Preparation of Hydrophilic and Shrink-Proofing Wool Fabrics Through Thiol-Ene Click Chemistry Reaction

WANG Litao(王利濤), ZHOU Aihui(周愛(ài)暉), DAI Chenlu(代琛露), YUAN Jiugang(袁久剛)*

1 Key Laboratory of Science & Technology of Eco-Textile, Ministry of Education, Jiangnan University, Wuxi 214122, China

2 Fujian Fiber Inspection Center, Fuzhou 350000, China

Abstract: To improve shrink-proofing performance and hydrophilicity of wool fabrics, the wool fibers were modified by poly (ethylene glycol) dimethacrylate (PEGDMA) through thiol-ene click chemistry reaction. Firstly, wool fabrics were reduced at room temperature with a high-efficiency disulfide bond reducing agent, tris (2-carbonxyethyl) phosphine hydrochloride (TCEP). Then the thiol-ene click chemistry reaction was initiated by dimethyl 2, 2’-azobis(2-methylpropionate) (AIBME) through the heating method. Fourier transform infrared (FTIR) spectroscopy, Raman spectroscopy, and scanning electron microscopy test results all showed that PEGDMA was successfully grafted onto wool fabric surface. Physical properties, hydrophilicity, and shrink-proofing performance were assessed. The wetting time of PEGDMA grafted wool fabrics decreased to about 3 s. After being grafted with PEGDMA, the felting shrinkage of wool fabrics rapidly decreased to about 8%. The anti-pilling properties of wool fabrics were also greatly improved to 5 class after 2 000 times of friction. Meanwhile, the load retention rate of fabrics could reach 90%. It provides a method of wool modification to improve hydrophilicity and anti-felting performance.

Key words: poly (ethylene glycol) dimethacrylate (PEGDMA); click chemistry; anti-felting; hydrophilic modification

Introduction

Wool fabrics are high-grade textile fabrics with excellent thermal function, soft feel, and other advantages. Wool fibers are covered by scales, known as the cuticles, which is the main cause of wool fabric felting shrinkage[1]. The high elasticity of wool fibers and the stable crimp of wool fibers are also the reasons for wool fabric felting[2]. The principle of anti-shrinkage finishing on wool fibers is reducing the directional friction effect (DFE) and changing the natural elasticity of wool fibers[3]. The anti-shrinkage finishing methods of wool fabrics mainly include chlorination[4], resin finishing, enzyme finishing[5], ultrasonic finishing, plasma finishing,etc.

Chlorine-Hercosett is the most used traditional anti-shrinkage method for wool fabrics. Chlorination has an excellent effect to improve the felting property of wool fabrics, but the process is rambunctious[6]. Resin finishing is also widely used in wool fabric anti-felting, for example, polyurethane finishing[7-8]. The recent sol-gel method[9]also belongs to this category. The disadvantage of resin finishing is that the method reduces the strength of the wool fabric and will affect the color of the fabric. This method may cause bleached fabrics to turn yellow. The enzymatic method mainly uses protease to deal with wool scales, but the effect of the enzymatic method alone is often not ideal. It is generally used in combination with other methods. There is still a long way to go for the industrialization of ultrasonic technology[10]and plasma finishing[11-13]technology.

The wool fabric surface is usually chemically inert because of the lipids layer which is arranged neatly on the epicuticle. The lipids layer also endows the wool fabric surface hydrophobic property. The hydrophobic surface of wool fabrics will hinder the absorption of dyes and consume more energy during dyeing and printing. Therefore, the hydrophilic modification of wool fabrics is very necessary. Cystine in the cuticle layer is present in the form of disulfide bonds, which results in the compact stability of the cuticle. Thus, the cuticle is a barrier that prevents the diffusion of various reagents during wool fabric bleaching and dyeing. However, the disulfide bond in cystine can be reduced to sulfhydryl groups, which has high chemical reaction activity and can be used as the reaction locus for wool surface modification.

Polyethylene glycol (PEG) is a kind of straight chain polymer whose chain body is chemically inert. The ether bonds in PEG can adsorb large amounts of water via hydrogen bonds. PEG has the advantages of low toxicity, good hydrophilicity, and good biocompatibility. Poly (ethylene glycol) dimethacrylate (PEGDMA) is formed by esterification of PEG and methacrylic acid. PEGDMA is often used as a surface modifier and an active monomer of polymer materials, which is widely used in food, medical, health gels,etc.[14-15]. There are two possible forms of grafting reaction between PEGDMA and wool fabrics, since both ends of PEGDMA have methacrylate.

