Thermodynamic Design of A Supercritical CO2Brayton Cycle for 40MW Shipboard Application*

Zhen LiuYa-ping JuChu-hua Zhang

(School of Energy and Power Engineering,Xi'an Jiaotong University,China)

Abstract:Although much attention has been paid to the supercritical CO2 (S-CO2) Brayton cycle, there are still fewworks on the analysis and design of S-CO2 cycle tailored to the needs of the shipboard propulsion and power system.The primary purpose of this study is to carry out the thermodynamic design of a S-CO2 recompression Brayton cycle forshipboard application with 40MW output power. Particular efforts are devoted to the analysis of the thermodynamicparameters of the cycle. The results show that the efficiency of the designed S-CO2 Brayton cycle with a relativelycomplex recuperation cycle is 45.06 percent, 8.28 percent higher than that of a simple recuperation cycle. This indicatesthe great influence of the recuperation design on the efficiency of the Brayton cycle. Meanwhile, the compressor inletpressure greatly affects the cycle efficiency, and the shunt flow percentage could partly reflect the cycle performance.This work is of important reference value for the development of future nuclear shipboard propulsion and power system.

Keywords: Supercritical Carbon Dioxide, Recompression Brayton Cycle, Shipboard Propulsion and Power,Thermodynamic Design, Cycle Efficiency

Nomenclature

hspecific enthalpy(kJ/kg)

m˙mass flow rate of working fluid(kg/s)

ppressure(kPa)

Qheat(kJ)

T temperature(K)

W work(kJ)

x shun t flow percentage

Greek symbols

ηefficiency

ΔTtemperature difference of recuperator(K)

Subscript

Ccompressor

CEcold end of recuperator

ininput of heat source

MCmain compressor

netnet output of the cycle

RCrecompressing compressor

s isentropic process

T turbine

thmthermodynamic

1,2,…,8state point of Figure 1

Superscript

*rate(per unit of time)

1 Introduction

High-efficiency and clean energy exploitation has become one of the hottest research topics in the area of energy and power engineering due to the increasing energy demand,the limited supply of fossil-fuel,and the associated environmental issues.The shipboard demand for larger propulsion and power,lower detrimental environmental impacts,lower life-cycle cost,and greater maneuverability,safety,and reliability has been rapidly growing[1].The development of Generation IV nuclear reactors makes it possible to improve nuclear shipboard thermal efficiencies,meeting these shipboard propulsion demands.The conventional steam Rankine cycle conversion system cannot fully utilize the advantage of high outlet temperature of reactors,which causes an adverse effect on the cycle performance[2].

Alternative power conversions to improve cycle efficiency are the helium Brayton cycle,the S-CO2Brayton cycle,and so on.Among these cycles,the S-CO2Brayton cycle is considered to be a good candidate for nuclear reactor power conversion systems because of the special properties of CO2.Firstly,CO2is a promising working fluid as it possesses relatively modest critical temperature and pressure,the non-toxicity and stability,the inertness within the reactor core coolant temperature range,abundance and natural existence,and so on[3].Secondly,as CO2becomes nearly incompressible near the critical point,the compression work can be dramatically decreased,which can substantially promote the thermal efficiency[4].Thirdly,the higher supercritical pressurized conditions are beneficial to a compact design of turbomachinery.This significant reduction in the size of power block is favorable in shipboard application where the space is valuable.

The concept of S-CO2Brayton power cycle was initially proposed by Feher(1967)[5]and Angelino(1968)[6].But then there was a long time when the closed Brayton cycle was obscured by the improvement of combustion gas turbines.Recently the technology has captured significant attention again and the publications on S-CO2Brayton cycle have risen exponentially[7].Dostal et al.(2004)[8]performed a systematic analysis and multiple-parameter design optimization of the S-CO2Brayton system and the major components.They also pointed out that when the turbine inlet temperature is above 823.15K,the S-CO2recompression Brayton cycle achieves the highest thermal efficiency in comparison with the helium Brayton cycle,the supercritical stream cycle,and the superheated stream cycle.Meanwhile,both the number and size of main components are smallest[2].There were also a series of thermodynamic analysis and optimization studies later[9-15].Along with those thermal analysis,the integral test loops and component experiments were conducted in United States(Sandia National Laboratory[16],Bechtel Marine Propulsion Corporation[17]),Asia(the Nuclear Power Institute of China[18],Tokyo Institute of Technology in Japan[19],Korean Atomic Energy Research Institute and Korea Advanced Institute of Science and Technology[20]),Europe(Research Centre Rez in Prague,Czech Republic[21])and Australia(University of Queensland[22]),demonstrating the technical feasibility of the concept.

