On the hydrodynamics of hydraulic machinery and flow control *

Hong-xun Chen (陳紅勛), Zheng Ma (馬崢), Wei Zhang (張偉), Bing Zhu (朱兵), Rui Zhang (張睿),Qun Wei (魏群), Zheng-chuan Zhang (張正川), Chao Liu (劉超), Jian-wu He (何建武)

1. Shanghai Institute of Applied Mathematics and Mechanics, Shanghai University, Shanghai 200072, China,

E-mail: chenhx@shu.edu.cn

2. Chinese Ship Scientific Research Center, Wuxi 214082, China

On the hydrodynamics of hydraulic machinery and flow control*

Hong-xun Chen (陳紅勛)1, Zheng Ma (馬崢)2, Wei Zhang (張偉)1, Bing Zhu (朱兵)1, Rui Zhang (張睿)1,Qun Wei (魏群)1, Zheng-chuan Zhang (張正川)1, Chao Liu (劉超)1, Jian-wu He (何建武)1

1. Shanghai Institute of Applied Mathematics and Mechanics, Shanghai University, Shanghai 200072, China,

E-mail: chenhx@shu.edu.cn

2. Chinese Ship Scientific Research Center, Wuxi 214082, China

Hydraulic machinery mainly includes turbine and pump, which is closely related to national economy and people's livelihood involving aerospace industry, marine engineering, hydropower engineering, petroleum industry, chemical industry, mining industry, biomedical engineering, environmental engineering, agricultural water-soil engineering, etc.. The internal flow of hydraulic machinery is extremely complex, and its characteristics can be summarized as high Reynolds number, multi-scales, inhomogeneous and vortex-dominant unsteady turbulence which interact with the rotating dynamic boundary (rotor blade). Based on the analysis of the internal flow characteristics of hydraulic machinery, the author and his research team successively proposed a rotation correction model,a curvature corrected filter-based model, a scalable detached eddy simulation method, and a non-linear hybrid RANS/LES turbulence model to capture unsteady flow structures and then predict hydraulic performance and dynamic characteristics more accurately.According to the analysis on the internal flow, the corresponding flow control measures were put forward. It was verified by experiments that these methods could significantly improve the hydraulic performance, anti-cavitation performance and dynamic characteristics (pressure pulsation and vibration) of hydraulic machinery in a certain range of operating conditions. In addition, the mechanism how flow control measures influence internal flow was analyzed in depth, aiming at finding a feasible and effective way to improve hydraulic performance, anti-cavitation performance and dynamic characteristics of hydraulic machinery.

Hydraulic machinery, unsteady flow, turbulence model, flow control method, dynamic characteristic

Introduction

Hydraulic machinery is a kind of mechanical equipment which takes water or other liquid as working mediums and energy conversion carrier to achieve the mutual transformation between liquid energy and mechanical energy. According to the way of working, it can be divided into positive displacement hydraulic machinery and blade type hydraulic machinery, of which the latter is a device to achieve energy conversion between the rotor with blades and the fluid medium flowing around blades. Blade type hydraulic machinery that mainly includes turbine,pump and hydraulic propulsion etc., has been applied widely in multiple fields which closely related to national economy and people's livelihood involving aerospace industry, marine engineering, hydropower engineering, petroleum industry, chemical industry,mining industry, biomedical engineering, environmental engineering, agricultural water-soil engineering , etc.. Though the blade type of hydraulic machinery need to be changed in different fields, the working principle and driving mode are actually the same.

Many scholars[1-9]have studied in depth the internal flow of hydraulic machinery by experimental and numerical simulation methods, indicating that the internal flow of hydraulic machinery is extremely complex, and its characteristics can be summarized as high Reynolds number, multi-scales, inhomogeneous and vortex-dominant unsteady turbulence which interact with rotating dynamic boundary (rotor blade).The solution of complicated internal flow in hydraulic machinery has to proceed from the comprehensive Navier-Stokes equation. As is known to all, DNS and LES have enough capacity to resolve these unsteady turbulence problems, but there still exist many difficulties for requiring huge computing resources.Therefore, it is crucial to explore more effectivenumerical simulation methods which reflect complex flow characteristics in hydraulic machinery and enhance prediction precision with the efficiency being taken into account.

1. Turbulence model

In order to take both efficiency and accuracy into account, effective turbulence models which include rotation correction with extend intrinsic mean spin tensor (EIMST), curvature corrected filter-based turbulence model (FBM-CC), scalable detached eddy simulation (SDES) and non-linear hybrid RANS/LES were developed to enhance the accuracy of capturing unsteady flow structures inside hydraulic machinery,and then effectively predict the hydraulic performance and dynamic characteristics.

1.1 Rotation correction with extend intrinsic mean spin tensor

Zhang et al.[10,11]proposed a method to modify the eddy viscosity coefficient of conventional turbulence model based on redefined Richardson number with extend intrinsic mean spin tensor (EIMST),which made turbulence models sensitive to the rotation.

