Mechanical properties and failure mechanisms of Mg-Zn-Y alloys with different extrusion ratio and LPSO volume fraction

Wujun Yin,Fabien Briffod,Takayuki Shiraiwa,Manabu Enoki

Department of Materials Engineering,The University of Tokyo,7-3-1 Hongo,Bunkyo-ku,Tokyo,113-8656,Japan

Abstract In long period stacking ordered (LPSO) phase containing Mg-Zn-Y alloys,high elastic modulus and deformation kinks of LPSO phase considerably enhance the tensile yield strength,with slight detriment of or benefit to the ductility depending on its volume fraction.In present work,uniaxial tensile tests and fracture toughness tests are carried out using Mg99.2Zn0.2Y0.6,Mg97Zn1Y2,Mg89Zn4Y7 and Mg85Zn6Y9 (at%)materials with different extrusion ratios.Extrusion processing enhances both strength and ductility due to the recrystallization of Mg grains.Variable plastic deformation mechanisms are activated depending on volume fraction of Mg and LPSO phase as well as their relative size during bending.{102}<10>tensile twins in Mg grains and deformation kinks in LPSO phase are observed,which dissipate large amount of deformation energy favoring for toughness.However,inherently brittle LPSO phase is detrimental to toughness.Microstructure-motivated empirical models for yield strength and fracture toughness prediction based on rule of mixtures are calibrated by experimental data.Energy release rates of individual mechanisms are estimated,which quantitatively indicate strong Mg/LPSO interaction.

Keywords: Mg-Zn-Y alloys;LPSO Phase;Fracture toughness;Rule of mixtures.?Corresponding author.

1.Introduction

Magnesium (Mg) alloys have received particular attention as ultra-lightweight structural materials with potential application in aerospace engineering and automotive systems [19].Significant research works have been carried out to investigate their mechanical properties and strengthening mechanisms including texture control,rare earth elements addition,grain refinement,etc [11,17,26,34].However,the inherent crystallography of hexagonal close packed (hcp) Mg crystal still causes some drawbacks such as low strength and limited ductility[18].

To overcome such a barrier and improve mechanical properties of Mg alloys,a Mg-Zn-Y ternary alloy containing a long period stacking ordered (LPSO) phase has been reported with outstanding tensile yield strengths and acceptable elongations[7,13,36].The LPSO phases may consist of 10H,14H,18R and 24R by periodically introducing stacking faults into the original Mg crystal [1,2].It was found that the microhardness and tensile yield strength of Mg/LPSO two-phase alloys were improved with the increase in LPSO phase volume fraction while ductility was decreased [32].The strength enhancement was attributed to the intrinsic elastic property and distinct deformation modes of LPSO phase.Indeed,experiments on directionally solidified single-phase LPSO crystal revealed that Young’s modulus and shear modulus are higher than those of pure Mg [31].In addition,the plastic deformation of LPSO phase strongly depends on the loading direction and initial crystal orientation.When loading stress is not in the basal plane,basal slip is the predominant mechanism.In contrast,deformation kinks are formed for strain accommodation when stress is applied parallel to the basal plane[10,29].Apart from single-phase LPSO material,Mg/LPSO binary materials have been considerably investigated.It was reported that the stability of Mg/LPSO interface plays an important role in inhibiting micro voids formation or cracks nucleation.The introduction of kink and grain boundaries by hot-extrusion is also beneficial for the strength and ductility of the alloys [9,21].Finally,additional strengthening related to the interaction between deformation twins in Mg grain and LPSO phase was clarified to strongly depend on their relative sizes [37].

Mechanical properties relating to failure resistance of Mg-Zn-Y alloys such as fatigue behavior and toughness were also explored.Both experiments and crystal plasticity finite element simulations revealed that LPSO phase is slightly detrimental to the fatigue life due to its limited number of deformation mechanisms [4,5].Likewise,it was reported that LPSO phase exhibit a consistent brittle behavior at room temperature and even at elevated temperature,while Mg/LPSO binary alloys exhibit a relatively ductile behavior owing to the higher ductility of Mg phase [15,16].Since Mg-Zn-Y alloys are mainly processed by extrusion,the effect of the extrusion ratio was investigated on Mg89Zn4Y7(~86-vol% LPSO)alloy [8].It was found that the yield stress is drastically increased by extrusion and such strengthening shows a strong anisotropy.However,combining effects of extrusion ratio and LPSO volume fraction simultaneously on fracture behavior of Mg-Zn-Y Mg/LPSO two-phase alloys has not been sufficiently investigated so far.The covered issues corresponding to critical failure mechanisms as well as crack initiation and propagation are not yet demonstrated.

This study is dedicated to the investigation of the effect of extrusion ratio and LPSO phase volume fraction on the mechanical and failure behavior of Mg/LPSO two-phase alloys.To this end,uniaxial tensile and fracture toughness tests are employed using multiple alloys with different extrusion ratios and LPSO volume fractions.The deformation and damage mechanisms are investigated by a combination of optical microscopy (OM) observation and electron backscatter diffraction (EBSD) measurements.Finally,empirical models for yield strength and fracture toughness prediction of Mg/LPSO alloys are proposed based on mixture rule and calibrated by experimental data.

2.Materials and methods

2.1.Material and specimen preparation

The materials investigated in this study were Mg/LPSO two-phase alloys with chemical composition by molar fraction given as: Mg99.2Zn0.2Y0.6,Mg97Zn1Y2,Mg89Zn4Y7and Mg85Zn6Y9(at%).The master ingots were prepared by induction melting of high purity Mg,Zn and Y followed by casting in a carbon crucible.As-cast ingots were extruded at a temperature range of 350-475°C and a speed range of 1.0-2.5 mm/s in air with extrusion ratio 2:1,5:1 and 10:1 hereafter referred to as R2,R5 and R10 specimen,respectively.Summary of individual extrusion temperatures and speeds of investigated materials are listed in Table 1.A quarter of cylinder was cut followed by mechanical polishing using grinding paper and 0.05 μm alumina solution to analyze the microstructures.OM (VHX-7000,Keyence,Japan) observations were performed on the surface of the longitudinal section.In addition,cross-section polishing (CP,IB-09010CP,JEOL,Japan) was conducted followed by EBSD (JIB-4700F,JEOL,Japan) observation with a step size of 0.5 μm.A sample for transmission electron microscopy (TEM) observation was prepared by ion slicer (EM-09100IS,JEOL,Japan) and then TEM (JEM-2010HC,JEOL,Japan) observations were conducted at an acceleration voltage of 200 kV.