Thiol-ene click chemistry reaction is an important way of molecular connection[16-17]. Click chemistry reaction can realize the connection of specific small molecular groups at the molecular level. Because of its fast, efficient and high selectivity, mild reaction conditions,etc., thiol-ene click chemistry reaction has been widely used in wool fabric modification. For example, Yuetal.[18]studied the graft reaction of hydrophilic acrylate sulfonate or arylamide sulfonate onto wool fiber surface through thiol-ene click chemistry reaction. The reaction improved the antistatic and liquid moisture management properties of wool fabrics. Zhangetal.[19]grafted methoxy polyethylene glycol methacrylate by combining enzymatic biotechnology and thiol-ene click chemistry reaction. The results showed that the hydrophilicity of the grafted fabric was improved.

In this study, tris (2-carbonxyethyl) phosphine hydrochloride (TCEP) is employed to break the disulfide bond of wool fabrics, so that the sulfhydryl groups can be used as the active site of click chemistry reaction, creating conditions for the subsequent grafting of PEGDMA on wool fabrics. This method cooperates with reduction finishing to realize the anti-felting effect of wool fabrics. The reaction formula is shown in Fig. 1, where AIBME stands for dimethyl 2, 2’-azobis(2-methylpropionate).

Fig. 1 Thiol-ene click chemistry reaction between wool fabrics and PEGDMA

1 Materials and Methods

1.1 Materials

Wool fabrics (Gabardine, 35 tex×2, 200 g/m2) are provided by Wuxi Xiexin Woolen Textile Co., Ltd., China. TCEP and PEGDMA (number-average molecular weight of 750) are purchased from Sigma-Aldrich (China). AIBME is purchased from Shanghai Yuanye Bio-Technology Co., Ltd., China. Other chemicals used in the experiment are purchased from Sinopharm (China). For all chemical reagents, no further purification is required.

1.2 Treatments

1.2.1Reductionofwoolfabrics

The reduction solution is prepared by dissolving TCEP in the alcohol-water mixture (a volumn ratio of 1∶1) with a 20 mmol/L TCEP solution. The bath ratio is 50∶1. The pretreatment is performed with a TCEP solution for 4 h at room temperature[18].

1.2.2Graftingmethod

The TCEP treated wool fabrics are put into PEGDMA solutions with different concentrations and headed in a water bath at 70 ℃ for 2 h. The bath ratio of the reaction system is 1∶50, and the amount of the initiator AIBME is 1% of the fabric weight. After the reaction, the modified wool fabrics are thoroughly washed and dried.

1.3 Characterization

1.3.1Fouriertransforminfrared(FTIR)spectroscopy

The Nicolet IS10 FTIR (Thermo Fisher Scientific, USA) is used for measurement. Wool fabrics are pasted on the glass slide to make sure that the wool fabrics are tightly arranged and opaque. The FTIR spectra are collected in the range of 4 000-500 cm-1with a resolution of 4 cm-1and 32 scans per sample.

1.3.2Ramanspectroscopy

The inVia-Reflex (Renishaw, UK) Raman spectrometer is used for the test. A 1 200 line/mm grating is used and the laser is provided by an argon ion laser (50 mW, 785 nm output).The magnification of the confocal microscope is 50 times. The Raman spectra are collected in the range of 4 000-500 cm-1and the scanning time is 10 s.

1.3.3Surfacemorphologycharacterization

The wool fabrics are sputtered gold coatings by the SU1510 (Hi-tachi, Japan) scanning electron microscope (SEM). Wool fabrics are sputter-coated with a thin layer of gold prior to scanning. The investigation is performed with an acceleration voltage of 5 kV, a current of 50 pA, and a working distance of 30 mm.

1.3.4Massgainratetest

The wool fabrics are dried at 105 ℃ for 2 h, and the moisture regain is calculated by the mass of wool fabrics before and after drying. A certain amount of fabrics is weighed for grafting experiment. After grafting, the wool fabric is dried to a constant mass. The mass gain rate of wool fabricsWis calculated by

W=[(1+ω)(C-A)-B]/B×100%,

(1)

whereAis the mass of the measuring bottle,ωis the moisture regain,Bis the mass of the wet wool fabrics, andCis the mass of the measuring bottle and dry wool fabrics.

1.3.5Tensiletest

Tensile breaking load of wool fabrics is determined according to the standard ISO 13934.1. A YG(B)026D250 fabric tensile load tester (Darong Textile Instrument, China) is used. The samples are conditioned at 25 ℃ and a relative humidity of 60% for 24 h before testing. The samples are tested at a stretching speed of 100 mm/min with an initial distance of 10 cm between clamps. The results are given as the arithmetic means of three different samples.

1.3.6Alkalisolubilityofwoolfabrics

The alkali solubility of wool fabrics is evaluated by using the standard ASTM D 1283-2005 (Kiro 2017). The wool fabrics oven-dried at 105 ℃ for 2 h is weighed as the original mass which can be used to calculate the moisture regain. Wool fabrics (1 g) are dropped into a beaker containing 100 mL sodium hydroxide with a concentration of 0.1 mol/L at 65 ℃ for 1 h. The residues are filtered and rinsed six times with deionized water, then are dried in an oven at 105 ℃ for 2 h, and weighed. Values are the average of three replicates.

