Microstructure,mechanical properties and wear resistance of Ti particles reinforced AZ31 magnesium matrix composites

Junliu Ye ,Xinhu Chen,b,? ,Hun Luo ,Jie Zho ,Jinbo Li,b,? ,Jun Tn ,Hong Yng,Bo Feng,Kihong Zheng,Fusheng Pn,b,?

a College of Materials Science and Engineering,Chongqing University,Chongqing 400045,China

b National Engineering Research Center for Magnesium Alloys,Chongqing University,Chongqing 400045,China

c Institute of New Materials,Guangdong Academy of Sciences,Guangzhou 510650,China

Abstract The compromise between strength and plasticity has greatly limited the potential application of particles reinforced magnesium matrix composites (MMCs).In this work,the Ti particles reinforced AZ31 magnesium (Mg) matrix composites achieved simultaneous improvement in strength,elongation and wear resistance.The Ti particles reinforced AZ31 composites were fabricated by ultrasonic-assisted stir casting with hot extrusion.The results showed that a strong interfacial bonding was obtained at Ti/Mg interface because of the formation of semicoherent orientation relationship of TiAl/Mg,TiAl/Al2Ti and Al2Ti/Mg interfaces.The as-extruded 6 wt.%Ti/AZ31 composite presented the best compressive mechanical properties and wear resistance with ultimate tensile strength,elongation and wear rate of 327 MPa,20.4%and 9.026 × 10-3 mm3/m,obviously higher than those of AZ31 alloys.The enhanced mechanical properties were attributed to the grain refinement and strong interfacial bonding.The improved wear resistance was closely related to the increased hardness of composites and the formation of protective oxidation films.

Keywords: Magnesium matrix composites;Ti particles;Microstructure;Mechanical properties;Wear resistance.?Corresponding authors at: College of Materials Science and Engineering,Chongqing University,Chongqing 400045,China.

1.Introduction

With the increasing requirement of energy saving and carbon emission reduction,the development of lightweight materials has been attracted wide attention [1,2].Due to the low density,high special strength,great special stiffness and excellent wear resistance,magnesium matrix composites (MMCs)have the potential to be applied in aerospace,automobile and military industries [3-5].The most commonly applied reinforcements in MMCs are discontinuous ceramic particles,such as SiC [6,7],TiC [8,9],Al2O3[10,11],B4C [12,13] etc.,which could significantly improve the strength,hardness,elastic modulus and thermal stability of MMCs.Nevertheless,due to the poor deformation characteristic of ceramic particles,the introduction of ceramic particles severely worsens the plasticity of MMCs [14-17],which would limit their potential application.Recently,metal reinforcements have been developed in MMCs.Compared to ceramic reinforcements,metal reinforcements show better plasticity and mechanical compatibility with MMCs [14,18].Therefore,metal reinforcements could be applied to improve the poor plasticity of MMCs.

To select suitable metal reinforcements for MMCs,two factors should be considered [19,20].The one is that the reinforcement shows higher strength than the matrix for getting high strengthening effect.In this condition,Ti [21],Fe [22],Ni [23] and Cu [24] etc.can be the considerable reinforcements for MMCs.The other is that the reinforcements possess similar crystal structure to matrix to obtain good interfacial bonding.Both Ti and Mg have a hexagonal closed-packed(HCP) crystal structure [25-28].Thus,Ti particles can be considered as an ideal metal reinforcement for MMCs.Previous study showed that the wettability between Ti and Mg was very good,as their contact angle is 31° at 800 °C [29].Hence,a good interfacial bonding may be obtained between Mg and Ti.Besides,the solubility of Ti in Mg is negligible and Ti hardly reacts with Mg to form brittle compounds[25,30,31],which is conducive to the plasticity.Hassan and Gupta[32]synthesized Ti particles reinforced Mg composites,and the Mg composites showed a significant increase in yield strength but a decrease in ultimate tensile strength.Wang et al.[33,34] prepared Ti alloy particles reinforced AZ91 composites by stir casting.The composites presented a better plasticity than SiC particles reinforced AZ91 composites,but a lower elongation than AZ91 alloy.Jiang et al.indicated that the strong interfacial bonding between secondary phase andα-Mg could contribute to the plasticity of Mg alloys [35].This means that the plasticity of Ti particles reinforced MMCs might further be improved by the formation of strong interfacial bonding.Besides the mechanical properties,the wear resistance is another important property for MMCs.To date,the wear resistance of MMCs has been widely investigated[36,37].Unfortunately,those MMCs with good wear resistance showed poor plasticity.Ti is deformable and possesses higher hardness than Mg [38,39].Therefore,a simultaneous increase in strength,plasticity and wear resistance may be achieved in Ti particles reinforced MMCs with strong interfacial bonding at Ti/Mg interface.However,the interfacial bonding between Ti particles and Mg matrix,and wear mechanism of Ti particles reinforced MMCs are still unclear.The purpose of this work is to investigate the interfacial bonding of Ti/Mg interface,wear mechanism of Ti particles reinforced MMCs,and achieve a simultaneous increase in strength,plasticity and wear resistance of MMCs.

In this work,the Ti particles reinforced AZ31 composites were fabricated by ultrasonic-assisted stir casting followed by hot extrusion.The microstructure,mechanical properties and wear resistance of as-extruded Ti/AZ31 composites were investigated.Especially,a strong interfacial bonding was achieved at Ti/Mg interface.The tensile strength,elongation and wear resistance of as-extruded Ti/AZ31 composites are increased simultaneously with the increment of Ti,which makes Ti/AZ31 composites possessing a prospect in aerospace,automobile industries.

