Filtering Surface Water with a Polyurethane-based Hollow Fiber Membrane: Effects of Operating Pressure on Membrane Fouling*

ZHAO Xuehui (趙學輝), ZHANG Hongwei (張宏偉)** and WANG Jie (王捷)Key Laboratory of Hollow Fiber Membrane Materials and Membrane Process, Ministry of Education, Tianjin Polytechnic University, Tianjin 300387, China

Filtering Surface Water with a Polyurethane-based Hollow Fiber Membrane: Effects of Operating Pressure on Membrane Fouling*

ZHAO Xuehui (趙學輝), ZHANG Hongwei (張宏偉)** and WANG Jie (王捷)

Key Laboratory of Hollow Fiber Membrane Materials and Membrane Process, Ministry of Education, Tianjin Polytechnic University, Tianjin 300387, China

Membrane fouling seriously restricts applications of membrane technology. A novel strategy was applied in this study to retard membrane fouling by changing operating pressure with the pressure responsibility membrane. A polyurethane-based hollow fiber membrane was used to treat surface water for evaluating the effect of operating pressure on membrane fouling. Some bench-scale tests in dead-end mode were carried out. In the experiments without backwashing, as operating pressure increased, severe membrane fouling occurred on membrane surface, while the permeate quality was improved obviously, which is considered to be due to shrinkage deformation. The total resistance, irreversible resistance and reversible resistance under different backwash pressures were determined in filtration/backwashing test. With the increase of backwash pressure, the total resistance decreased, and more importantly, the irreversible resistance also decreased, which implies that small particles deposited inside membrane pores and cake layers on membrane surface are effectively removed. Similar results could be obtained in mass balance tests. The results of the present study indicate that the application of pressure responsibility membrane in surface water treatment may be an effective strategy for reducing membrane fouling.

membrane fouling, surface water treatment, pressure responsibility

1 INTRODUCTION

Membrane technology, as an effective method to remove particles, colloidal species, bacteria and virus in surface and ground water, has received considerable attentions. The critical problem in its successful application for drinking water treatment is membrane fouling [1, 2], which negatively affects productivity, product quality and process costs. In general, membrane fouling is classified into two kinds: reversible fouling and irreversible fouling. Reversible fouling can be removed by periodic backwashing, while irreversible fouling evolves even with periodical backwashing. It is reported that the causes of irreversible fouling are surface fouling by formation of gel layers on the membrane surface and pore fouling by partial blocking of the membrane due to small particles and adsorption of molecules on the pore surface [3]. Therefore, reducing or controlling the matter deposited on membrane surface and adsorbed on pore surface is very important for solving the membrane fouling problem. Dong et al. [4] and Katsuki et al. [5] reported that acidic condition could decrease contaminant size and enhance the adsorption onto membrane, resulting in significant irreversible fouling. Katsoufidou et al. [6], Hao et al. [7], and Paulavanden et al. [8] also indicated that controlling the concentration of metal ions such as Ca2+and Fe3+was important for mitigating irreversible fouling. Furthermore, some researchers [9-12] indicated that pretreatment methods, including coagulation, adsorption and pre-oxidation, could partially remove suspended solids, colloidal particles and natural organic matters and effectively alleviate the membrane fouling. However, all these methods need chemical reagents, which greatly increase the operating cost.

The properties of smart membrane can be changed according to external environmental stimulation [13], such as temperature, pH, substance concentration, operating pressure, etc. Polyurethane-based hollow fiber membrane is a smart membrane, whose pores can be changed with operating pressure, named pressure responsibility membrane. The pressure responsibility of membrane means that the pores on membrane surface can be changed with operation pressure in a separation system. Therefore, pressure responsibility membrane can separate different substances by varying operating pressure towards its varying pore size. Meanwhile, when a membrane is fouled during working, the foulant can be easily eliminated by enlarging its pore size. Liang et al. [14] and Hu et al. [15] prepared polyurethane-based hollow fiber membranes, whose pore sizes on membrane surface can be adjusted by changing operating pressure. Liu et al. [16] and Liu et al. [17] investigated the effects of post-treatment on morphology and performance of polyurethane-based hollow fiber membrane. Most of the previous researches about pressure responsibility membrane have focused on the membrane structure and property, while its application to alleviating membrane fouling in drinking water treatment is rarely reported.

