Experimental study of polyurethane foam reinforced soil used as a rock-like material

Eren Komurlu,Ayhan Kesimal

Department of Mining Engineering,Karadeniz Technical University,Trabzon 61080,Turkey

Full length article

Experimental study of polyurethane foam reinforced soil used as a rock-like material

Eren Komurlu*,Ayhan Kesimal

Department of Mining Engineering,Karadeniz Technical University,Trabzon 61080,Turkey

A R T I C L E I N F O

Article history:

Received 15 January 2015

Received in revised form

13 May 2015

Accepted 1 July 2015

Available online 11 July 2015

Polyurethane reinforced soil(PRS) Rock-like material Polyurethane Environmental resistance of rocks Rock testing

In this study,polyurethane foam type thermoset polymerizing,due to chemical reaction between its liquid ingredients,was tested as binder after solidifying and then a rock-like material mixing with a sandy silt type soil was prepared.The uniaxial compressive strengths(UCSs)of polyurethane foam reinforced soilspecimens were determined for different polyurethane ratios in the mixture.Additionally, a series of tests on slake durability,impact value,freezing-thawing resistance,and abrasion resistance of polyurethane reinforced soil(PRS)mixture was conducted.The UCS values over 3 MPa were measured from the PRS specimens.The testing results showed that treated soil can economically become a desirable rock-like materialin terms of slake durability and resistances against freezing-thawing,impact effect and abrasion.As another characteristic of the rock-like material made with polyurethane foam, unit volume weight was found to be quite lower than those of natural rock materials.

?2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

Polyurethane was fi rstly synthesized by Otto Bayer in 1937 as an alternative of rubber(Bayer,1947).Flexible polyurethane foam was fi rstly produced in 1954,and started to be applied as spraying insulation material in the 1960s.Polyurethane is an isocyanatebased copolymer nowadays used for many different kinds of insulation applications,such as buildings,tanks,pools and waste depositionplants,because ofits good resistivity againstthe seasonal and environmental changes(Komurlu and Kesimal,2012a,2014).

Polyurethane polymerizes owing to the chemical reaction between the liquid ingredients of polyol and isocyanate.The liquid phase time of mixture can be chosen according to the type of product.The polyurethane foam material used in this study is activated within a minute after the ingredients are mixed.As a result of polymerization,the foam can swell in three dimensions with a good expansiveness(Guo et al.,1999;Li et al.,2000;Bilir, 2009;Muynck et al.,2009).

There are three stages ofpolyurethane foam polymerization.The fi rstone is creamtime;atthis stage,polymerization does notstart to work,and the mixture is liquid.Typicalcreamtime for polyurethane foams changes from5 s to 240 s.By the end ofthis time,the geltime and polymerization start.Atthe third stage called tack free time,the material solidi fi es completely and the polymerization ends.Therefore,the maximummechanicalstrength is reached at the end ofthe tack free time varying between 18 h and 24 h for most of the polyurethane foams(Komurlu and Kesimal,2012b).

Freezing-thawing resistance,slake durability,ductility,crack resistivity against the thermal changes of polyurethane are more convenient in comparison with those of the natural rock materials (Gao et al.,1993;Han et al.,2010;Komurlu and Kesimal,2013). Polyurethane materials are also used due to their resistance to chemicaldegradation from water(Guan et al.,2004;Yilmaz,2013). In addition,they are non fl ammable,and can reduce air leakage and the passage of moisture(Li et al.,2014).Therefore,polyurethane foam based rock-like materials were suggested to have a good resistivity against different issues of the environmental change.

In this study,a sandy silt soil material was mixed with the polyurethane foam having different volumetric ratios in the mixture.To prepare the rock-like specimens,dry form of the soil material was used due to the factor that water affects the polymerization performance.The aim of this study is to de fi ne the strength of polyurethane reinforced soil(PRS)material and to understand its properties of resistivity against some environmental effect.To assess the PRS as an alternative of the natural rocks,the experimental results were discussed in comparison with the suggestions in relevant standards.

2.Experimental study

In this study,uniaxial compressive strength(UCS)of the PRS specimens was determined.In addition,a series of tests on slakedurability,freezing-thawing resistance,impact value,and abrasion resistance was carried out.