2.Experimental procedures

2.1.Fabrication of Ti/AZ31 composites

Spherical Ti particles of an average size of 8 μm and commercial AZ31 alloy ingot were used as raw materials.The Ti/AZ31 composites were prepared by ultrasonic-assisted stir casting followed by hot extrusion.Firstly,the AZ31 alloy was molten at 720 °C in a steel mold using an electronic resistance furnace under the protective atmosphere of CO2and SF6.The molten AZ31 was then cooled to 630 °C to obtain semi-solid condition.Ti particles were added in the molten AZ31 alloy in semi-solid state,and then mechanically stirred for 5 min.After stirring,the molten Ti/AZ31 composite was rapidly reheated to 660 °C to be in liquid state and ultrasonicated at 1600 W for 10 min.After ultrasonication,the molten Ti/AZ31 composite was quenched by water to get composite ingot.Before extrusion,the composite ingot was preheated at 350 °C for 1 h The preheated composite ingot was hot extruded at 350 °C with an extrusion ratio of 16:1.For comparison,the AZ31 alloy was prepared using the same method.

2.2.Characterization

The microstructures of as-extruded alloy and composites were investigated by optical microscope (OM,OLYMPUS OLS4000),emission scanning electron microscope (SEM,JEOL JSM-7800F) equipped with an energy dispersive spectrometer (EDS) and a HKL Chanel 5 electron backscattered diffraction (EBSD) system.For OM and SEM characterization,samples of 7 × 5 × 3 mm were mechanically ground with 2000 grid SiC paper.Samples for EBSD observation of 7 × 5 × 3 mm were electropolished with AC2 solution.The interfacial structure of 6 wt.%Ti/AZ31 composite was identified using transmission electron microscopy (TEM,FEI Talos F200x).For TEM characterization,thin foil samples were ground to~50 μm and ion-beam thinned using Gatan Precision Ion Polishing System.

The tensile tests of as-extruded alloy and composites were determined parallel to the extrusion direction (ED) by an universal testing machine (GMT5105) at room temperature.The tensile toughness was obtained by calculating the area under the stress-strain curve of alloy and composites.The Vickers microhardness was conducted on a Zwick tester at a constant load of 0.1 g with dwell time of 10 s.Dry sliding test was conducted by pin-on-disk using an UTM-2 tribometer with a load of 20 N and sliding velocity of 50 mm/s at room temperature.Samples for wear test with dimensions of 12 × 9 × 3 mm were made from Ti/AZ31 composites as flat to against Al2O3ball.

3.Results

3.1.Microstructure

Fig.1 shows the OM images of as-extruded Ti/AZ31 composites.In Fig.1(a),the unreinforced alloy contains dynamic recrystallization (DRX) zone and deformation zone.In Fig.1(b-d),the deformation zone disappears and the Mg matrix is composed of equiaxed grains.Thus,a full DRX is achieved in Ti-containing composites.In the zone close to Ti particles,the grains are much finer than those in Ti particle free zone,indicating the Ti particles can accelerate the DRX during extrusion.The measured average grain size is 4.6 μm for the unreinforced AZ31 alloy.While for the Ti/AZ31 composites,the measured average grain sizes are refined from 4.6 μm to 3.3 μm,as the content of Ti from 0 to 6 wt.%,respectively.However,with the further addition of Ti,the grain size of 9 wt.%Ti/AZ31 composite is increased inversely to 3.5 μm.Moreover,the distribution range of Ti/AZ31 composites shows a similar trend to the change of grain size.

Fig.1.OM images and corresponding distribution maps of grain size of as-extruded Ti/AZ31 composites: (a) AZ31,(b) 3 wt.%Ti/AZ31,(c) 6 wt.%Ti/AZ31 and (d) 9 wt.%Ti/AZ31.