Table 1 Summary of extrusion temperatures and speeds of Mg-Zn-Y alloys.

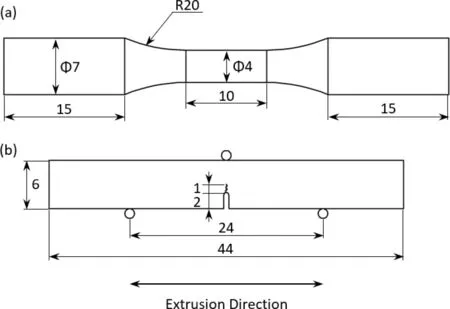

Fig.1.Schematic illustrations of employed specimen in this study:(a)tensile specimen,(b)three-point bending specimen.All dimensions are shown in unit of mm.

Cylindrical specimens for tensile test were machined along the extrusion direction (ED) with a diameter of 4 mm in the gauge section and a gauge length of 10 mm as shown in Fig.1(a).Rectangular specimens for fracture toughness tests were cut with dimensions of 44 mm (L) × 6 mm (W) ×3 mm (B) where the ED was along the long direction and the transverse direction (TD) was along the width as shown in Fig.1(b).An initial notch with a diameter of 300 μm and a length of 2 mm was introduced in the center of the specimen.A fatigue pre-crack was introduced with a fatigue machine(Servopulser 50kN,Shimazu,Japan) at room temperature,a frequency of 20 Hz,a stress ratio ofRσ=0.1 with peak stresses ranging from 33 MPa to 100 MPa for the different materials.The length of fatigue pre-cracks was controlled to reach 1 mm contributing to the total effective crack length a=3 mm and ratioa/W=0.5.

2.2.Experimental procedure

2.2.1.Tensile test

Uniaxial tensile test was performed at a strain rate of 10-3s-1at room temperature.The strain was measured by a clip-on extensometer (3442,Extensometer,Epsilon technology,USA).All specimens were deformed to complete failure.Fracture surfaces were observed by SEM (SEM,JCM-6000,JEOL,Japan) at an acceleration voltage of 5 kV.

2.2.2.Fracture toughness test

Complete fracture and interrupted three-point bending tests were performed using micro-bending machine (MT5000DL,Deben,UK) at a speed of 0.2 mm/min on a movable stage of OM.During uninterrupted bending tests,specimen under-went the states of pre-crack opening,bending-crack initiation and propagation until failure,whereas interrupted bending test was stopped when bending-crack slightly propagated around 70 μm with moderate plastic deformation ahead of the crack tip.Fracture toughness test was performed for each material at least on 3 individual specimens.

Fracture toughnessKc,for three-point bending specimen can be estimated by [3]:

wherePcis the critical applied load,Sis the support span,Bis the thickness,Wis the width andais the effective crack length andis expressed by following equation:

Due to the dimensional limitation of the extruded bars,a valid thickness for three-point bending specimen could not be achieved.Thus,theKccalculated above can not meet all the requirements for a valid plane strain fracture toughness as described in ASTM standard.However,the estimated toughnessKcwere in the range of fracture toughness of Mg alloys as described by Ritchie and can still be seen as an essential parameter correlating to material’s resistance to fracture [20].Finally,to clarify the distinct failure mechanisms,SEM observations were performed on the fracture surface of completely fractured samples,while digital image correlation (DIC) analysis and EBSD analyses were performed for morphology investigation on the free surface of interrupted bending samples.

3.Results

3.1.Initial microstructures

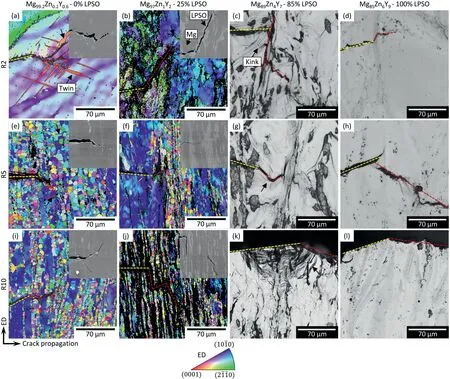

Fig.2 shows the EBSD analysis of Mg in Mg/LPSO two phase alloys and the OM observation of 100%-LPSO alloy with different extrusion ratio on longitudinal section along the ED.OM was used for 100%-LPSO as no clear diffraction pattern could be obtained for this phase.The LPSO volume fractions of Mg99.2Zn0.2Y0.6,Mg97Zn1Y2,Mg89Zn4Y7and Mg85Zn6Y9alloys are approximately 0%,25%,85% and 100%,respectively.Mg phase consists of two types of grains:fine dynamically recrystallized(DRXed)grains and coarse un-DRXed grains.The DRXed grains shown in the inverse pole figure (IPF) maps possess small grain size and random crystal orientation,while unDRXed grains are much larger with their basal planes mainly parallel to the ED,resulting in a strong texture.The portion of DRXed grains tends to increase when both extrusion ratio and LPSO volume fraction increase.Pole figure (PF) maps also reveal that maximum intensities decrease continuously.Since DRXed volume fraction plays an important role in the microstructure,it was evaluated from EBSD analysis and will be used as a crucial parameter in the following discussion section.From Fig.2(b),(f) and (j),LPSO phase in black varies from a form of quasi-continuous network to an extremely elongated fine fiber when extrusion ratio increases from 2 to 10.OM observations in Fig.2(d),(h)and (i) display similar trend with the increasing presence of intra-granular defects and initial deformation kinks generated when increasing the extrusion ratio.

A sliced sample made from Mg97Zn1Y2alloy (~25%LPSO) with extrusion ratio 2 was prepared for TEM observation.A lenticular shaped twin embedded in a Mg grain is observed in the TEM bright field image in Fig.3(a).Clarified by the selected area electron diffraction (SAED) pattern(Fig.3(c)),a rotation angle of basal plane by 86°is in agreement to the theory of {102}<10>tensile twin in Mg.Higher magnification observation in Fig.3(b) revealed basal slip traces in both the matrix and the twin.Observation of tensile twin provides a potential explanation for the recrystallization happening in the Mg phase.As noted in EBSD Fig.2(a),the dynamic recrystallization can be summarized as three steps: nucleation of twin marked as A;growth of twin(increase the thickness slowly) marked as B;recrystallization within relatively large twin marked as C.Fig.3(d) shows the bright field image of a fine LPSO grain consisting of multiple thin plates coexisting with the same c?direction.From the diffraction peak appearances along c?direction of SAED pattern in Fig.3(f),the 18R type-stacking structure of LPSO phase is identified.The high magnification image of Fig.3(e)displays not only the trace of basal plane indicated by the yellow line,but also kink boundaries indicated by the white arrow.