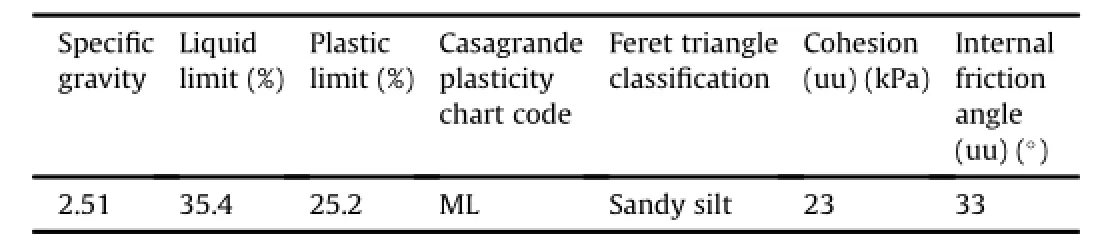

Table 1 Physicaland mechanicalproperties of the soil.

2.1.Materials tested

The polyurethane foam used in this study has density of 65 kg/ m3in case of free swelling during its polymerization.Its raw materials,polyol and isocyanate whose densities are similar with the density of water,start to react chemically within a minute at 24°C. Therefore,an ef fi cient mixing time for the product can be accepted as one minute.After this time interval,polymerization and frothing start and continue during the gel time.Especially,the period of the fi rst 15 min is very active time for increase of the foam volume.At the end offrothing,the mixture volume is 16 times higher than that at the start of polymerization.For an ef fi cient polymerization,the liquid ingredients should be mixed with the same(1:1)volumetric amounts(BASF,2009).Typical tensile strength and elastic modulus of the normally frothed polyurethane foam product with density of 65 kg/m3used in this study can be considered as 800 kPa and 25 MPa,respectively(Bomberg and Lstiburek,1998;Witkiewicz and Zieli'nski,2006;Komurlu and Kesimal,2012c).

Soil used in this study was classi fi ed as sandy silt and inorganic silt with ML code in the Casagrande plasticity chart(Komurlu,2012; Komurlu and Toptas,2012).Some physical and mechanical parameters of the soil are summarized in Table 1.

2.2.Preparation of specimens

To prepare for dry soil mixed with the polyurethane foam,soil material used in this study was put in the stove at 105°C for 6 h before mixing with polyurethane.The soilmass was kept constant at 160 g for all specimens used in uniaxial compression test. Different weights of the liquid ingredients were mixed with soil with varying polyurethane/soil ratios of 1/7,1/8 and 1/9 by weight. To prepare the PRS specimens,polyol and isocyanate were mixed with the same ratios by weight fi rst.Then,the dry soil was added on frothing materialstep by step as polymerization started.Because the air in the fl uid foam was removed,expansion of the froth stopped when mixing with a metal spoon during the early time of the gel(Fig.1).After a couple of seconds,the polyurethane gel started to froth again.However,the frothing height decreased after allsoilsprinkling and mixing steps totally applied in 3 times.After a critical period in the gel time,the foam viscosity increased and the PRS materialsolidi fi ed.Fig.2 shows two forms of the solidi fi ed PRS which were allowed to froth freely after the last soil adding step, and compressed to make a fl at surface of PRS in molds with NXcore size diameter and the ratio of height to diameter of2.The period of the fi rst 2 min of the geltime was the most criticalperiod to make a well-mixed material.After 10 min passed following the start of frothing,the mixture became hard to be mixed by hand and had a little expansion tendency.Therefore,all of the soil in a specimen was completely added and mixed in early stage of the gel time.

As around halfhour elapsed,i.e.the last stage ofpolymerization, the tack free time for full solidifying started.In the tack free time, there was no visualchange of the PRS specimens except some small surface swelling in the fi rst hour.In the early stage of tack free time, specimens were sometimes compressed to make the surface fl at. The mechanical properties of specimens were signi fi cantly improved by curing reactions during the tack free time.All the PRS specimens were waited at least 1 d to be sure that polymerization reactions ended.

Abrasion test specimens with regular shape were sampled by using cutter head circular molds with 6.25 cm in diameter and 2 cm in height.Specimens were taken from soft polyurethane and soil mixture in the geltime using the core sampler.The specimens were compressed to forma fl at surface during the geltime and early tack free time in common with the specimens for uniaxial compression test.Abrasion test specimens were prepared to investigate the performances of PRS materialwith the ratio of polyurethane to soil of 1/8 by weight.Soil and polyurethane were mixed in a vessel bigger than the specimen molds for uniaxial compression test, following the same procedure of specimens for uniaxial compression test.

