The Tensile Properties and Creep Performance of a Long-term Thermally Aged Plastic Bonded Explosive

ZHOU Hong-ping, HE Qiang, LI Ming, PANG Hai-yan, WEI Xing-wen, WEN Mao-ping

(Institute of Chemical Materials, China Academy of Engineering Physics, Mianyang 621999, China)

1 Introduction

The physical and chemical changes of polymer bonded explosives(PBXs) with aging under diverse storage environments have been extensively studied, for instance, the effects of thermal aging at elevated temperatures on well known composition of PBX-9501 have been studied and the changes resulted from this type of treatment have been found[1-2]. It shows that the major aging mechanism, i.e., the hydrolysis of the binder, for instance Estane, may occur and the molecular weight may decrease and, thus degrade the tensile or compression mechanical properties of PBX 9501[3]. Similar studies have been done for LX-14 and many other compositions[4-6]. Most of the surveillance methods for aging evaluation were to inspect the conventional mechanical properties, which involve measurements of compression/tensile strength and elastic modulus[7-8]. According to the previous studies, it seems that there is no evidence of catastrophic structural integrity loss for all known PBXs which have been exposed to various aging environments[9]. But, as well known, the measurement of conventional mechanical properties, for instance, the tensile strength testing just takes less minutes and thus has its weakness to manifest the time-dependent effects of the PBXs. Lots of PBX compositions, such as EDC37, LX-17 and PBX 9501, show strongly time-dependent behaviors resulted from the polymer binders inside the compositions[11-13].

Although the time-depend behaviors of creep of PBXs have been investigated extensively[12-13], very few studies on the creep performance for those PBXs having been long-term aged up to years are available. Most of the published studies attributed the time-dependent behaviors of PBXs to the binders, and forgot that the physical interfaces between the binder and the energetic crystals may play a key role on the creep behavior, especially on the sustainable creep time until to failure. In fact, in a long-term aging environment, especially when the temperature of storage is above the glassy transition temperature of the binder, the interfaces may change slowly and the residual stains induced by the mould pressing may release. The slowing changes in interfaces can not be easily inspected through conventional mechanical strength testing. The principal motivation of this study is to find and evaluate measurable changes of a pressed PBX after 6 month and 3 year storage under different temperature environments through mechanical tensile testing and creep testing.

2 Experimental

2.1 PBX Composition and Specimen Preparation

PBX-901 employed in this study, is a PBX pressed from molding powder, which comprises about 95% crystalline cyclotetramethylen tetranitramine (HMX) and a small portion binder of 5% fluoro-rubber binder by mass. The pressed PBX-901 stocks were machined to standard cylindrical dumbbell specimens (Fig.1) which meet the requirements of the Chinese military standard for tensile strength and tensile creep testing. All the specimens had been inspected by Non-destructive methods to ensure those with pre-exiting defects were eliminated before thermally storage and mechanical testing started.

Fig.1 Size of the specimen

2.2 Thermal Aging Treatment

The dumbbell specimens were stored in different environmental ovens at the temperature of 25, 45, 55, 65 ℃ and 75 ℃, respectively. Each oven was equipped with safety thermostats, the temperature variation was maintained within ±1 ℃ and monitored by a remote-controlled recording device. Some of the specimens were stored for 6 months and some up to 36 months. After treatment, the aged specimens were removed from the environmental chambers for tensile testing and tensile creep testing.

2.3 Tensile Testing

The clamp-method tensile testing was carried out by an Instron 5582 universe test machine equipped with an environmental temperature chamber as well as a high precise dual- extensometer. The constant crosshead speed is 0.05 mm·min-1that gives a nominal strain rate of 0.0033 s-1,and the testing temperature was at 45 ℃ which has been proved as a transition temperature in term of mechanical property for this type of PBX[14]. The stress-strain curve was obtained and Young′s modulus of each specimen can be calculated. It should be noted that each tensile strength or elastic modulus was an average output of five replicate tensile specimens per condition. The tensile strength for pristine and aged specimen at 25 ℃, i.e. the ambient temperature, were also measured in order to determinate the creep testing stress level, which will be detailed later.

