Prediction of Coke Yield of FCC Unit Using Different Arti fi cial Neural Network Models

(State Key Laboratory of Heavy Oil Processing, China University of Petroleum, Beijing 102249)

Prediction of Coke Yield of FCC Unit Using Different Arti fi cial Neural Network Models

Su Xin; Wu Yingya; Pei Huajian; Gao Jinsen; Lan Xingying

(State Key Laboratory of Heavy Oil Processing, China University of Petroleum, Beijing 102249)

In fluid catalytic cracking (FCC) unit, it is greatly important to control the coke yield, since the increase of coke yield not only leads to the reduction of total liquid yield, but also affects the heat balance and operation of FCC unit. Consequently, it is signifcant to predict the coke yield accurately. The coke formation and burning reactions are affected by many parameters which infuence each other, so it is diffcult to establish a prediction model using traditional models. This paper combines the industrial production data and establishes a generalized regression neural network (GRNN) model and a back propagation (BP) neural network model to predict the coke yield respectively. The comparison and analysis results show that the accuracy and stability of the BP neural network prediction results are better than that of the GRNN. Then, the particle swarm optimization to optimize BP neural network (PSO-BP) and genetic algorithm to optimize the BP neural network (GA-BP) were further used to improve the prediction precision. The comparison of these models shows that they can improve the prediction precision. However, considering the accuracy and stability of the prediction results, the GA-BP model is better than PSO-BP model.

FCC; coke yield; GRNN neural network; BP neural network

1 Introduction

Fluid catalytic cracking (FCC) is one of the important processes for converting the heavy petroleum hydrocarbons into light oil products including dry gas, LPG, gasoline and diesel and into by-products, such as slurry oil and coke, at high temperature and in the presence of catalyst. Currently, the residual FCC (RFCC) dominates the catalytic cracking techniques in China and the residual oil is co-processed in more than 95% of the RFCC units[1]. As feedstock oil becomes increasingly heavier and inferior, the coke yield increases in the FCC process. The coke is formed from the condensation reaction during the cracking of feedstock oil. The increase of the coke yield will decrease the yields of the desired light oil products like gasoline and diesel. The coke will deposit on the surface of the catalyst, which reduces the catalytic activity of the catalyst and further reduces the yield of the light oil products[2]. In addition, the coke yield in the FCC process determines the heat balance[3]and the fuctuation of the coke yield will affect the heat balance of the unit and increase the operation complexity[4]. Therefore, it is of great importance to control the coke yield at lower levels and a small scale fluctuation to improve the operating stability and to increase economic benefts, which is highly dependent on the prediction of the coke yield of the unit accurately under its current state. The coke yield is closely related to the reaction extent of feedstock oil and also to the regeneration process of the catalyst. The FCC process is complex and continuous and involves large amount of reactions, which are complicated[5]and are affected by the properties of feedstock oil, the activity of catalyst and the operating conditions of the reaction-regeneration system. It is diffcult to describe the whole reaction process in the FCC with traditional models[6]. Currently, the establishment of the mathematical models based on the data analysis has become a new tool to deal with the FCC process. The artificial neural network (ANN) is a promising modeling technique which tries to simulate the brain’s problem solving process. ANN can deal with non-linear problems and it has strong ability of self-learning andself-adaptation. ANN has the ability of parallel processing and can deal with the multivariable systems and nonlinear problems[7-9]. Currently, some mature techniques of the neural network include the Back Propagation (BP) Neural Network[10], the General Regression Neural Network (GRNN)[11], the Radial Basis Function (RBF) Neural Network[12], etc. Guo, et al.[13]applied the GRNN neural network to develop a model for the thickness of the heavy and medium plate mill and it was found that this technique could correctly predict the change of the thickness of the mill bar and the relative error was small, and in addition, the accuracy and the stability of the GRNN were better than the BP neural network. Fan, et al.[14]applied the BP neural network to develop a model in order to predict the power of the wind-driven generator and they also developed a model to predict the error, and they confirmed the feasibility of the BP neural network in predicting the power of the wind-driven generator and its error. Zhang, et al.[15]applied the genetic algorithm (GA) to optimize the BP neural network and they developed a model to improve the prediction accuracy for the gasoline yield of RFCC unit. Their results showed that the optimized BP neural network had better accuracy. According to the previous studies, different neural networks have their merits and demerits in dealing with different systems. However, none of the current neural networks can directly predict the coke yield of FCC process based on the actual production data. Therefore, the models, which are based on the GRNN, the BP neural network and the optimized neural network for predicting the coke yield of a FCC unit, have been developed in the present study.