The purpose of this study is to investigate the mechanism how the pressure responsibility membrane effectively alleviates the membrane fouling. The emphasis is on the effect of operating pressure on the evolution of membrane fouling and on the removal of contaminant deposition on the membrane surface. For this purpose, a polyurethane-based hollow fibre membrane with the property of pressure responsibility istested with surface water in a lab-scale apparatus.

2 THEORETICAL MODEL

2.1 Membrane filtration resistance model

Generally, the membrane permeability is associated with three resistances: membrane hydraulic resistance (Rm), reversible resistance (Rc) and irreversible resistance (Rn). The resistance in series model is employed to describe the filtration resistance (Rt),

Rccan be obtained by the resistance difference between the end of filtration and the initial filtration in next cycle. Rnis obtained by the difference in the initial resistance between adjacent filtration cycles. Rc/Rmand Rn/Rmcan be expressed as

where Jeis the end flux of filtration and Jiis the initial filtration flux in next cycle.

2.2 Mass balance model

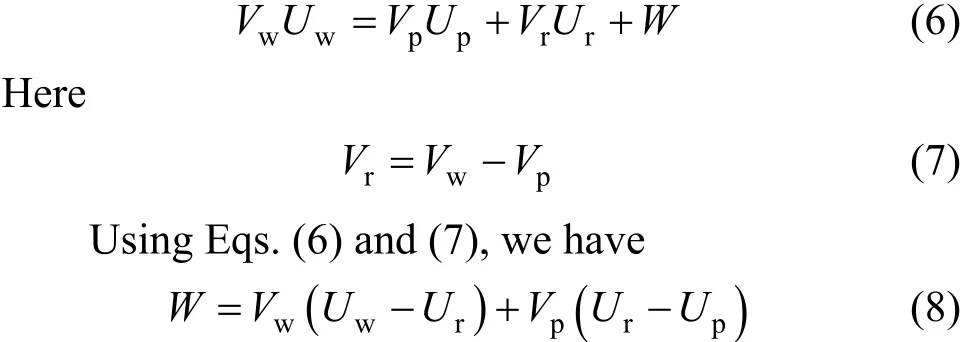

In this study, UV254is used to indicate organic foulant. Remize et al. [18] reported that mass balance method could precisely estimate backwash efficiency, which is used to evaluate the backwash efficiency under different backwash pressures. According to the rule of mass conservation, we have

where Vwis raw water volume, Vris residual water volume, Vpis permeate volume, Vbis backwash drain water volume, Ubis the UV254concentration of backwash drain water, Upis the UV254concentration of permeate, Uris the UV254concentration of residual water, Uwis the UV254concentration of raw water, and W stands for the amount of foulant accumulated on membrane surface after filtration.

3 MATERIALS AND METHODS

3.1 Materials

3.1.1 Feed water

The source water used in this work was the surface water taken from a drinking water treatment plant, the characteristic parameters of the surface water were as follows: pH=7.2-7.9, turbidity=1.45-3.23 NTU, UV254=0.148-0.226 mg·L?1, and temperature= 13-24 °C.

