Incident analyses of frost heaving failure of municipal underground gas pipelines in cold regions of northern China

YaMin Li , HongSheng Li , ZengLi Liu , LiShun Chen

1. College of Environmental Science & Engineering, Dalian Jiaotong University, Dalian, Liaoning 116028, China

2. Department of Engineering Mechanics, Dalian University of Technology, Dalian, Liaoning 116024, China

3. Dalian Municipal Fuel Gas Administration Department, Dalian, Liaoning 116021, China

Incident analyses of frost heaving failure of municipal underground gas pipelines in cold regions of northern China

YaMin Li1*, HongSheng Li2, ZengLi Liu2, LiShun Chen3

1. College of Environmental Science & Engineering, Dalian Jiaotong University, Dalian, Liaoning 116028, China

2. Department of Engineering Mechanics, Dalian University of Technology, Dalian, Liaoning 116024, China

3. Dalian Municipal Fuel Gas Administration Department, Dalian, Liaoning 116021, China

In the cold regions of northern China, incidents of municipal underground gas pipeline rupture and leakage occur quite frequently,most often in winter. To prevent harm to citizen safety and property, analysis of the causes of such cracking and leakage is therefore valuable. Two incident analyses are discussed here and the reasons why most of these types of cases occur during winter are clarified.The effects of vehicle loadings above buried pipelines are calculated and compared with the effects and calculations of frost heaving forces. We demonstrate that when the soil layer above a pipeline freezes rapidly, the soil generates repeated frost heaving, which exerts heaving forces on the pipeline that can result in fatigue crack propagation and ultimate pipeline failure. Therefore, the incident induced by frost heaving is one of the primary reasons of gas pipeline failure. Based on these analyses, we present some recommendations pertaining to the proper design, construction, and management of gas pipelines.

cold regions; underground gas pipeline; frost heaving failure; incident analysis

1. Introduction

Cracking of pipelines due to frost heave is a typical cause of freezing damage to engineering projects in cold regions. Many researches, utilizing both numerical modeling and physical experiments, have been conducted on how to solve this problem (Riseboroughet al., 1993; Shah and Razaqpur, 1993; White and Williams, 1993; Williams 1993; Foriero and Ladanyi, 1994; Li and Yang, 2000; Liet al., 2001).

Because municipal underground gas pipelines constitute long-term projects, their safe operation is crucial to the safety of life and property. In cold regions of northern China, incidents of underground gas pipeline cracks most often occur in winter. For example, one northern city suffered from several cases of underground gas pipeline cracking and leakage during the winter of 2002-2003, including some serious accidents that led to loss of life. Another example is an explosion ignited by leaks of an underground gas pipeline in a different northern city during the winter of 2003, inflicting serious hardships on population’s daily life. Accordingly, analysis of the causes of pipeline cracking and leakage during winter is of high value. Effective preventive actions can be taken only when the causes of cracking incidents are clearly identified,leading to a means of ensuring safe operation of pipelines and preventing serious accidents, thus diminishing losses of life and property.

This study analyzes two past cracking incidents that occurred on underground gas pipelines in cities in northern China and clarifies the reasons why these cases occurred during winter. Recommendations for some practical schemes and measures with respect to the design, construction, and management of pipelines are also presented.

2. Causes of underground gas pipeline cracking

Cracking damages to underground gas pipelines have complicated causes and result in a variety of damage types,but the ultimate damage is always pipe rupture and leakage.Common causes of pipe rupture and leakage fall into the following categories: defects in the pipe material, such as uneven deformation during cyclic heating and cooling, and impurities in the steel or other internal defects may lead to cracking and leakage; geometric deformation of the pipe,either during manufacture or placement, can lead to an elliptical shape which results in unevenly distributed stresses; the pipe can also experience metal loss due to corrosion, mechanical damage, delaminating, and/or disbanding; rupture failures can be attributed to cracking from fatigue, stress corrosion, or diminished wall thickness; and welding defects,including lack of weld penetration, slag inclusions, and perforation.

In addition to these intrinsic problems, external factors can also lead to pipeline failures. Problems may arise due to defective design of the pipeline system itself. If an underground gas pipeline must cross beneath municipal transportation corridors, adequate burial depths are necessary. When there is insufficient burial depth, the pipeline may be susceptible to fatigue damage inflicted by vehicle-generated load stresses. Appropriate bedding materials are required underneath the pipeline to ensure that the pipeline will not experience excessive external forces at fixed points of support. Inadequately designed support points can also subject the pipeline to excessive crushing or shearing forces. Also, improper subsequent construction projects can lead to pipeline failures.