In rotating coordinate system, the rotation effect affects the distribution of turbulent kinetic energy, and the turbulent kinetic energy spectrum in inertial sub area should be k-3(negative third power) instead of k-5/3(negative three-fifths power). The results showed that the modified turbulence model could successfully capture the stall phenomenon of the interphase channel of centrifugal pumps under offdesign conditions, and obtain more abundant turbulent structure.

1.2 Curvature corrected filter-based turbulence model

Consideringthemulti-scaleand unsteady characteristics inside axial-flow pumps, as well as the effect of streamline curvature which caused by the curvy surface of flow passage components and the rotation of impellers, Zhang[12]proposed a curvature corrected filter-based turbulence model(FBM-CC). It was tested and verified that FBM-CC model could not only capture more abundant scales of turbulent structures, but also improve the sensitivity to the effect of streamline curvature and accuracy of computation. For the curvature correction of FBM model, it was considered that the generated itemskG in the k and ε transport equations could be corrected by referring to the method proposed in literature[13].

1.3 Scalable detached eddy simulation method

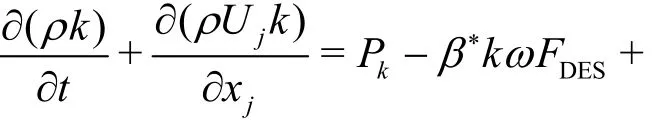

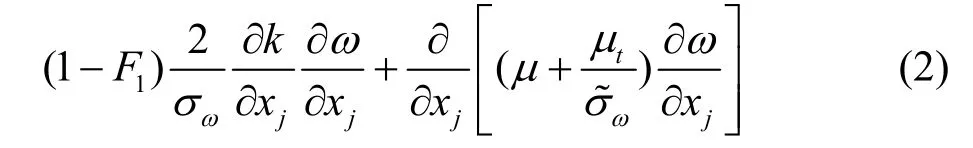

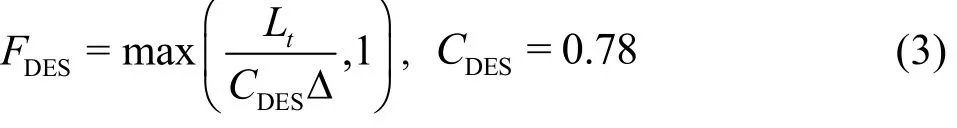

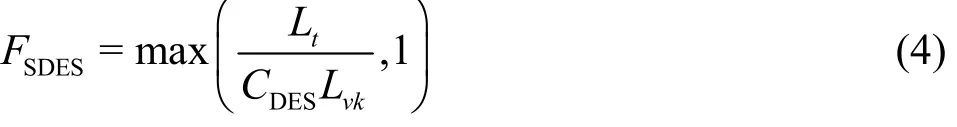

Zhu[14]modified the traditional DES method by introducing the von Karman scale based on local flow field. The newly developed scalable detached eddy simulation(SDES) method improved the shortage of direct dependence on grids for traditional DES method in identification simulation regions, which made RANS/LES method switched adaptively to solve the steady or unsteady area. The Strelets[15]two-equation DES model based on the SST turbulence model is

where the hybrid-functionDESF is given by

The von Karman length scale is redefined as Lvk= κ S/▽?duì)? so the hybrid-function is corrected as

The newly-defined criteria for identification of simulation region is directly determined by local flow field, rather than the density and distribution of grids divided by users, so that the physical significance is expressed more correctly and the actual physical characteristics of flow field is reflected more clearly.

1.4 Non-linear hybrid RANS/LES turbulence model

In order to effectively simulate unsteady flow structures and pressure pulsation inside vane centrifugal pumps, Wei et al.[16,17]have proposed a new non-linear hybrid RANS/LES method.

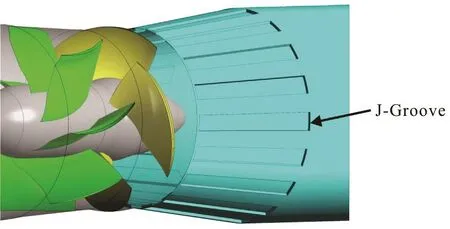

A non-linear eddy viscosity model has been developed based on data obtained from experiment[18,19]and DNS[20,21]to construct the coefficient of eddy viscosity, which well avoid imprecise predictions in the flows with a strong flow separation and adverse pressure gradients or streamline curvatures, and the expressions are as follows:

In addition, a hybrid strategy was proposed to allow the adoption of the RANS in the near-wall region and the LES in the outer unstable flow region by introducing von Karman length scalevkLas the critical parameter to determine the transition instead of the local grid size in this hybrid RANS/LES frame system. The eddy viscosity and the smoothing function are as follows:

2. The controlling of unsteady flow inside hydraulic machinery

On the basis of the analysis on internal flow,corresponding flow control measures were put forward by the authors. It was proved that these methodscould improve hydraulic performance,anti-cavitation performance and dynamic characteristics of hydraulic machinery in a certain range of operating conditions.