3.1.2 Membrane

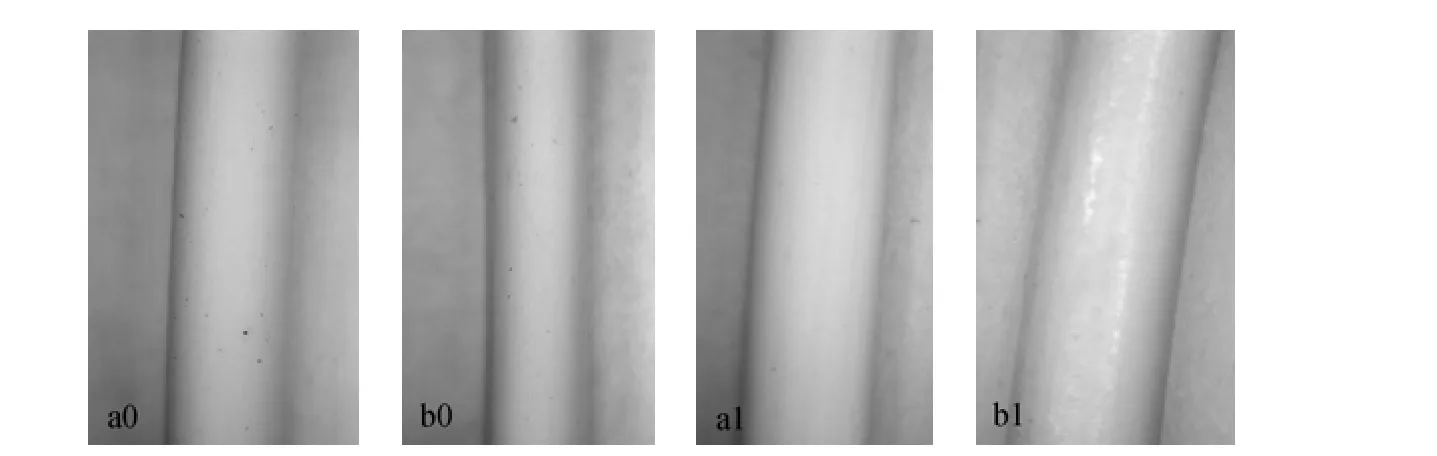

The polyurethane-based hollow fiber membrane with the property of pressure responsibility was used. The fiber has an internal diameter of 0.8 mm, an outer diameter of 1.8 mm, and a length of 10 cm. Fig. 1 shows the morphology of the membrane. The crosssection morphology exhibits a sponge-like structure. Outer and inner surfaces of the membrane present significantly different morphology. The scanning electron microscope (SEM) image of inner surface reveals a relatively high porosity and big pores, while no obvious pore is found on the outer surface with the magnification of 1000.

3.2 Methods

3.2.1 Filtration experiment

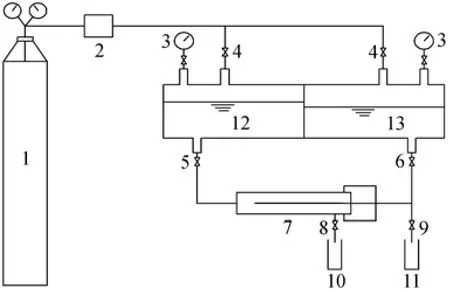

The filtration experiment was performed in our laboratory and the schematic diagram of experimental apparatus is presented in Fig. 2. Nitrogen gas was used to provide required operating pressure. All experiments were carried out in the dead-end mode. Before each experiment, the apparatus was thoroughly washed with distilled water. Prior to filtration, new fiber was immersed in distilled water at least for 24 h to remove coating and wetting agents from the membrane and then the clean water flux (J0) was measured in each experiment. During the filtration, permeate was collected by measuring the content in the cylinder and the filtration time was recorded by stopwatch. The filtration experiment mainly includes following aspects.

(1) To investigate the pressure responsibility of polyurethane-based hollow fiber membrane, pure waterflux (J0) was measured at different pressures with outside-in and inside-out mode.

(2) Filtration experiments without backwashing were performed in the bench-scale apparatus. The surface water was forced to permeate from the outside to inside of the membrane for 60 min at the filtration pressures of 0.03, 0.04, 0.05 and 0.06 MPa. After filtration, the turbidity and UV254of permeate ware measured. The ratio of fluxes J/J0, measured every 10 min for filtration (J), was used for comparison.

(3) Filtration/backwashing experiments were performed in the same apparatus. Each experiment was operated at a constant pressure of 0.03 MPa with outside-in mode. Each experiment consisted of four cycles of filtration, with each cycle for 30 min and followed by backwashing for 1 min. The flux recovery was investigated under backwashing pressure of 0.04, 0.05, 0.06 and 0.07 MPa. The ratio of fluxes (J/J0) was measured at an interval of 10 min.

(4) The mass balance experiment was carried out at a fixed filtration pressure of 0.03 MPa with dead-end mode, each for 60 min. The surface water passed through the membrane from its outside surface to inside surface and the permeate was collected for analysis. After the filtration, one hydraulic backwash was carried out and the backwash pressure was set at 0.03, 0.04, 0.05 and 0.06 MPa. The backwash drain water was also collected for analysis.

3.2.2 Analytical methods

A Quanta 200 scanning electron microscope (FEI, Netherlands) was used to investigate the surface and cross-section morphology of the membrane. A CCD camera (MLM3XMP-CCD, Dongguan, China) was used to take photos for the membrane. UV absorbance at 254 nm of the samples was measured by a spectrophotometer (UV-2450, Shimadzu, Japan). Turbidity was determined using a turbidimeter (2100N, Hach, America).