1.3.7Feltingshrinkagetest

The dimensional stability to washing of the PEGDMA grafted wool fabric is tested according to the Woolmark Test Method TM31: Washing of Wool Textile Products and the standard ISO 6330∶2012. The samples are subjected to 4N wash cycles up to five times for felting shrinkage. The final result is the average of two tests. Afterward, the felting shrinkage of wool fabricsSis calculated by

S=LS+WS+WS×LS/100,

(2)

whereLSis the warp shrinkage ratio, andWSis the weft shrinkage ratio.

1.3.8Fuzzingandpillingcharacterization

Fuzzing and pilling properties of wool fabrics are determined according to the standard ISO 12945-2∶2000. The pilling tester is the YG401 G fabric abrasion tester (Ningbo Textile Instrument Factory, China). Each sample is tested three times.

1.3.9Waterretentionratetest

The water retention rate is measured according to the standard ASTM D 2403-2007(2018). The experiment is conducted by placing a wool fabric (1 g) in deionized water (200 mL) and leaving it at room temperature for 2 h to fully soak. The completely wetted wool fabric was placed in a centrifuge tube with a sieve plate and centrifuged for 5 min at 9.81 N. Then, the wool fabric is weighed together with the weighing bottle, baked in an oven at 105 ℃ for 2.5 h until it is absolutely dry, and then weighed again. The water retention rate of wool fabricsRis calculated by

R=(D-E)/(E-A)×100%,

(3)

whereDis the mass of the measuring bottle and the wet wool fabrics, andEis the mass of the measuring bottle and the oven dry wool fabrics.

1.3.10Surfacehydrophilicitytest

The surface hydrophilicity parameters include wetting time and wetting area. The fabric is pre-humidified in a humidity room at a constant temperature for 24 h before the experiment. The fabric is affixed to the slide through the double-sided tape, and weak acid dye solution (20 μL) is dropped on the top 15 cm of the fabric to allow free diffusion. Wetting time and wetting area are recorded. The experiment environment is standard atmospheric environment.

1.3.11Handvaluetest

According to the standard AATCC 202-2012, A076 PhabrOmeter (Nu Cybertek, Inc., USA) is used to test the hand value of fabrics.

2 Results and Discussion

2.1 Thiol-ene click chemistry reactions between wool fabrics and PEGDMA

The functional groups of samples are analyzed from the FTIR spectra as shown in Fig. 2.

Fig. 2 FTIR spectra of wool fabrics

The Raman spectra of raw wool fabrics, TCEP treated wool fabrics and PEGDMA grafted wool fabrics are shown in Fig. 3.

Fig. 3 Raman spectra of wool fabrics

2.2 Wool fabric surface morphology

SEM images in Fig. 4 show the surface characteristic of wool fabrics. The raw wool fabric has intact scales and sharp edges. In the image of the TCEP treated wool fabric, there are broken cuticle fragments on the surface. The scale layer can still be observed, but the sharpness of cuticle becomes slightly gentle, indicating that the wool fabric is treated by TCEP without suffering severe damage. The surface of PEGDMA grafted wool fabrics has obvious sediment, which is the evidence of PEGDMA grafted on wool fabric surface. However, PEGDMA polymer fails to form a uniform continuous coating on the wool fabric surface.