Fig.1.(a)Frothing polyurethane after the fi rst step of soil adding.(b)Mixing polyurethane and soil.

Fig.2.(a)Uncompressed specimen.(b)Compressed specimen with fl at surface.

PRS specimens prepared for slake durability,impact value and freezing-thawing tests had irregular shapes like rock aggregate. Polyurethane was mixed with ratio of polyurethane to soil of 1/8, following the same procedure of specimens prepared for uniaxial compression test.However,the surface of PRS mixed in the molds of uniaxial compression test was not compressed,and the mixture was allowed to rise as shown in Fig.2a.Specimens were taken plucking from soft mixture before the end of gel time and continued to swelluntil the early stage of tack free time.Therefore, specimens were compressed by hand to produce suitably sized specimens after plucking from the swelling mixture(Fig.3).To compare with PRS,different types of natural rock materials (marble,limestone,granite,andesite,diorite,basalt,rhyodacite) were also used in freezing-thawing test and aggregate impact value test(Fig.4).Solidi fi ed PRS specimens and rock aggregates were sieved to have particle size distribution between 9.52 mm and 12.7 mm.

2.3.Methods

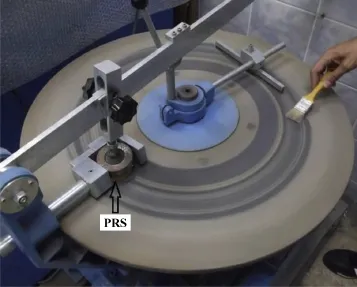

Unit volume weights of PRS specimens with different ratios of polyurethane to soil were determined considering the weight and volume of the cylindrical specimens for uniaxial compression test. PRS specimens were weighed using a digital scale with the sensitivity of 0.01 g to determine their unit volume weights.Totally,15 specimens consisting of 3 groups of different polyurethane to soil ratios(1/7,1/8,1/9)were tested to determine the UCS and unit volume weight values of PRS materials.The uniaxial compression tests(Fig.5)were performed following the method suggested by International Society for Rock Mechanics(ISRM,2007,2014).

Slake durability test was used to determine the weakening and disintegration of PRS specimens in contact with water.According to the ISRM suggested method,slake durability test was applied on totally 200 cm3ten pieces of PRS specimens shown in Fig.6.The water tank was fi lled to 20 mmbelow the drumrotating axis.Motor rotated the wire drum in water at 20 revolutions per minute(rpm), for 200 revolutions to complete a cycle.Specimens were dried and weighed before and after the rotating cycles in water.To make specimens dry,the heating time and temperature of stove were respectively selected as 4 h and 105°C according to the test procedure suggested by ISRM(2007,2014).

Freezing-thawing resistance of PRS specimens and 9 different types of rocks were compared by measuring the mass loss after the test cycles of cooling-heating in the cabin which were applied according to Turkish standard for aggregate freezing-thawing test TS EN 1367-1(2008).All the rocks and PRS specimens were covered with water and put in the cabin together(Fig.7).As the fi rst step of a cycle,specimens were cooled to 0°C in 150 min and kept at 0°C for 210 min.Then,the temperature in the cabin decreased from 0°C to-20°C in 180 min and was kept at-20°C for 240 min.As the following step,the temperature immediately reached 20°C in1 min and was kept at 20°C for the last 660 min of the cycle.One cycle continuing for 24 h was repeated for 10 times according to Turkish standard TS EN 1367-1(2008).In this way,freezingthawing process took time of 10 d.After the freezing-thawing process,wet specimens were sieved using the aperture of half of minimum particle size before freezing and thawing as stated in the standard followed.Specimens were dried in stove at 105°C before and after freezing-thawing process to determine the material loss by weighing sieved material.

Fig.4.PRS and rock specimens for aggregate impactvalue test and freezing-thawing test.

Fig.5.Uniaxial compression test on PRS specimens.