Figure 1 The morphology of polyurethane-based hollow fiber membrane(a) partial enlargement of cross section, ×400; (b) outer surface, ×1000; (c) inner surface, ×1000

Figure 2 Schematics of the experimental set-up1—nitrogen gas; 2—regulation valve; 3—pressure gauge; 4—intake valve; 5—feed water valve; 6—backwash valve; 7—membrane module; 8—backwash water drain valve; 9—permeate valve; 10, 11—measuring cylinder; 12—feed water tank; 13—backwash water tank

4 RESULTS AND DISCUSSION

4.1 Membrane pressure responsibility

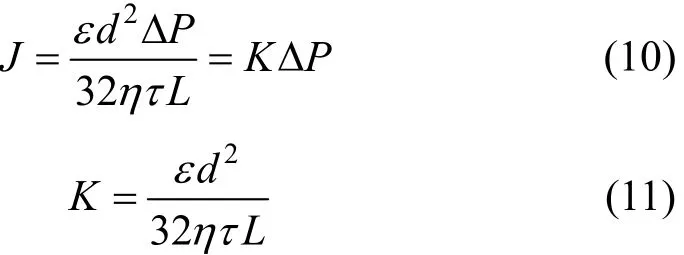

In order to examine the pressure responsibility of the polyurethane-based hollow fiber membrane, the pure water flux (J0) was measured under different pressures with outside-in and inside-out modes separately. The pure water flux of membrane is usually described by Hagen-Poiseuille equation [19] and is a linear relationship with trans-membrane pressure (TMP).

where ε is the surface porosity, d is the diameter of pore, η is the viscosity, τ is the tortuosity of pore, L is the membrane thickness, and ΔP is the trans-membrane pressure.