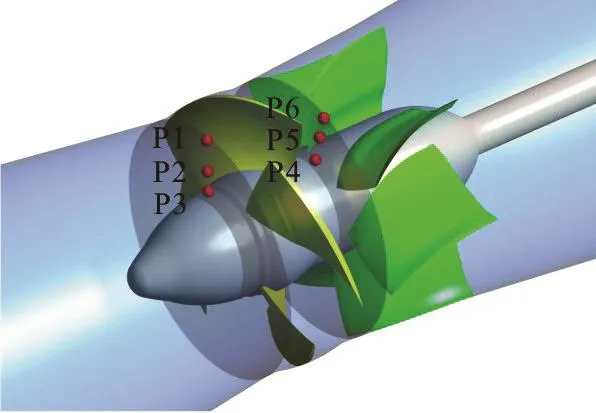

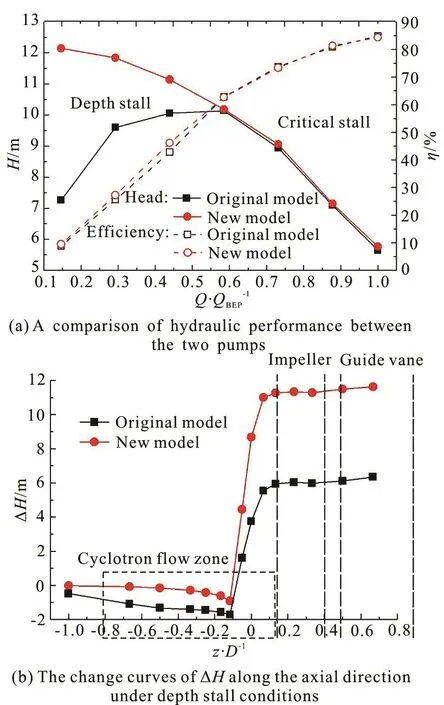

2.1Improvement on stall characteristics of a vane axial flow pump by applying the J-Groove flow control technology

