On the evolution and formation of discharge morphology in pulsed dielectric barrier discharge

Xingyu CHEN (陳星宇),Mengqi LI (李孟琦),Weiyi WANG (王威逸),Quanzhi ZHANG (張權(quán)治),Tao PENG (彭濤) and Zilan XIONG (熊紫蘭),*

1 State Key Laboratory of Advanced Electromagnetic Technology,Huazhong University of Science and Technology,Wuhan 430074,People’s Republic of China

2 School of Physics,Dalian University of Technology,Dalian 116024,People’s Republic of China

3 Wuhan National High Magnetic Field Center,Huazhong University of Science and Technology,Wuhan 430074,People’s Republic of China

Abstract The discharge morphology of pulsed dielectric barrier discharge (PDBD) plays important roles in its applications.Here,we systematically investigated the effects of the voltage amplitude,discharge gap,and O2 content on the PDBD morphology,and revealed the possible underlying mechanism of the U-shaped formation.First,the morphological evolution under different conditions was recorded.A unique U-shaped region appears in the middle edge region when the gap is larger than 2 mm,while the entire discharge region remains columnar under a 2 mm gap in He PDBD.The width of the discharge and the U-shaped region increase with the increase in voltage,and decrease with the increase of the gap and O2 content.To explain this phenomenon,a two-dimensional symmetric model was developed to simulate the spatiotemporal evolution of different species and calculate the electric thrust.The discharge morphology evolution directly corresponds to the excited-state atomic reduction process.The electric thrust on the charged particles mainly determines the reaction region and strongly influences the U-shaped formation.When the gap is less than 2 mm,the electric thrust is homogeneous throughout the entire region,resulting in a columnar shape.However,when the gap is larger than 2 mm or O2 is added,the electric thrust in the edge region becomes greater than that in the middle,leading to the Ushaped formation.Furthermore,in He PDBD,the charged particles generating electric thrust are mainly electrons and helium ions,while in He/O2 PDBD those that generate electric thrust at the outer edge of the electrode surface are mainly various oxygen-containing ions.

Keywords: low-temperature plasma,dielectric barrier discharge,discharge morphology,particle distribution,electric thrust

1.Introduction

Cold atmospheric pressure plasma (CAP) plays a vital role in many fields and is currently a prominent area of research in discharge plasma.The advancement of pulsed power technology has led to the emergence of pulsed dielectric barrier discharge (PDBD),which has found applications in medical sterilization,material modification,pollution control,agriculture,and the food industry [1–6].In comparison to conventional AC DBD,PDBD can rapidly generate ionization waves with higher electron energy during ultra-fast rising and falling pulse edges.PDBD offers several advantages,including slight temperature increase during discharge,a wide range of chemical reactions,and various active components [7–10].Under specific conditions,it can produce large,uniform,and highly active non-equilibrium plasma,which has received increasing attention from researchers.

Numerous studies have emphasized the significance of the source configuration,charged particle density,type of active components,and spatial distribution of CAP in its practical applications [11,12].Understanding the evolution of plasma morphology and its formation mechanism is crucial for comprehending the physical processes of plasma,optimizing plasma treatment procedures,and enhancing the performance of plasma equipment.In the case of DBD,several investigations have explored the impact factors of different DBD morphologies under various driving power sources,DBD structures,and working gases [13–18].Current studies demonstrate the close relationship between the morphological development and evolution of the discharge and microscopic factors such as the electric field distribution,particle species,and spatial distribution of the plasma [19–23].However,the development and evolution of the morphology of PDBD and the related impact factors have been less explored.

Numerical simulations are also conducted to understand the influence of microscopic parameters of the DBD on the discharge morphology [24–26].Liet alutilized a twodimensional (2D) fluid model and discovered that the density of the positive ion cloud influenced the path and development speed of the jet streamer [27].Qiaoet alsimulated the pattern evolution in a glow DBD system and found that the localized lateral electric field and its induced electron focusing effect are the controlling mechanism [28].Mareket alrevealed that the length of the surface streamlines along the dielectric surface was found to be voltagedependent after a critical value of the charge density was reached [29].Although the simulations helped to confirm and reveal the related factors in the development of plasma morphology,the underlying mechanism is not fully understood yet.

Current literature on the morphological changes of PDBD with parallel electrodes primarily focuses on the discharge mode transition and homogeneity [30,31].However,there is a strong need for more systematic research on the overall evolution of morphology and its formation mechanism [32].In our previous study,we discovered that the 2D morphology distribution of PDBD significantly impacts the sterilization effect on a 2D membrane [33].To further elucidate the evolution of the discharge morphology in PDBD,its formation mechanism,and the influencing factors,we systematically investigated the effects of parameters such as voltage amplitude,discharge gap,and O2content on the formation of the PDBD morphology through a combination of experiments and 2D numerical simulations.Initially,dynamic photos of the discharge process and static photos of the discharge morphology were captured using an intensified charge coupled device (ICCD) camera.The morphological evolution under different conditions was compared and analyzed.Subsequently,a 2D fluid model was developed,incorporating 34 selected particle reactions.This 2D model allowed us to obtain the 2D distributions of each charged particle and photon,as well as the electric thrust during the evolution process in the rising edge of the pulse.Finally,we analyzed the formation and development mechanism of the morphological features based on the obtained results.