2 Neural Network

With the development of computer science and data analysis techniques, the approach of mathematical modeling emerges and its typical application of the mathematical modeling is to predict the future development of an event based on the neural network technique. ANN tries to simulate the function of human brain and it can achieve linear and non-linear mapping with the network and it can simulate the actual working conditions. The merits of ANN can be listed as follows: (1) It can approximate any non-linear mapping theoretically; (2) It can deal with multivariable systems; (3) It can perform parallel distributed computing; (4) It has strong ability of self-learning and self-adaptation; and (5) It can simultaneously deal with various qualitative and quantitative data. Recently, the ANN has been widely applied[16], while the GRNN[17]and the BP neural network[18]have been predominating in the application feld.

2.1 GRNN

The GRNN was developed by Specht D. F. in 1991, and it is a radial basis network[19]which is often applied for function approximation. The GRNN is capable of dealing with non-linear mapping characteristic of high fault-tolerance and robustness. The GRNN is strong in approximation, self-learning and dealing with non-linear problems effciently. The GRNN has been widely used in felds like signal processing, control decision system and fnancial sector.

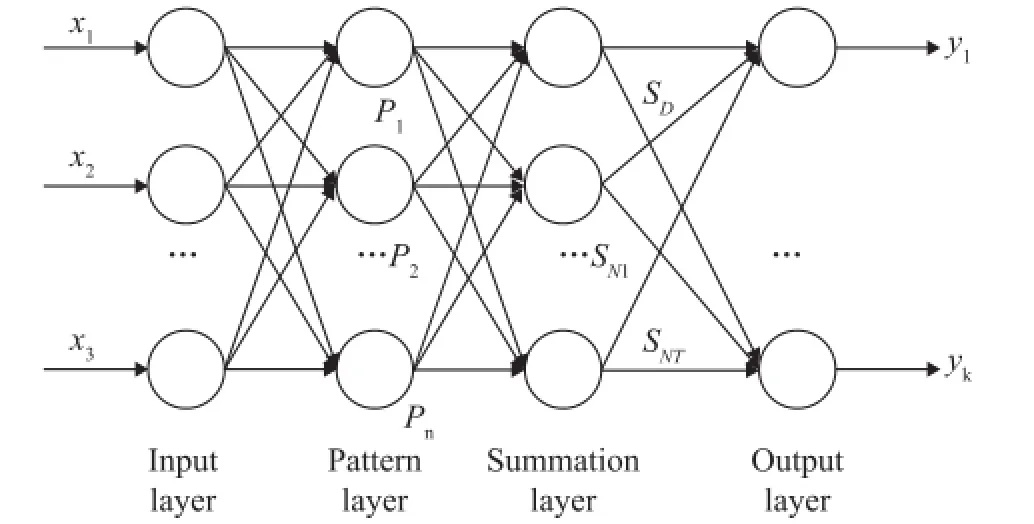

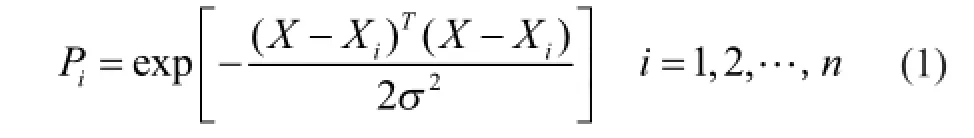

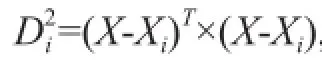

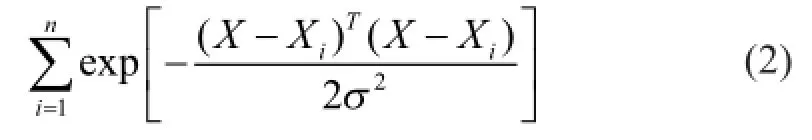

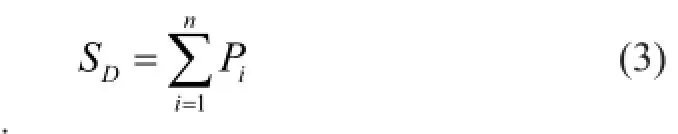

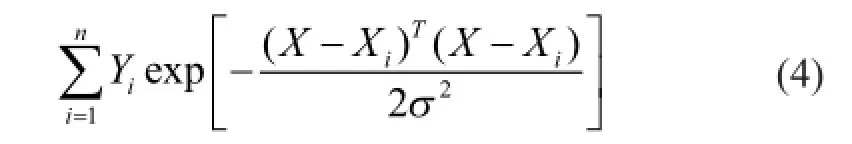

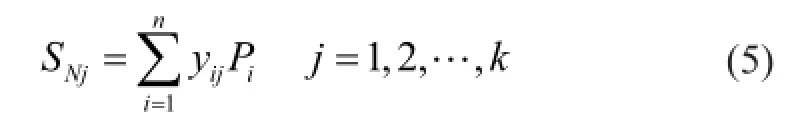

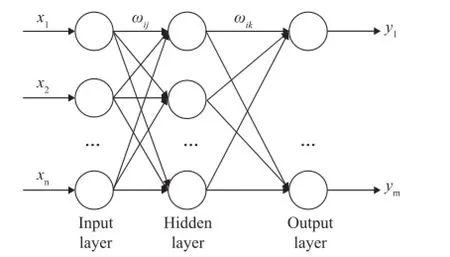

The GRNN has four layers as shown in Figure 1, viz.: the input layer, the pattern layer, the summation layer and the output layer. The format for the input isX=[x1,x2, …,xn]Tand that for the output isY=[y1,y2, …,yk]T.