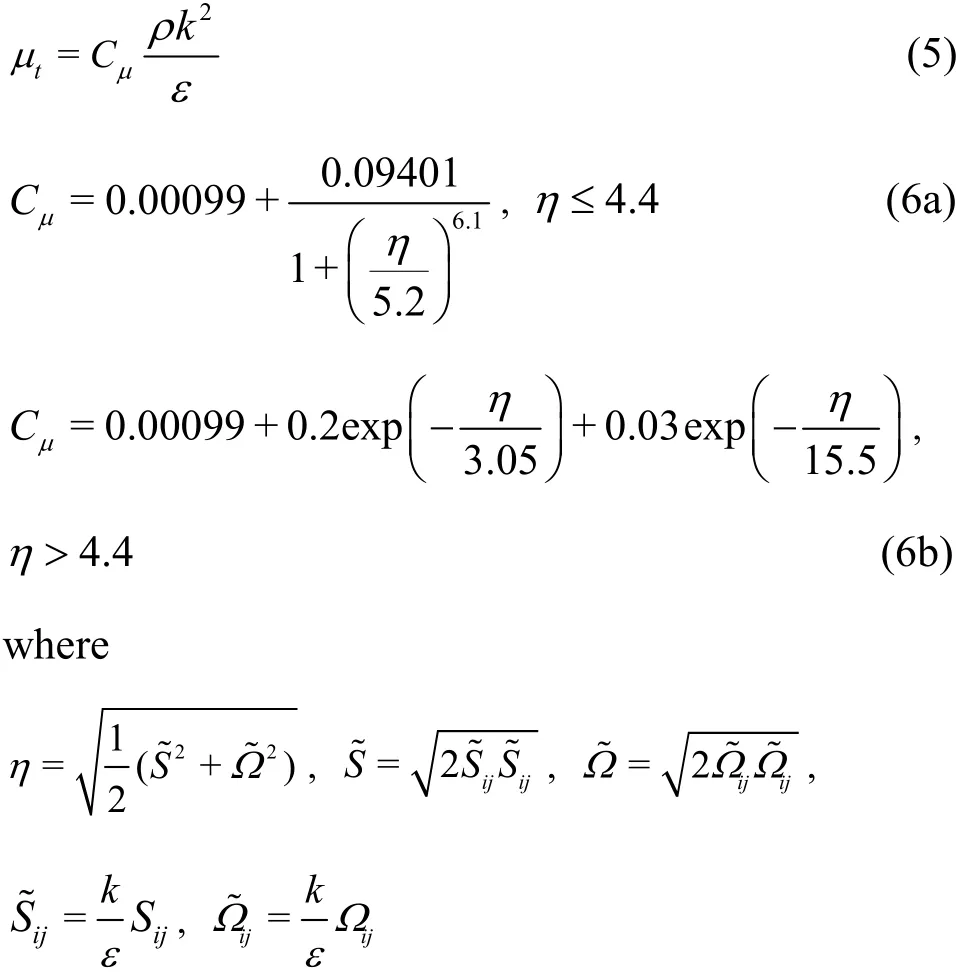

Under stall conditions, swirling flow appears at the inlet of the impeller, which is a main factor to promote the formation of “saddle zone”. When flow rate is lower, the swirling flow become stronger, and the performance and operation stability of the axial pump will be influenced more seriously. The feasibility was studied that the stall characteristics of a vane axial pump could be improved by setting a J-Groove in the inlet channel shown in Fig.1 and Fig.2,which was learned from Kurokawa's J-Groove flow control technology[22]that strip structures were distributed uniformly on the tube wall.

Fig.1 (Color online) Axial flow pump model with additional

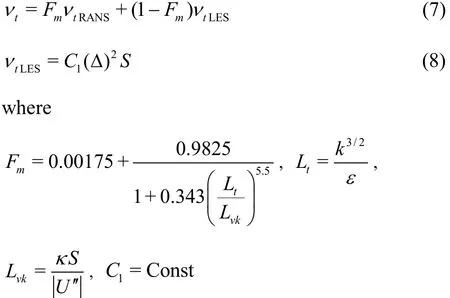

Fig.2 (Color online) Pressure monitoring points at the impeller

As shown in Fig.3, the intensity of swirling flow could be effectively weakened, which improved the uniformity of flow at the inlet of the impeller. This not only improved the work capacity of blades and restrained the formation of “saddle zone”, but also made low frequency pressure pulsation at the inlet of impeller reduced and the stability of axial flow pumps enhanced.

2.2Improvement on hydraulic performance of a vane axial pump by applying a guide impeller

Fig.3 (Color online) Impact of J-Groove on the performance of axial flow pumps[12]

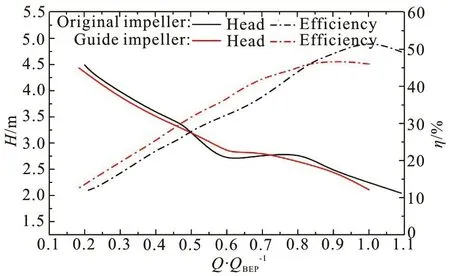

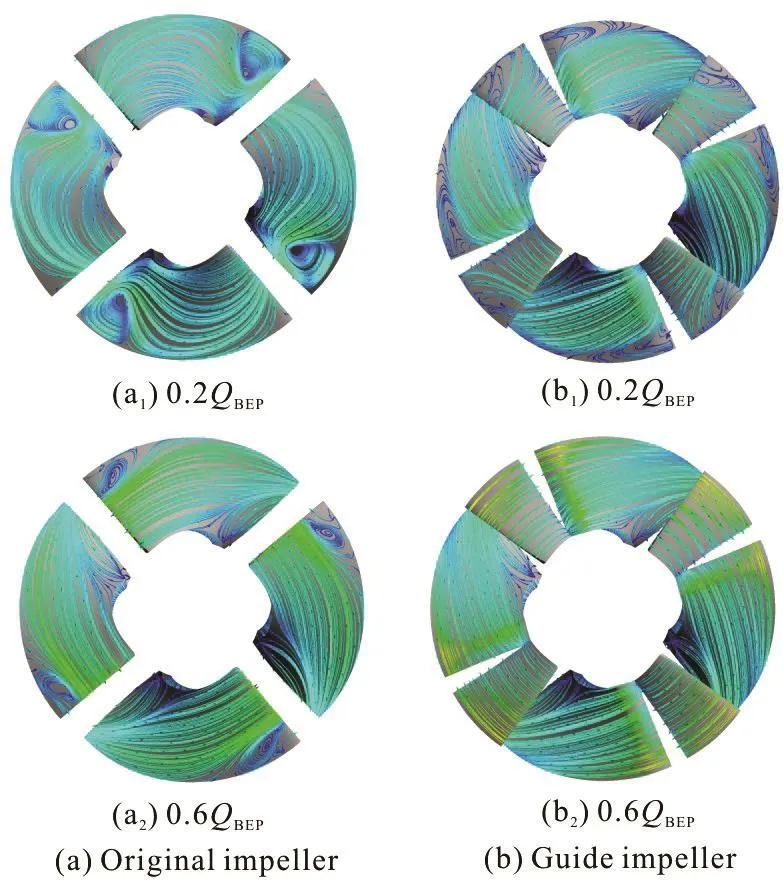

In order to control the flow separation around blade surfaces and improve the performance of axial flow pumps under low flow rate conditions, a new type of guide impeller based on the idea of the “flap” flow control technology was put forward. By comparing the internal flow field of original impeller with the one of guide impeller, it could be found that the flow separation around blade surfaces were inhibited under low flow rate conditions as a result of the front vice blades' function of guiding flow, and thus the performance of axial flow pumps was improved as shown in Fig.4 and Fig.5.

