ns (a) and 300 ns (b).

Figure 12.The radial distributions of WCA of samples treated under pulse rise times of 50 ns and 300 ns.

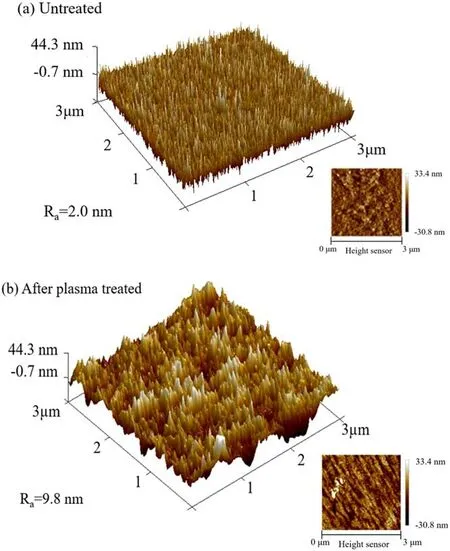

Figure 13.Surface morphology of PP measured by AFM (3D and 2D) under untreated condition (a) and 50 ns pulse rise time (b).

3.5.The characterization of physical morphology and chemical composition

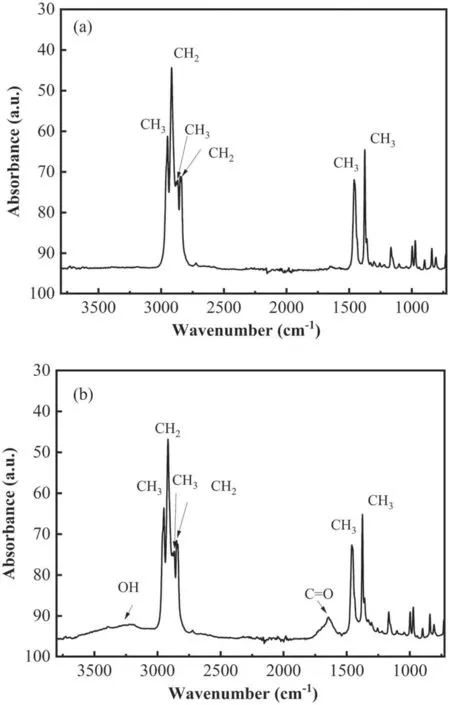

Figure 14.FTIR spectra of PP sample under untreated conditions(a)and 50 ns pulse rise time (b).

From the measurements of WCA, it can be seen that the hydrophilicity of PP material has been significantly improved after DBD treatment.In order to further explore the changes in physical morphology and chemical composition of PP surface after plasma treatment.AFM is used to measure the change in surface morphology of untreated and DBD-treated PP after 80 s at 50 ns pulse rise time.The observation range is 3 μm × 3 μm, and the three-dimensional structure diagram and two-dimensional plane diagram are obtained to characterize the surface micro morphology, and the average roughness Raof the material surface is measured.In addition,FTIR spectroscopy is used to analyze the corresponding samples, and the effect of DBD treatment on the surface chemical composition of PP is studied.It can be seen from figure 13 that the untreated PP surface is generally flat, Raof the sample surface is only 2.0 nm,while after DBD treatment,a large number of hills like protrusions appeared on the surface of PP, the corresponding Rais 9.8 nm.It can be seen from the figure 14 that compared with the FTIR spectra of untreated PP, a new absorption peak appeared in the FTIR spectra of polypropylene after DBD treatment.Among them,the wide absorption peak between 3620 and 3300 cm?1corresponds to the stretching vibration of OH, while the absorption peak at 1738 cm?1corresponds to the stretching vibration of carbonyl (C=O).The results showed that after DBD treatment, hydrophilic groups such as hydroxyl (?OH)and carbonyl (C=O) were formed on the surface of PP.The above results show that when the pulse voltage rise time is short,the discharge has higher Teand ne,which improves the chemical reaction rate between the plasma and the material surface, thus increasing the roughness of the material and the number of hydrophilic groups.

4.Conclusion

This work studied the impact of various pulse voltage rise times on the modified surface of PP by using ns pulsed nitrogen DBD.The GVSD approach is used to define the discharge uniformity, the DBD equivalent model is used to calculate the electrical parameters,and the emission spectrum measurements are used to determine the plasma activity.The WCA measuring method is used to study the synergistic relationship between discharge uniformity and material modification uniformity, while AFM and FTIR are used to characterize the physical morphology and chemical composition.The findings demonstrate that the GVSD value increases from 0.7 to 3.29 with an increase in pulse rise time(50-500 ns), which suggests that the DBD discharge uniformity deteriorates.Due to the stronger E/n produced by the shorter pulse voltage rise rate, which also contributes to a large increase in Te(the intensity ratio of N2/N+2emission spectrum from 17.4 to 15.9) and nefrom 6.6 × 1011to 5.5 × 1011cm?3, the associated η also falls from 20% to 10.8%.The average value of WCA increases from 48°to 57°for the modification effect of nitrogen DBD as the pulse rise time increases from 50 to 500 ns.The radial distribution and fixed-point distribution of WCA under pulse rise times of 50 ns and 300 ns are compared.When the pulse rise time is 50 ns, the deviation value of average WCA on PP surface is about 3°comparing with the deviation value of 8°under pulse rise time of 300 ns, which indicates that there is better treatment uniformity under the shorter pulse rise time.Before and after plasma treatment, the physical morphology and chemical composition of PP sample surface changed obviously.The surface roughness increases from 2.0 to 9.8 nm.The hydrophilic oxygen-containing groups, hydroxyl(?OH)and carbonyl(C=O)on the surface are also increased significantly.

Acknowledgments

This work is supported by National Natural Science Foundation of China (Nos.52037004, 51777091 and 52250410350) and Postgraduate Research & Practice Innovation Program of Jiangsu Province (No.KYCX22_1314).

Plasma Science and Technology2023年10期

Plasma Science and Technology2023年10期

- Plasma Science and Technology的其它文章

- 3D fluid model analysis on the generation of negative hydrogen ions for negative ion source of NBI

- Enhancing surface adhesion of polytetrafluoroethylene induced by two-step in-situ treatment with radiofrequency capacitively coupled Ar/Ar+CH4+NH3 plasma

- Etching characteristics and surface modification of InGaSnO thin films under Cl2/Ar plasma

- Pulsed gas-liquid discharge plasma catalytic degradation of bisphenol A over graphene/CdS: process parameters optimization and O3 activation mechanism analysis

- A homogeneous atmospheric pressure air plasma in a 10mm gap based on a threeelectrode configuration

- Effect of gas flow on the nanoparticles transport in dusty acetylene plasmas