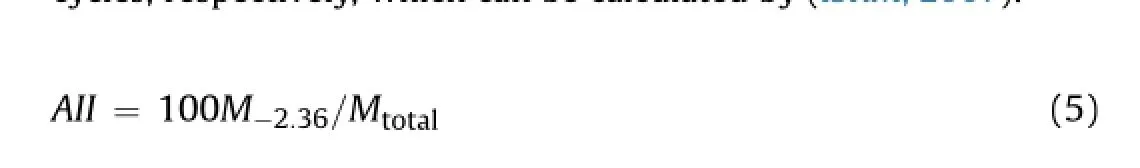

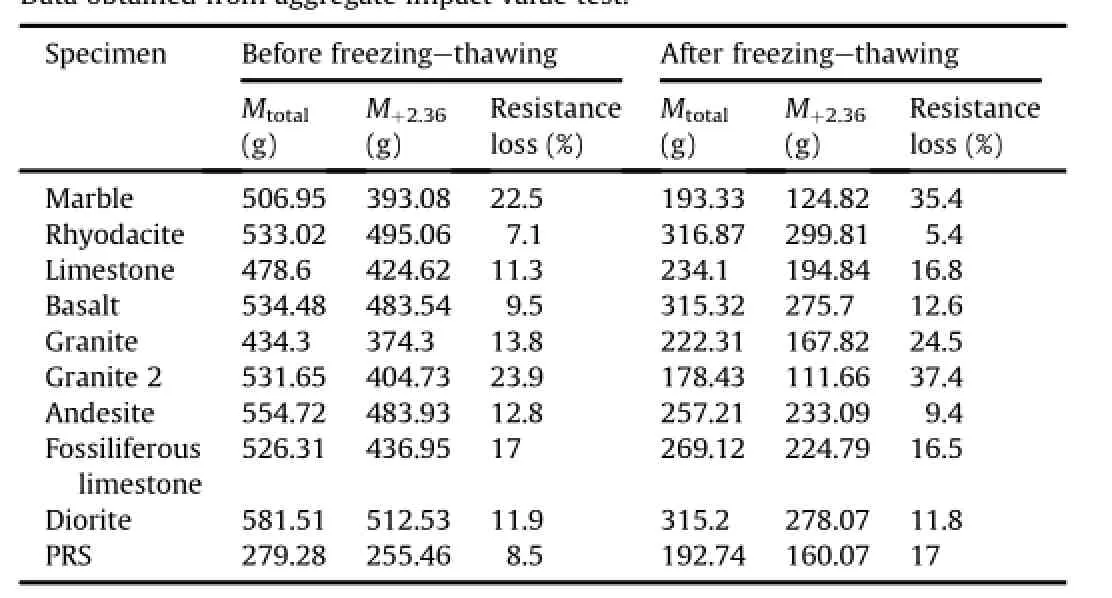

Aggregate impact value test was applied before and after freezing-thawing cycles,following Turkish standard for aggregate impact value test TS EN 1097-2(2000).Specimens having particle size between 9.52 mm and 12.7 mm were used for impact value test.Around 500 g of each rock types were put into aggregate impact value test mold to be impacted by the hammer with 13.6 kg mass which was dropped from 37.5 cm height(Fig.8).Time between the hammer falls was not longer than 2 s.Hammer was dropped 15 times for each type of specimen.Because PRS material has about half density of those of the rock materials,279 g PRS was used in the impact value test(Fig.9).To determine the loss ofmass, the specimens were sieved with 2.36 mm aperture as stated in the Turkish standard TS EN 1097-2(2000).Therefore,frozen-andthawed specimens were sieved with 1.18 mm aperture as half of the minimum particle size before the process in the cabin(Fig.10).

Fig.7.Specimens in freezing-thawing cabin.

Fig.6.Slake durability test applied PRS specimens(left)and slake durability test equipment(right).

Fig.8.Aggregate impact value test(hammer automatically falls when raised to height of37.5 cm).

Fig.9.PRS in impact value test.

Fig.10.Wet sieving of frozen-and-thawed specimens.

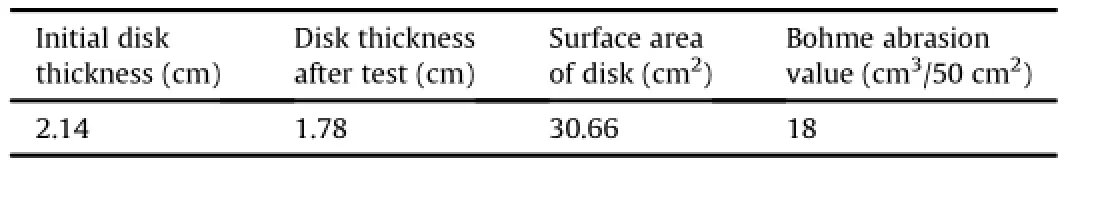

Abrasion resistance of PRS was tested with Bohme abrasion test which is a widely applied method for rock specimens.Tests were carried out according to Turkish standard TS EN 14157(2005).In the test,rock specimens were abraded due to the contact with iron disk rotating at 30 rpm(Fig.11).The vertical load of 295 N was applied on abrasion test specimens,and 20 g abrasive corundum dust was sprinkled on friction area of the iron disk between each cycles automatically completed after 22 revolutions.Totally,16 cycles(352 revolutions)were applied to fi nish abrading.Then, material volume loss due to the surface friction was determined by measuring the decrease in thickness through nine different points with high-precision digital vernier caliper.