2.4 Tensile Creep Testing

The tensile creep experiments were conducted by using Instron 8862 creep testing machine equipped with a temperature-controlled chamber[15]. The creep strains were recorded by a dual extensometer. All creep testing temperatures were at 45 ℃, same as the tensile testing. The tensile creep stress of the specimens aged for 3 years was kept constant of 2.88 MPa, which was about 60 percent of the tensile strength of 4.8 MPa at 45 ℃ or 52 percent of the tensile strength of 6.90 MPa at 25 ℃. For those stored for 6 months, the tensile creep stress level was kept constant of 3.58 MPa, which was about 75 percent of the tensile strength at 45 ℃. Setting such higher creep stress was to accelerate the time to rupture(TTR). In this work, the TTR can be an indictor to evaluate the aging effect on the creep performance of PBXs. To start the creep testing, the specimen was firstly loaded to the pre-determinate creep stress with the crosshead speed of 0.05 mm·min-1and then the stress was kept constant by load-hold method of the testing machine. The tensile creep strains were recorded automatically. For those specimens stored at room temperature, the creep rupture occurred very early and the creep testing will stop automatically after rupture, otherwise the testing will stop intentionally after the creep maintains for 8 hours since the beginning.

3 Results and Discussion

3.1 Tensile Mechanical Properties after Aging

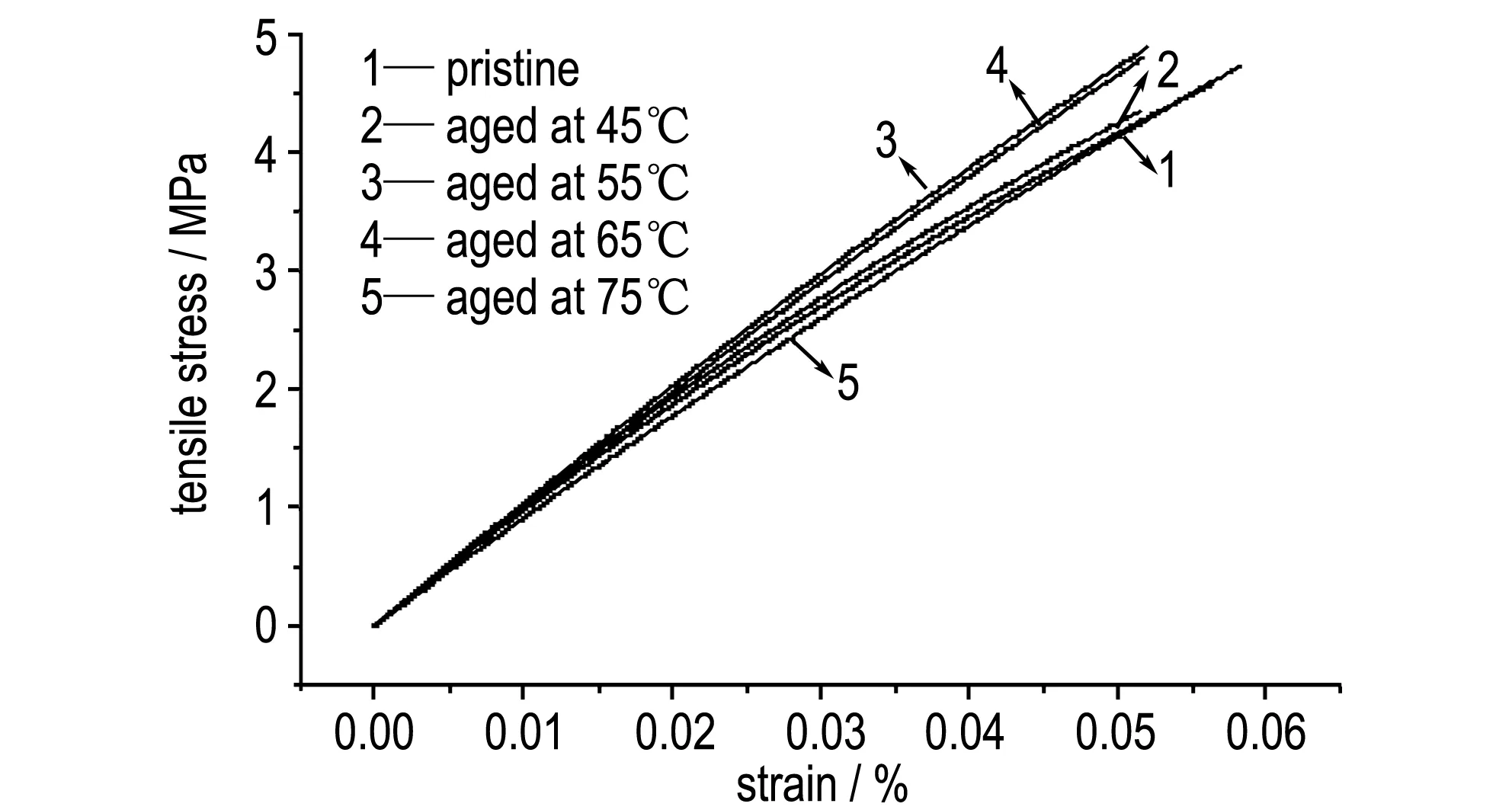

The tensile stress-strain curves at 45 ℃ for the specimens stored for 3 years under the temperature of 45, 55, 65 ℃ and 75 ℃, respectively, are given in figure 2, where the curve of the pristine specimen is presenting together. The tensile strength and Young′s modulus as well as the standard deviation are listed in table 1. From the figure 2 and table 1, it shows that the tensile strength and Young′s modulus at 45 ℃ are almost unchangeable even after 3 year thermally storage at difference temperature regarding the test uncertainty, except for slightly increasing for those stored at 55 ℃ or 65 ℃. The tensile strength (4.64 MPa) and Young′s modulus (9.17 GPa) of those stored at 75 ℃ for 3 years were slightly degraded and it suggests that above the temperature of 45 ℃ the thermal aging takes effect on the mechanical properties.

Fig.2 Tensile stress-stain curves at 45 ℃ of 3 year stored specimens under difference temperature (the pristine specimens included)

Table 1 Tensile strength and modulus at 45 ℃

agingtemperature/℃tensilestrength/MPatensilemodulus/GPapristine4.73±0.279.92±0.4545(3year)4.74±0.1410.27±0.3055(3year)5.03±0.2210.45±0.3265(3year)5.20±0.2110.05±0.2775(3year)4.64±0.139.17±0.29