Figure 1 The topological structure of GRNN

(3) Summation layer: two kinds of neurons are usually used for summation and one is

and this equation arithmetically sums the output neurons from the pattern layer, and the connection weights between the pattern layer and every neuron is 1, with the transfer function equating to

Another equation is

and this equation performs weighted summation for the output neurons from the pattern layer. The connection weights between the neuroniin the pattern layer and the neuronjin the summation layer is thejth element of theith output neuronYi. And the propagation function is

(4) Output layer: the number of neurons in the output layer is equal to the output vector dimensionskin the sample.

2.2 BP neural network

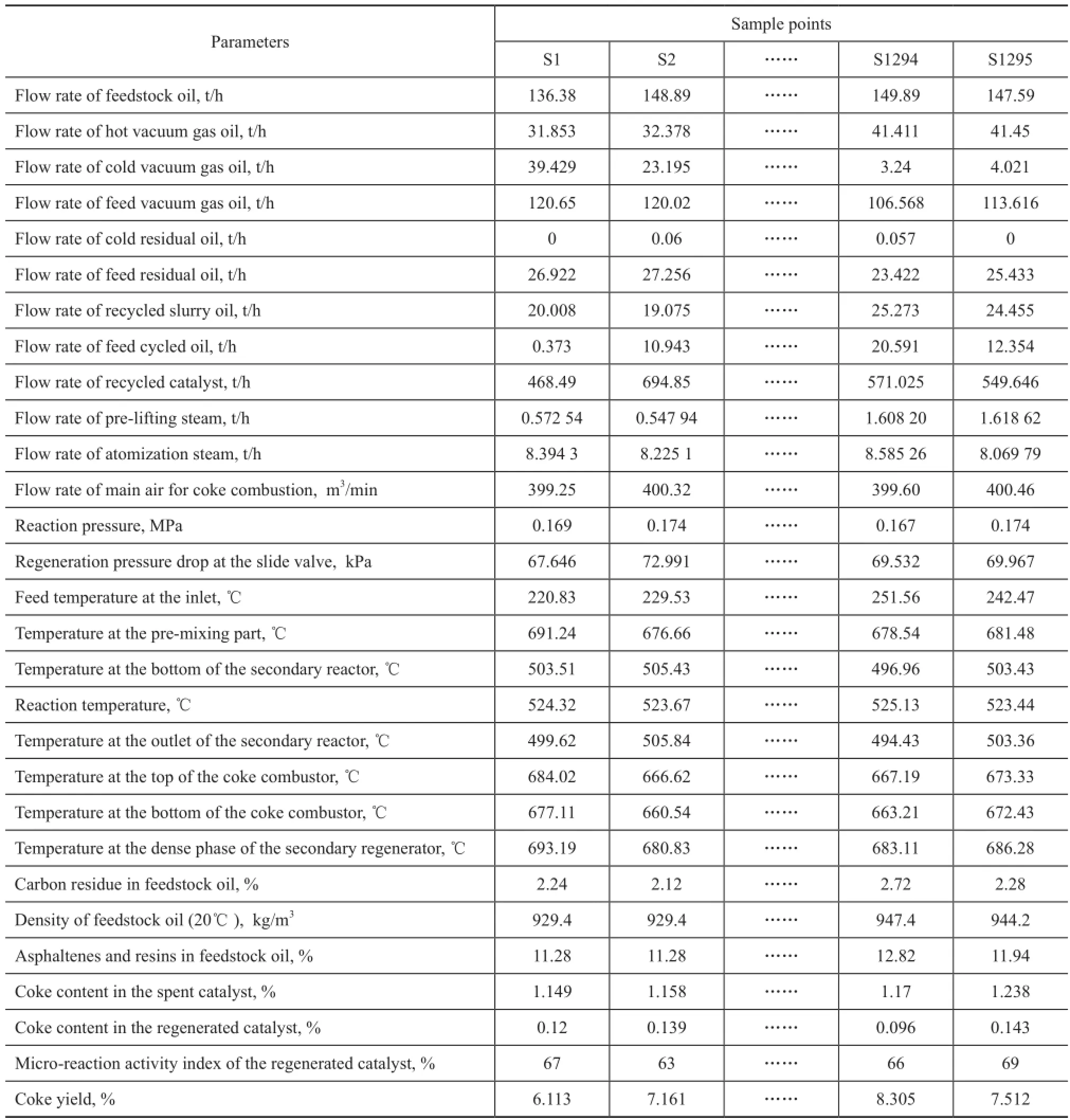

BP neural network[18]is a neural network with multilayer and feed-forward. The BP neural network is characterized by the forward propagation of signals and backward propagation of errors. The S-shaped function (Log-Sigmoid or Tan-Sigmoid) is usually selected as the propagation function. The BP neural network contains three layers, namely: the input layer, the hidden layer and the output layer. If the output layer cannot output the desired result, the BP neural network will move backwards and return the error through the original path along which the signal is propagated. By modifying the weighted and the threshold values, the error signal can be minimized.

The structure of the BP neural network is shown in Figure 2.

Figure 2 The topological structure of BP neural network

3 Modelling Method

3.1 The pretreatment of industrial data

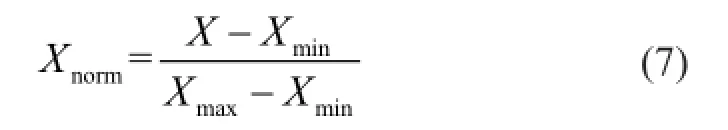

More than 550 monitor data points were collected, based on the industrial data from the DCS system of a RFCC unit. According to the reaction-regeneration process of the FCC unit, 28 key parameters influencing the coke yield were selected and the production data spanning two months were studied. These data were pretreated based on the following principle: Each parameter had an effective value and its average value was used to substitute the odd value so that the time and frequency of the data collection were unifed. 1 295 sets of data were obtained after pretreatment as shown in Table 1. The values of the parameters in Table 1 were regarded as the input values and the coke yields as the output values. 647 sets of the total data were selected as the training set and others were treated as the samples for prediction.

3.2 Development of the GRNN model

The GRNN model was developed with the neural network toolbox in Matlab, and the development steps are shown as follows:

Step 1: input the data for training and prediction;

Step 2: use thenewgrnnfunction to develop the GRNN for training and prediction;

Step 3: use the trained GRNN to predict.

3.3 Development of the BP neural network model

With the neural network toolbox of Matlab, the BP neural network model was developed as follows:

Step 1, input data for training and prediction.