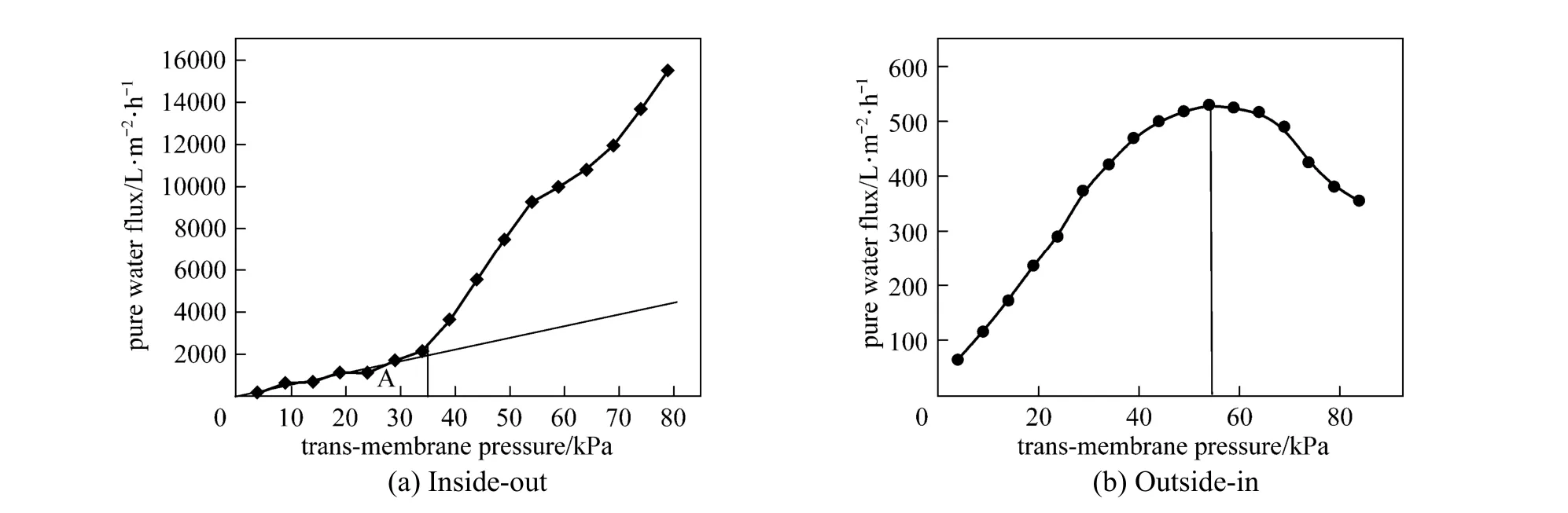

Figure 3 shows the pure water flux as a function of TMP. With the inside-out mode, the flux increases with TMP, increasing slowly in a low pressure range from 0 to 0.035 MPa and then dramatically at pressures higher than 0.035 MPa. This behavior could be explained as follows. At low operating pressures, pore diameter (d) and wall thickness (L) of membrane are almost constant. According to Eqs. (10) and (11), the flux is related to TMP only and increases slowly. At higher operating pressures, expansive deformation [Fig. 4 (b1)] occurs on membrane surface, increasingthe pore size and thinness of membrane wall. Accordingly, the flux increases in addition to that resulted from TMP. Thus the polyurethane-based hollow fiber membrane presents pressure responsibility at higher pressure. In the outside-in mode, the membrane flux increases initially and then decreases as operating pressure increases. An inflection point appears (0.054 MPa), which could be explained by contraction deformation [Fig. 4 (b0)] on the polyurethane-based hollow fiber membrane surface at higher operating pressure. This deformation could result in the shrinkage of pore and the decrease of lumen, increasing membrane resistance (Rm). According to Eq. (2), when the effect of membrane resistance (Rm) on pure flux (J0) is larger than the effect of operating pressure, the flux will decrease as operation pressure increases. Moreover, with different porosity on outside and inside surfaces of the membrane, the pure water fluxes are different.

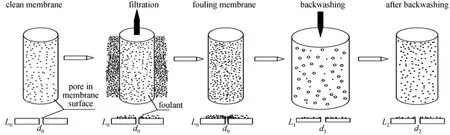

Compared to traditional membrane filtration, an evident difference is that the pressure responsibility membrane produces expansive deformation in a hydraulic backwash. Fig. 5 shows the working schematic diagram of pressure responsibility membrane. The hydraulic backwash results in expansive deformation, increasing pore size on membrane surface, so that the deposition in membrane pores and pore-blocking by small particles could be removed to a great degree. As a consequence, the application of pressure responsibility membrane is an effective strategy to reduce membrane fouling.

Figure 3 Variations of pure water flux with TMP

Figure 4 Deformation of pressure responsibility membrane (a0) raw membrane; (b0) contraction deformation (0.04 MPa); (a1) raw membrane; (b1) expansive deformation (0.05 MPa)