So far,numerous theoretical and experimental works have been devoted to the S-CO2cycle.Nevertheless,the researches concerning the S-CO2cycle in shipboard applications are relatively few.Combs(1977)[23]investigated the performance of a S-CO2engine for propulsion and power in a naval ship using basic thermodynamic approach.Combs(1977)selected the simple recuperation cycle as a primary option from the view of compactness and economics.Nowadays as the continuing requirement of higher efficiency and the emergence of more compact heat exchangers,a more complex cycle layout for shipboard propulsion and power applictions could be put on the agenda.

The present study aims at the S-CO2thermodynamic cycle design for a 40MW output power of nuclear shipboards.In the next section,the S-CO2cycle description and modeling are illustrated.Then the parameter analysis of the 40MW cycle is discussed along with the thermodynamic analysis.Finally,the design results are presented.

2 System Description and Modeling

2.1 S-CO2Brayton Cycle System

The power conversion of a basic S-CO2Brayton cycle mainly contains four processes:compression,heating,expansion,and cooling.It is similar with gas turbines nevertheless the latter cooling process occurs in the open air condition.In the meantime,the cycle layout resembles a steam Rankine cycle except that in S-CO2Brayton cycle all of the four processes occur above the critical condition.

In a simple recuperation Brayton cycle,the fluid is compressed in the compressor firstly.Then it passes through the recuperator to be preheated by the turbine exhaust.After the pre-heat,the fluid enters the heater where it achieves the highest temperature from the heat source.Then this high temperature fluid expands in the turbine providing work for the generator and compressor.The remaining heat after expansion is firstly utilized in the recuperator for preheating and then rejected through the precooler,returning to the initial states.

The recuperation process in the S-CO2Brayton cycle greatly influences the thermal efficiency,since the relatively smaller cycle pressure ratio(because the minimum pressure is high)results in a relatively high turbine outlet temperature,leading to a large amount of heat remaining in the turbine outlet.However,due to the great variation in the specific heat in the cycle,the temperature difference between hot side fluid and cool side fluid in the recuperator is large.This pinch-point problem undermines the recuperation performance.On this account,other cycle layouts such as recompression and pre-compression are considered.