Fig.4 (Color online) Hydraulic performance of axial-flow pumps with different impellers[12]

Fig.5 (Color online) The distribution of relative velocity limi- ting streamline on suction surfaces of blade

Fig. 6 (Color online) A barrier strip at the suction side of a

Fig.7 (Color online) The change trend of vapor volume in axial flow pumps under different cavitation stages[12]

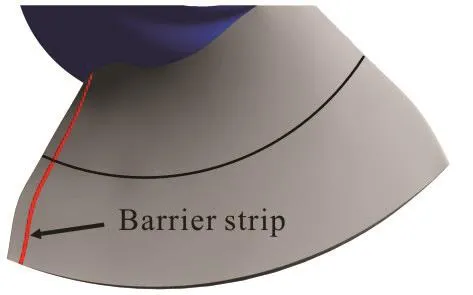

2.3Improvement on anti-cavitation performance of a vane axial flow pump by setting barriers

The blade cavitation of axial pumps, which belongs to a type of hydrofoil cavitation, is located at the rear edge of blades. On this account, a barrier strip was set along the radial direction of at 90%cLof suction side wherecLis the length of airfoil chord of middle section (blade inlet edge is defined as reference position), shown in Fig.6. As illustrated in Fig.7, the anti-cavitation performance of axial flow pump was improved to a certain extent as a result of setting barrier strips.

2.4Influence of gap drainage blades on internal flow of a vane centrifugal pump

2.4.1 Improvement on the hydraulic performance of centrifugal pumps by applying two-dimensional gap drainage blades

Fig.8 (Color online) Traditional impeller and gap impeller[14]

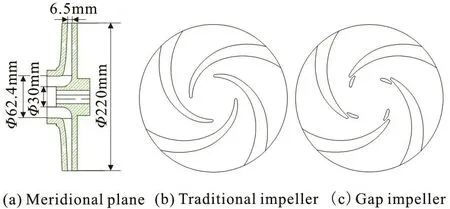

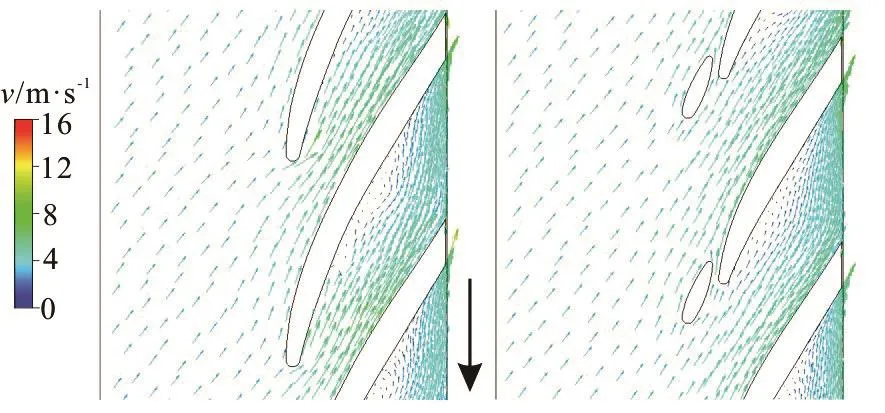

Fig.9 (Color online) Velocity surface[14] distribution on central stream

Gap drainage blade is a newly-designed blade structure based on flow control theory[23-25]. Compared with a traditional impeller, a gap impeller was added with a vice blade overlapped with main blade and hold a narrow gap at the suction side of the leading edge of main blade, shown in Fig.8. The essential reason that gap drainage blades improve the hydraulic performance of centrifugal pumps is its improving of the distribution of velocity fields in the flow channel, so that the velocity field become more smooth and uniform shown as Fig.9.Gap impeller was designed with the vice blade at the leading edge deviating from original position and overlapping partly with main blade. On one hand, this would increase flow area to avoid the blocking effect at the inlet zone. On the other hand, due to the guiding flow function of vice blade, some fluid on the pressure surface would pass through the gap into the suction surface which makes the velocity field distribution more uniform in the flow channel.