3.2 Tensile Creep Behaviors

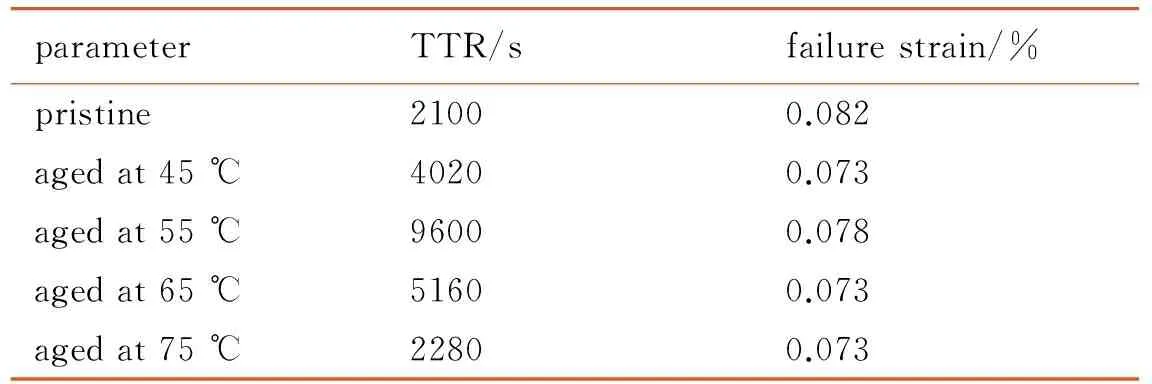

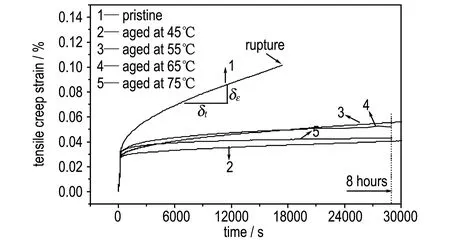

The tensile creep curves of those specimens stored for 3 years were plotted together with pristine specimen in figure 3. It is found that the pristine specimen ruptured after 17326 s, much less time than those thermally treated specimens, which kept intact for 28800 s, i.e. 8 h. Similar results were obtained for those 6 month thermally treated specimens. Table 2 gives the creep testing results of those 6 month thermally aged specimen at a constant tensile stress of 3.58 MPa. Because the creep stress level for 6 month aged specimens was higher than 3 year stored specimens, the TTR was shortened accordingly. The pristine specimen has the shortest TTR of 2100 s, compared to all 6 month thermally treated specimens, in which those stored at 55 ℃ bear the longest TTR of 9600 s. But, for those at 75 ℃ for 6 months, the TTR was dramatically shortened to 2280 seconds and this shortened TTR result was similar with the slightly degraded tensile strength and Young′s modulus for those 3 year stored specimens as described previously. Although we do not present the tensile results for 6 month stored specimens, we can safely say that the temperature of 75 ℃ is not a safe condition for PBX-901 and the specimens will be assuredly thermally damaged at 75 ℃. It suggests that for PBX-901 a suitable long-term thermally storage environment will improve the creep performance and the storage temperature should be below 75 ℃.

Table 2 Creep parameters of 6-month aged and pristine under 3.58 MPa and 45 ℃

parameterTTR/sfailurestrain/%pristine21000.082agedat45℃40200.073agedat55℃96000.078agedat65℃51600.073agedat75℃22800.073

Fig.3 Tensile creep curves of pristine (marked “1” in the plot) and 3 year stored specimens (2, 3, 4, and 5) at different temperature, all tests were performed under 2.88 MPa and 45 ℃

3.3 Morphology of Cross Section of Ruptured Specimen

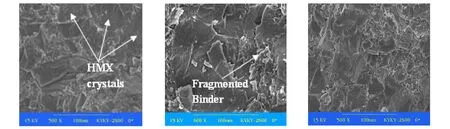

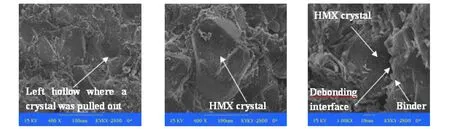

To understand the failure mechanism of tensile testing as well as creep testing, the SEM observations of the broken faces were carried on. Figure 4 gives the morphology photos of a broken pristine and two 3 year aged specimens, which were tensile failures at 45 ℃ as described previously in chapter 3.1. From figure 4, it shows that the tensile broken sections of pristine resemble the aged specimens with much smoother faces, which are big different from the creep failure (figure 5) sections. In tensile testing, the HMX crystals inside the specimen have been transgranular sectioned and the smooth morphology was left as shown in figure 4a. This transgranular failure model is contradiction to de-bonding model that is accepted as a very common failure model for PBXs. The tensile creep failure of the specimens still comply with the de-bonding model as shown in figure 5, which presents the morphology of creep rupture of 6-month-aged specimens. As figure 5 shows, there was a hollow left in position 1 (figure 5a) and a HMX single crystal (figure 5b) was left in position 2 for the pristine specimen which was creeping ruptured, and a clear de-bonding interface in position 3 can be found in the failure face (figure 5c).