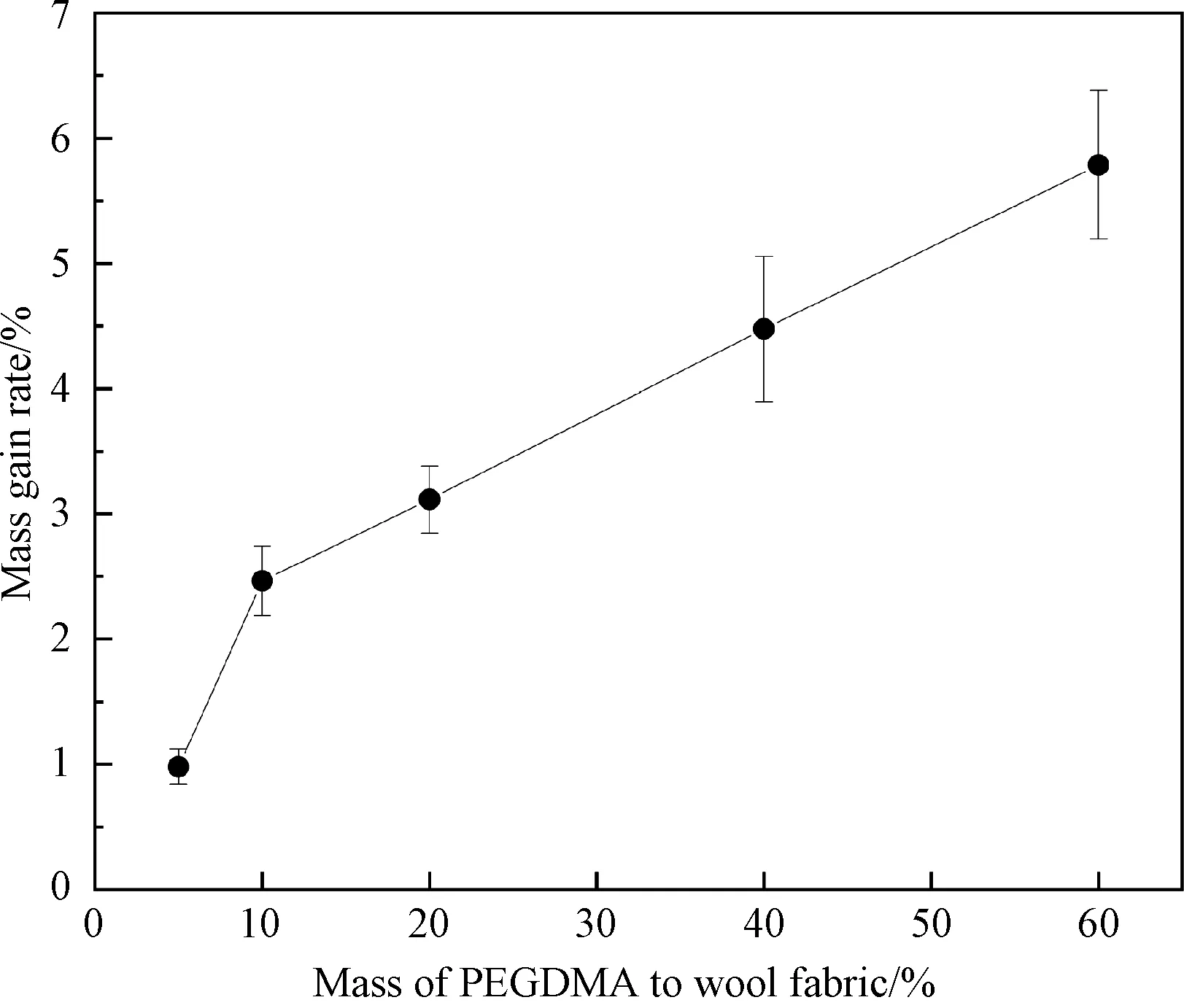

2.3 Mass gain rate

The mass gain rate indicates the extent of mass change before and after grafting. The mass gain rate is influenced by the addition amount of PEGDMA. The results are demonstrated in Fig. 5.

Fig. 5 Effect of PEGDMA dosage on mass gain rate of wool fabrics

The ratio of mass enhancement of wool fabric increases with the growth of PEGDMA addition. Nevertheless, the added amount of PEGDMA is far greater than the mass gain, indicating that a large amount of PEGDMA is not grafted on wool fabric surface. There are two reasons for the difference between the mass gain rate and the addition amount. Firstly, the inner sulfhydryl groups of the wool fabrics are difficult to react with PEGDMA, due to steric hindrance. Secondly, the self-crosslinking of PEGDMA is also an influential factor.

2.4 Damage degree of wool fabrics

The tensile breaking load of wool fabrics is assessed, and the results are shown in Fig. 6.

Fig. 6 Tensile breaking load of wool fabrics

In comparison to that of the raw wool fabric, the tensile breaking load of the TCEP treated wool fabric shows a modest decline, indicating that the wool fabric has not suffered severe damage during the TCEP treated process. The high load retention rate provides the beneficial conditions for the industrialization of this process. The tensile breaking load of the PEGDMA grafted wool fabric is further reduced due to the crosslinking among the fabrics formed by PEGDMA. Crosslinking reduces the relative slippage ability of wool fibers and makes the fibers prone to stress concentration, leading to a decrease in the tensile breaking load. The load retention of wool fabrics is over 90% even after the entire process.