Figure 5 The working schematic diagram of pressure responsibility membrane

4.2 Effect of operating pressure on membrane fouling

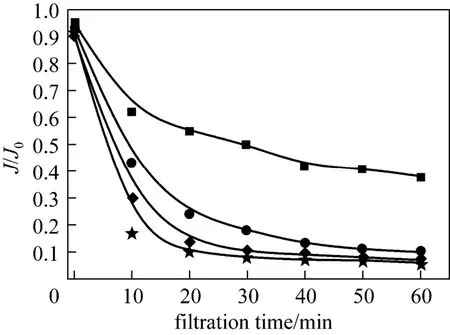

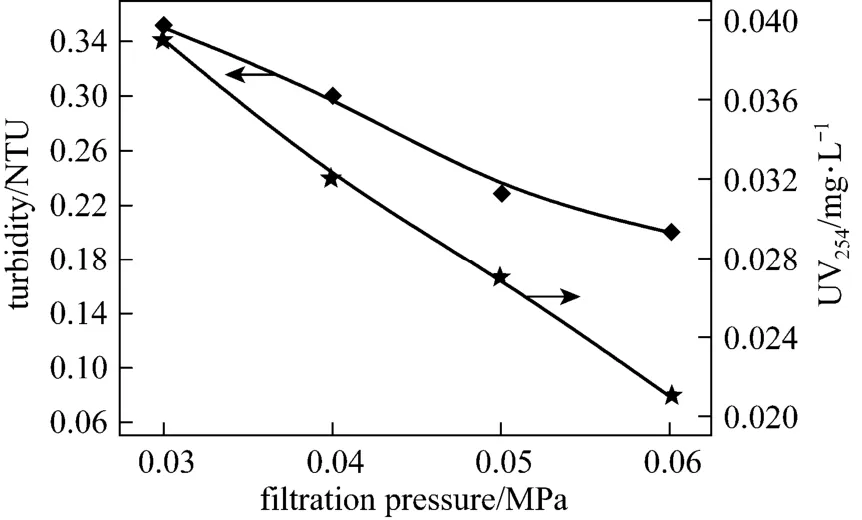

In order to investigate the effects of operatingpressure on membrane fouling, some bench-scale tests without backwashing in dead-end mode were performed. The relative permeability (J/J0) is used as the indicator of membrane fouling. Fig. 6 shows the decrease of relative permeability during the outside-in filtration of surface water under different operating pressures. The relative permeability attenuated quickly at the beginning of filtration and reached 0.62, 0.43, 0.3 and 0.19 after 10 min under operating pressures of 0.03, 0.04, 0.05 and 0.06 MPa, respectively. With 60 min filtration, the membrane flux under 0.03 MPa lost about 60% of the initial permeability, while more than 85% of the initial permeability was lost at other operating pressures. Thus the increase of operating pressure accelerates membrane fouling. Fig. 7 represents the variation of permeate quality under different operating pressures. The effect is significant. The turbidity and UV254under 0.03 MPa were 0.35 NTU and 0.039 mg·L?1, respectively, but decreased to 0.20 NTU and 0.021 mg·L?1under 0.06 MPa, indicating that the increase of operating pressure improves the permeate quality. These results could be attributed to the contraction deformation [Fig. 4 (b0)], with better rejection of foulant on membrane surface.

Figure 6 Variation of J/J0at different operating pressures filtration pressure/MPa: ■ 0.03; ● 0.04; ◆ 0.05; ★ 0.06

Figure 7 Variations of permeate turbidity and UV254at different operating pressures

4.3 Effect of backwash pressure on membrane foulings

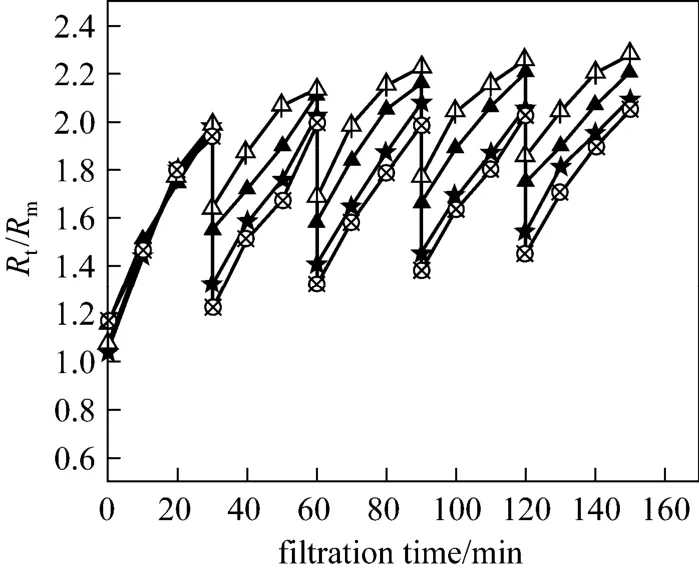

To understand the mechanism of mitigating membrane fouling for pressure responsibility membrane, dead-end filtration of surface water using the polyurethane-based hollow fiber membrane was carried out with periodic backwashing. Fig. 8 shows the variation of total resistance as a function of time under different backwash pressures, with outside-in mode performed at 0.03 MPa and the backwash pressure ranged from 0.04 MPa to 0.07 MPa. As expected, the total resistance Rt/Rmdecreased rapidly with the increase of backwash pressure. The value of Rt/Rmwas about 2.0 with the filtration of 30 min and decreased to 1.65, 1.55, 1.3 and 1.2 after backwashing at 0.04, 0.05, 0.06 and 0.07 MPa, respectively. After 150 min filtration, the total resistance increment at backwash pressure of 0.07 MPa was less than that at other backwash pressures. These results suggest that increase of backwash pressure could reduce membrane fouling.

Figure 8 Variations of total filtration resistance at different backwash pressures (operating pressure: 0.03 MPa)

Usually, irreversible fouling is considered as the main cause for the deterioration of membrane performance. How to control the evolution of irreversible fouling is a key for maintaining desired membrane performance. It is reported that the removal of small size substance deposited in membrane pores and cake layer formed on membrane surface is very important for controlling irreversible fouling. Fig. 9 shows the effects of backwash pressure on irreversible resistance. The value of Rn/Rmat backwash pressure of 0.04, 0.05, 0.06 and 0.07 MPa increased from 0.65, 0.55, 0.32 and 0.21 at 30 min of filtration time to 0.85, 0.75, 0.54 and 0.40 at 120 min of filtration time. The irreversible fouling reduces as backwash pressure increases. The variation of reversible resistance under different backwash pressures is presented in Fig. 10. The Rc/Rmpercentage of total resistance at backwash pressure of 0.07 MPa is distinctly higher than that at other backwash pressures. As the backwash pressure increases, the expansive deformation [Fig. 4 (b1)] occurs, which results in the crack and loose of dense cake layer and the increase of pore size on membrane surface, which is the reason that irreversible resistance decreases and reversible resistance increases with the increase of backwash pressure. Therefore, the irreversible fouling on membrane surface could be partly transformed into reversible fouling and removed with pressure responsibility membrane by increasing backwash pressure.