3.Results and discussion

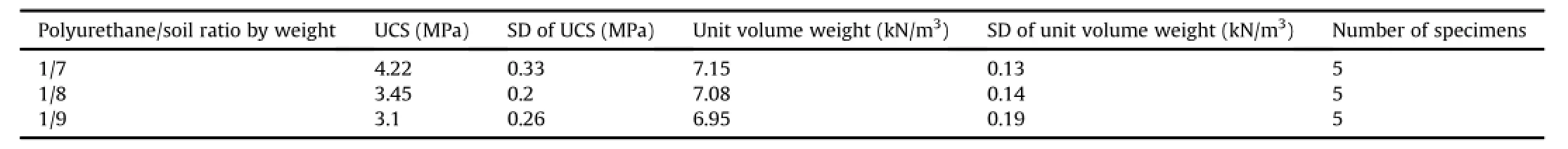

As the volume of a mold with diameter of NX size and height to diameter ratio of2 is known to be 248 cm3,unit volume weights of PRS mixtures having 1/7,1/8 and 1/9 polyurethane to soil ratios by weight can be calculated as 7.23 kN/m3,7.12 kN/m3and 7.03 kN/m3, respectively.However,the unit volume weight measured by weighing the specimens for uniaxial compression test was calculated a little lower in comparison with the values given above due to materialloss during specimen preparation.On the other hand,an increase in the mass of specimens was assumed due to the air humidity.Because dry soilwith speci fi c gravity of 2.51 was used in the tests,the polyurethane foam whose density offree froth form is 65 kg/m3had around 184 cm3volume to expand in the mold.Therefore,the foam in PRS specimens can be accepted to respectively have 52%,59%and 67%volumes of those of the free frothing forms for 1/7,1/8 and 1/9 ratios of polyureathane to soil by weight. The UCS values of the PRS specimens were found to signi fi cantly increase with the increase in percentage of polyurethane amount in the mixture.The uniaxialcompression test results and unit volume weights of the specimens are given in Table 2.

Fig.11.Bohme abrasion test for PRS.

Table 2 UCSs and unit volume weights of PRS specimens.

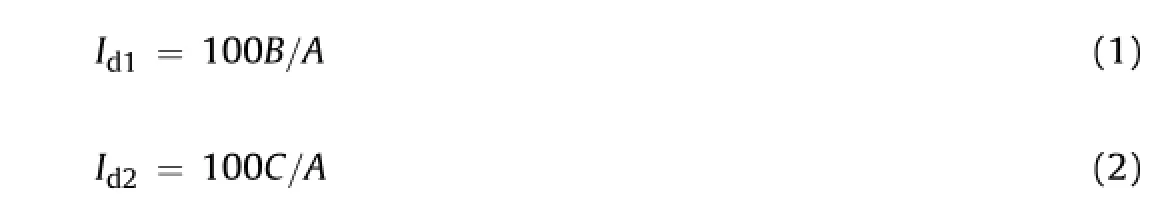

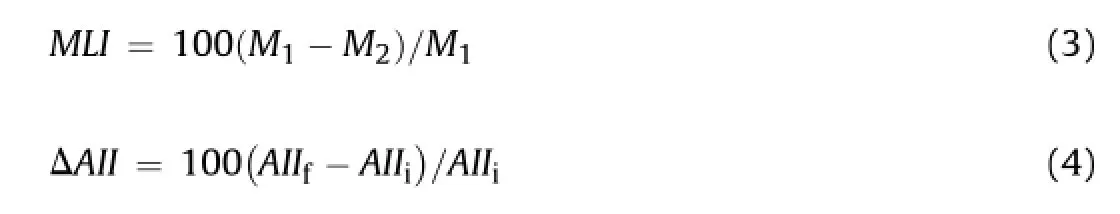

The slake durability indexes(Id1and Id2)were de fi ned with following equations suggested by ISRM(2007):

where A,B and C are the dry masses of specimens before slake durability test,after the fi rst and second cycles,respectively.