Step 2, use themapminmaxfunction to normalize the data.

Table 1 Data after pretreatment

Step 3, use thenewfffunction to develop the BP neural network for training and prediction;

Step 4, renormalize the data from Step 3 and obtain the predicted results.

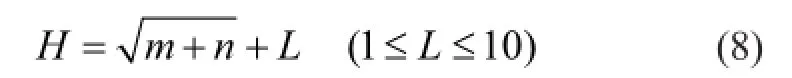

The normalization equation is shown in Equation (7),

In the present work, the values from 28 key parameters are normalized and regarded as the input values, and the coke yield after renormalization is the output value. Therefore, the number of neurons is 28, with each one assigned for the input layer and the output layer, respectively. The number of nodes in the hidden layer is obtained from Equation (8)[12],

wheremis the node number in the input layer andnis the node number in the output layer.

According to Equation (8), the number of nodes in thehidden layer varies from 6 to 16. The S-shaped propagation function (Tan-Sigmoid) is applied between the input layer and the hidden layer, and the linear propagation function is applied between the hidden layer and the output layer. Thenewfffunction is used for data training. The comparison of the relative errors between different hidden layers shows that the prediction is the best when the node number in the hidden layer is 12. Therefore, the present work is based on the 28-12-1 topological structure of BP neural network model.

3.4 PSO optimized BP neural network model (PSO-BP)

PSO is an optimization algorithm based on the theory of swarm intelligence[20]and it is effective in global searching which can converge rapidly. Through the cooperation and competition of particles in the swarm, the searching is intellectually instructed and optimized. All the particles are updated at each iteration until a new generation set of particles is obtained. The optimization steps are shown as follows:

Step 1: It starts with parameter initialization, including the size of the swarm, the acceleration coefficient, the learning rate and the iteration times;

Step 2: Upon setting the end criterion, the algorithm will come to an end if the results are desired or the iteration times will exceed the upper limit. Otherwise, Step 1 will be executed;

Step 3: For each particle, it propagates forward in the network and the error is evaluated for the output value;

Step 4: During the iteration of the PSO algorithm, each particle updates its velocity and position according to its own extremum and the global extremum in order to fnd the value in its best position (P-best);

Step 5: For each particle, the value in its best position (P-best) and the value in the historical best position (G-best) of the swarm are compared. If P-best is better than the G-best, the P-best is regarded as the new G-best or otherwise, the G-best is unchanged;

Step 6: The best position of the swarm is used to update the weight and the threshold value of the BP neural network;

Step 7: If the end criterion is achieved, the algorithm will be ended, or otherwise Step 4 will be performed.