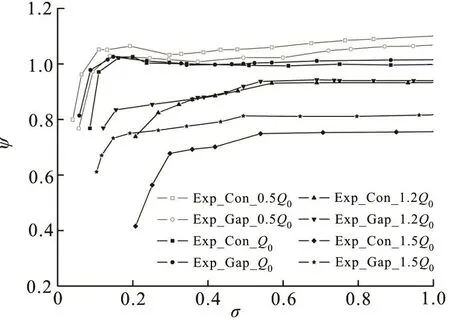

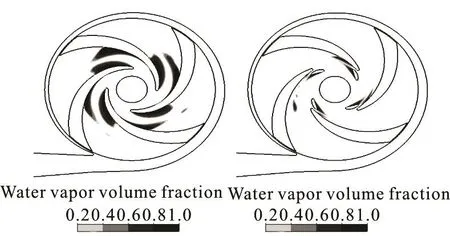

2.4.2 Improvement on the anti-cavitation performance mensional gap drainage blades

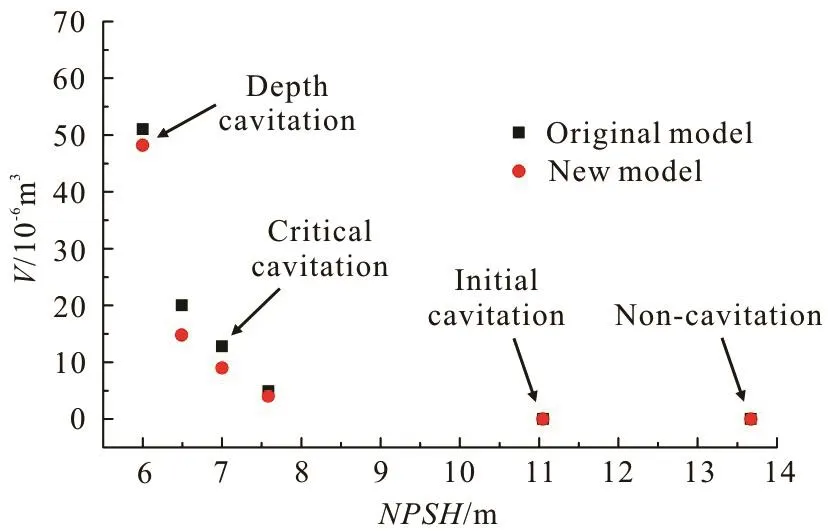

The anti-cavitation performance of centrifugal pumps could be improved by applying the gap drainage blades. Under the characteristic flow rate and large flow rate conditions, the centrifugal pump with gap impeller had better anti-cavitation characteristics than the one with traditional impeller, illustrated in Fig.10 and Fig.11. On one hand, the vice blade at the leading edge of gap drainage impeller played a role in guiding flow and changed the attack angle of main blades, so that the flow separation at the leading edge of main blades would be inhibited, especially near the pressure under the large flow rate condition. On the other hand, high pressure fluid on the pressure surface would be guided through the gap into the suction surface, which compensated pressure to low pressure zones to some extent. At the same time, the fluid ejected from the gap would isolate the cavitation zone between main blades and vice blades, and have a disturbance to the cavitation regions that have been formed, which accelerated the cavity shedding and suppressed the formation of the large cavitation area to improve the cavitation performance. Obviously, the single blades of the traditional impeller cut off the ties between the fluids on the pressure surfaces and suction surfaces, so that the anti-cavitation mechanism above could be achieved. of vane centrifugal pumps by applying two-di-

Fig.10 Comparison of the anti-cavitation between the two impellers[14]

Fig.11 Vapor volume fraction distribution on the central plane[14]

Fig.12 The layout of monitoring points of pressure pulsation

Fig.13 The change curves of amplitude of pressure pulsation at different monitoring points along the circumferential di- rection of blades

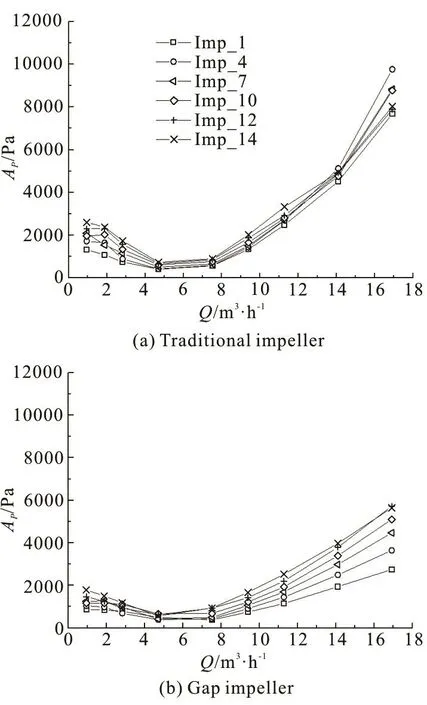

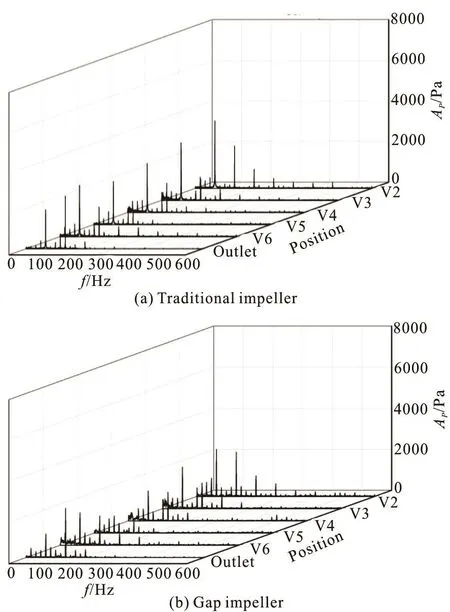

2.4.3 Improvement on dynamic characteristics of a vane centrifugal pump by applying two-dimen- sional gap drainage blades