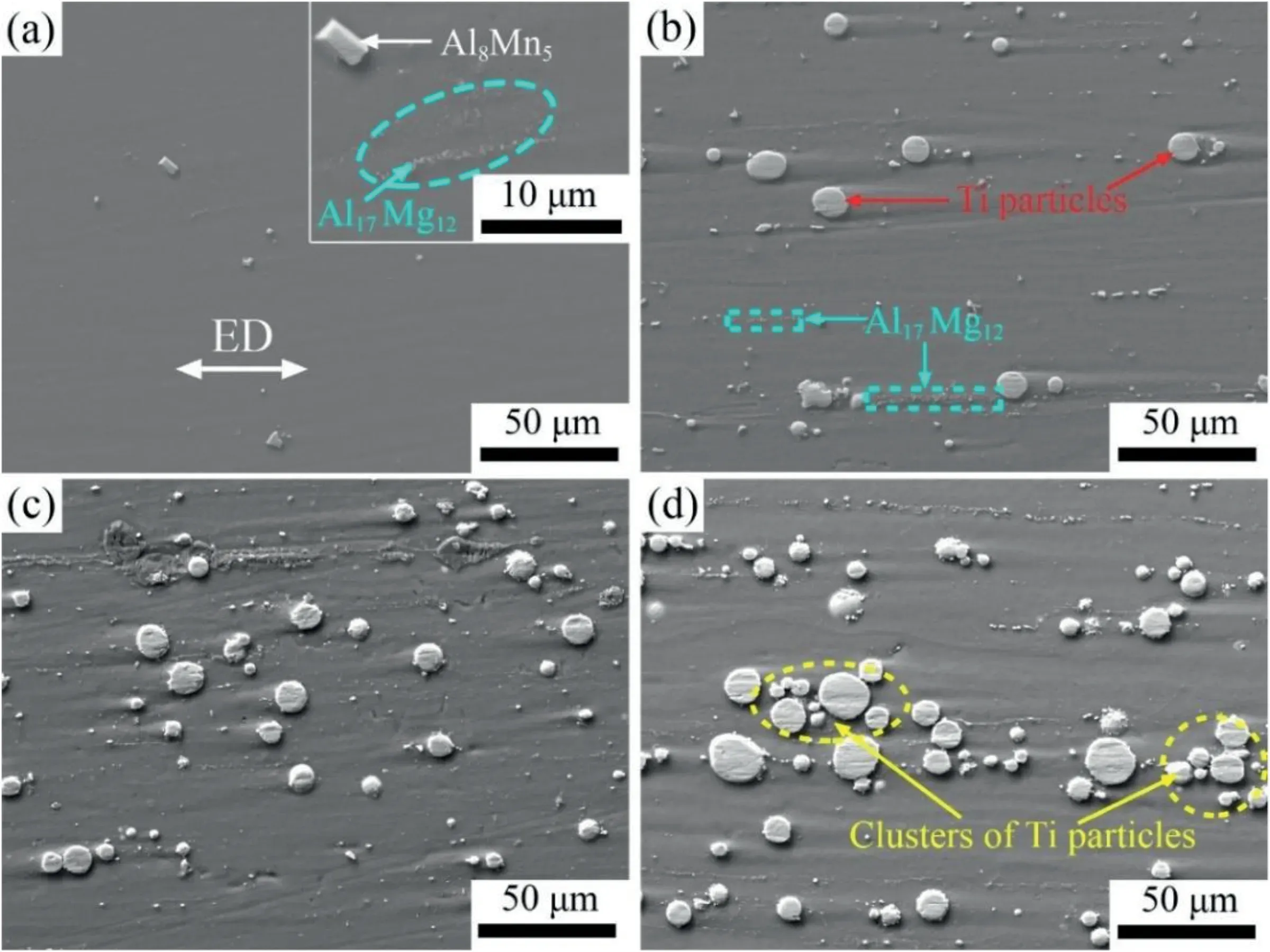

Fig.2 shows the SEM microstructures of as-extruded Ti/AZ31 composites.In Fig.2(a),only a few secondary phases are observed.The magnified image shows that there are two kinds of secondary phases.One is Al8Mn5particles in micro size while the other is Mg17Al12particles below submicro.With the increment of Ti,the amount of secondary phase particles increases.In Fig.2(b,c),spherical Ti particles uniformly disperse in Mg matrix.However,agglomerate regions occur in 9 wt.%Ti/AZ31 composite (Fig.2d).The agglomerate of reinforcements has been widely reported in previous literature.When the reinforcements up to a high volume,the inter-spacing between reinforcements would be shorted,as compared to that for low volume reinforcements reinforced composites [40,41].As a result,the interaction between particles becomes inevitable,which leads to the agglomerate of reinforcements in composites during synthesis process.The agglomerate of reinforcements not only recedes the grain refinement of Mg matrix,but also serves as defects during deformation,which results in a decrease in mechanical properties.