3.5 GA optimized BP neural network model (GA-BP)

GA is an optimization algorithm with the ability of parallel random search[21]. GA is designed to mimic the principles of evolution in natural genetic system with the ‘survival of the fttest’. The GA can solve linear and non-linear problems by searching all regions of the state space and fnding the promising area through operations of mutation, crossover, and selection, which are applied to individuals in the population[22]. The optimized initial weight and threshold value from the GA will improve the accuracy and stability of the BP neural network. The optimization steps are as follows:

Step 1: The code for the weight value (threshold value) can randomly generate a group of linked weight value (threshold value) for the neural network;

Step 2: Input the sample for training and calculate the error and define the total sum of absolute error as the ftness function. Lower error means a lower ftness;

Step 3: Select the individual with lower ftness and pass down to the next generation;

Step 4: Through operations of crossover and mutation for the current generations, new generations will be formed;

Step 5: Repeat Step 2 to Step 4 in order to update the initial weight value (threshold value) for the neural network until the fitness of the evolution generation is unchanged.

4 Results and Discussion

There are 1 295 groups of data after the pretreatment of industrial data. 647 groups are selected randomly as the training samples and the others are considered as the testing samples. The GRNN and BP neural network models are developed by using the training samples and tested by the testing samples. Then we use the GA and PSO to optimize the BP neural network to improve the accuracy and stability and compare the results of different prediction models.

4.1 Comparison between GRNN and BP neural network models

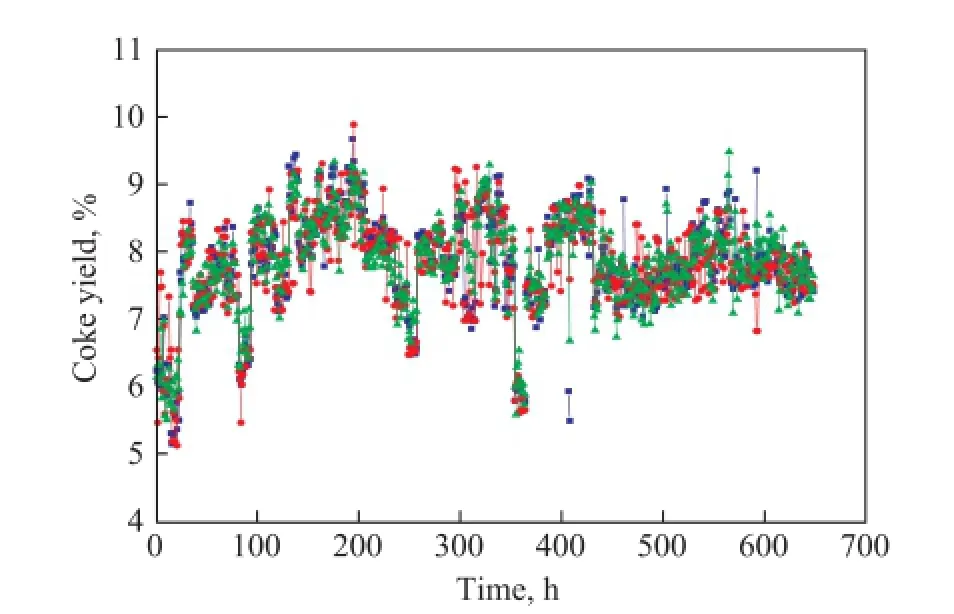

The prediction models for the coke yield were developed based on the GRNN and the BP neural networks, respectively. The predicted coke yields were compared with industrial production data as shown in Figure 3. Figure 3 shows that the two models can both accurately predict the coke yield[23].

Figure 3 Comparison between the industrial and predicted coke yield from GRNN and BP neural network models

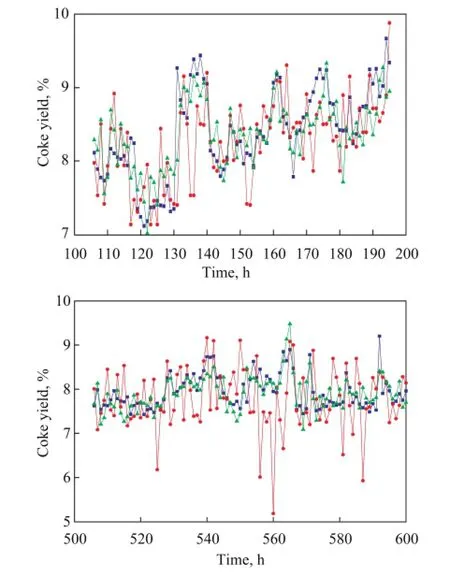

A part of Figure 3 was magnifed for comparison analysis. During the time interval of 100—200 h and 500—600 h as shown in Figure 4, the trend from the predictions with BP neural network model agrees well with industrial production data, while the predictions by the GRNN model deviate from the industrial production data sometimes, indicating that the BP neural network model is better than the GRNN model.