With the onset of freezing temperatures, especially at the beginning of the winter season, gas pipelines frequently suffer cracking incidents due to frost heave shock, when the uppermost layer of soil above the pipeline freezes rapidly. If the depth of the freezing front approaches that of the buried pipeline, additional frost heaving forces will be developed and exerted on the pipeline, potentially inducing cracking.Cracking damage induced by frost heave is a typical mechanism of pipeline failure in cold regions, especially when non-uniform soil conditions exist along the pipeline corridor.Therefore, frost heaving should be taken into account during the pipeline system design process. The burial depth must exceed the local maximum freezing depth.

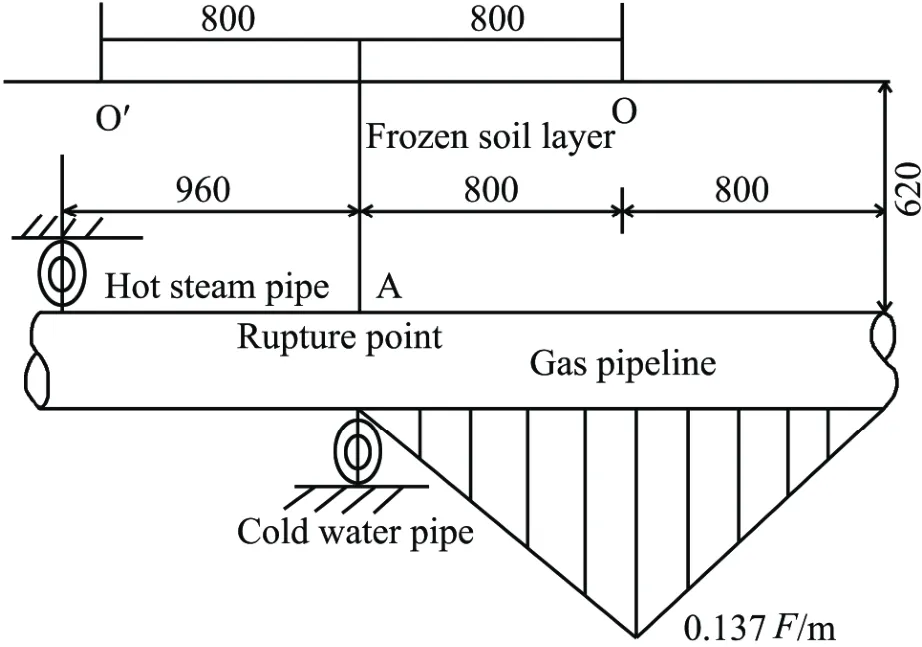

3. Incident analysis of a gas pipeline passing beneath a road

In mid-December of 2002, an incident of gas pipeline cracking occurred in a small city (population 5 million) in Liaoning Province of northern China. The cast iron pipeline was constructed in the 1980s and had been in use since then.As shown in Figure 1, the pipe had an outside diameter of 220 mm and an internal diameter of 200 mm. The burial depth of the pipeline was 620 mm and it passed beneath a residential area road, which was kept snow-free. On top of the pipeline, two hot steam pipelines intersected with the gas pipeline. On the outside of the hot stream ducts, a 50-mm layer of bound insulation had been installed to maintain the temperature of the hot stream. The gas pipeline was encased in a 250-mm-diameter steel sleeve as it passed through the heating duct. There was also a 150-mm-diameter cold water pipeline which was located just to the right side of and under the steel sleeve. The cold water pipe, as a hard support, was located beneath the pipeline rupture point as shown in Figure 1. The gas pipeline generally had intermediate pressure with a maximum operating pressure of less than 0.2 MPa.Meteorological data showed that this region was experiencing fairly extreme cold air temperatures one week prior to the incident, with a minimum temperature of -15 °C.

Figure 1 Diagram of the analyzed gas pipeline crossing beneath a utility corridor and a roadway, showing the location of the crack(all measurements are in mm)

When discovered, there was distinct evidence of fatigue cracking with a crack depth of 4-5 mm, as shown in Figure 2, indicating that damage had occurred over many years.Mechanical tests were performed to determine the material strength of the pipeline, and analysis and calculations were carried out to determine the mechanism of the pipe failure.The pipeline material was cast iron and exhibited an average tensile strength of 109 MPa.