Figure 9 Variations of irreversible resistance at different backwash pressures (operating pressure: 0.03 MPa) backwash pressure/MPa: ■ 0.04; ● 0.05; ▲ 0.06; ★ 0.07

Figure 10 Variations of reversible resistance at different backwash pressures (operating pressure: 0.03 MPa) backwash pressure/MPa: ■ 0.04; ● 0.05; ▲ 0.06; ★ 0.07

4.4 Backwash efficiency by the mass balance method

Figure 11 presents the backwash efficiency under different backwash pressures. The amount of foulant deposition on membrane surface decreased almost 50% as backwash pressure increased from 0.03 MPa to 0.06 MPa. More foulant on membrane surface could be removed efficiently with the increase of backwash pressure, which is consistent with the result in the filtration/backwashing test.

Figure 11 Variations of backwash efficiency at different backwash pressures

5 CONCLUSIONS

In the bench-scale tests using a polyurethane-based hollow fiber membrane to filter surface water to investigate the effect of operating pressure on the membrane fouling, it is revealed that the operating pressure has an important influence on the evolution of membrane fouling in different filtration modes. The experimental results without backwashing and with outside-in mode indicate that increment of operating pressure accelerates membrane fouling, while significantly improves the permeate quality, which could be attributed to contraction deformation and enhancement of rejection of foulant on the membrane surface. The total resistance, irreversible resistance and reversible resistance determined in the filtration/backwashing test suggest that as backwash pressure increases, the total resistance and especially irreversible resistance decrease, implying that the foulant deposited on membrane surface and in membrane pores could be swept away effectively. The determination of backwash efficiency also proves that increment of backwash pressure is benefit to removal of foulant. This is considered to be due to expansive deformation, enlarging the pore and loosening the cake on membrane surface. Therefore, the present study provides a simple and effective approach to mitigate membrane fouling.

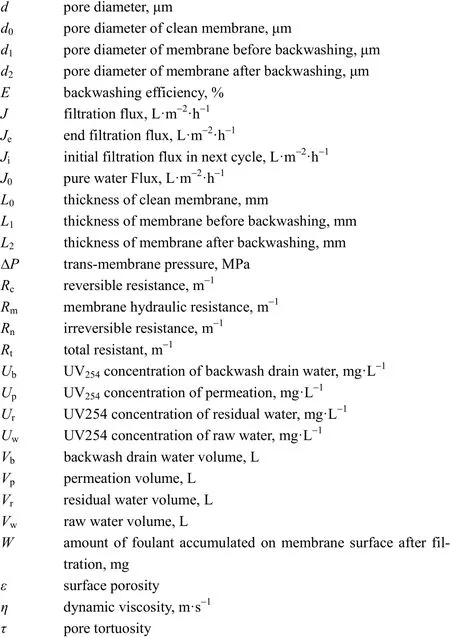

NOMENCLATURE

REFERENCES

1 Amy, G., “Fundamental understanding of organic matter fouling of membranes”, Desalination, 23,144-511 (2008).

2 Gao, W., Liang, H., Ma, J., “Membrane fouling control in ultrafiltration technology for drinking water production: A review”, Desalination, 272, 1-8 (2011).

3 Katsoufidou, K., Yiantsios, S.G., Karabelas, A.J., “Experimental study of ultrafiltration membrane fouling by sodium alginate and flux recovery by backwashing”, J. Membr. Sci., 300, 137-146 (2007).

4 Dong, B.Z., Chen, Y., Gao, N.Y., Fan, J.C., “Effect of pH on UF membrane fouling”, Desalination, 195, 201-208 (2006).

5 Katsuki, K., Tomohiro, M., Hiroshi, Y., Yoshimasa, W., “Irreversible membrane fouling in microfiltration membranes filtering coagulated surface water”, J. Membr. Sci., 320, 356-362 (2008).