Figure 4 Comparison between the industrial and predicted coke yield originated from GRNN and BP neural network models at some time intervals

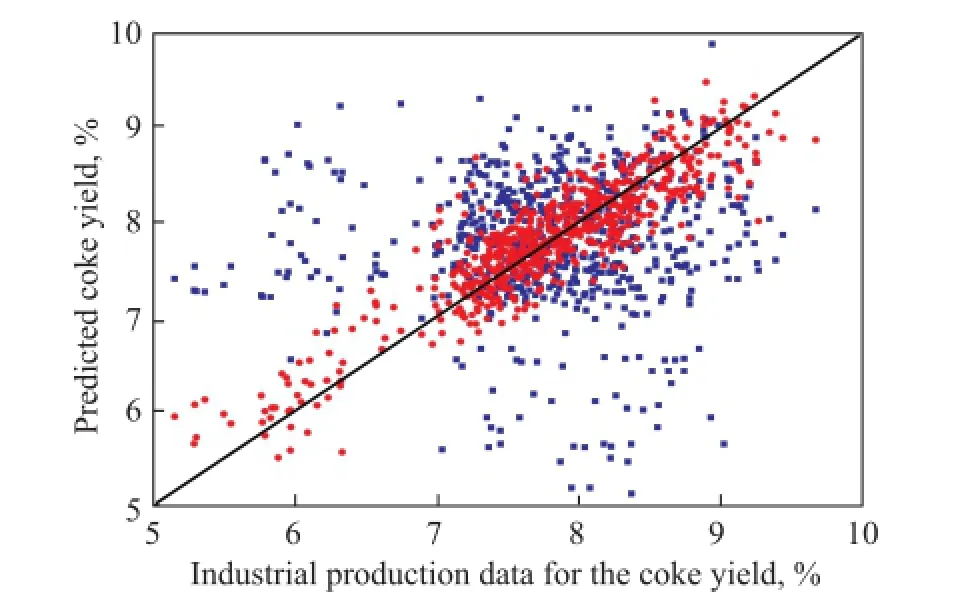

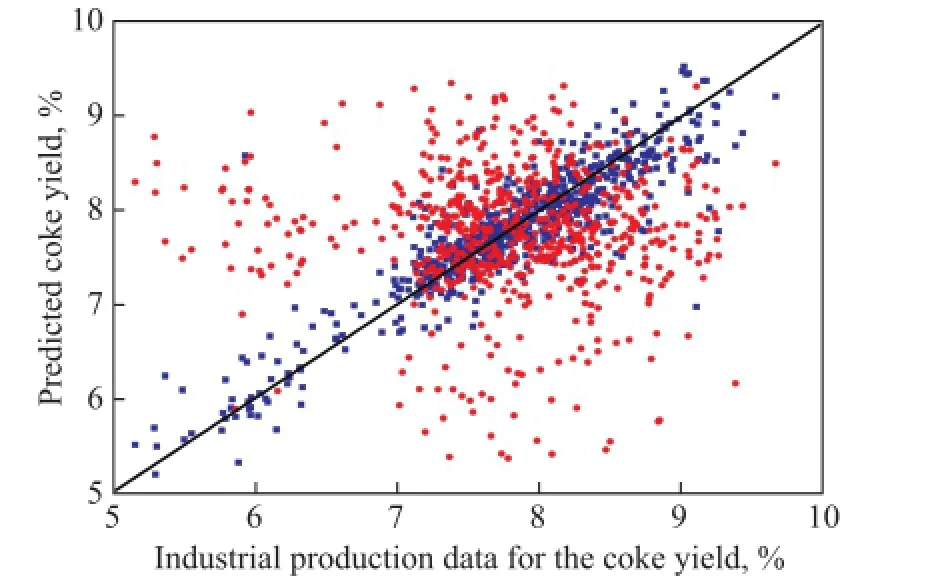

Figure 5 further shows the comparison between the prediction results and the industrial production data, indicating that the BP model gave smaller prediction errors than the GRNN model.