Figure 2 Fatigue cracking of the ruptured pipeline section

3.1. Analysis of Vehicle Stress

Loads generated by moving vehicles on the road were transmitted to the pipeline, initiating stress inside the pipeline. However, the initiating point was not fixed. The worst initiating point was at the midpoint between the sets of vehicle tires, as shown in Figure 3. In Figure 3, O and O′ are the initiating points made by the sets of vehicle tires; each of them would support half of the vehicle load separately. The rupture was located near the midpoint between O and O′.The vehicle load on each tire was distributed on the pipeline in an approximate triangle form (Chen, 1990). The cold water pipe, as a hard support, was located beneath the pipeline rupture point. At about 960 mm above and to the left of the rupture point another hot steam pipe was located, in effect binding the gas pipeline.

Figure 3 The distribution of the vehicle load on the tires

The effects from these two pipelines on the gas pipeline can be simplified as an elastic foundation beam model with fixed points. Because the backfill soil beneath the gas pipeline was very loose, the elastic support was weak and thus can be neglected. The gas pipeline can be further simplified by considering it as a beam. Using the beam calculation equations,the stress of the gas pipeline can thus be calculated as:

whereMxis the bending moment of the gas pipeline section formed by vehicle load (MN·m);ymaxis the radius of the gas pipeline section (m); andJxis the inertia moment of the gas pipeline section (m4).

If the vehicle load isF(kN), thenMx=0.089F(kN·m)andymax=0.11 m,Jx=3.64×10-5m4. From Equation(1),σz=269F(kN/m2).

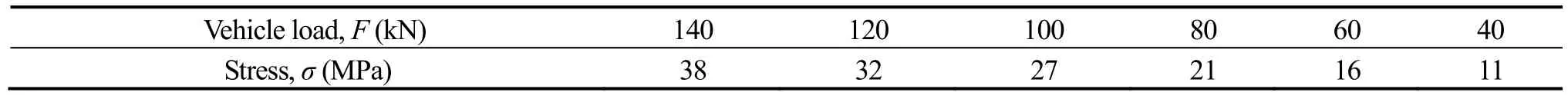

Therefore, once the loadFis known, the corresponding pipeline stress can be obtained as shown in Table 1.

Table 1 Stress produced by different vehicle loads

Tensile strength testing showed that the average strength of the cast iron pipe material was 109 MPa. This indicated that only vehicle loads greater than 400 kN would cause failure of the pipeline. Because this road was located within a residential district, heavy-duty truckloads greater than 400 kN were rare. Mainly small and intermediate-sized automobiles utilized this road and these vehicles, while not heavy enough to cause failure, could induce fatigue damage to the pipeline over time.

3.2. Analysis of Frost Heaving Stress

This is the result of observed and measured at the site.The frozen depth of soil was 0.62 m, and frost-heaving stress occurred on the pipeline because of the frozen soil.Below the unfrozen soil was liquid clay. According to the standards for construction of groundwork in frozen soil areas, Code for Design in Frozen Soil Region (JGJ118-98,1998), this soil was general frost-heaving soil with a 6%frost heaving ratio. If the frozen depth was 0.62 m, the frost-heaving forceqfwas 0.05 MN/m. If the soil above the pipeline was assumed to be uniform, the frost-heaving force was also uniformly distributed on the pipeline, as shown in Figure 4. The frost-heaving force was only incurred on the right side of the ruptured point, even though the frost-heaving force would have effects within the distance of 5 to 7 times the pipeline diameter (Li and Zhu,2002). In our analysis we took the 5-times value of the pipeline diameter. The left side of the gas pipeline intersected with a hot steam pipe channel, so it incurred no frost-heaving stress.

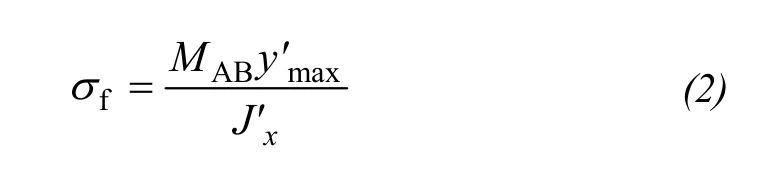

We considered the pipeline with the same simplifications as in the vehicle load stress analysis above, so the stress on the ruptured pipeline section was:

whereσfis the stress incurred on the gas pipeline due to soil frost heaving;MABis the bending moment incurred on the ruptured section under the frost heaving force (MN·m);y′maxis the pipeline section radius (m); andJ′xis the inertial moment when in consideration of the fatigue crack (m4).