As the morphology of the tensile broken sections nearly keep same whether in pristine or aged specimens (figure 4), it suggests the conventional tensile testing can not reveal the aging effects in terms of degradation of mechanical properties, whereas short-term creep testing within several hours in this work can disclose the slowing change during thermally storage, and the interface de-bonding between the crystals and binder can be clearly demonstrated.

3.4 Analysis of Contact Angle

The SEM observations demonstrate that the failure model of PBX-901 in tensile testing is different from the creep testing and we attribute this difference to the evolution of the interface status between HMX crystals and fluoro-rubber binder during aging treatments. However, few investigations are availably so far on the time-dependent interfacial property when PBX creeps. The contact angle measurement is considered as an effective method to evaluate the interface statue. Further the contact angle measurements were carried on this work.

a. pristine b. aged at 45 ℃ for 3 years c. aged at 75 ℃ for 3 years

Fig.4 Morphology of tensile failure specimens at 45 ℃

a.position 1 b.position 2 c. position 3

Fig.5 Morphology of tensile creep rupture specimens at 45 ℃

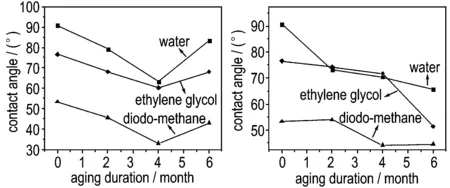

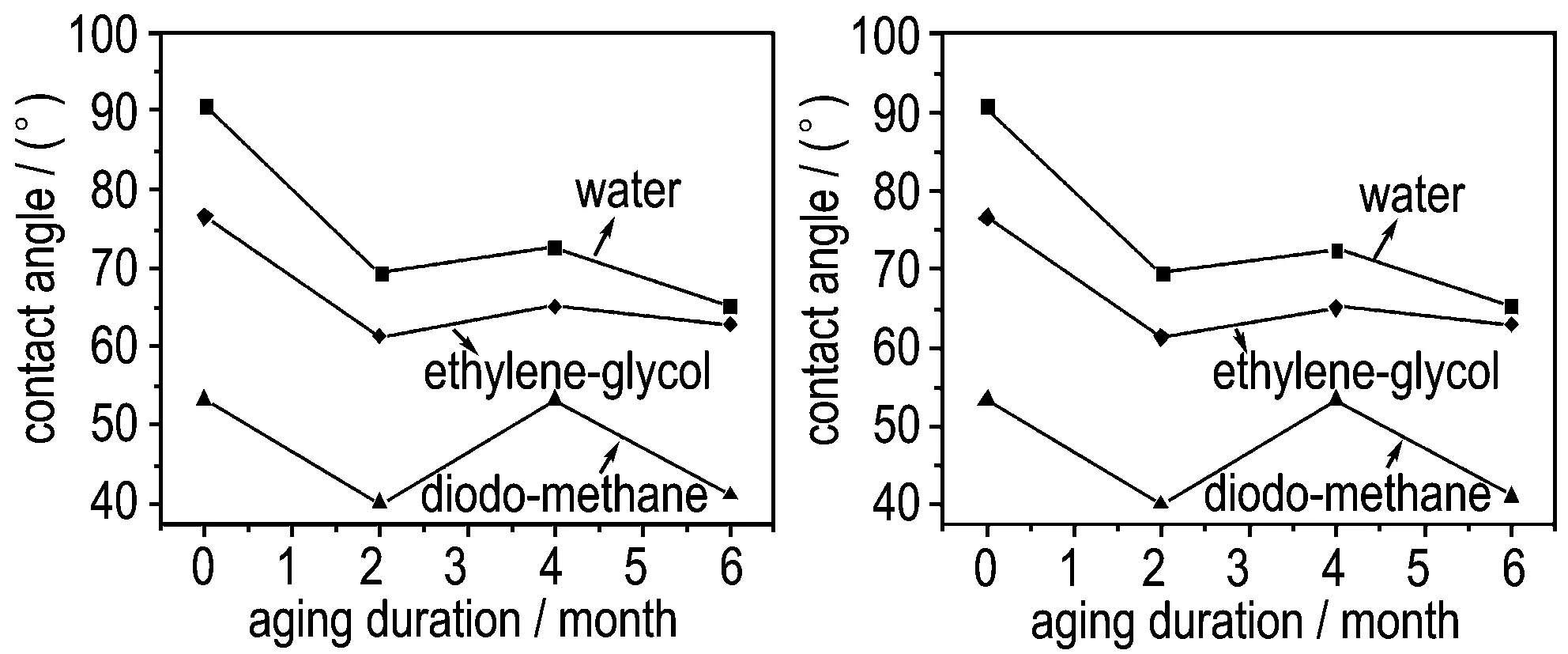

a. binder aged at 45 ℃ b. binder aged at 55 ℃

c. binder aged at 65 ℃ d. binder aged at 75 ℃

Fig.6 Contact angles of binder with different reference liquids

Small pellets for the Wihelmy plate method were fabricated from fluoro-rubber binder used in PBX-901 and were respectively stored at temperature of 45, 55, 65 ℃ and 75 ℃ for 2 months, 4 months and 6 months. A series of reference liquids including water, ethylene glycol and diodo-methane were employed to measure the static contact angle using contact angle analyzer(JY-82) and the results are plotted in figure 6.

It can be found that at each aging temperature the contact angle decreases as time passed at early aging stage, but this trend did not keep monotonic decreasing except for the case of 55 ℃, contrarily, the contact angle goes up after a certain aging period. For the binder aged at 45 ℃ or 55 ℃ the turning time is in 4 months or less, and 2 months is for those aged at 65 ℃ and 75 ℃. It helps to understand that the wetting resulted from the long-term dependent thermo rheological mechanism of the binder takes effects, and the slower interaction between binder and crystals can release the residual strains resulted from pressing process. After turning time, for instance, the binder aged at 75 ℃, the contact angle goes up rapidly, it suggests that the thermally damage inside the interface dominates and in turn to shorten the TTR during creeping.