3.2.Uniaxial tensile behavior

Fig.4 depicts the engineering stress-strain curves measured by uniaxial tensile tests along the ED for the different materials.Young’s moduli are in the range of 45-55 GPa,which is consistent with some reports [33].After yielding,0% and 25%-LPSO materials undergo a limited work hardening,while the 85%-LPSO alloy fractures just at the yielding point and 100%-LPSO alloy fractures even before yielding.It suggests that LPSO phase has an intrinsic brittle behavior when loading along ED.It is also apparent that materials with high volume fraction of LPSO phase exhibit a low ductility but a high tensile yield strength (TYS),whereas materials with relatively low volume fraction of LPSO phase show an increased strength-ductility balance.Extrusion ratio tends to increase both TYS and elongation(EL)properties in most cases,except the TYS decreasing of 25% alloy from R2 to R5.This anomaly may be caused by the existence of networklike LPSO phase.The scattered fine LPSO grains separate large Mg matrix into small grains,working as grain refinement strengthening mechanism even with few DRXed Mg grains.0%-LPSO material with extrusion ratio 2 in Fig.4(a)shows a dramatically low TYS and EL compared with the other alloys.

Fig.2.IPF and PF of EBSD maps and OM observations of Mg-Zn-Y alloys with dependence on extrusion ratio and LPSO volume fraction on longitudinal section along ED.(a-d) R2 with approximately LPSO volume fraction of 0%,25%,85% and 100%;(e-h) R5 and (i-l) R10 with same compositions.LPSO grain boundaries are highlighted by the blue dash lines.(For interpretation of the references to colour in this figure legend,the reader is referred to the web version of this article.)

Fig.5 shows SEM images of fracture surfaces of uniaxial tensile specimens.From side views,a significant difference is that ductile materials (0%-LPSO and 25%-LPSO) show a limited necking deformation with inclined and rough surface,while brittle materials (85%-LPSO or 100%-LPSO) fractured without necking but with relatively flat and smoother surfaces.The fracture surfaces of 0%-LPSO materials mostly consist of cleavage planes as shown in Fig.5(a),(e) and (i),especially in R2 and R5 materials whose grain size are relatively large as illustrated by the EBSD IPF maps(Fig.2(a)and(e)).However,fracture surfaces of 25%-LPSO materials are comprised of numerous shallow dimples as shown in Fig.5(b),(f) and(j).The uniformly dispersed dimples at both periphery and central region indicate a uniform deformation when applied load is along the ED.By contrast,fractographies of 85%-LPSO and 100%-LPSO materials consist of cleavage facets and tear ridges instead of dimples.No significant variation when changing extrusion ratio was also noted.

3.3.Fracture behavior

Fig.3.TEM bright images and SAED patterns of (a-c) twins in Mg matrix and (d-f) LPSO phase obtained from Mg97Zn1Y2 alloy sample.

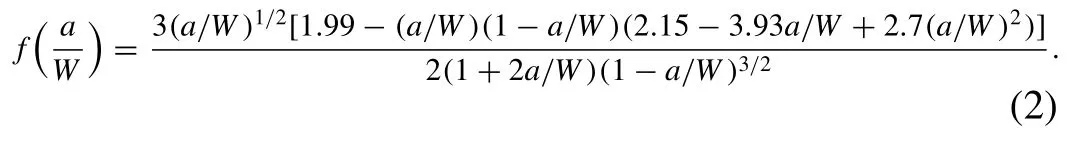

Fig.6 presents the fracture toughnessKcof as-cast and extruded Mg-Zn-Y alloys with dependence on the extrusion ratio and LPSO volume fraction.The fracture toughness is calculated based on Eqs.1 and 2,in which one requirement is adopting a conditional loadPQ.0%-LPSO and 25%-LPSO materials exhibit a ductile behavior which allow the acquirement ofPQ,whereas 85%-LPSO and 100%-LPSO materials exhibit an extremely brittle behavior and fractured before perceptible plastic deformation.Thus,for 85%-LPSO and 100%-LPSO materials,the peak loads are used for fracture toughness estimation instead ofPQ.By comparing the fracture toughness of extruded materials to that of as-cast [30],it is apparent that extrusion process even for low extrusion ratio improve the fracture toughness.Increasing the extrusion ratio improved the fracture toughness of 0%-LPSO and 25%-LPSO materials,whereas 85%-LPSO and 100%-LPSO materials exhibit a lower effect of the extrusion ratio,maintaining a relatively low resistance ability.Scattering of fracture toughness seems to decrease with the increase in extrusion ratio which may be attributed to more uniform microstructures at high extrusion ratio.The large scattering of R2 specimens may be atttributed to the large grain size and strong texture.On the other hand,for a given extrusion ratio,increasing the LPSO volume fraction leads to an evident decrease of fracture toughness,except for the increase observed within R2-0%-LPSO and R2-25%-LPSO materials.Highest fracture toughness is observed for R10 0% and 25%-LPSO specimens.

Fig.7 displays strain fields maps:?xxof crack initiation(ac)and propagation(d-f),estimated by DIC analysis using high resolution OM images.The Mg97Zn1Y2(25%-LPSO) alloys are chosen because of the good contrast between LPSO and Mg phase,which is favorable for accurate DIC analysis.The finer morphology of R5 and R10 alloys contribute to smoother outputs.All the three materials exhibit similar contours of?xxstrain fields,featuring two symmetric lobes ahead of the crack tip.The two lobes undergo tension along the ED,while small area (in white) in between undergoes slight compression.The intensity of strain is enhanced and tension region spreads out when applied load increases and crack extends.However,due to the crack propagation and extreme strain concentration at the crack tip,the pattern quality for DIC decreases,resulting in small region where DIC fail as shown in Fig.7(a) and (d).