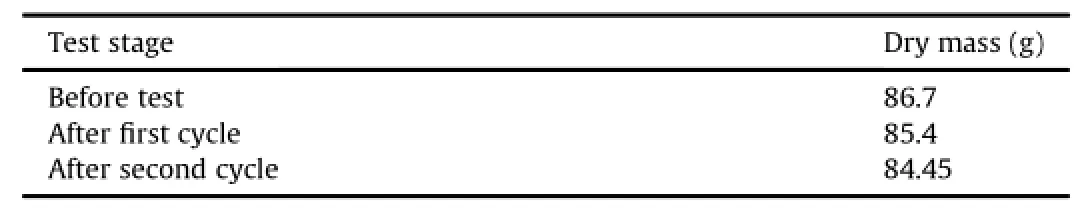

As seen in Table 3,1.3 g and 0.95 g of the PRS specimen were respectively lost after the fi rstand second cycles.Therefore,the fi rst slake durability index(Id1)and second slake durability index(Id2) were respectively determined as 98.5%and 97.4%,which means PRS is in the high slake durability class according to Table 4(ISRM, 2007).

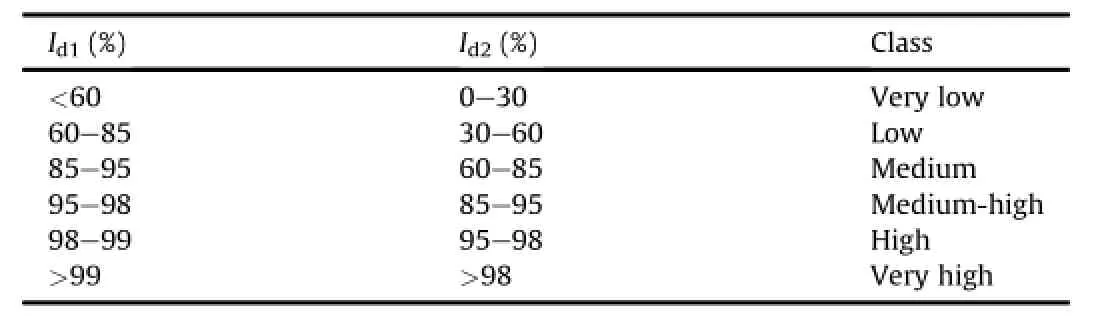

Mass loss index(MLI)for freezing-thawing specimens and decrease in impact resistance index(ΔAII)were calculated using the following equations suggested in Turkish standard TS EN 1097-2(2000):

where M1is the dry mass of freezing-thawing test specimens before the cabin process;M2is the dry mass of particles coarser than the sieve aperture ofhalfofminimumparticle size in the cabin after the freezing-thawing process;AIIiand AIIfare the aggregateimpact values of specimens before and after the freezing-thawing cycles,respectively,which can be calculated by(ISRM,2007):

Table 3 Dry masses of slake durability test specimens.

Table 4 Classi fi cation of rocks according to slake durability index.

where M-2.36is the mass of materialpassing the sieve aperture size of 2.36 mm,and Mtotalis the total specimen mass before applying aggregate impact value test.Freezing-thawing test data and aggregate impact value test data obtained from the experimental study are respectively listed in Tables 5 and 6.

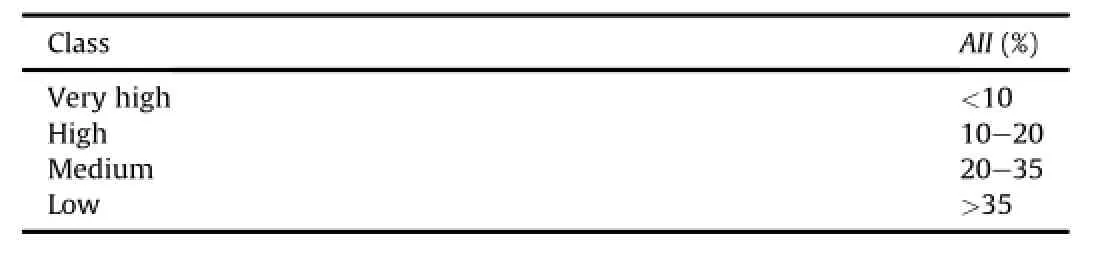

As seen fromthe test results,PRS has higher impact resistance in comparison with many of rock specimens before freezing-thawing.Even though decrease in impact resistance of PRS was higher than those of many of the rocks tested after freezing-thawing,PRS was competitive with rock materials with high impact values.According to the classi fi cation in the Turkish standard TS EN 1097-2 (Table 7),PRS material was assessed to be in classes of very high and high impact resistances before and after the freezing-thawing cycles,respectively.