Interesting result comes from the binder aged at 55 ℃ when the contact angle keeps monotonic decreasing. If referring to the creep testing, the specimen treated at 55 ℃ bears the longest TTR compared to the rest specimens. These two results are consistent very well with each other and it implies that for this kind of PBX the best stored temperature should be at 55 ℃.

Base on the results and analysis, we propose that there are two competing mechanisms during thermally aging process: one, for store environment at lower temperatures, is the wetting induced by thermally rheological evolution which makes better interface, where the initial micro-defects such as the microvoids and micro delaminating induced probably from pressing can be healed and the residual strains are released slowly. The other, with the temperature increasing, is the thermal damage which poses a severe de-bonding stress in the interface that may come from the mismatch between the HMX crystal and the binder. But, the long time-dependent aging evolution can not be revealed distinctly by tensile testing, so we recommend using short-term creep testing within several hours to evaluate the long-term aging effects for plastic bonding explosives, especially for those pressing made PBXs.

4 Conclusions

It demonstrates that the short-term creep testing within several hours is a very useful method to evaluate the thermally effects on the mechanical properties and mechanical performance of long-term aged PBX. The TTR during creep testing can be a characteristic indicator to quantify the effects compared to the conventionally employed tensile strength testing.

The thermally treated specimenemployed in the work shows much resistance to the creep failure in terms of much longer TTR compared to the pristine specimen and it suggests that for the types of pressed PBXs, much longer storage duration under a suitable storing temperature benefits eliminating the residual strains caused by pressing.

Acknowledgement:The authors would like to thank the Environment Testing Group at ICM for the valuable long term aging experiments.