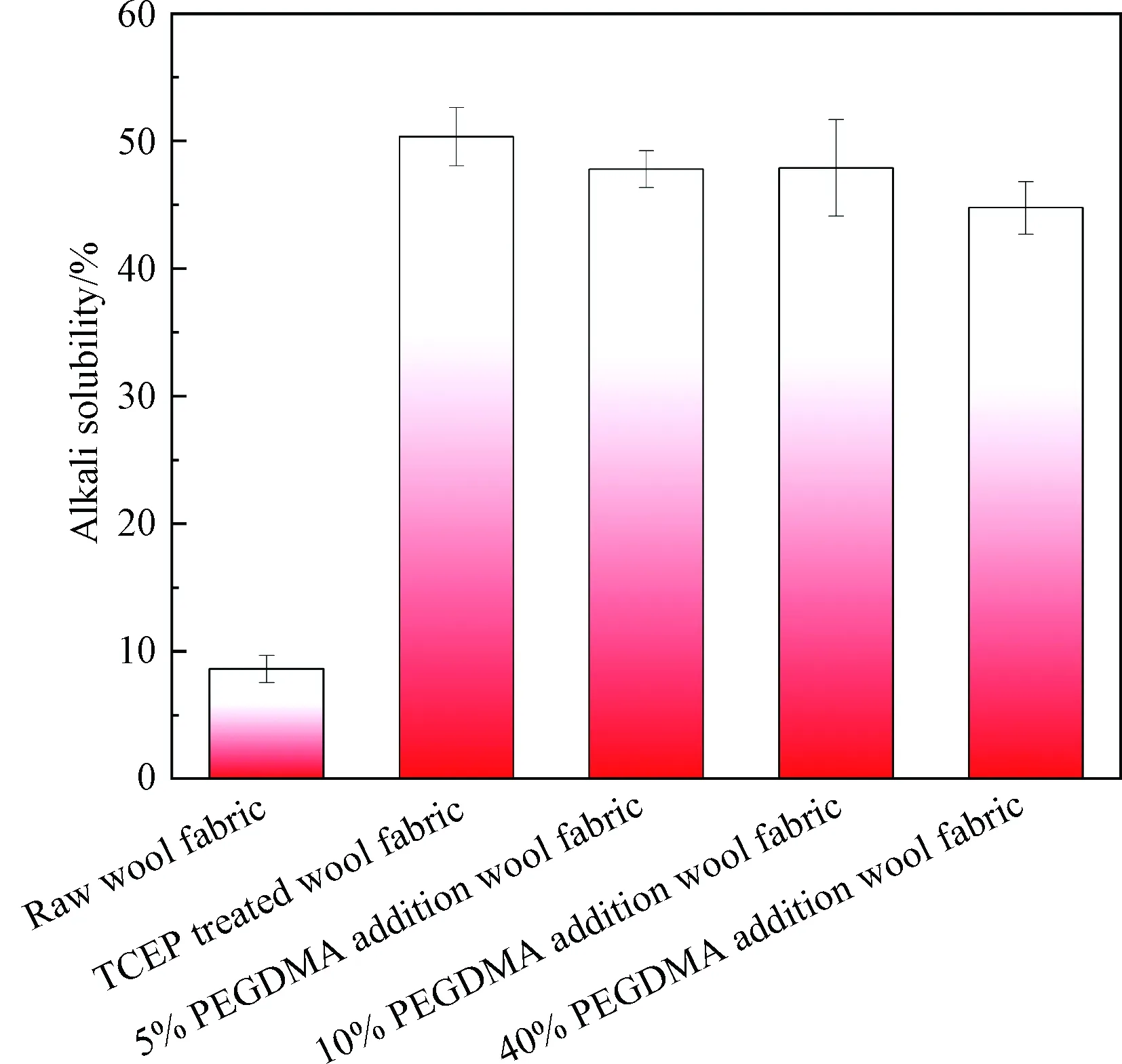

The alkali solubility of wool fabrics is shown in Fig. 7. Alkali has a significant damaging effect on wool fabrics because protein is sensitive to alkali while keratin is soluble in alkali. The internal structure of wool fibers is less chemically stable than the scale layer. When the cuticle is damaged, the internal structure is exposed and the alkali solubility increases[22].

Fig. 7 Alkali solubility of wool fabrics

The alkali solubility of raw wool fabrics is only 8%, and that of both reduced and grafted wool fabrics is between 45% and 50%. The phenomenon indicates that TCEP reduction treatment causes potential damage to wool fabrics. After TCEP treatment, parts of disulfide bonds on wool fabric surface are destroyed, so that the crosslinking degree of wool fabrics decreases and alkali solubility increases. The alkali solubility of PEGDMA grafted wool fabrics is slightly lower than that of TCEP treated wool fabrics. The reason is that the click chemistry reaction between wool fabrics and PEGDMA makes a part of the S—S bond in cystine change to the S—C bond, and PEGDMA acts as a crosslinker. When disulfide bonds are replaced by more stable cross bonds, alkali solubility decreases. The introduction of additional crosslinking between peptide bonds results in a net polymer with enhanced alkalinity tolerance[23].

The decrease of wool fabric tensile breaking load is not as great as that of alkali solubility because of the different alkali tolerance between the scale layer and the cortex layer, and the scale layer has a low alkali tolerance. After TCEP treatment, the scale layer is damaged, the crosslinking degree decreases, and the tensile breaking load of wool fabrics decreases. Due to decreased crosslinking, the cortex is more vulnerable to alkali damage when being attacked. Therefore, the alkali resistance of wool fabrics decreases more than the tensile breaking load.