6 Katsoufidou, K., Yiantsios, S.G., Karabelas, A.J., “A study of ultrafiltration membrane fouling by humic acids and flux recovery by backwashing: Experiments and modeling”, J. Membr. Sci., 266, 40-50 (2005).

7 Yan, H., Akihito, M., Tatsuo, M., “Effect of metal ions on humic acid fouling of hollow fiber ultrafiltration membrane”, J. Membr. Sci., 376, 247-253 (2011).

8 Paulavanden, B., Arie, Z., Geo, S., “Effect of free calcium concentration and ionic strength on alginate fouling in cross-flow membrane filtration”, J. Membr. Sci., 345, 207-216 (2009).

9 Wolfgang, N., Steffen, V., Mathias, E., Martin, J., “Lab and pilot scale investigation on membrane fouling during the ultrafiltration of surface water”, Desalination, 250, 968-972 (2010).

10 Chihpin, H., Jr-Lin, L., Wen-Shan, L., “Effect of coagulation mechanism on membrane permeability in coagulation-assisted microfiltration for spent filter backwash water recycling”, Colloids and Surfaces A: Physicochemical and Engineering Aspect, 378, 72-78 (2011).

11 Xu, W.Y., Gao, B.Y., Mao, R.R., “Influence of floc size and structure on membrane fouling in coagulation-ultrafiltration hybrid process-the role of Al13 species”, J. Hazard. Mater., 93, 249-256 (2011).

12 Gao, W., Liang, H., Ma, J., Han, M., Chen, Z.L., Han, Z.S., Li, G.B.,“Membrane fouling control in ultrafiltration technology for drinking water production: A review”, Desalination, 272, 1-8 (2011).

13 Chu, L.Y., Xie, R., Ju, X.J., “Stimuli-responsive membranes: smart tools for controllable mass-transfer and separation processes”, Chin. J. Chem. Eng., 19, 891-903 (2011).

14 Liang, H.X., Xiao, C.F., Hu, X.Y., “Pressure-responsibility of melt-spinning polyurethane based hollow fiber membranes”, Polym. Mater. Sci. Eng., 12, 130-133 (2008).

15 Hu, X.Y., Xiao, C.F., An, S.L., “Structure and properties of polyurethane/polyvinylidene difluoride blending hollow fiber”, Journal of Donghua University, 5, 76-79 (2006).

16 Liu, M.T., Xiao, C.F., Hu, X.Y., “Optimization of polyurethane-based hollow fiber membranes morphology and performance by post-treatment methods”, Desalination, 275, 133-140 (2011).

17 Liu, H.L., Xiao, C.F., Hu, X.Y., Liu, M.T., “Post-treatment effect on morphology and performance of polyurethane-based hollow fiber membranes through melt-spinning method”, J. Membr. Sci., 427, 326-335 (2013).

18 Remize, P.J., Guigui, C., Cabassud, C., “Evaluation of backwash efficiency, definition of remaining fouling and characterization of its contribution in irreversible fouling: Case of drinking water production by air-assisted ultra-filtration”, J. Membr. Sci., 355,104-111 (2010).

19 Zhao, C.S., Zhou, X.S., Yue, Y.L., “Determination of pore size and pore size distribution on the surface of hollow-fiber membranes: a review of methods”, Desalination, 129, 107-123 (2000).

2013-03-18, accepted 2013-09-27.

* Supported by the National Natural Science Foundation of China (51078264, 51108314, 51108315, 51138008).

** To whom correspondence should be addressed. E-mail: zhanghw@tjpu.edu.cn

Chinese Journal of Chemical Engineering2014年5期

Chinese Journal of Chemical Engineering2014年5期

- Chinese Journal of Chemical Engineering的其它文章

- Soft Sensor Model Derived from Wiener Model Structure: Modeling and Identification*

- Kinetics of Forward Extraction of Boric Acid from Salt Lake Brine by 2-Ethyl-1,3-hexanediol in Toluene Using Single Drop Technique*

- Influence of Solvent on Reaction Path to Synthesis of Methyl N-Phenyl Carbamate from Aniline, CO2and Methanol*

- Effect of Adsorbent Diameter on the Performance of Adsorption Refrigeration*

- High-Thermal Conductive Coating Used on Metal Heat Exchanger*

- A Facile Route for Synthesis of LiFePO4/C Cathode Material with Nano-sized Primary Particles*