The author also carried out the researches about the pressure pulsation characteristics and related mechanism of centrifugal pumps with gap drainage blades. The gap drainage blades with the function of guiding flow improved the problem about the asymmetrical rate of inflow in different flow channels under characteristic to large flow rate conditions, which was leaded by non-uniform circumferential pressure in volute, and made the distribution of the flow and the relative velocity of the trailing edge of each pressure surface more uniform, so that the fundamental frequency pressure pulsation in the volute was radically improved. In addition, the unsteady flow problem caused by the excess flow rate of the individual flow channel was also weakened, and the amplitude of the fundamental frequency pressure pulsation was further reduced. Figures 12-14 respectively show the layout of monitoring points of pressure pulsation, amplitude of pressure pulsation at different positions, and the spectrum of pressure pulsation.

Fig.14 Comparison of pressure pulsation spectrums in the volu- tes of two pumps

Fig.15 (Color online) The three-dimensional model of two im- pellers

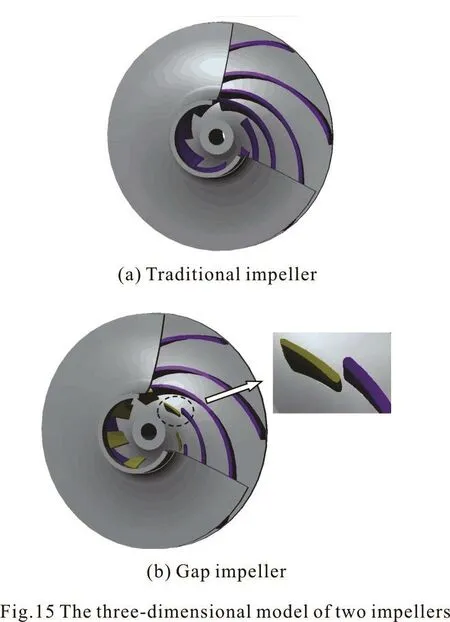

2.4.4 Study on improving the performance of a vane centrifugal pump by applying three-dimensional gap drainage blades

Based on the above researches, it was verified that the two-dimensional gap drainage blade structure could effectively improve the hydraulic performance and anti-cavitation performance of vane centrifugal pumps, and enhance the hydraulic dynamic characteristics to a certain extent. In order to introduce this technology into practical application, a new threedimensional gap drainage impeller was designed as shown in Fig.15.

The experimental results showed that the new three-dimensional gap drainage impeller significantly improved the hydraulic performance, anti-cavitation performance and dynamic characteristics of the vane centrifugal pumps, which laid a solid foundation for introducing the gap drainage technology to the practical application.

3. Conclusion

(1) Based on the study of turbulence models,which is suitable for the internal flow characteristics of hydraulic machinery, the author effectively achieved the simulation of the internal flow and performance prediction of hydraulic machinery. This provides the basis for improving the performance of hydraulic machinery by applying flow control measures, and confirms that these methods are effective by a series of measures such as experiments, calculation and analysis.

(2) In the aspect of controlling flow, the relationship between geometry and performance, anti- cavitation and pressure pulsation will be further studied and more effective flow control methods will be proposed to improve the performance of hydraulic machinery.

(3) The relationship between pressure pulsation and vibration would be studied and the mechanism how internal flow induce the structure vibration,which provides the theoretical basis for restraining harmful vibration during the operation process of hydraulic machinery.

[1] Paone N., Riethmuller M. L., Braembussche R. A. V. D.Experimental investigation of the flow in the vaneless diffuser of a centrifugal pump by particle image displacement velocimetry [J]. Experiments in Fluids, 1989, 7(6):371-378.

[2] Abramian M., Howard J. H. G. Experimental investigation of the steady and unsteady relative flow in a model centrifugal impeller passage [J]. Journal of Imaging Science and Technology, 1994, 116(2): 269-279.

[3] Hasmatuchi V., Farhat M., Roth S. et al. Experimental evidence of rotating stall in a pump-turbine at off-design conditions in generating mode [J]. Journal of Fluids Engineering, 2011, 133(5): 051104.

[4] Medvitz R. B., Kunz R. F., Boger D. A. et al. Performance analysis of cavitating flow in centrifugal pumps using multiphase CFD [J]. Journal of Fluids Engineering,2002, 124(2): 377-383.

[5] Huang B., Wang G. Y. Partially averaged Navier-Stokes method for time-dependent turbulent cavitating flows [J].Journal of Hydrodynamics, 2011, 23(1): 26-33.

[6] Byskov R. K., Jacobsen C. B., Pedersen N. Flow in a centrifugal pump impeller at design and off-design conditions-Part II: Large eddy simulations [J]. Journal of Fluids Engineering, 2003, 125(1): 73-83.