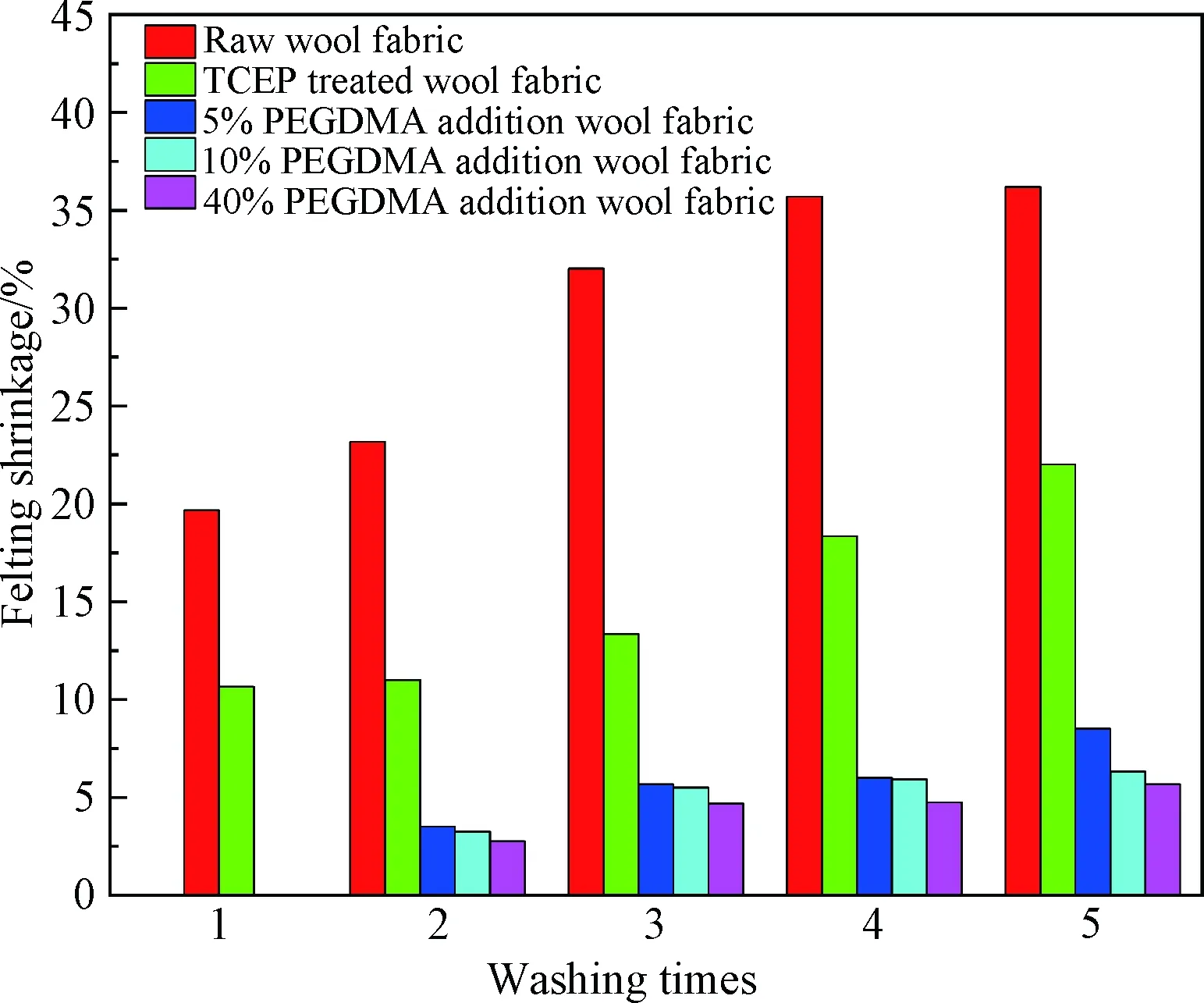

2.5 Felting shrinkage

The felting shrinkage of wool fabrics is shown in Fig. 8.

Fig. 8 Felting shrinkage of wool fabrics

The felting shrinkage of raw wool fabrics is high because of the DFE. Its shrinkage reached 35% after five times of washing. After TCEP treatment, the felting shrinkage of wool fabrics quickly decreased to 20% mainly due to the elasticity loss. However, the reduction of elasticity is not enough to achieve the purpose ofshrinkage resistance. After being grafted with PEGDMA, the felting shrinkage of wool fabrics decreased greatly to about 8%. This is mainly due to the introduction of PEGDMA. On the one hand, PEGDMA has a good lubricating property and can quickly reduce the friction coefficient of fibers. On the other hand, PEGDMA contains a large number of ether bonds, which can adsorb water molecules on the surface of the fiber, and form a hydration layer on the scales[24]. These changes lead to a decrease in the DFE, and the felting shrinkage quickly decreases.

2.6 Fuzzing and pilling properties

The fuzzing and pilling test results are shown in Table 1.