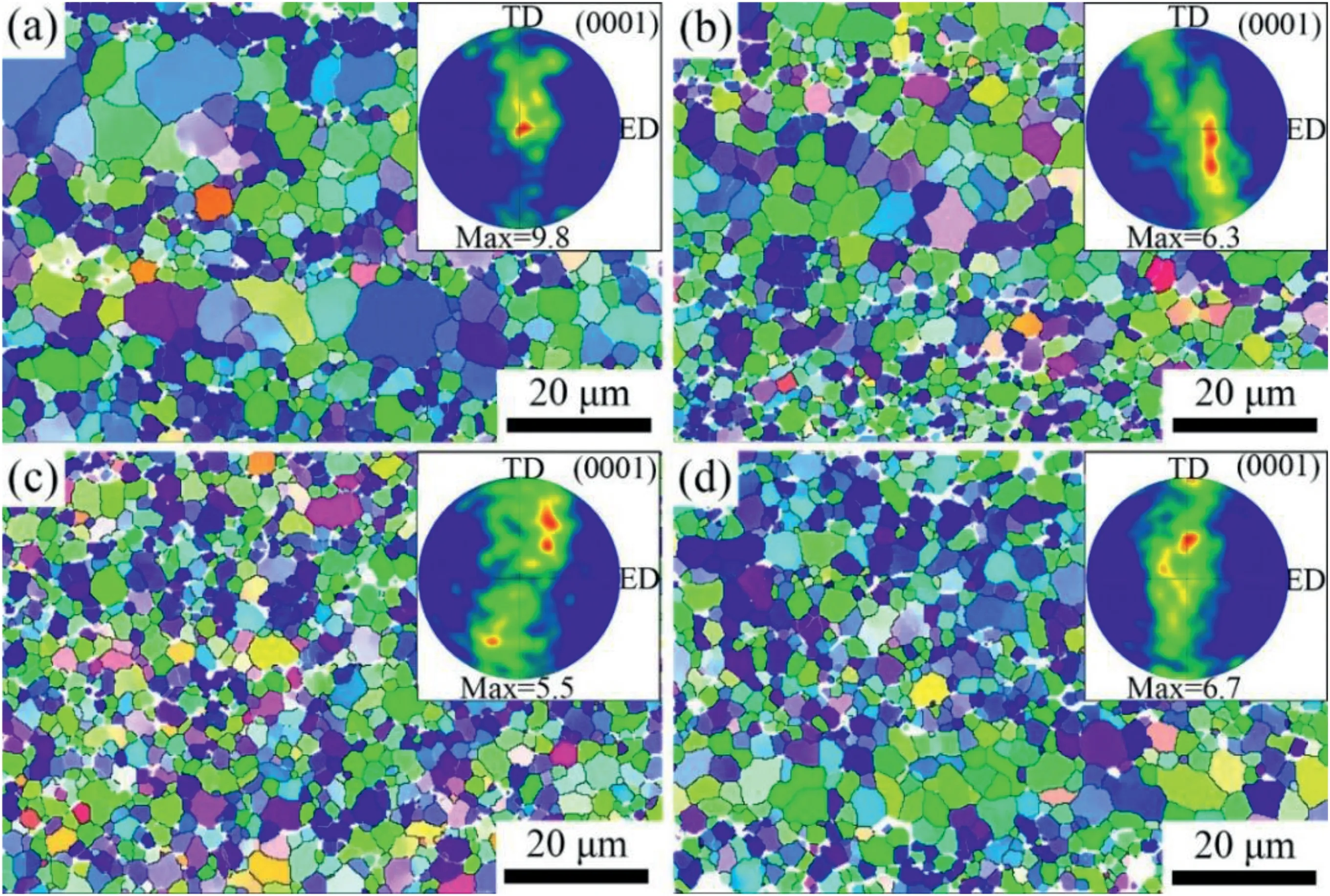

Fig.3 shows the inverse pole figures with corresponding pole figures of as-extruded Ti/AZ31 composites.It shows that the changes of grain size are consistent with the OM results.The value of the maximum texture intensity is 9.8,while the corresponding values are decreased to 6.3,5.5 and then increased to 6.7,with the addition of Ti from 0 to 9 wt.%.The change of the maximum texture of composites is the result of accumulated DRX process by Ti particles addition.

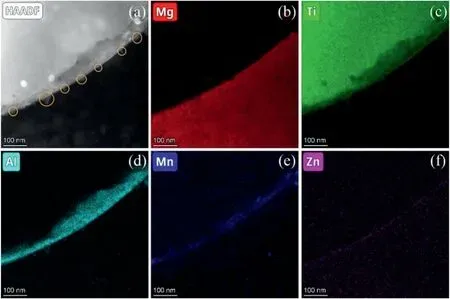

Fig.4 shows the high angel annular dark field (HAADF)mapping of as-extruded 6 wt.%Ti/AZ31 composite.Based on Fig.4(b,c),it can be confirmed that the gray region is the spherical Ti particle while the black region is Mg matrix in Fig.4(a).At Ti/Mg interface,there are precipitates with a size of 10-20 nm as marked by orange circles.In Fig.4(c),it shows that a layer of Al element with a width of 50-100 nm occurs at the edge of spherical Ti.This indicates that there exists diffusion of Al atoms from Mg matrix to Ti particles forming Al-Ti compounds during synthesis process.

Fig.5 presents the TEM line scanning of as-extruded 6 wt.%Ti/AZ31 composite.The scanning position and scanning direction are marked in Fig.5(a).The content of Mg increases sharply to 85 at.%,and the corresponding value of Ti decreases to 3 at.%at the position of~170 nm,which indicates the position of Ti/Mg interface (Fig.5b).At the side of Ti,there exists a plateau of Al,inferring that Al atoms diffuse in Ti particles forming Al-Ti compound.The content of Al close to the Ti/Mg interface is 40-50 at.%,while the value of Ti near the Ti/Mg interface is 40-45 at.%.Correspondingly,the atomic ratio of Al: Ti is about 1: 1.Therefore,the compound at Ti/Mg interface may be TiAl.

Fig.2.SEM microstructures of as-extruded Ti/AZ31 composites: (a) AZ31,(b) 3 wt.%Ti/AZ31,(c) 6 wt.%Ti/AZ31 and (d) 9 wt.%Ti/AZ31.

Fig.3.Inverse pole figures and pole figures of as-extruded Ti/AZ31 composites: (a) AZ31,(b) 3 wt.%Ti/AZ31,(c) 6 wt.%Ti/AZ31 and (d) 9 wt.%Ti/AZ31.

The final mechanical properties of composites are highly dependent on the interfacial bonding between reinforcements and matrix.To reveal the interfacial structure of Ti/Mg,the TEM images of as-extruded 6 wt.%Ti/AZ31 composite are illustrated in Fig.6.Fig.6(b) is the magnified image of position B in Fig.6(a).It shows that there is an obvious interface.Thus,the upper of the image is denoted as region I,and the bottom of the image is region II.The measured d-spacings of region I are 0.1822 nm and 0.1798 nm,respectively,giving a parametera=0.4020 nm andc=0.4087 for TiAl.In region II,the measured d-spacings are 0.2765 nm and 0.1884 nm,respectively,which gives a parametera=3.191 nm andc=0.5139 nm for Mg matrix.The calculated lattice parameters and corresponding standard lattice parameters [42] are presented in Table 1.The calculated values are matched well with the standard values.Therefore,region I is TiAl,and region II is Mg.At the interface in Fig.6(c),TiAl and Mg matrix possess an obvious orientation relationship.The (012)plane of TiAl is parallel to the(0-112)plane of Mg.the calculated misfit between (012)TiAland (0-112)Mgis 3.2%,which is accordant with standard value of 5.1%.Baed on privious studies [43,44],a semi-coherent interface forms between Ti particles and Mg matrix.

Fig.4.(a) HAADF image and corresponding EDS maps of 6 wt.%Ti/AZ31 composite: (b) Mg,(c) Ti,(d) Al,(e) Mn,(f) Zn.

Fig.5.Line scanning maps of 6 wt.%Ti/AZ31 composite: (a) HAADF image,(b) line results of the dotted line in (a).

Fig.6(d) is the magnified image of position D in Fig.6(a).It shows that rod-like particles (marked as region III) with a length of 20-50 nm and a width of 10 nm form at Ti/Mg interface.The EDS results indicate that the precipitates mainly consist of Al and Ti.The atomic ratio of Al:Ti is about 2: 1.It is deduced that the nanoprecipitates are Al2Ti.During synthesis process,Ti particles could stimulate the precipitation of secondary phase.Braszczynska-Malik and Prze?o˙zy′nska [30] reported that Al2RE phase formed on Ti particle in Mg-5Al-5RE alloy during casting.However,the effect of Al2RE on mechanical properties is still unknown.Zhang et al.[45] found that Al2Ti e forms on the surface of Ti particles,which finally contributed to mechanical properties.