The ratio of volume loss to friction surface area was calculated as the Bohme surface abrasion value.Test data obtained from the abrasion testare listed in Table 8.According to Turkish standards TS 2513(1977),TS EN 10449(2004)and TS EN 14157(2005),natural stones must respectively have Bohme abrasion values smaller than25 cm3/50 cm2,15 cm3/50 cm2and 10 cm3/50 cm2to be used for wall plating,fl oor covering and applications of road parquet or bordure in motorways.It can be concluded from the Bohme abrasion value of 18 cm3/50 cm2that PRS should not be used in the applications that high abrasion resistance is needed for.Nevertheless,PRS can be assessed as a rock-class material in terms of its resistance against abrasive forces.

Table 6 Data obtained from aggregate impact value test.

Table 7 Classi fi cation ofrocks according to aggregate impact value.

Table 8 Bohme abrasion test data for PRS specimens.

Polyurethane usage amount was 0.08 g/cm3for the UCS specimens of PRS with the ratio of polyurethane to soil of 1/8.As the price of a kilogram of polyurethane foam product used in the experimental study is 2 US dollars,the material cost can be considered as 160 US dollars per m3.

4.Conclusions

In this study,polyurethane foam was found to be a convenient binder to make a materialwith light density and rock-class strength mixing with the silt type soil.However,it should be noted herein that the PRS materialwas assessed to be in the class oflow-strength rock materials.According to the experimental analyses,the PRS material has good slake durability and resistivity against impact effect.Especially,impact resistance of PRS was better than those of many other rocks assessed to be in desirable classes.The abrasion resistance and freezing-thawing resistance of the PRS material were con fi rmed to reach a good rock class level.In contrast to the other properties,an important difference between the natural rocks and the PRS was found in unit volume weight which is quite low for the PRS.

Con fl ict of interest

The authors con fi rm that there are no known con fl icts of interest associated with this publication and there has been no signi fi cant fi nancial support for this work that could have in fl uenced its outcome.

BASF.Solutions for tunneling and mining injections(Broschure of injection products).Zurich,Switzerland:BASF;2009.

Bayer O.Das di-isocyanat-polyadditionsverfahren(polyurethane).Angewandte Chemie 1947;59(9):257-72(in German).

Bilir MH.Investigation ofthe adsorption ofthe safranin and remazolbrillant blue R with polyurethane type foam produced from peanut shell.MS Thesis.Kilis, Turkey:Kilis University;2009.

Bomberg MT,Lstiburek JW.Spray polyurethane foam in external envelopes of buildings.CRC Press;1998.

Gao NZ,Jia RG,Wang JY.Research on protection of ancient sites fl oor tiles in the Mogoa Grottoes.In:Proceedings of Conservation of Ancient Sites on the Silk Road,Dunhuang,China;1993.p.120-6.

Guan SW,Liu D,Moreno M,Garneau R.100%solids rigid polyurethane coatings technology for corrosion protection ofballast tanks.In:CORROSION 2004,New Orleans,Louisiana,USA;2004.p.1-13.

Guo A,Jauni I,Petrovic Z.Rigid polyurethane foams based on soybean oil.Journal of Applied Polymer Science 1999;77(2):467-73.

Han DS,Park I,Kim M,Noh B,Kim W,Lee J.The effects of glass fi ber reinforcement on the mechanical behavior of polyurethane foam.Journal of Mechanical Science and Technology 2010;24(1):263-6.

ISRM.The blue book-the complete ISRM suggested methods for rock characterisation,testing and monitoring:1974-2006.In:Ulusay R,Hudson JA,editors. Ankara,Turkey:ISRM and Turkish National Group of ISRM;2007.

ISRM.The orange book-the ISRM suggested methods for rock characterization, testing and monitoring:2007-2014.Springer;2014.

Komurlu E,Kesimal A.Improved performance of rock bolts using sprayed polyurea coating.Rock Mechanics and Rock Engineering 2014.http://dx.doi.org/10.1007/ s00603-014-0696-4.