Table 1 Fuzzing and pilling properies of wool fabrics with different friction times

The fuzzing and pilling characterization of the raw wool fabric is prominent and reaches level 3 after 1 000 times of friction. The TCEP treated wool fabric or PEGDMA grafted wool fabric shows good anti-pilling performance with no pilling in the test. However, some broken fibrous may appear during the test. The friction causes the wool fabric to deform plastically, pulling the fibers to the surface and forming a fuzz, which is bound into balls and attached to the surface of the fabric by the fastening fibers. The reason that TCEP treated wool fabrics and PEGDMA grafted wool fabrics perform good anti-pilling effect is that the wool fiber strength has been damaged after reduction. In addition, PEGDMA polymers hinders the relative slip of yarns in the wool fabric. Therefore, wool fibers are likely to break, while the fabric is difficult to fuzz and pill.

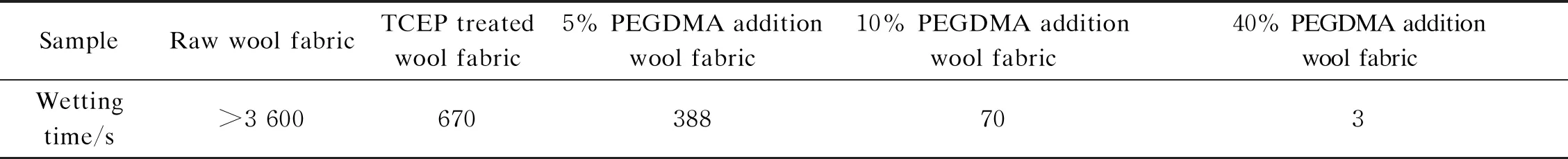

2.7 Surface hydrophilicity of wool fabrics

The wetting area of wool fabrics is shown in Fig. 9 and the wetting time of wool fabrics is shown in Table 2.

Table 2 Wetting time of wool fabrics

As shown in Fig. 9, the diffusion area of TCEP treated wool fabrics is almost as large as that of raw wool fabrics. In contrast, the area of PEGDMA grafted wool fabrics is significantly larger and resulted in a lighter color. It indicates that the surface hydrophilicity of PEGDMA grafted wool fabrics is significantly improved.

Fig. 9 Wetting area of wool fabrics: (a) raw wool fabric; (b) TCEP treated wool fabric; (c) 5% PEGDMA addition wool fabric; (d) 10% PEGDMA addition wool fabric; (e) 40% PEGDMA addition wool fabric

The reason for this phenomenon is that PEGDMA deposits on the surface of wool fabrics. There are many ether bonds in PEGDMA molecules, and ether oxygen can form hydrogen bonds with water molecules. This effect can increase the hydrophilicity of wool fabrics, thus making the liquid diffusion on the surface of wool fabrics easier. When there are more PEGDMA grafts, hydrogen bonds can be formed between PEGDMA and water, and water molecules adsorbed by PEGDMA will form a layer of hydration film on the surface of wool fabrics, which will also improve the water retention rate of wool fabrics.

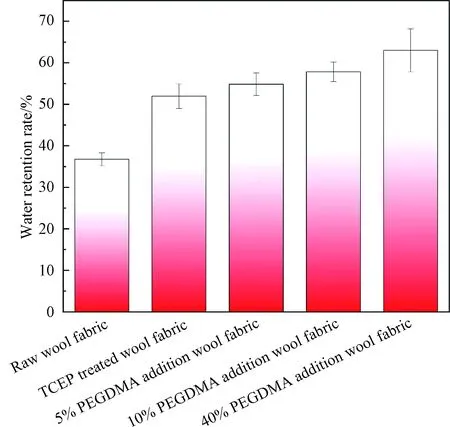

2.8 Water retention rate of wool fabrics

The water retention rate of wool fabrics is shown in Fig. 10.

Fig. 10 Water retention of wool fabrics

As shown in Fig. 10, the water retention rate of raw wool fabrics is only about 36%, while the water retention rate of TCEP treated wool fabrics is 52%. The water retention rate of PEGDMA grafted wool fabrics can be further improved. Normally, the hydrophobic lipid layer on the wool surface is also removed during TCEP treatment. At the same time, oxygen atoms in the PEGDMA molecules can form hydrogen bonds with water molecules, thus increasing the water retention rate of the fabric.