In region III,the measured d-spacings are 0.1965 and 0.2538 nm,giving a parametera=0.3930 nm andc=2.4926 nm for Al2Ti.The rod-like particles are confirmed to be Al2Ti.In Fig.6(e),it is clear that Al2Ti has an orientation relationship with TiAl.Namely,the (-2-10)plane of TiAl is parallel to the (0-20) plane of Al2Ti.The calculated misfit between TiAl and Al2Ti is 8.8%,matched well with the standard value of 10.4%.Therefore,the interface between TiAl and Al2Ti is semi-coherent.In Fig.7(f),the (114) plane of Al2Ti is parallel to the (10-11) plane of Mg.the calculated misfit between (114)Al2Tiand (10-11)Mgis 4.0%,which is accordant with the standard value of 3.8%.Thus,the interface between Al2Ti and Mg matrix is defined as a semi-coherent interface.

Fig.6.Interfacial structure of 6 wt.%Ti/AZ31 composite: (a) TEM,(b) HRTEM of position B in (a),(c) TiAl/Mg interface,(d) HRTEM of position B in (a),MgO/Mg interface,(e) TiAl/Al2Ti interface and (f) Al2Ti/Mg interface.

3.2.Mechanical properties

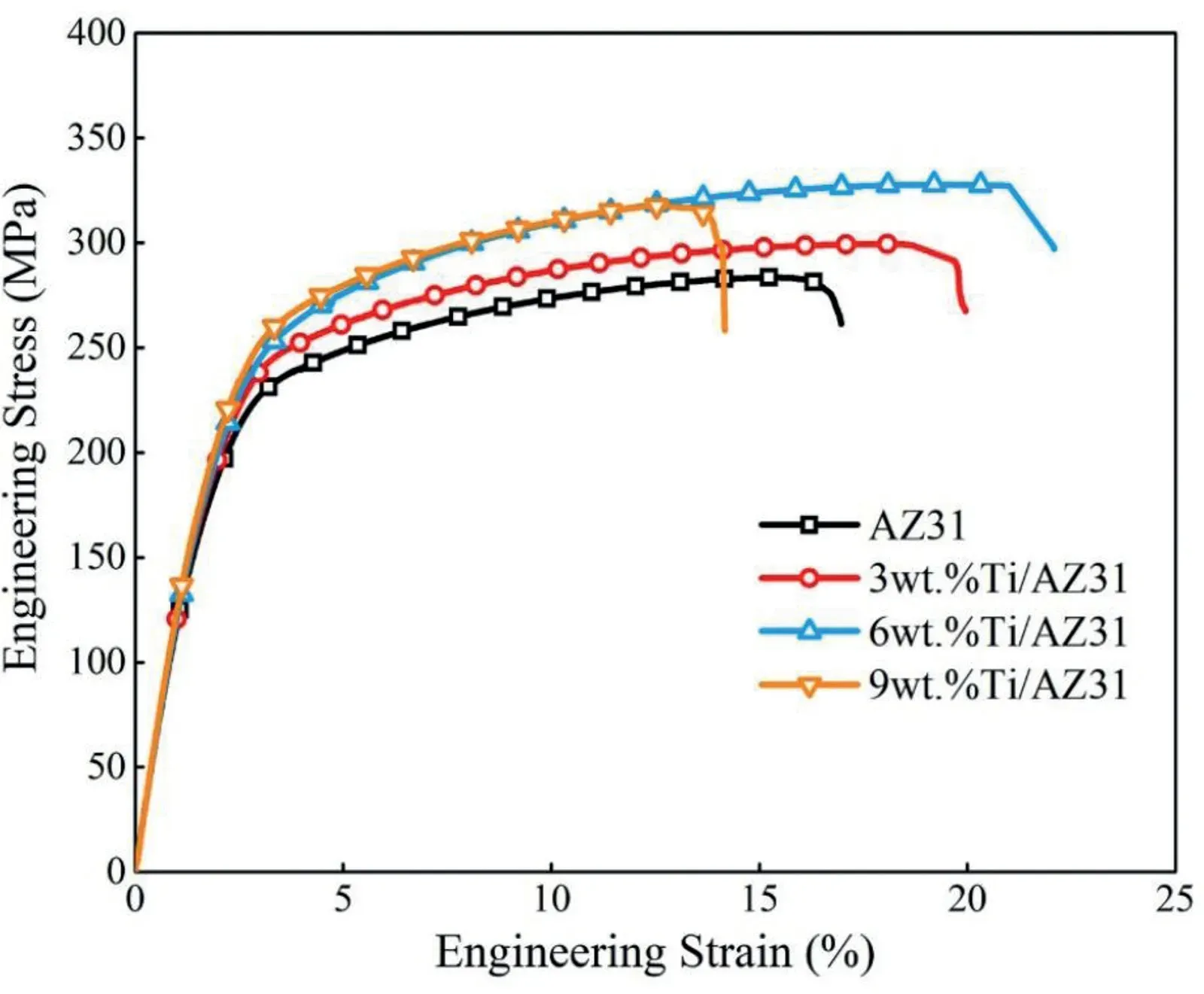

Fig.7 displays the engineering tensile curves of asextruded Ti/AZ31 composites.And the yield strength (YS),Ultimate tensile strength (UTS),elongation and Vick hardness are presented in Table.2.The YS of unreinforced AZ31 alloy is 227 MPa,while the corresponding value of9 wt.%Ti/AZ31 composite is increased to 251 MPa finally.The UTS and elongation show a similar trend.The UTS,elongation and tensile toughness of Ti/AZ31 composites are increased firstly and then decreased with the increment of Ti.Especially,the 6 wt.%Ti/AZ31composite possesses the highest UTS of 327 MPa,elongation of 20.4% and tensile toughness of 63.4 MJ/m3,respectively.Furthermore,the hardness of Ti/AZ31 composites is increased with the increasing content of Ti from 64.3 to 68.2 HV.Therefore,the Ti/AZ31composites achieved a simultaneous increase in YS,UTS,elongation and hardness.

Table 1 Experimental and standard values of the lattice parameters for TiAl,Al2Ti and Mg.