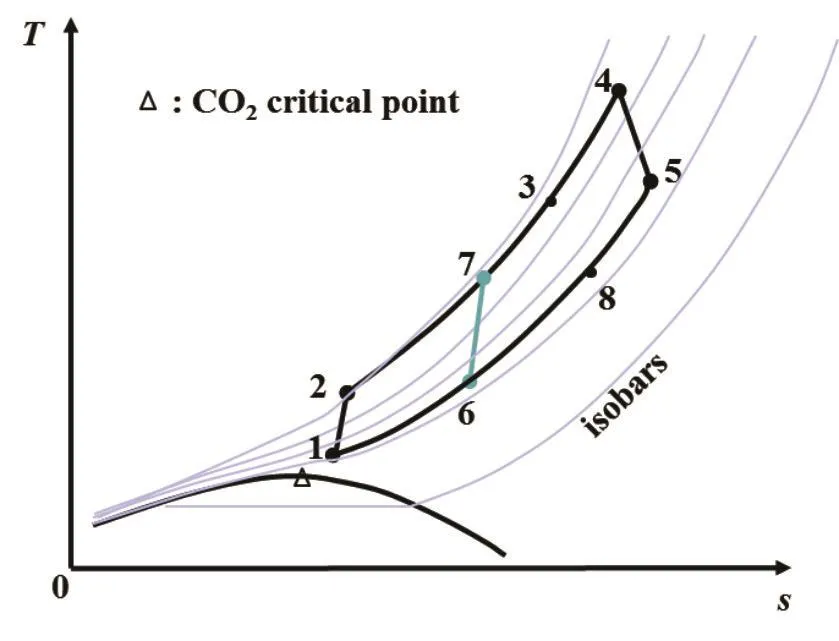

Among these layouts,the recompressing layout is generally considered to be the most efficient in the conditions of interest.Besides,it is relatively simple and compact.Therefore this cycle layout is chosen for the 40MW cycle of the nuclear-powered shipboard.The S-CO2recompression cycle layout is depicted in Figure 1.Another compressor and recuperator(showed in the red dashed box in Figure 1)are intro-duced compared with the simple recuperation Brayton cycle discussed above.In this cycle,the flow is split before entering the pre-cooler(at point 6)and only a part of the fluid flow rejects the heat.This fraction of fluid flow is compressed in the main compressor and preheated through the low temperature recuperator to the recompressing compressor outlet temperature.While the rest of fluid flow enters recompressing compressor and then it is merged with the flow out of the low temperature recuperator(at point 7).The entire fluid flow is preheated in the high temperature recuperator,and then it passes through heat resources,turbine,high and low temperature recuperator successively.The temperature-entropy diagram of the recompression cycle is shown in Figure 2.

Fig.2 T-S diagram of S-CO2recompression cycle

2.2 Thermodynamic Model

The thermodynamic cycle system contains two main types of components:turbomachinery components and heat exchangers.Its modeling is conducted using Aspen HYSYS V8.4 with REFPROP as the fluid package[24].The detailed modeling of the S-CO2Brayton cycle system is presented with the following assumptions:(1)The cycle is under steady state and the fluid maintains supercritical state in the whole possess.(2)Pressure loss in pipes and mass flow loss in the cycle are negligible.(3)The adiabatic efficiency of turbomachinery components is fixed with given values.

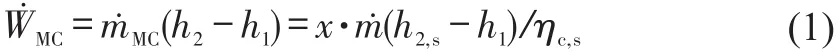

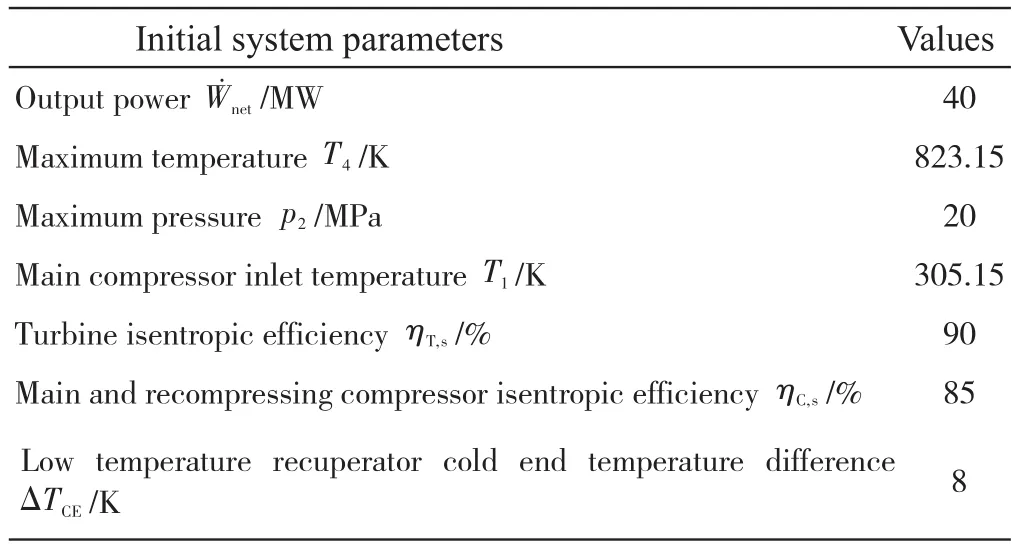

The thermodynamic model is mainly based on the first law of thermodynamics.The main formulas are described in the following.