Komurlu E,Kesimal A.Investigation of polyurethane reinforced soil strength.In: Proceedings of the 14th National Soil Mechanics and Foundation Engineering Congress of Turkey,Isparta,Turkey;2012.p.631-42.

Komurlu E,Kesimal A.New engineering materials for underground constructions. In:Proceedings of the 16th International Metallurgy and Materials Congress, Istanbul,Turkey;2012.p.307-19.

Komurlu E,Kesimal A.Tunneling and support materials from past to present.The Journal of the Chamber of Mining Engineers of Turkey 2013;52:33-47.

Komurlu E,Kesimal A.Using sprayed polymer as tunnelsupport.In:Proceedings of the 7th Asian Rock Mechanics Symposium,Seoul,South Korea;2012.p.1486-99.

Komurlu E,Toptas S.Investigation about durability of steep foundations excavated in urban places.Mining Turkey Scienti fi c Journal of Underground Resources 2012;1:13-57.

Komurlu E.Effects of rock and granular material horizontal stresses on support design.MS Thesis.Trabzon,Turkey:Karadeniz Technical University;2012.

Li J,Song F,Kang H.Experimental research on major properties of the sealant to control toxic and harmful gases leakage in coal mine.In:Progress in Mine Safety Science and Engineering,II.Beijing,China:CRC Press;2014.

Li S,Vatanparast R,Lemmetyinen H.Cross-linking kinetics and swelling behaviour of aliphatic polyurethane.Polymer 2000;41(15):5571-6.

Muynck WD,Belie ND,Verstraete W.Effectiveness of admixtures,surface treatments and antimicrobial compounds against biogenic sulfuric acid corrosion of concrete.Cement and Concrete Composites 2009;31(3):163-70.

TS 2513.Natural building stones.Ankara,Turkey:Turkish Standards Institution; 1977.

TS EN 10449.Marble-calcium carbonate based-used for building and facing amendment 1.Ankara,Turkey:Turkish Standards Institution;2004.

TS EN 1097-2.Tests for mechanicaland physicalproperties ofaggregates-part 2: methods for the determination of resistance to fragmentation.Ankara,Turkey: Turkish Standards Institution;2000.

TS EN 1367-1.Tests for thermaland weathering properties of aggregates-part 1: determination of resistance to freezing and thawing.Ankara,Turkey:Turkish Standards Institution;2008.

TS EN 14157.Natural stone-determination of the abrasion resistance.Ankara, Turkey:Turkish Standards Institution;2005.

Witkiewicz W,Zieli'nski A.Properties of the polyurethane(PU)light foams.Advances in Materials Science 2006;6(2):35-51.

Yilmaz H.Comparison of tensile-bond strength of thin spray-on liners.International Journal of Mining,Reclamation and Environment 2013;27(1):56-71.

Eren Komurluobtained the Bachelor and M.Sc.degrees from Hacettepe University in 2010 and Karadeniz Technical University in 2012,respectively.He is now a Ph.D. candidate and working as a research assistant at Karadeniz Technical University as well.He visited School of Civil Engineering at the University of Queensland between 2014 and 2015 as a visiting researcher for a year.He authored or co-authored more than 30 scienti fi c papers and reports. He is a member of International Society for Rock Mechanics(ISRM),Turkish National Society for Rock Mechanics,and Chamber of Mining Engineers of Turkey.His research interests cover rock mechanics,instability problems in underground mining,tunneling and support design.

*Corresponding author.Tel.:+90 462 3774297.

E-mail address:ekomurlu@ktu.edu.tr(E.Komurlu).

Peer review under responsibility of Institute of Rock and Soil Mechanics, Chinese Academy of Sciences.

1674-7755?2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.05.004

Journal of Rock Mechanics and Geotechnical Engineering2015年5期

Journal of Rock Mechanics and Geotechnical Engineering2015年5期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Microseismic monitoring and numerical simulation on the stability of high-steep rock slopes in hydropower engineering

- Slope mass rating and kinematic analysis of slopes along the national highway-58 near Jonk,Rishikesh,India

- Investigation of meso-failure behaviors of Jinping marble using SEM with bending loading system

- Regressive approach for predicting bearing capacity of bored piles from cone penetration test data

- Prediction ofroadheaders’performance using arti fi cialneuralnetwork approaches(MLP and KOSFM)

- Computing in-situ strength of rock masses based upon RQD and modi fi ed joint factor:Using pressure and damage sensitive constitutive relationship