Table 2 Mechanical properties and hardness of as-extruded Ti/AZ31 composites.

Fig.7.Engineering tensile curves of as-extruded Ti/AZ31 composites.

Fig.8 shows the comprehensive mechanical properties of Ti/AZ31 composites and other AZ31 composites [11,46-59].It shows Al2O3+Cu particles reinforced AZ31 composites possess UTS of 365 MPa,but their elongation is only~5.5%.The elongation of VN particles reinforced reaches to 14%.However,the UTS of VN/AZ31 composites is lower than 200 MPa.Those results indicate that it is still a great challenge to fabricate particles reinforced MMCs with both high strength and good elongation.It is noted that the Ti/AZ31 composites in this work show a simultaneous increase in strength and plasticity.

Fig.8.The tensile strength and elongation of Ti/AZ31 composites and other AZ31 composites.

3.3.Wear resistance

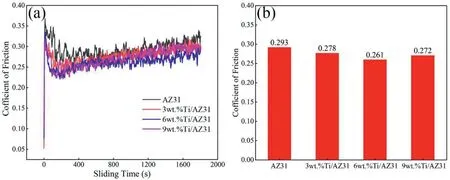

Fig.9 shows the coefficient of friction (COF) of asextruded Ti/AZ31 composites.The friction of coefficient composites decreases firstly for 0.293-0.261 with the addition of Ti from 0 to 6 wt.%,indicating that the Ti particles can effectively reduce the COF of Ti/AZ31 composites during sliding.With further increment of Ti,the friction coefficient increases inversely to 0.272.

Fig.9.(a) the coefficient of friction curves and (b) the average coefficient of friction of as-extruded Ti/AZ31 composites.

Fig.10 shows the 3D morphology images and corresponding 2D profiles across the wear tracks of as-extruded Ti/AZ31 composites after wear tests.The morphology of composites shows a semicircle shape,accordant with the morphology of Al2O3milling ball.By measuring the values of peaks in 2D profiles in Fig.9,the maximum width and depth of wear scar are summarized in Fig.11(a,b),which illustrates that the wear width decreases firstly with increasing content of Ti and then increases with further increment of Ti.Besides,the wear depth reduces with Ti addition.The measured wear loss (volume loss) of composites shows a similar trend to the wear width.The measured wear loss and wear rate decrease from 1.045 to 0.813 mm3as the addition of Ti from 0 to 6 wt.%,indicating that Ti particles improve the wear resistance of Ti/AZ31 composites.The 6 wt.%Ti/AZ31 composite possesses the best wear resistance with wear volume and wear rate of 0.813 mm3and 9.026 × 10-3mm3/m.

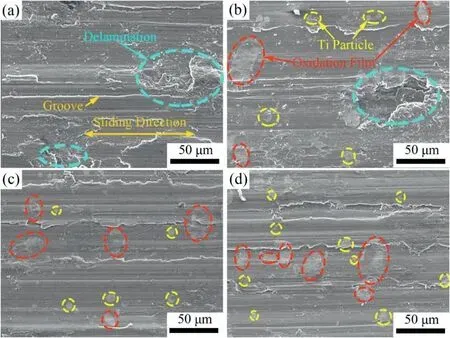

Fig.12 shows the sliding surface of as-extruded Ti/composites after sliding.Along the sliding direction,the grooves are observed in all samples.Therefore,the main characteristic of sliding of Ti/AZ31 composites is confirmed to be abrasive wear.In Fig.12(a),the delamination regions (as marked by blue dotted line) are observed and the sliding surface is quite rough.As the increment of Ti,the sliding surface becomes smoother as compared to the unreinforced alloy.Besides,circular-like and strip-like gray regions occur in Fig.12(b),as marked by yellow and red dotted lines,respectively.The EDS results show that the content of Ti is the highest in the circular-like regions and the circular-like regions present a similar shape to Ti particles.Therefore,the circular regions are the undeformed Ti particles.Before wear testing,the Ti particles are spherical as shown in Fig.2(b-d).However,the strip-like regions show similar EDS results to that of Ti particles.Moreover,the area of strip-like region is obviously bigger than that of circular-like region (Ti particles).Thus,it can be deduced that the strip-like regions are the deformed Ti particles.During dry sliding,the Ti particles deform under the repetitive press,and form films of Ti-Mg-O,which could protect the sliding surface.

4.Discussion

4.1.Grain refinement

The microstructure evolution of as-extruded Ti/AZ31 composites reveals that Ti particles can effectively refine the grains of Mg matrix.The mechanisms of grain refinement for particles reinforced MMCs have been studied in literature.Generally,the reinforcements with different sizes show various mechanisms of grain refinement.Previous studies indicated that the reinforcements larger than 1 μm could promote the DRX process during extrusion (particle stimulated nucleation,PSN),while the reinforcements smaller than1 μm would hinder the growth of dynamic recrystallized (DRXed)grains by pinning the grain boundaries [41,60].In present work,the average size of used Ti particles is 8 μm larger than 1 μm.Therefore,the Ti particles will accelerate the nucleation process by PSN mechanism,which leads to the grain refinement of Ti/AZ31 composites.Besides the size of reinforcements,the interfacial structure between reinforcements and Mg matrix would also affect the grain refinement of composites.During synthesis process,a TiAl layer forms at Ti/Mg interface.It was reported that the crystallographic criterion for effective nucleation is that the misfit between match planes is lower than 10% along the closed packed direction [61].The misfit between TiAl layer and Matrix is 3.2% much lower than 10%.Thus,the Ti particles with the TiAl layer can serve as an effective nucleation substrate for Mg matrix,accelerating the nucleation effectiveness,and finally contributing to the grain refinement of composites.