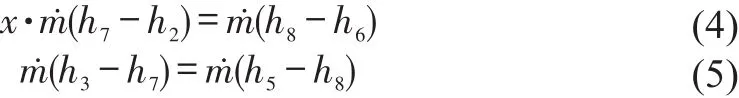

For the compression process in the main compressor,the work consumed can be written as:

Whereh2,sdenotes the compressor outlet enthalpy under the isentropic compressing assumption which can be obtained by the compressor inlet entropy and the outlet pressure,and x is the ratio of mass flow rate in main compressor to the total mass flow rate.

Similarly,the compression and expansion process in the recompression compressor and turbine can be expressed respectively as:

For heat exchangers,the Printed Circuit Heat Exchanger(PCHE)is adopted for its high compactness and favorable heat transfer efficiency.To avoid heat transfer deterioration arising from pinch point problem,the minimum temperature approach between hot side fluid and cool side fluid in the recuperator cold end is stipulated no less than 8K.The energy balance equation in the low and high temperature recuperator can be expressed respectively as:

In the heater,the energy absorbed from the heat source can be written as:

Based on the net output power and total absorbed energy from heat source,the thermal efficiency of the S-CO2recompression cycle system can be derived as:

3 Results and Discussion

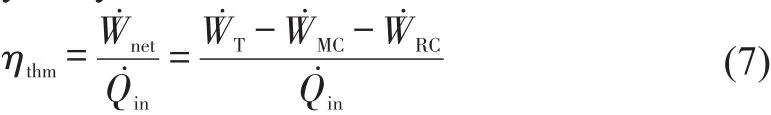

The selections of parameters for the 40MW S-CO2recompression Brayton cycle are mainly based on the components'capacities presented in the literature[8,14].As have been investigated,the key cycle parameters affecting greatly the cycle thermodynamic performance include main compressor inlet temperature,turbine inlet temperature,cycle pressure ratio,pinch temperature difference of heat exchanger.In the considered ranges,a lower compressor inlet temperature is favorable for cycle efficiency,but it has to be above the CO2critical temperature to avoid condensation in the compressor.Thus 305.15K,a little higher than the CO2critical temperature,is chosen for compressor inlet temperature.The higher turbine inlet temperature also leads to a higher thermal efficiency.Considering the nuclear reactor temperatures,it is selected as 823.15K,which is attractive for varieties of advanced nuclear reactor concepts.As Dostal et al.(2004)[8]pointed out,it is reasonable to select 20MPa as the compressor outlet pressure since continuing to increase pressure from 20 to 25MPa obtains negligible cycle efficient improvement while increasing great component cost.Further-more,due to the lower viscosity of S-CO2cycles,the polytropic efficiencies of compressors and turbines are expected to be higher than those of stream gas cycles in the same volumetric flow rate.The selections of these parameters are listed in Table 1.

Tab.1 Initial Conditions and Equipment Parameters

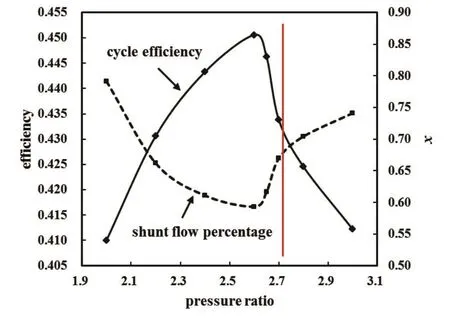

The parameters listed in Table 1 mainly affect the cycle efficiency in an almost monotonic manner.Thus those selections are a balanced compromise between the capability of current materials and the technological economics.However,the pressure ratio of the cycle has a non-monotonic effect on the cycle performance,since the turbine output increases as the pressure ratio increases,while the compressor consumption augments at the same time.The cycle generally achieves the best thermodynamic cycle efficiency when the pressure ratio is between 2 and 3 under those preset conditions.Therefore,several selections of main compressor pressure ratio are simulated to find the reasonable value,and the shunt flow percentage is calculated under each pressure ratio to obtain the maximum cycle efficiency.The results are shown in Figure 3.The left part of the red line locates in the supercritical state.