[1] Burgess C E, Woodyard J D, Rainwater K A, et al. Literature Review of the Lifetime of DOE Materials: Aging of Plastic Bonded Explosives and the Explosives and Polymers Contained Therein[R], ANRCP-1998-12, Amarillo National Resource Center for Plutonium, 1998.

[2] Skimore C B, Idar D J, Buntain G A, et al. Aging and PBX9502[R], LA-UR-98-1206, LANL, 1998.

[3] Salazar M R, Kress J D, Lightfoot J M, et al. Experimental study of the oxidative degradation of PBX 9501 and its components[J].Propellants,Explosives,Pyrotechnics, 2008, 33(3): 182-201.

[4] Deanne J. Idar Sheldon A. Larson, Cary B. Skidmore, Joanne R. Wendelberger, PBX 9502 Tensile Analysis[R], LA-UR-004948 LANL, 2000.

[5] Ellis K, Leppard C, Radesk H. Mechanical properties and damage evaluation of a UK PBX[J].Mater.Sci. ,2005, 40 6241-8.

[6] Rae P J, Palmer S J P, Goldrein H T, et al. Quasi-static studies of the deformation and failure of PBX 9501[J].Proc.R.Soc.Lond.A, 2002, 458, 2227-42.

[7] Idar D J, Thompson D G, Gray III G T, et al. Influence on polymer molecular weight, temperature, and strain rate on the mechanical properties of PBX 9501[R], Shock Compression of Condensed Matter—2001 ed M D Furnish et al (Melville, NY: American Institute of Physics) 2002: 281-4.

[8] Cady C M, Blumenthal W R, G.T. Gray G T III, Idar D Mechanical properties of plastic-bonded explosive binder materials as a function of strain-rate and temperature[C]∥Polymer Engineering and Science, 2006, 46(6): 812-819.

[9] Lundberg A W. High explosives in stockpile surveillance indicate constancy[J].Science&TechnologyReview,December, 1996: 13-17.

[10] Mang J T, Skidmore C B, Son S F, et al. An optical microcopy and small angle scattering study of porosity in thermally treated PBX9501[C]∥Shock Compression of Condensed Matter-2001, M. D. Furnish, N. N. Thadhani and Y. Horie, eds., AIP Press Conference Proc. 620, New York, 833-836.

[11] Saw, Cheng K., Tarver, Craig M. ,Binder/HMX interaction in PBX9501 at Elevated Temperatures (UCRL-CONF-200156),13th Annual APS Topical Conference Portland, OR. 2003.

[12] Williamson D M, Siviour C R, Proud W G, et al. Temperature-time response of a polymer bonded explosive in compression[J]. (EDC37),J.Phys.D:Appl.Phys, 2008, 41: 085404.

[13] Gagliardi F J, Cunningham B J. Creep Testing Plastic Bonded Explosives in uniaxial Compression[C]∥10th International Conference on Experimental and Applied Mechanics, Orlando, Florida, 2008, June 2-5.

[14] ZHOU Hong-ping, HE Qiang , LI Ming, et al. Experimental study on aging of pbx under low tensile stress[J].ChineseJournalofExplosives&Propellants, 2009, 32(5): 8-10.

[15] LI Ming, WEN Mao-ping, HE Qiang, et al. The Compressive creep behaviour of PBX based on TATB[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2005,13(3): 150-154.

- 含能材料的其它文章

- Coatings of Activated Metal Hydride and Application in the Fuel-rich Propellant

- A Density Functional Theory Study on the Structures and Thermochemical Properties of Azo-bridged Azoles

- Constitutive Behavior of RDX-based PBX with Loading-history and Loading-rate Effects

- Synthesis and Characterization of a Novel Energetic Inner-salt 5,5′-Bis(3-diazo-1,2,4-triazole)

- 3,4-Bis(3-fluorodinitromethylfurazan-4-oxy)furazan: A New Thermally Stable Plasticizer with High Energy Density

- The Initiation Parameter of Detonation Wave Aiming Warhead