4.2.Interfacial bonding analysis

Fig.10.3D morphology images and corresponding 2D profiles across the wear tracks of as-extruded Ti/AZ31 composites after wear tests: (a) AZ31,(b)3 wt.%Ti/AZ31,(c) 6 wt.%Ti/AZ31 and (d) 9 wt.%Ti/AZ31.

The interfacial structure between reinforcements and Mg matrix has been reported in SiC [62],graphene [63],carbon nanotubes (CNTs) [44],and MgBO5[64] reinforced MMCs.In previous literature,a good interfacial bonding could be achieved,when no nano-crack or nanogap occurred at the interface between reinforcements and Mg matrix [65,66].Although,many graphene reinforced MMCs were fabricated,and no crack was observed at graphene/Mg interface.However,the graphene/Mg interface is defined as poor bonding interface,because of the poor wettability between graphene and Mg [67].The wettability between graphene and Mg is 120° [63].Yuan et al.[68] reported that the MgO nanoparticles at graphene/Mg interface could significantly improve the interfacial bonding of graphene/Mg owing to the formation of semi-coherent interface.Han et al.’ s work [69] indicated thatin-situformed Mg2Ni at CNTs/Mg interface possessed a coherent relationship with Mg matrix,finally contributing to the interfacial bonding of CNTs/Mg.Based on the studies above,it can be concluded that to obtain a strong interfacial bonding between reinforcements and Mg matrix,the following aspects need to be considered: (i) absence of nanogaps or nano-cracks at interface,(ii) a good lattice spacing matching.In the present work,a nanolayer of TiAl forms at Ti/Mg interface.The misfit between TiAl and Mg matrix is 3.2%,and the TiAl/Mg interface is semi-coherent interface.Moreover,many Al2Ti nanoparticles form at TiAl/Mg interface.The Al2Ti nanoparticles possess semi-coherent relationship with TiAl layer and Mg matrix,respectively.The semi-coherent interfacial bonding is commonly considered as strong interfacial bonding [41,43,44].Therefore,a strong interfacial bonding is achieved at Ti/Mg interface owing to the formation of semicoherent crystallographic orientation relationship of TiAl/Mg,TiAl/Ti2Al,Ti2Al/Mg.

Fig.11.(a) Wear width,(b) wear depth,(c) volume loss and wear rate of as-extruded Ti/AZ31 composites.

4.3.Strengthening and toughening mechanisms

The tensile strength of Ti/AZ31 composites increases greatly,as the increment of Ti.The enhancement in tensile strength of composites can be attributed to the refined grain of Mg matrix,strong interfacial bonding of Ti/Mg interface.Therefore,four possible strengthening mechanisms contribute to the strength of Ti/AZ31 composites,namely grain boundary strengthening,load transfer strengthening,dislocation multiplication strengthening and Orowan strengthening.

Firstly,the grain boundary strengthening significantly affects the YS of Ti/AZ31 composites.The improvement in YS is usually illustrated by the Hall-Petch equation:σy=σ0+kd-1/2[70].The YS shows an inverse relationship with the grain size.Namely,the finer the grain size,the higher the YS.As discussed in Section 4.1,the Ti particles in micro size can act as nucleation sites and then accelerate the PSN process.And the semi-coherent interface of TiAl/Mg improves the efficiency of nucleation for Mg matrix.As a result,shown the Fig.1,the average grain sizes of Ti/AZ31 composites were refined from 4.6 to 3.3 μm.The refined grains imply that the dislocations in grains are more probably to be impeded by the grain boundaries,which leads to an increase in YS of composites.Secondly,load transfer strengthening will significantly influence the YS of composites.Based on the TEM observations,a strong interfacial bonding is achieved at Ti/Mg interface.Therefore,during strength testing,the load could effectively transfer from Mg matrix to Ti particles,contributing to the increasement of YS.In addition,the dislocation multiplication strengthening has a great effect on YS.The thermal coefficient of Ti is 7.1 × 10-6K-1[71],while the corresponding value of Mg is 25 × 10-6K-1[67].The difference coefficient between Ti and Mg results in the multiplication of dislocations close to of Ti particles after extrusion,which leads to an increase in YS of composites.Orowan strengthening is commonly considered for MMCs.In present work,the contribution of Orowan strengthening may be insignificant.The Orowan strengthening highly depends on the volume fraction and particle size of reinforcements [72].In present work,the used Ti particles belong to micro size.As reported in previous literature,only a limited increasement could be achieved in microparticles reinforced MMCs [73].

Fig.12.The sliding surface of as-extruded Ti/composites after sliding.(a) AZ31,(b) 3 wt.%Ti/AZ31,(c) 6 wt.%Ti/AZ31 and (d) 9 wt.%Ti/AZ31.

In addition to the strength,the elongation of composites presents a comparable improvement as well.The increase in elongation of composites is due to the refined grains,weakened texture and deformable reinforcements.As presented in Fig.1,the grain sizes of Ti/AZ31 composites are obviously refined with the increment of Ti.For metal materials,on the one side,the fine grains are beneficial to offsetting stress to more grains and avoiding the inhomogeneous deformation[74].On the other side,the finer grains mean more grain boundaries,impeding the propagation of cracks [75].Therefore,the smaller the grains,the better the plasticity.Next,the texture could also influence the plasticity of composites.The unreinforced AZ31 alloy possesses the highest maximum texture intensity of 9.9,which means that there are more grains with their c-axis perpendicular to extrusion direction (ED).It is unfavorable to tensile deformation along ED.With the increment of Ti,the maximum texture of Ti/AZ31 composites decreases to 5.5,which means that the orientation of grains becomes more random in Ti-containing composites [65].The grains with random orientation can coordinate the deformation,contributing to the plasticity of composites.Moreover,Ti is a metallic material with high plasticity.Based on the studies [76,77],the yield strength of pure Ti is lower than the UTS of Ti/AZ31 composites in this work.Namely,when the stress equal to the UTS of Ti/AZ31 composites is conducted to Ti particles,both elastic deformation and plastic deformation will occur in Ti particles.Therefore,the Ti particles will synergistically deform with Mg matrix during tensile testing,which is conducive to plasticity.Moreover,a strong interfacial bonding is achieved at Ti/Mg interface,which can impede the debonding of Ti particles from Mg matrix during deformation and then contribute to the plasticity of composites [35,78].However,as the Ti content reaches 9 wt.%,the grain size becomes coarse and clusters of Ti particles occur.As a result,the elongation of 9 wt.%Ti/AZ31 composite deteriorates.