Figure 5 Comparison between the prediction results from GRNN and BP neural network models and the industrial production data

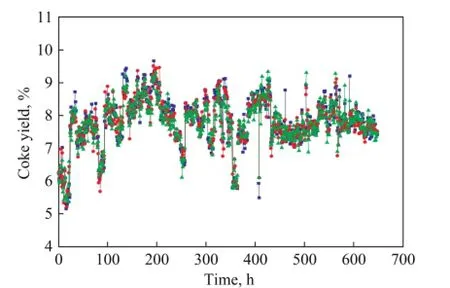

4.2 Comparison between the PSO and GA optimized BP neural network models

Since the initial weight value and threshold value were random in the BP neural network, the optimum initial weight value and threshold value were determined with the PSO and GA separately[24]. The prediction model for the coke yield is developed based on the PSO and GA optimized BP neural network. The predicted coke yields obtained from these two optimized models were compared with the industrial production data as shown in Figure 6. Figure 6 shows that the predicted coke yields from these two models agree well with the industrial data[25-26]and a limited difference between these two model predictions can be observed.

Figure 6 Comparison between the industrial and predicted coke yield originated from PSO-BP and GA-BP neural network models

Figure 7 further shows the comparison between the industrial data and the prediction results obtained from the two optimized models. Figure 7 indicates that the trend of the GA-BP model is different from that of the PSO-BP model. While the prediction results from the two models agrees well with the industrial production data, the predicted coke yields obtained from the PSO-BP model largely fuctuate around the industrial production data, indicating to a larger error than GA-BP model. Therefore, the GABP model is better than the PSO-BP model in predicting the coke yield.

Figure 7 Comparison between the prediction results obtained from PSO-BP and GA-BP neural network models and industrial production data

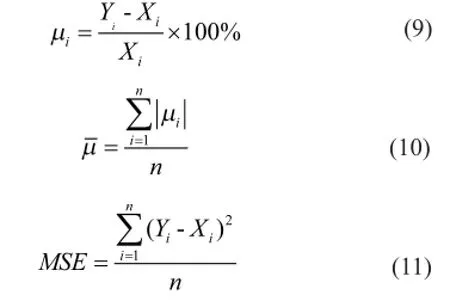

The equations (9)—(11) are applied to calculate the average relative error and the mean square error (MSE), with the results shown in Table 2.

Table 2 indicates that the BP neural network model gives a smaller prediction error than the GRNN model. The optimized BP neural network model is better in accuracyand stability than the original BP neural network model. Therefore, the GA-BP model is the best in predicting the coke yield for RFCC unit among the four models.

Table 2 Results obtained from different models

5 Conclusions

Based on the FCC process, 28 key parameters (involving feedstock oil, catalyst and operating conditions) infuencing the coke yield of the FCC unit were selected as the input values and the coke yield as the output value for establishing GRNN, BP, PSO-BP and GA-BP neural network models. The following conclusions can be obtained:

1) The prediction models for the coke yield can be developed with GRNN and BP neural network based on the industrial production data.

2) The BP neural network model is better in predicting the coke yield of the FCC unit than the GRNN model.

3) The optimized algorithm can provide the optimized initial weight value and threshold value, which can improve the accuracy and stability of the BP neural network model.

4) The optimized PSO-BP and GA-BP models can achieve better accuracy than the BP neural network model without optimization. The GA-BP model is also better in stability than the PSO-BP model. The GA-BP neural network model is better in predicting the coke yield of the FCC unit.

[1] M i Yingze. Study on optimization technology of 1.2 Mt/a vacuum residue RFCC unit [J]. Energy Chemical Industry, 2015, 36(2): 35-38 (in Chinese)

[2] X u Chunming, Yang Zhaohe. Petroleum Processing Engineering [M]. Beijing: Petroleum Industry Press. 2009: 294-315 (in Chinese)

[3] C hen Junwu. FCC Technology and Engineering [M]. Beijing: China Petrochemical Press, 2005: 896-901 (in Chinese)

[4] Cao Hanchang, Hao Xiren, Zhang Han. FCC Process Calculation and Technical Analysis [M]. Beijing: Petroleum Industry Press. 2000: 150-153 (in Chinese)

[5] Li Wei. Studies on Process Modeling and Its Application for Catalytic Cracking [D]. Zhejiang University, 2010 (in Chinese)

[6] Michaelopoulos J, Papadokonstadakis S, Arampatzis G, et al. Modelling of an industrial fluid catalytic cracking unit using neural networks [J]. Chemical Engineering Research and Design, 2001, 79(2): 137-142

[7] Liu Chunyan, Ling Jianchun, Kou Linyuan, et al. Performance comparison between GA-BP neural network and BP neural network [J]. Chinese Journal of Health Statistics, 2013, 30(2): 173-176+181 (in Chinese)

[8] Deswal S, Pal M. Artifcial neural network based modeling of evaporation losses in reservoirs [J]. International Journal of Mathematical, Physical and Engineering Sciences, 2008, 2(4): 177-181

[9] Hao Xin. The Study of General Regression Neural Network and Genetic Algorithms and their Application for Chemical Engineering [D]. Zhejiang University, 2004 (in Chinese)