Fracture surfaces near pre-cracks were observed by SEM and reported in Fig.8.The ED is in the out-of-plane direction and crack propagation direction is from left fatigue pre-crack to right bending crack with pre-crack boundaries indicated by red dash lines.For brittle materials such as 85%-LPSO and 100%-LPSO alloys,the transition from fatigue pre-crack to bending crack is not clear with flat sliding surface and homogeneous river-like branch structures observed in both sides.Conversely,there is a clear frontier of fatigue pre-crack for ductile 0%-LPSO and 25%-LPSO alloys.For 0% and 25%-LPSO materials,crack segments propagating perpendicular to the main crack propagation direction can be observed as highlighted by marks A and C.A void (marked as B) with a distance of 150 μm from the pre-crack boundary stems from a central small void coalescing with adjacent ones,resulting in a round shape and knife-edge alike periphery.In addition,a group of parallel elongated stripes maintaining same orientation and separated by a boundary (marked as D) suggests the presence of deformation twins with twins boundary indicated by yellow dash line.It is consistent to the report from Kaushik et al.[12].Finally,no distinct difference can be found in fracture surfaces of 85%-LPSO and 100%-LPSO materials.As shown in Fig.8(d),tearing ridges and slip traces in cleavage facets are depicted clearly (region marked as E).

Fig.5.SEM images of fractography observed on uniaxial tensile fracture surface.(a-d) R2,(e-h) R5 and (i-l) R10 with four LPSO volume fractions.The corresponding characteristic and side view are inset in each case.

Fig.6.Comparison of fracture toughness of as-cast and as-extruded alloys.The fracture toughness of as-cast 25% and 100%-LPSO alloys are reported in ref.[30].Multiple markers of each material mean individual experiments results.

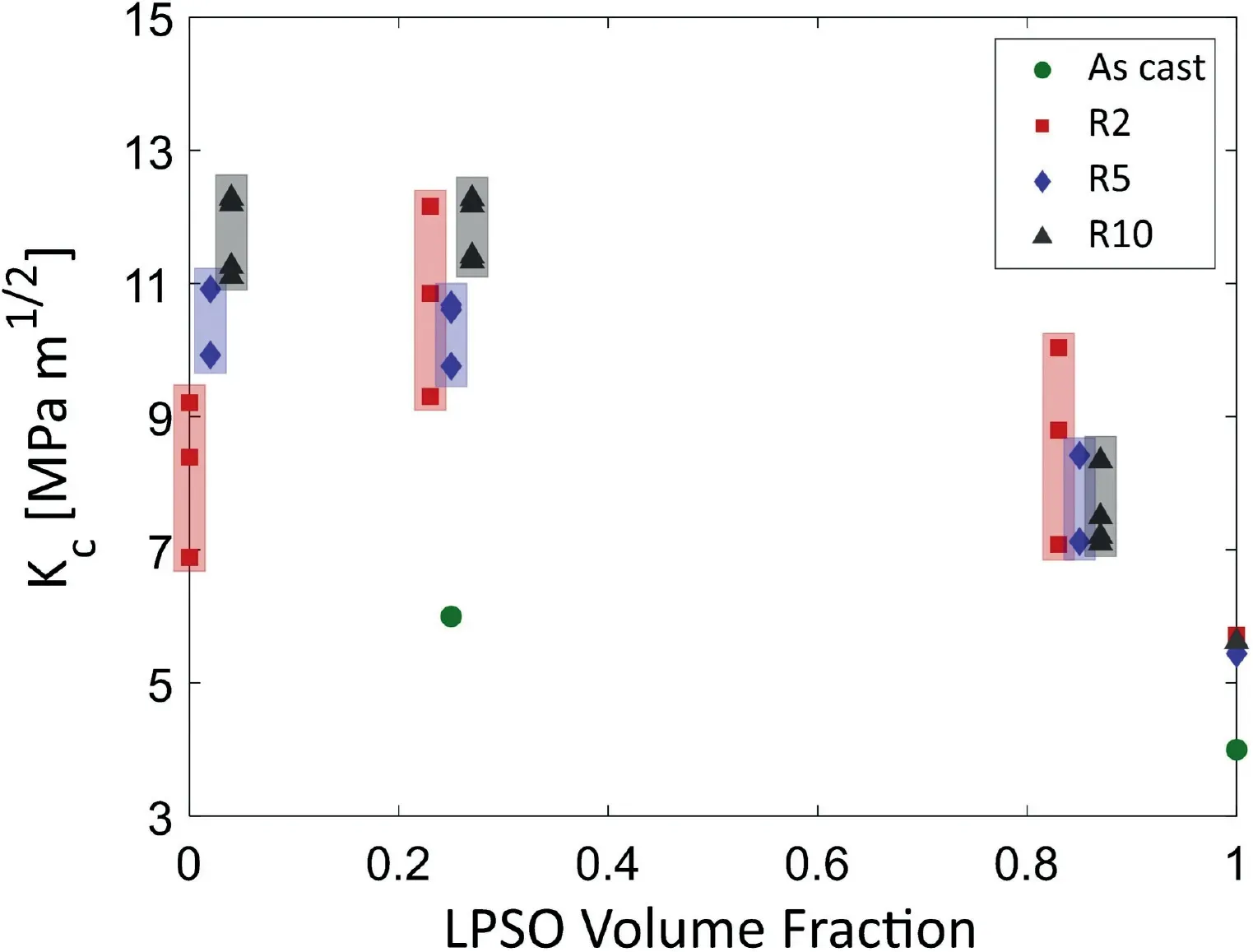

In Fig.9,the EBSD IPF maps,SEM images and OM high resolution images of crack morphology on free surface from interrupted samples are shown.The EBSD and SEM are conducted here to reveal Mg crystal orientation and deformation mechanism near crack tip pertaining to low LPSO volume fraction materials (0% and 25%),while high resolution OM is conducted to illustrate the deformation pertaining to high LPSO volume fraction materials (85% and 100%).The fatigue pre-crack and bending crack are indicated by yellow and red dash line,respectively.A large Mg grain with small interior misorientation of R2-0%-LPSO material is shown in Fig.9(a).A set of {102}<10>tensile twins are observed ahead of bending crack tip,whereas there is no significant plastic deformation around pre-crack.In other word limited plastic deformation is introduced by fatigue test during the specimen preparation.Apart from the major twins in large unDRXed Mg grains in Fig.9(a) and (b),some minor twins also form in the DRXed Mg grains farther away from crack tip highlighted by black arrows in Fig.9(e) and (i).