4.4.Wear mechanism

Many factors could affect the wear resistance of composites,including hardness,roughness of wear surface,lubrication and temperature etc.In the present work,the samples are dry slid against the Al2O3ball at room temperature.Therefore,the hardness will significantly influence the wear resistance of composites.On the one side,the grain size of Ti/AZ31 composites is reduced with the increment of Ti.Generally,the finer the grain,the higher the hardness [79].On the other side,high density dislocations occur in the vicinity of Ti particles during extrusion.The high density dislocations offer diffusion channels for atoms,and then stimulate the precipitation of secondary phase particles,increasing the amount of precipitation of secondary phase particles [73,80].In Mg-Al based alloy,the secondary phases,such as Mg17Al12and Al8Mn5,have higher hardness than Mg matrix [81,82],which improves the hardness of composites.Based on the Archard’s law [37]:

Fig.13.Schematic of wear surface of Ti/AZ31 composites during sliding.

WhereVis the volume loss,Kis the Archard’s constant,Fis the applied load,Lis the sliding distance,His the hardness of texted samples.The wear loss shows an inverse proportion to the hardness.The less wear loss means better wear resistance.Therefore,the wear resistance of Mg matrix is enhanced with the addition of Ti.

Besides,the Ti particles greatly influence the wear resistance.The Ti particles have a hardness of 120 HV much higher than that of Mg matrix [38],which means that the Ti particles have better resistance than Mg matrix.Thus,it is more difficult to be ground off for Ti particles,as compared to the soft Mg matrix.As the surface layer of Mg is ground off,the emerged Ti particles from Mg matrix could further slide against the Al2O3ball,which improves the wear resistance of composites.In Fig.11(a),delamination regions are observed.The delamination is caused by repeated sliding loads.Under the repeated load,cracks nucleate and propagate at subsurface,which results in the removal of material,leaving caves on the sliding surface [83].With the addition of Ti,the delamination regions are reduced,which is beneficial to the decrease in the volume loss.In Fig.11(b-d),films of Ti-Mg-O form on the sliding surface.During the repeated sliding motion,the emerged Ti particles are deformed and oxidized,forming films of Ti-Mg-O.In previous studies,the oxidation film was commonly defined as tribofilm[84].The oxidation films coating on sliding surface can effectively protect sliding surface [85].As the increment of Ti,more oxidation films form on the sliding surface.Therefore,the wear resistance of composites is significantly improved.The schematic of wear surface during sliding is illustrated in Fig.13.During sliding,the soft Mg is ground off from the sample surface.Then,Ti particles emerge from Mg matrix and resist against the milling ball.Next,the Ti particles form oxidation films under repeated sliding to protect the sliding surface.

5.Conclusions

AZ31 composites reinforced with Ti particles were fabricated using ultrasonic-assisted stir casting followed by hot extrusion.The microstructure,mechanical properties and wear resistance of the as-extruded Ti/AZ31 composites were studied.The main conclusions can be summarized as follows:

(1) With the increasing Ti content,the grains of Ti/AZ31 composites were refined and the basal texture was weakened.

(2) The Al atoms diffused to the edge of Ti particles,forming a nanolayer of TiAl at Ti/Mg interface.Rod-like nanoparticles of Al2Ti precipitated at TiAl/Mg interface.A strong interfacial bonding was achieved because of the semi-coherent crystallographic orientation relationship of TiAl/Mg,TiAl/Al2Ti,Al2Ti/Mg interfaces.

(3) The mechanical properties of Ti/AZ31 composites were obviously enhanced owing to the refined grains and strong interfacial bonding.The 6 wt.%Ti/AZ31 composite possessed YS,UTS and elongation of 245 MPa,327 MPa and 20.4%,respectively.

(4) The Ti/AZ31 composites showed a higher wear resistance than the unreinforced AZ31 alloy,which was due to the increased hardness of the composites and the formation of protective oxidation films.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors would like to thank the financial supports from the Guangdong Major Project of Basic and Applied Basic Research (2020B0301030006),the National Natural Science Foundation of China (Nos.52171103,52171133),the Natural Science Foundation of Chongqing (cstc2019jcyjmsxmX0234),the “111 Project” (B16007) by the Ministry of Education,the Fundamental Research Funds for the Central Universities (No.2020CDJDPT001) and Graduate Research and Innovation Foundation of Chongqing,China (No.CYB21001).The author would like to thank joint lab for electron microscopy of Chongqing University.

Journal of Magnesium and Alloys2022年8期

Journal of Magnesium and Alloys2022年8期

- Journal of Magnesium and Alloys的其它文章

- Effect of vibration on interfacial microstructure and mechanical properties of Mg/Al bimetal prepared by a novel compound casting

- Corrosion protection and mechanical properties of the electroless Ni-P-MOF nanocomposite coating on AM60B magnesium alloy

- In vitro evaluation of degradation,cytocompatibility and antibacterial property of polycaprolactone/hydroxyapatite composite coating on bioresorbable magnesium alloy

- Bending properties of extruded AZ91-0.9Ca-0.6Y alloy and their improvement through precompression and annealing

- Development and screening of (Ca-P-Si-F)-PEO coatings for biodegradability control of Mg-Zn-Ca alloys

- Degradation of Mg-Zn-Y-Nd alloy intestinal stent and its effect on the growth of intestinal endothelial tissue in rabbit model