[7] Luo X., Zhang Y., Peng J. et al. Impeller inlet geometry effect on performance improvement for centrifugal pumps[J]. Journal of Mechanical Science and Technology, 2008,22(10): 1971-1976.

[8] Shi Y., Xiao Z., Chen S. Constrained subgrid-scale stress model for large eddy simulation [J]. Physics of Fluids,2008, 20(1): 011701.

[9] Zhang R., Mao F., Wu J. Z. et al. Characteristics and control of the draft-tube flow in part-load Francis turbine[J]. Journal of Fluids Engineering, 2009, 131(2): 021101.

[10] Zhang W., Ma Z., Yu Y. C. et al. Validation and verification study of RANS simulation in centrifugal pump impeller: Design and off-design condition [J]. Chinese Journal of Hydrodynamics,2011, 28(1):73-74(in Chinese).

[11] Zhang W. Analysis and prediction of the internal flow in the vane pump impeller at off-design condition [D].Doctoral Thesis, Shanghai, China: Shanghai University,2010(in Chinese).

[12] Zhang R. Research on the stall and cavitation flow characteristics and the performance improvement of axial-flow pump [D]. Doctoral Thesis, Shanghai, China: Shanghai University, 2014(in Chinese).

[13] Smirnov P. E., Menter F. R. Sensitization of the SST turbulence model to rotation and curvature by applying the Spalart-Shur correction term [J]. Journal of Turbomachinery, 2009, 131(4): 1-8.

[14] Zhu B. Research on the mechanism of performance improving in low specific speed centrifugal pump with gap drainage blades [D]. Doctoral Thesis, Shanghai, China:Shanghai University, 2014(in Chinese).

[15] Strelets M. Detached eddy simulation of massively separated flows [R]. AIAA paper 2001-0879, 2001.

[16] Wei Q. Chen H. X., Ma Z. A hybrid RANS/LES model for simulation of complex turbulent flow [J]. Journal of Hydrodynamics, 2016, 28(5): 811-820.

[17] Wei Q. Chen H. X., Ma Z. Numerical simulation of flow around airfoil with non-linear RANS model [C].ASME/JSME/KSME 2015 Joint Fluids Engineering Conference. Seoul, Korea, 2015.

[18] Champagne F. H., Harris V. G., Corrsin S. Experiments on nearly homogeneous turbulent shear flow [J]. Journal of Fluid Mechanics, 1970, 41(1): 81-139.

[19] Tavoularis S., Corrsin S. Experiments in nearly homogeneous turbulent shear flow with a uniform mean temperature gradient. Part 1 [J]. Journal of Fluid Mechanics, 1981, 178: 459-475.

[20] Lee M. J., Kim J., Moin P. Structure of turbulence at high shear rate [J]. Journal of Fluid Mechanics, 2006, 216(4):561-583.

[21] Rogers M. M., Moin P. The structure of the vorticity field in homogeneous turbulent shear flow [J]. Journal of Fluid Mechanics, 1987, 176: 33-66.

[22] Kurokawa J., Imamura H., Choi Y. D. et al. Effect of J-Groove on the suppression of swirl flow in a conical diffuser [J]. Journal of Fluids Engineering, 2010, 132(7):1773-1780.

[23] Chen H. X., Liu W. W., Jian W. et al. Development of low specific-speed centrifugal pump impellers based on flow control technique [J]. Journal of Drainage and Irrigation Machinery Engineering, 2011, 29(6): 466-470(in Chinese).

[24] Chen H. X., Huo C. C., Liu W. M. Study on control of multi-element airfoil based on CFD [J]. Journal of Drainage and Irrigation Machinery Engineering, 2012,30(5): 513-516, 557(in Chinese).

[25] Chen H. X., Lin Y. Z., Zhu B. Experimental study cavitation performance of centrifugal pump with impeller having leading edge slots [J]. Journal of Drainage and IrrigationMachinery Engineering, 2013, 31(7):570-574(in Chinese).

August 1, 2017, Revised August 5, 2017)

* Project supported by the National Natural Science Foundation of China (Grant Nos. 51379120, 51179100 ).

Biography: Hong-xun Chen (1962- ), Male, Ph. D., Professor

水動(dòng)力學(xué)研究與進(jìn)展 B輯2017年5期

水動(dòng)力學(xué)研究與進(jìn)展 B輯2017年5期

- 水動(dòng)力學(xué)研究與進(jìn)展 B輯的其它文章

- On the clean numerical simulation (CNS) of chaotic dynamic systems *

- Flowstructure and phosphorus adsorption in bed sediment at a 90° channel conflunce

- Determination of urban runoff coefficient using time series inverse modeling *

- An ISPH model for flow-like landslides and interaction with structures *

- Capillary-gravity ship wave patterns *

- Stationary phase and practical numerical evaluation of ship waves in shallow water *