The calculation results wereMAB=0.030 (MN·m),J′x=7.6×10-5m4, andy′max=0.107 m. From Equation(2)the value ofσf=123 MPa, which obviously exceeded the pipeline’s tensile strength. Thus, even when no vehicle loading was expected, the pipeline would still be vulnerable to cracking damage from frost heaving. This analysis indicates that the frost heave force induced by freezing soil when temperature shock occurred was the direct cause of this pipeline crack damage and failure.

Figure 4 Diagram of the frost heave stress

4. Incident analysis of a gas pipeline buried in powder clay

Another cracking accident occurred on February 23,2003 in another cold nothern city of China, which was one of the coldest winter days in that year. The soil frozen depth was 1.0 m and the burial depth of the pipeline was 1.1 m,and there was little snow on the ground. The pipeline crossed under the northern part of a residential building. The water content of the soil was about 30% and the soil was powder clay, which is a strong frost heaving type. According to the Code for Design in Frozen Soil Region (JGJ118-98,1998), the average frost heaving ratio of the soil was estimated to beη=7%-8%. At a burial depth of 1.0 m, the average frost heaving force would be 30-40 kN/m. The outer diameter of the pipelinedwas 100 mm, and the pipeline was made of cast iron. Above the pipeline there were no vehicle loads or other stresses. Thus, the most likely reason for this damage was frost-heaving stress, which we calculated and analyzed in detail as follows.

The pipeline with the lengthLcan be simplistically considered an elastic foundation beam; thus, the frost-heaving forceqfwas evenly distributed on the pipeline. Figure 5 shows the O-O′ section, including point A which was the rupture section. The distances between A and the two starting load points (O and O′) arebandc, respectively. When the values ofbandcare large enough, the bending moment at point A would be as follows (Du, 1960):

whereqfis the distributed frost heaving force (MN/m);dis the diameter of the pipeline (m);kis the modulus of the foundation (MN/m3); andEJis the flexural rigidity of the pipeline (MPa·m4).

If the bending momentMAin point A is known, the stress is:

Figure 5 The frost-heave stress calculation model

The calculated value ofσAis according to Equation(4);its parameters areqf=0.035 MN/m,d=200 mm,E=150 GPa,J=2.69×10-5m4, andk=30 MN/m3.σAwas thus calculated to be 107 MPa. However, the average bending strength of the pipeline materialsσm=105 MPa, so the frost heaving stress was greater than the bending strength of the pipeline, causing the cracking to occur.

5. Recommendations for design and management of underground gas pipelines

From analysis of the above causes of pipeline cracking damages, it is evident that there are important problems concerning the design, construction, and management of pipelines that are sometimes overlooked or neglected.Therefore, to avoid future incidents of pipeline cracking,rational design and stringent management measures are essential for ensuring safe operation of pipelines. We present the following recommendations for design, construction, and management of underground gas pipelines.

(1) When designing the pipeline burial depth, the local maximum freezing depth should be exceeded in order to protect the pipeline from the effects of frost heave.

(2) When a pipeline intersects with a transportation corridor, calculations must be performed to thoroughly evaluate the vehicle loads and their transmission to the pipeline.

(3) Burial of pipelines should be carried out in exact compliance with the relevant rules and regulations; under no circumstances should rigid points of support be allowed within close proximity to the pipeline, especially when differential rates of frost heave are possible.

(4) Gas pipelines should not be combined within utilities or ductwork bringing other utilities to buildings (such as steam, water, or sewer lines), to prevent gas from entering into a building if leakage occurs.

(5) Adequate clearances should be observed when gas pipelines intersect or cross other pipelines.

(6) Valves and cut-offs for gas pipelines should be located outside of buildings to avoid loss of life associated with gas leakage and to allow for convenient and rapid isolation of problems.

(7) The operating conditions of pipelines should be inspected to repair existing damages; leakage alarm systems should be installed; and detected problems should be addressed as soon as possible.

6. Conclusions

(1) In the northern part of China, municipal underground gas pipeline rupture and leakage incidents frequently occur during the cold winters. Because safe pipeline operation is crucial to protect citizen safety and property, analysis of the causes of underground gas pipeline rupture and leakage during winter is critically important and valuable.