[10] Ding Yun, Yu Jingjiang, Zhou Chunhui. Quality estimation and supervision for a crude distillation column [J]. Petroleum Processing and Petrochemicals, 1994, 25(5): 23-28 (in Chinese)

[11] Zhao Chuang, Liu Kai, Li Diansheng. Freight volume forecast based on GRNN [J]. Journal of the China Railway Society, 2004, 26(1): 12-15 (in Chinese)

[12] Wang Wenxin, Pan Lideng, Li Rong, et al. Development of RBF neural network with double model structure and its application to atmospheric and vacuum distillation units [J]. Journal of Beijing University of Chemical Technology (Natural Science Edition), 2004, 31(5): 23-28 (in Chinese)

[13] Guo Bin, Meng Lingqi, Du Yong, et al. Thickness prediction of medium plate mill based on GRNN neural network [J]. Journal of Central South University (Science and Technology), 2011, 42(4): 960-965 (in Chinese)

[14] Fan Gaofeng, Wang Weisheng, Liu Chun, et al. Wind power prediction based on artificial neural network [J]. Proceedings of the CSEE, 2008, 28(34): 118-123 (in Chinese)

[15] Zhang Zhongyang, Li Zeqing, Li Yulong, et al. GA-ANN method for prediction of gasoline yield of RFCCU [J]. Petroleum Processing and Petrochemicals, 2014, 45(7): 91-96 (in Chinese)

[16] Zhu Daqi. The research progress and prospects of artifcial neural networks [J]. Journal of Jiangnan University (Natural Science Edition), 2004, 3(1): 103-110 (in Chinese)

[17] Liao Zhiwei, Ye Qinghua, Wang Gang, et al. Adaptive multi-fault diagnosis of power system based on GRNN [J]. Journal of South China University of Technology (Natural Science Edition), 2005, 33(9): 6-9 (in Chinese)

[18] Mao Yingke, Guan Zhicheng, Wang Liming, et al. Prediction of leakage current of outdoor insulators based on BP artificial neural network [J]. Proceedings of the CSEE, 2007, 27(27): 7-12 (in Chinese)

[19] Specht D F. A general regression neural network [J]. IEEE Transactions on Neural Networks, 1991, 2(6): 568-576

[20] Zeng Wanli, Wei Renyong, Chen Hongling. Research and application of BP neural network based on improved PSO algorithm [J]. Computer Technology and Development, 2008, 18(4): 49-51 (in Chinese)

[21] Wang Xiaochuan, Shi Feng, Yu Lei, et al. Matlab Neural Network 43 Case Studies [M]. Beijing: Beihang University Press, 2013: 20-32 (in Chinese)

[22] Hou Mandan. Modeling and Optimization for the Procedure of Reaction Regeneration of Catalytic Cracking Based on Genetic Algorithms[D]. Harbin: Harbin Institute of Technology, 2007 (in Chinese)

[23] Lu Chunhua, Liu Ronggui. Carbonation depth prediction of pre-stressed concrete based on artifcial neural network [J]. Journal of Harbin Institute of Technology, 2008, 40(10): 1649-1652 (in Chinese)

[24] Wang Chongjun, Yu Wendi, Chen Zhaoqian, et al. A BP neural network algorithm based on genetic algorithms and its application [J]. Journal of Nanjing University (Natural Sciences), 2003, 39(5): 459-466 (in Chinese)

[25] Chen Shouyu, Wang Dagang. Study on distribution of total amount of drainage water pollutant in a region [J]. Journal of Hydraulic Engineering, 2003, 05: 116-121 (in Chinese)

[26] Li Zuoyong, Wang Jiayang, Guo Chun, et al. A new method of BP network optimized based on particle swarm optimization and simulation test [J]. Acta Electronica Sinica, 2008, 36(11): 2224-2228 (in Chinese)

Received date: 2016-03-07; Accepted date: 2016-04-24.

Dr. Lan Xingying, E-mail: lanxy@ cup.edu.cn.

- 中國(guó)煉油與石油化工的其它文章

- Effect of Magnetic Field on Tribological Properties of Lubricating Oils with and without Tricresyl Phosphate

- Preparation and Lubricating Properties of A New Antibacterial Emulsion Containing Nano-TiO2for Cold Rolling Strips

- An Extraction Process for Optimal Utilization of Naphtha Based on Molecule Management

- Hydrodynamic Characteristics in an External Loop Airlift Slurry Reactor

- Microwave-Assisted Synthesis of Poly(Aspartic Acid-Itaconic Acid) Copolymer and Its Characterization

- Effects of Solution Chemistry Conditions and Adsorbent Surface Properties on Adsorption of Ni(II) on Laiyang Bentonite