By comparing the crack paths among 0%-LPSO materials,there are more branches of micro cracks in R10 than that of R2 as shown in SEM images (Fig.9(a),(e) and (i)).Some of them are even perpendicular to the crack extension direction.In contrast,the crack paths in 25%-LPSO materials predominantly follow the shape of LPSO phase sometimes even deflect with an angle of about 90°,and then are blocked by the interface of Mg matrix and LPSO phase as displayed by SEM images in Fig.9(b),(f) and (j).R10-85%and 100%-LPSO alloys are extremely brittle and cracks propagated rapidly so the segments of completely fractured samples are shown here.Despite of lacking slip systems and other plastic deformation modes inside of LPSO phase,deformation kinks are formed tremendously near LPSO/Mg interface area as marked by black arrows in 85%-LPSO materials,while no perceptible plastic deformation in 100%-LPSO materials is observed.Moreover,main crack path without branch always deflects with a substantial angle compared with the original pre-crack direction.

Fig.7.Strain fields extracted by DIC analysis with interrupted fracture toughness tests of 25%-LPSO containing materials.(a-c) ?xx of crack initiation of R2,R5 and R10 materials,respectively;(d-f) ?xx of crack propagation of the same materials.

Fig.8.SEM images of fractography observed on three-point bending fracture surface.(a-d) R2,(e-h) R5 and (i-l) R10 with four LPSO volume fractions.The interface of fatigue pre-crack and bending crack is indicated by red dash line in each case.(For interpretation of the references to colour in this figure legend,the reader is referred to the web version of this article.)

4.Discussion

4.1.Effects of microstructure on mechanical behaviors

4.1.1.Effects of microstructure on tensile behaviors

As noted in Fig.2,the multiple extrusion ratios and LPSO volume fractions affect the microstructure of materials including texture and grain size significantly.The proportion of DRXed Mg grains of each alloy and its average grain size as well as corresponding mechanical properties (TYS,EL andKc) are listed in Table 2.The TYS of Mg-Zn-Y materials with small amounts of alloying elements (0% and 25%-LPSO) is in agreement to other Mg-rare earth alloys,ranging from 100 to 300 MPa [27].While 85%-LPSO material which is significantly enhanced by rare-earth elements has an outstanding TYS (450 MPa) [8].Moreover,strengthening by extrusion process reported in Mg rare-earth alloys is also revealed by the achieved data [35].For Mg-dominant(0% and 25%-LPSO) materials,increasing the extrusion ratio and LPSO volume fraction enhanced the recrystallization rate of Mg grains resulting in a decrease of the basal texture.The average grain size of fine DRXed Mg grain itself does not change drastically.Therefore the general decreasing of average grain size working as grain refinement strengthening mechanism enhances both the TYS and the ductility as shown in Fig.10(a).Meyers et al.pointed out that grain boundaries act as strong obstacles to dislocations motion[14].Mobile dislocations gather against the boundaries leading to a localized stress concentration.One evidence from Fig.5(a),(e) and (i) is that relatively large concave planes and ridges are usually located at grain boundaries which can be seen as the initiation of cracks.Another evidence from Fig.5(b),(f)and (j) is that numerous shallow dimples can be seen and are related to ductile void nucleation and growth.In addition,recrystallization leads to a random reorientation among DRXed Mg grains which weakens the basal texture as shown in Fig.2.Due to the strong basal texture,when tensile stress is along the ED,neither basal slip nor {102}<10>deformation twin can be readily activated.Thus,the weakened texture results in better deformation accommodation which is beneficial for the ductility.It is consistent to what was reported by Stanford et al.[28].

Table 2 Summary of mechanical properties evaluated from experiments.

For LPSO-dominant (85% and 100%-LPSO) materials,no significant changes of EL but moderate strength increase happen with the increase in extrusion ratio as shown in Fig.10(a).The origin of consistent brittleness probably results from the intrinsic lacking of independent deformation systems of LPSO phase.From fracture surface observations (Fig.5(c-d),(g-h)and (k-l)),all specimens consist of uniform cleavage planes showing a flat fracture surface.According to Hagihara et al.,when stress is applied parallel to the basal plane,even basal slip is inhibited,resulting in a catastrophic fracture before perceptible yielding forming as in Fig.4(d) [10].Conversely,high extrusion ratio causes LPSO grains parallel to the ED,leading to a strong basal texture and more initial pre-kinks[8].Both of them prohibit basal slip and micro voids from generating resulting in a slight strength improvement.

Fig.9.EBSD IPF maps,SEM images and OMs of morphologies near crack tip observed on interrupted three-point bending free surface.(a-d) R2,(e-h)R5 and (i-l) R10 with four LPSO volume fractions.The fatigue pre-crack and bending crack are indicated by yellow and red dash line,respectively.The deformation twinning and kink are indicated by black arrows.(For interpretation of the references to colour in this figure legend,the reader is referred to the web version of this article.)

Fig.10.Plots showing (a) UTS-EL and (b) Kc-TYS relationships of alloys with multiple extrusion ratios and LPSO volume fractions.The comparison of Kc and TYS properties of AZ31 and ZK60 are reported in Ref.[23,24].

4.1.2.Effects of microstructure on fracture toughness

Since the investigated materials in this study are Mg/LPSO two phase alloys with multiple extrusion ratios,the microstructures are extremely complex so that multiple mechanisms may activate concurrently,including {102}<10>deformation twins among Mg grains,rapid failure among LPSO phase as well as minor twins and kinks near interfaces.Thus,the effects of microstructure on fracture toughness will be discussed in three parts: fracture in Mg phase,fracture in LPSO phase and at Mg/LPSO interfaces.A comparison of fracture toughness from current work and from commercial and conventional Mg alloys is shown in Fig.10(b).The diagonal lines represent the plastic-zone size,

Considering Mg grains in 0%-LPSO alloys,there is an evident difference between cracks of unDRXed and DRXed Mg grains.According to DIC analysis (Fig.7),limited compression strain field and intensive strain concentration ahead of the crack tip may promote {102}<10>deformation twins formation in unDRXed grains as observed in Fig.9.Crack propagation may take place along twin boundary (Fig.8(a))with potential deflections at twin-twin interfaces as shown in Fig.9(a).These findings are in agreement with Kaushik et al.who found that profuse twins formed around crack tip and may contribute to the dissipation of large strain energy [12].Hence,this factor contributes to an improvement of the fracture toughness.However,the fact that cracks tend to propagate along twin boundary highlights its brittle character,potentially detrimental for fracture resistance.Indeed,these high-angle boundaries may act as barrier for dislocations that may pile-up at these interfaces,leading to the nucleation of micro-voids or micro-cracks.Thus,there are simultaneous positive and negative effect of deformation twins on the fracture toughness.As for DRXed Mg grains,some minor twins form above and below the crack tip but far from it (Fig.9(e)and (i)),indicating large strain field spreading out.Grain refinement of DRXed Mg crystals introduces high-angle misorientation between adjacent grains and increases the number of boundaries,limiting twin propagation across multiple grains as often observed in highly textured Mg alloys.Besides,random orientation of DRXed grains allows both basal and non-basal slip systems to be activated.While high-angle boundaries pin dislocation movements enhancing strain hardening and acting as barrier for crack propagation[22,25],they may also give rise to high stress concentration leading to void nucleation which may explain the lower toughness of the investigated materials compared with those of Somekawa et al.[23,24].