(2) The two incident analyses presented here help to clarify why most of these types of cases occur during winter.The first case was a gas pipeline that passes beneath a road.We calculated the loads generated by moving vehicles on the road, and although they were transmitted to the pipeline,they were not large enough to cause the pipeline failure;however, they could have caused fatigue damage cracks to the pipeline over time. The more likely cause of this rupture incident was that in winter, when the temperature dropped suddenly and the uppermost layer of the soil above the pipeline froze rapidly, sudden frost-heaving forces were developed and exerted on the pipeline. The gas pipeline experienced excessive external forces which resulted in rupture and leakage.

The other analysis is of a pipeline buried in powder clay,a strong frost-heaving type of soil. When the temperature dropped suddenly, we calculated that the frost-heaving stress was greater than the strength of the pipeline. Therefore, the cracking incident occurred. This outcome indicates that rupture and leakage incident induced by heaving is one of primary reasons of gas pipeline failure in cold regions, and that temperature shock aggravate the factor of pipeline rupture and leakage, especially at the beginning of the winter season.

(3) In addition to these ultimate reasons, there also exist certain extrinsic factors, including improper pipeline system design, poor construction practices, and lack of stringent management. With respect to pipeline system design, insufficient buried depth and ignoring the effects of frost heaving are common errors. Therefore, rational design and stringent management measures are essential to prevent frost heaving failure of underground gas pipelines.

This research is supported by the National Natural Science Foundation of China (NNSF) (No. 10472020) and the Special Foundation of Dalian University of Technology (DUT)(DUTTX2009-103).

Chen XZ, 1990. Rudiments of Soil Mechanics on the Foundations. TsingHua University Press, Beijing, China. 52-66.

Du QH, 1960. Mechanics of Materials. Higher Education Press, Beijing,China. 147-157.

Foriero A, Ladanyi B, 1994. Pipe uplift resistance in frozen soil and comparison with measurements. Journal of Cold Regions Engineering, ASCE,8(3): 93-111.

JGJ118-98, 1998. Code for Design of Soil and Foundation of Building in Frozen Soil Region. Industrial Standards of the People’s Republic of China. Construction Industry Publishing House, Beijing, China. 56-62.

Li HS, Yang HT, 2000. Experimental investigation of fracture toughness of frozen soils. Journal of Cold Regions Engineering, ASCE, 14(1): 43-49.

Li HS, Yang HT, Chang C, 2001. Experimental investigation on compressive strength of frozen soil versus strain rate. Journal of Cold Regions Engineering, ASCE, 15(2): 125-133.

Li HS, Zhu YL, 2002. Fracture mechanics of frozen soil and its application.Maritime Press, Beijing, China. 58-78.

Riseborough DW, Williams PJ, Smith MW, 1993. Pipelines buried in freezing soil: A comparison of two ground-thermal conditions. Proceedings of the 12th International Conference on Offshore Mechanics and Arctic Engineering. American Society of Mechanical Engineers. 187-193.

Shah KR, Razaqpur AG, 1993. A two-dimensional frost-heave model for buried pipelines. International Journal of Numerical Methods in Engineering, 15(36): 2545-2566.

White TL, Williams PJ, 1993. Microstructural alteration of a frost heave susceptible soil adjacent to a buried chilled pipeline. Proceedings, Sixth International Conference on Permafrost, Beijing, China, July 5-9, (1):700-705.

Williams PJ, 1993. Gas pipelines, oil pipelines, civil engineering in Arctic climates. Proceedings of a Canada-France Seminar. Caen and Paris Geotechnical Science Laboratories, Ottawa. 181-185.

10.3724/SP.J.1226.2011.00473

*Correspondence to: YaMin Li, College of Environmental Science & Engineering, Dalian Jiaotong University, Dalian, Liaoning 116028, China. Tel: +86-411-84106809; Email: ymli@djtu.edu.cn

19 June 2011 Accepted: 9 September 2011

Sciences in Cold and Arid Regions2011年6期

Sciences in Cold and Arid Regions2011年6期

- Sciences in Cold and Arid Regions的其它文章

- Analysis on the temporal-spatial distribution character and effect factors of PM10 in the hinterland of Taklimakan Desert and surrounding area

- Variability of atmospheric freezing level height derived from radiosonde data in China during 1958-2005 and its impact to cryosphere changes

- Impacts of snow cover and frozen soil in the Tibetan Plateau on summer precipitation in China

- Simulation and analysis of river runoff in typical cold regions

- Characteristics of dynamic strain and strength of frozen silt under long-term dynamic loading

- Climatic changes have led to significant expansion of endorheic lakes in Xizang (Tibet) since 1995