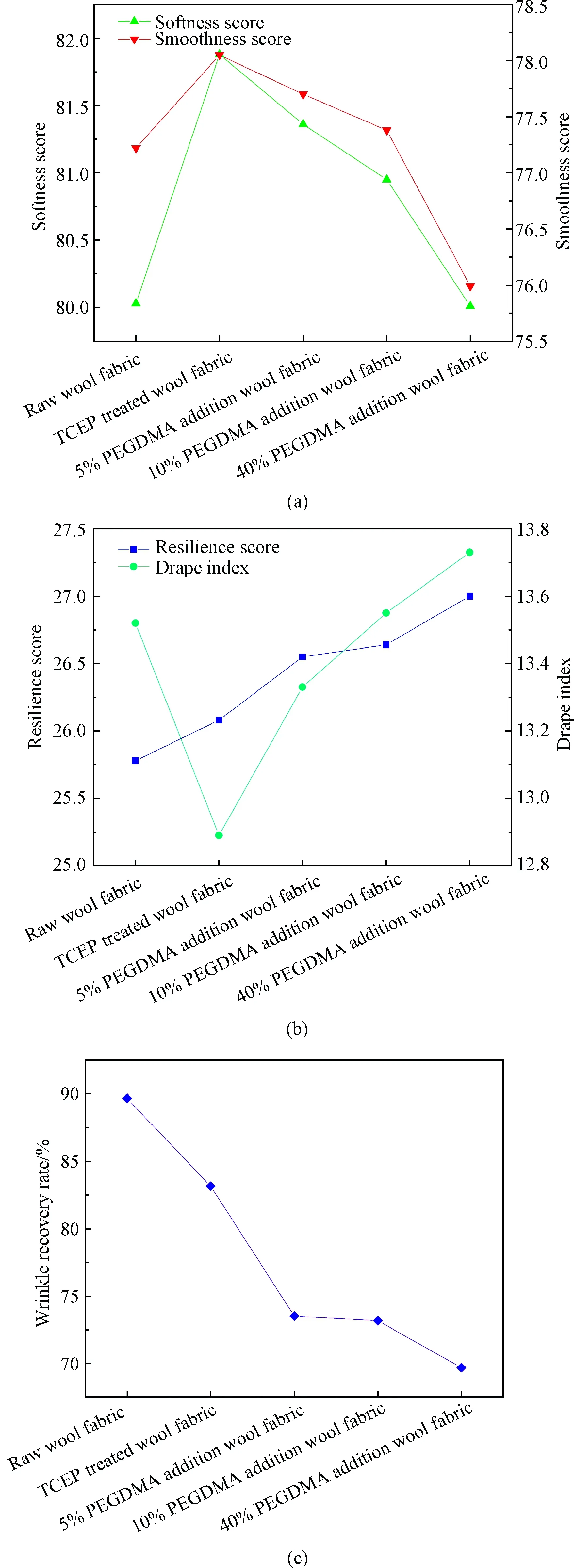

2.9 Hand value of fabrics

The hand value of wool fabrics is assessed, and the results are shown in Fig. 11.

Fig. 11 Hand value of wool fabrics: (a) softness score and smoothness score; (b) resilience score and drape index; (c) wrinkle recovery rate

The softness score and the smoothness score of TCEP treated wool fabrics increase compared with those of raw wool fabrics. Part of the cuticle is removed during the reduction process. As a result, the friction on the fabric surface decreases and the fabric becomes smooth and soft. Compared with TCEP treated wool fabrics, the softness score and the smoothness score of PEGDMA grafted wool fabrics decrease, which is due to that the deposition of PEGDMA on wool fabric surface increases the roughness of wool fabric surface and decreases the smoothness score and the softness score. Smoothness scores and softness scores do not change much during the whole process.

The reduction process breaks the disulfide bonds of wool fabrics, which results in a decrease in wool fabric elasticity. The excellent chain flexibility of PEGDMA improves the elasticity of wool fabrics. After TCEP treatment, the increased tightness of wool fabrics leads to an increase in the drape index. The increase of wool fabric stiffness caused by grafting will increase the drape of wool fabrics, and the hydrothermal environment during grafting process is also one of the factors. The increased tightness of the fabric and the resin finishing during the treatment can reduce the wrinkle recovery rate.

3 Conclusions

Through the thiol-ene click chemistry reaction, PEGDMA can be successfully grafted to the wool fabric surface, and the PEGDMA modified wool fabric has a high retention rate of more than 90%. Through PEGDMA modification, the felting shrinkage and the hydrophilicity of wool fabrics are greatly improved. The felting shrinkage of 40% PEGDMA addition wool fabric is only about 5%, and the wetting time of the fabric is only 3 s. There is no significant change in hand feel after PEGDMA grafting. However, the alkali resistance and the wrinkle recovery rate of wool fabrics decrease. This is mainly due to the breakage of disulfide bonds during TCEP processing.

Journal of Donghua University(English Edition)2022年5期

Journal of Donghua University(English Edition)2022年5期

- Journal of Donghua University(English Edition)的其它文章

- Evaluation of Tactile Comfort of Underwear Fabrics

- Classification of Young Females’ Body Shape in Jiaodong Area Based on 3D Morphological Characteristics

- Property of Polyimide/Flame-Retardant Viscose Blended Fabrics

- Electromagnetic Transmission Characteristics of Y-Shaped and Y-Ring-Shaped Frequency Selective Fabrics

- Adaptive Neural Network Control for Euler-Lagrangian Systems with Uncertainties

- Adaptive Single Piecewise Interpolation Reproducing Kernel Method for Solving Fractional Partial Differential Equation