Focusing on LPSO phase in 100%-LPSO alloys,no perceptible plastic deformation is generated near the crack tip as observed in Fig.9(d),(h) and (l).This is probably due to the strong texture and peculiar deformation mechanism of LPSO phase.According to Hagihara et al.[8],the {0001} planes of LPSO phase align parallel to the ED due to the extrusion processing even with a small extrusion ratio.The tendency that the higher extrusion ratio the stronger the texture was also illustrated.Hence,stronger texture leads to a low Schmid factor for basal slip.The strain energy not accommodated by plastic deformation contributes to the early failure of LPSO phase.Mine et al.employed the micro-bending tests and found that the CRSS of the basal slip was 30 MPa and that of prismatic slip was approximately 360 MPa [15].All the 100%-LPSO materials fracture before perceptible yielding in Fig.4,and considerable tearing up structures as well as cleavage planes in Fig.8(d) suggests the brittle behavior of LPSO phase.

The effect of the Mg/LPSO interface is finally discussed.When the relatively lower volume fraction of LPSO phase(25%-LPSO)is embedded in Mg matrix in the shape of threedimensional quasi-continuous elongated network,crack seems to propagate more easily within the LPSO phase as noted in the crack paths in Fig.9(b),(f) and (j).A single major crack path propagates straightforward,without branching,until reaching a Mg/LPSO interface.The straight crack path in LPSO phase is likely caused by the strong basal texture of elongated LPSO grains.Alternatively,Mg/LPSO interface acts as a barrier keeping numbers of dislocation defects accompanying with micro voids from further spreading into adjacent crystals.It was reported by Shao et al.that the stable interface were not favored nucleation sites for voids and micro-cracks during deformation since no debonding or defects were detected even at the atomic level [21].Thus,crack stopped at the interface leads to localized stress concentration when applied load keeps increasing,ultimately causing adjacent Mg or LPSO grains to yield as confirmed by the presence of deformation twins or kink bands in Fig.9.Both mechanisms result in the improvement of plastic deformation energy absorption,and are beneficial to the fracture toughness.Compared with the absence of kinks in 100%-LPSO materials,it suggests that Mg/LPSO interface is stronger than LPSO/LPSO interface.

4.2.Empirical models based on rule of mixtures

As an outcome of this study,several empirical models for YS and fracture toughness prediction based on rule of mixtures are proposed to estimate the optimal Mg/LPSO alloy.The models are microstructure motivated and calibrated by experimental data.According to previous discussion in Section 4.1,two variables are selected as microstructural descriptors: the LPSO volume fractionφLPSOand the DRXed volume fractionφDRXed.The former parameter is essential to the contribution of not only high strength from LPSO phase but also intrinsic brittleness,while the latter parameter is a direct consequence of the extrusion effect and can relate to the average grain size,texture and the amount of initial pre-kinks inside LPSO phase.

4.2.1.Empirical model for yield strength

As for the model of YS,for simplicity,linear combination of contributions from Mg phase and LPSO phase are considered,as presented below:

whereσLPSO=k1φDRXed+b1andσMg=k2φDRXed+b2are yield strength of LPSO phase and Mg phase,respectively.By polynomial fitting experimental data,the coefficientsk1,b1,k2andb2are calibrated as shown in Table 3 and prediction model of YS is shown in Fig.11.Fig.11(a) and(b) depict a drastic enhancement of YS due to the increasing of LPSO and DRXed volume fractions.The significantly extruded 100%-LPSO alloy is estimated to have the highest TYS,while insufficient plastic deformation always leads to fracture before perceptible yielding like the 100%-LPSO experimental results showing.

Table 3 Coefficients calibrated by experimental data.

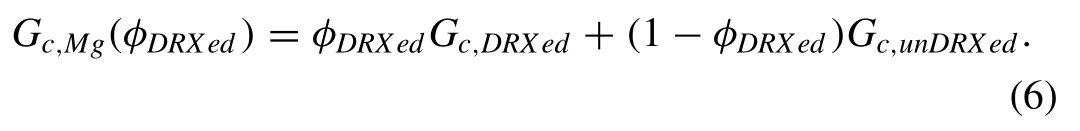

4.2.2.Empirical models for fracture toughness

As for the model of fracture toughness,since it should not be linearly added,the energy release rateGcdefined as