It can be found from Figure 3 that the cycle efficiency firstly increases and then decreases as the pressure ratio increases,while the shunt flow percentage varies in a nearly opposite way.Besides,the variation becomes more intensely when the inlet pressure is in the vicinity of critical point(around the red line in Figure 3),since the CO2property varies greatly near the critical point.The tendency indicates that the turbine output increment is initially higher and then lower than the compressor work increment with the increase of pressure ratio.Since the maximum pressure of the cycle is fixed with 20MPa,the pressure ratio increases with the decline of main compressor inlet pressure.The fluid tends to be more compact as the inlet pressure is relatively high.Therefore,in the beginning when the pressure ratio is relatively small,an increasing of cycle pressure ratio will not require too much compressing work increment since the fluid density is high,while the turbine can produce more work,making the cycle net output increase.However,as the cycle pressure ratio continuously increases,the compressor inlet pressure approaching the critical point,the fluid density decreases dramatically.This sharp decline of fluid density in the compressor inlet makes the compressor consume greater work than the turbine output increment,the cycle net output decreasing.Therefore the cycle efficiency trend is reversed when the pressure ratio is larger than 2.6.As for the variation of shunt flow percentage,when the pressure ratio is low,the state difference between the hot side fluid and cool side fluid in the recuperator is small since the pressure difference between hot side and cool side fluid is small,reducing the necessity of using bypass flow to ameliorate heat transfer deficiency arising by the big fluid property difference between the hot side fluid and cool side fluid in the recuperator.Therefore fluid flowing in the main compressor is large.And as the cycle pressure ratio increases,the fluid property difference in the recuperator becomes larger,making the shunt flow percentage decrease.When the pressure ratio continuously increases,however,the compressor outlet temperature sharply increases due to the big decline of fluid density.Therefore the pinch point problem in the recuperator also falls down,increasing the shunt flow percentage.Hence the trend of shunt flow percentage is nearly in contrast with the trend of cycle efficiency.

Fig.3 Thermodynamic cycle efficiency and shunt flow percentage vs.cycle pressure ratio

From the above analysis,the cycle pressure ratio is selected as 2.6.The state points'data are summarized in Table 2.The thermodynamic cycle efficiency is 36.78%,while the thermal efficiency of corresponding simple recuperator is 36.78%.The former outperforms the latter by 8.07 percent,indicating that the addition of recompressing process is beneficial to the cycle performance.Besides,the efficiency achieved by the designed S-CO2Brayton cycle,i.e.,45.06%,is actually on the same order as the efficiency of a helium Brayton cycle operating at an even higher temperature or a more complex system layout[25].

Tab.2 Pressure and temperature at typical state points

Overall,the present design meets the design requirement.The generation IV nuclear reactor with the S-CO2Brayton cycle power conversion system is an appropriate and promising choice for ship propulsion and power application.

4 Conclusions

The thermodynamic design of a S-CO2Brayton cycle for shipboard application with 40MW output power is conducted in the present study.In this designed cycle,the cycle performance in different pressure ratio is particularly simulated.From detailed analysis of the selection of thermodynamic parameters of the cycle,compressor inlet conditions are found to significantly affect the compressor performance as well as the whole cycle efficiency.The efficiency achieved by the designed S-CO2recompression cycle is 45.06 percent at 823.15K,which meets the design requirement and superior to the simple recuperation cycle by 8.28 percent.The recuperation process is found to have a dramatic influence on the cycle state.Besides,the shunt flow percentage could partly reflect the cycle performance.The high efficiency and more compact size make S-CO2recompression cycle be well suited for shipboard power conversion system.This work is useful for the design of power conversion system for ship propulsion and power application.

- 風(fēng)機(jī)技術(shù)的其它文章

- 基于數(shù)值計算和實驗測試方法的引風(fēng)機(jī)煙氣循環(huán)煙道設(shè)計方法探究*

- 大型工業(yè)表面凝汽器結(jié)構(gòu)的有限元分析

- A Numerical Investigation on Cooling Effectiveness for Advanced Fan-shaped Film Cooling

- 顆粒阻尼技術(shù)在離心風(fēng)機(jī)降噪中的應(yīng)用研究*

- Experimental and Numerical Studies of Aerodynamic and Aeroacoustics Characteristics of Cooling Fan in Traction Motor*

- Prediction of Noise Directivity of An Impinging Jet Using LES and Acoustic Analogy Method*