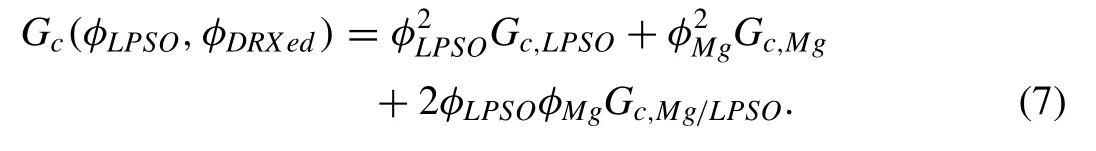

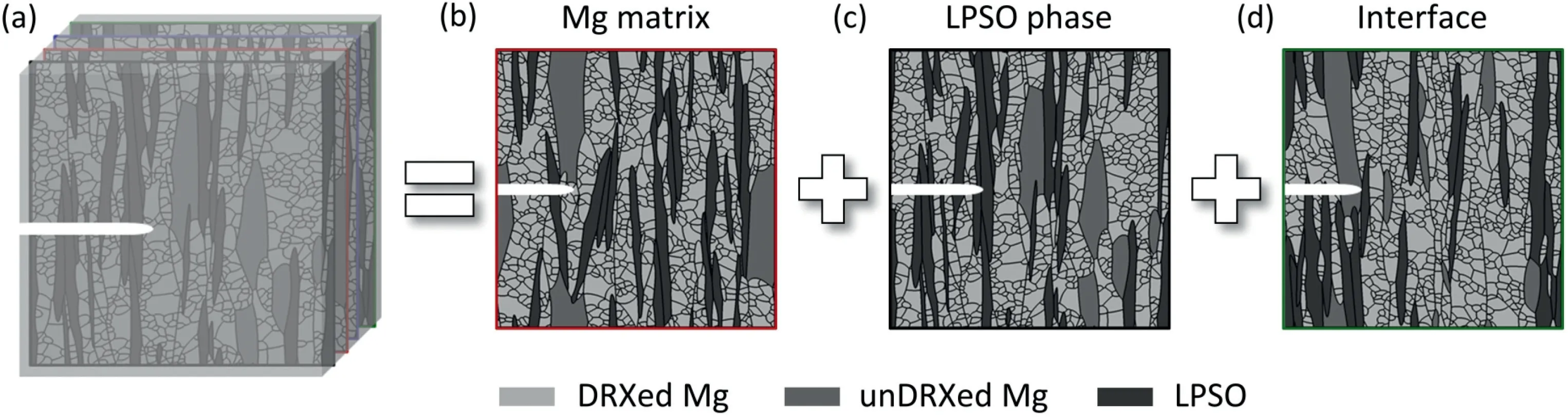

was used instead,whereKcis the fracture toughness,Ethe Young’s modulus (45 GPa) andνthe Poisson’s ratio (0.3).Fig.12 depicts a schematic diagram of the mixture rule where the strain energy release rates of the different accounted mechanisms are linearly added.

Similar to the prediction of YS,a simple model referred as Model-1 is employed by combining contributions from Mg phase and LPSO phase linearly as expressed below:

where theGc,LPSOandGc,Mgare the energy release rate of LPSO phase and Mg phase,respectively.Since the fracture toughness of 100%-LPSO does not change with the extrusion ratio,it is assumed thatGc,LPSOis a constant.However,regarding the 0%-LPSO alloys,it appears thatGc,Mgshould vary with the extrusion ratio and consequently withφDRXed.Accordingly,Gc,Mgis assumed to be a linear interpolation betweenGc,DRXedandGc,unDRXedas:

Gc,LPSOandGc,Mgare estimated separately via linear regression method using experimental data of 100%-LPSO and 0%-LPSO materials.Estimated parameters are listed in Table 4,and the toughness predictions are shown in Fig.13(a)and (d).From Fig.13(a),the experiments data of 0%-LPSO and 100%-LPSO materials are consistent to our model,whereas the deviations between prediction and experiments data of 25%-LPSO and 85%-LPSO materials are significant.It probably results from neglecting the contribution of Mg/LPSO interaction.Despite some inaccuracy,Model-1 presents a general trend of fracture toughness decreasing as the LPSO volume fraction increases,especially for highly DRXed materials.Mg alloy with no LPSO phase but entirely DRXed grains is predicted to exhibit the best fracture resistance property.

To reduce deviation caused by the absence of Mg/LPSO interaction,the energy release rate of such mechanism,Gc,Mg/LPSOis introduced in Model-2,as a function ofφDRXed:

Fig.11.(a) 2D and (b) 3D schematic illustrations of empirical model for yield strength estimation based on rule of mixtures.

Fig.12.Schematic illustration of rule of mixtures for fracture toughness prediction.Model-1 considers contributions from (b) Mg matrix and (c) LPSO phase,whereas Model-2 and Model-3 consider additional contribution from (c) Mg/LPSO interface.

Fig.13.2D and 3D schematic illustrations of (a,d) model-1,(b,e) model-2 and (c,f) model-3 empirical models for fracture toughness estimation based on rule of mixtures.All the parameters for calculation are validated by experimental data as listed in Tables 3 and 4.

In addition to the effect of LPSO volume fraction,Gc,Mg/LPSOalso accounts for the effect of extrusion ratio as a function ofφDRXed.To keep the sum of contributions equal to 1 and considering the volume fraction of LPSO phase and Mg phase as the probability of crack tip location as shown in Fig.12,a second-order polynomial function is used.

Likewise,Gc,Mg/LPSOis calibrated via linear regression method using the experimental data of 25%-LPSO and 85%-LPSO materials.Fig.13(b) and (e) show the fracture toughness prediction based on Model-2.From Fig.13(b),the increase in LPSO phase is not straightforwardly detrimental to fracture behavior due to the influence of DRXed volume fraction.In case of high DRXed volume fraction (over 60%),increasing the LPSO volume fraction causes a significant decrease in fracture toughness similar to the estimation from Model-1.This is because high DRXed volume fraction induces tremendous pre-kinks which inhibit additional kink band formation leading to a lacking of mechanisms for energy accommodation.In contrast,the increasing of LPSO volume fraction for lower DRXed intensity materials (less than 50%) improves the fracture resistance.The fracture toughness reaches a local peak value around 50% LPSO-50% Mg composition,followed by a decrease due to the contribution of LPSO phase.The convex shape at low extrusion ratio can be attributed to the interaction between the two phases having the highest contribution when the material consists of half volume fraction for each.However,one drawback of this model is that a slight LPSO volume fraction increase from 0% should cause fracture toughness to decrease,since brittle LPSO phase is embedded and no significant interaction can be activated.One evidence is that as-cast 25%-LPSO material with low DRXed volume fraction has a low fracture toughness,it conflicts with the prediction from Model-2.In addition,this model can only derive an expression of interaction item roughly without detailed descriptions about the individual deformation mechanisms.

In the third model,referred to as Model-3,two sets of separated formulas are employed to quantify phase interactions,in which one illustrates crack propagation from Mg to LPSO phase by overcoming the energy thresholdGc,Mg-LPSOand reverselyGc,LPSO-Mgfor propagation from LPSO to Mg phase.According to the discussion in Section 4.1,the strong Mg/LPSO interaction promoting deformation kink formation is only observed when the size of LPSO phase is large enough.The size of LPSO phase is strongly dependent on its volume fraction.Thus,one assumption is that forGc,Mg-LPSO,the higher LPSO volume fraction,the larger kink generates with more energy dissipation.Since high DRXed volume fraction induces pre-kinks inhibiting deformation kink,another assumption is that the lower DRXed volume fraction,the more kink generates.On the other hand,Gc,LPSO-Mgconsists of two different Mg grains: the DRXed and unDRXed Mg grains ahead of LPSO phase crack tip.HenceGc,Mg-LPSOandGc,LPSO-Mgin Model-3 can be expressed as:

whereGc,kinkis the energy release rate of deformation kinks with coefficientsk3,b3,k4andb4,H(φLPSO-φLPSO,c)is the Heaviside step function with a transform point associating to LPSO volume fractionφLPSOand critical fractionφLPSO,cfor kink activation,represent the energy release rates of interactions between LPSO phase and DRXed as well as unDRXed Mg grains,respectively.Subsequently the following expression for model-3 is obtained:

The parametersGc,DRXed,Gc,unDRXedandGc,LPSOare the same as in Model-1,which are estimated from experimental data of 0%-LPSO and 100%-LPSO materials.By subtracting the contribution of Mg phase and LPSO phase from experimental results of 25%-LPSO and 85%-LPSO materials,the remaining deviation corresponds to the contribution of Mg/LPSO interaction.In 25%-LPSO materials,no kinks but interaction between LPSO phase and unDRXed as well as DRXed Mg grains can be used forandestimation.While in 85%-LPSO materials,the observed kinks allow the estimation ofGc,kink.The calibrated coefficients and parameters are listed in Tables 3 and 4.Energy release rates of DRXed MgGc,DRXedand unDRXed MgGc,unDRXedevaluated from Model-3 are consistent with reference reports [6,12].It is interesting to note that the magnitude ofGc,DRXedis over 3 times larger thanGc,unDRXed.It suggests that despite major twinning is a key mechanism for energy dissipation of large unrecrystallized Mg grains,the grain boundaries of refined Mg grains play a more important role in the fracture toughness.However,energy release rateGc,LPSOindicated by Mine et al.is far below what is obtained from our estimation model [16].This inconsistency may be due to the micro-scale bending sample employed by Mine et al.including a single LPSO grain.It likely caused a near plane stress loading condition and no strengthening from grain boundaries.Therefore,theGc,LPSOobtained by our model is more conservative and reliable at the macroscale.On the other hand,the interaction of Mg and LPSO phase varies dramatically depending on their relative size and volume fraction.has the largest energy release rate suggesting that the DRXed Mg/LPSO interface can dissipate deformation energy most efficiently.In addition,it quantitatively suggested that the DRXed Mg/LPSO interface is stronger than that of Mg/Mg and LPSO/LPSO.

By substituting each estimated value of energy release rate for Eq.6,8-11,the microstructure-motivated Model-3 can be verified as displayed in Fig.13(c) and (f).Similar to the prediction from Model-2,the fracture toughness decreases slightly regardless of how significant DRXed is as LPSO volume fraction increases from 0% to around 30%.The trend changes for low DRXed volume fraction (less than 50%) alloys when LPSO volume fraction approaches 30% due to the activation of deformation kinks.Subsequently,a considerable enhancement of toughness sustains till around 80% volume fraction of LPSO phase where an extreme value appears.It should be noted that according to the microstructure analysis in Table 2,high LPSO volume fraction seems to be beneficial for the recrystallization rate.For instance,R2-85%-LPSO alloy have a DRXed volume fraction of 0.45.Hence the estimation of materials with high LPSO but low DRXed volume fraction is plotted in dash lines.The rapid fracture toughness decrease from 80% to 100% LPSO volume fraction is caused by the predominant contribution from brittle LPSO phase with the decrease in Mg/LPSO interface.However,similar to the prediction of former models,highly DRXed materials (over 60%) maintain their tendency of decreasing the toughness when LPSO volume fraction increases.Interestingly,as demonstrated in all models,the highest toughness is obtained by totally DRXed Mg material,even though the highest strength is obtained for Mg/LPSO binary alloys.

5.Conclusions

In this study,a comprehensive and systematic investigation of mechanical properties and failure mechanisms of Mg-Zn-Y alloys with different extrusion ratio and LPSO volume fraction was performed by uniaxial tensile tests and fracture toughness tests.The obtained results are summarized as follows:

1.Mg phase mainly consists of two types of grains,which are fine DRXed grains and coarse unDRXed grains.The former has small grain size and reorients randomly,while latter has large size whose basal plane parallel to ED.The higher extrusion ratio and the more LPSO volume fraction,the more portion of DRXed Mg grains.The 18R type of LPSO phase consists of multiple thin plates with initial kinks inside.

2.The LPSO predominant materials (85%-LPSO and 100%-LPSO) exhibit a high tensile yield stress with limited elongation,while Mg predominant materials (0%-LPSO and 25%-LPSO) exhibit a great balance between the strength and ductility.Moreover,the increase of extrusion ratio enhances the strength and ductility simultaneously.

3.In general,Mg predominant materials have higher fracture toughness than LPSO predominant materials.The increase of extrusion ratio changes fracture behavior of Mg predominant materials more significantly due to grain refinement strengthening.The 100%-LPSO materials maintain a relatively low fracture toughness owing to the intrinsic brittle behavior of LPSO phase.However,due to the strong Mg/LPSO interaction,the deformation kinks are observed in 85%-LPSO materials.

4.Several empirical models for yield strength and fracture toughness estimation are proposed based on rule of mixtures and calibrated by experimental data.All the fracture toughness models predict that alloy with no LPSO phase and entirely DRXed exhibits the best fracture behavior.From the estimations of energy release rates,it is quantitatively confirmed that DRXed Mg/LPSO interaction has the highest value,which suggests that DRXed Mg/LPSO interface can dissipate energy most efficiently.

Acknowledgments

Sincere thanks are expressed for financial support from JSPS KAKENHI for Scientific Research on Innovative Areas MFS Materials Science (Grant Number JP18H05478).Prof.M.Yamasaki is acknowledged for providing extruded Mg-Zn-Y alloys.

Journal of Magnesium and Alloys2022年8期

Journal of Magnesium and Alloys2022年8期

- Journal of Magnesium and Alloys的其它文章

- Effect of vibration on interfacial microstructure and mechanical properties of Mg/Al bimetal prepared by a novel compound casting

- Corrosion protection and mechanical properties of the electroless Ni-P-MOF nanocomposite coating on AM60B magnesium alloy

- Microstructure,mechanical properties and wear resistance of Ti particles reinforced AZ31 magnesium matrix composites

- In vitro evaluation of degradation,cytocompatibility and antibacterial property of polycaprolactone/hydroxyapatite composite coating on bioresorbable magnesium alloy

- Bending properties of extruded AZ91-0.9Ca-0.6Y alloy and their improvement through precompression and annealing

- Development and screening of (Ca-P-Si-F)-PEO coatings for biodegradability control of Mg-Zn-Ca alloys