2.Experimental setup and simulation

2.1. Experimental setup

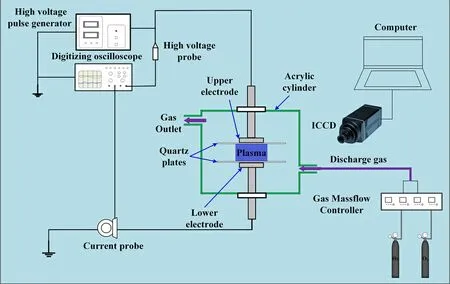

A sketch of the experimental setup is shown in figure 1.The experimental platform primarily consists of a pulse generator (PVX4100),a high-voltage DC power supply(SL30PN300),a homemade DBD device,and various measurement instruments.The pulse generator and the highvoltage DC power supply were used to generate the highvoltage pulse signals.The applied voltage frequency was fixed at 8 kHz,and the pulse width at 2μs,with rising and falling edges of 50 ns.To measure the electrical parameters,a high-voltage probe (Tektronix P6015A) and a current probe (Pearson P6585) were utilized.The discharge power was calculated through voltage–current integration.A highspeed camera ICCD (Andor DH712) was employed to record the static and dynamic discharge images.The gain of the microchannel plate (MCP) was 4095 and the gate width was 2 ns.The static discharge image is an accumulation of discharges during 80 periods (~0.01 s),while the dynamic image was recorded every 4 ns during the discharge period.

The DBD device comprises a pair of parallel electrodes mounted in the center of an acrylic cylindrical box.The copper electrode has a diameter of 25 mm and is covered with a threaded Teflon cylinder with a diameter of 45 mm for insulation.Dielectric sheets in the form of quartz plates with a diameter of 80 mm and a thickness of 1.2 mm were attached to the surface of the upper and lower electrodes.The distance between these quartz sheets,known as the gas gap,can be adjusted according to the requirements of the experiment.The working gas used in the experiments was either pure He or a mixture of He and O2.The flow rate of the gas was maintained at a constant value of 0.5 L min-1,controlled by a mass flow controller (MFC,D07-19B,0-5 SLM).The ratios of O2in the mixture were adjusted between 1% and 12%.

2.2. Plasma simulation

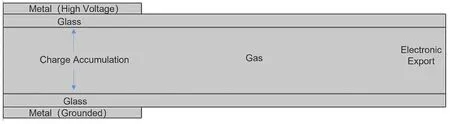

COMSOL software was used to simulate the discharge process.A 2D symmetric model was employed,which closely resembled the structure of the device.Figure 2 shows a schematic diagram of the model,featuring a 6 mm gap.In the model,the electrode and dielectric sheet are represented as cylindrical,symmetrical structures.The dimensions of these structures in the model were set to match the actual values used in the experiment.The voltage at the high-voltage end was the same as in the experiment.A grid boundary layer was set at the interface of the quartz plate and gas to improve the accuracy of the calculation,and the complete grid contained 15220 domain cells and 696 boundary cells.Considering the periodicity of the discharge,the simulation time was 1 cycle (125μs),and the time step of the simulation calculation was 1 ns.

The initial density of the electrons,ne0,is 1013m-3,the initial velocityμis 0.Reis the source term of the rate and has an initial value of 0.The relationship between its concentration and timetsatisfies the convective diffusion equation [34]:

where Γeis the electron density flux,which is used to obtain the spatial distribution of electron energy.The electron energy mobility and diffusivity are functions of the average electron energy calculated from the electron collision crosssection data.The solution equation is as follows:

whereμeis the electron mobility with an initial value of 0.1131 m2(V s)-1.Decharacterizes the diffusive action term,which can be neglected concerning the drift term during the discharge.Eis the electric field strength,which is calculated based on the Poisson equation:

The potential shift on the surface of the dielectric sheet satisfies the following equation:

whereDdenotes the potential shift andεdenotes the relative permittivity.The relative permittivity of air is 1,approximately the same as a vacuum.The relative permittivity of the dielectric sheet is 3.7.

The charge accumulated on the surface of the dielectric sheet satisfies the following equation:

wherenis the normal vector.D1andD2represent the potential shifts of quartz and gas.

The accumulation of charge and the surface current density satisfy the following equation:

whereJiandJedenote the ion and electron current density,respectively.

In order to consider the energy exchange during the discharge process,the energy conservation equation is introduced:

whereSεis the average net production rate of electron energies.jεis the flux density of electron energy,satisfying the following equation:

nεis the average electron energy density,which satisfies the following equation:

Here,erepresents the fundamental charge with a value of 1.6×10-19C,andkrepresents the Boltzmann constant with a value of 1.38×10-23J K-1.Tedenotes the electron temperature.The plasma reactions involving He and O2consist of numerous particles and reactions.The major particles considered in our simplified model are e,He*,He+,O,O3,O+,,O-,and.The reactions involved and their corresponding rate coefficients are listed in table 1.

2.3. Electric thrust calculation

During the discharge process,the space-charged particles are accelerated by the electric field.When these particles collide with neutral gas molecules,new charged particles are ionized.These charged particles then move to the other electrode and out of the electrode area due to the force exerted by the electric field and other charged particles.This movement,known as electric thrust,causes the particles to diffuse,resulting in changes in the shape of the discharge.The electric thrust is the main factor responsible for the morphological changes [49].In the presence of gas,the magnitude of the charged particle flow is a crucial physical parameter that characterizes the DBD thrust [50].

Using the fluid model,the thrust generated by each charged particle in the unit volume is obtained from the momentum theorem:

wherespresents the various charged particles,including e,the negative ions,and the positive ions.Only electrons and helium ions are included in pure He.The addition of O2,O+,O-,,andalso needs to be considered.nsdenotes the number of charged ions per unit volume,msdenotes the mass of differently charged particles,νsmdenotes the molecular momentum transfer frequency of different charged particles with neutral gas molecules,andμsdenotes the average velocity of differently charged particles.

The current density equation is

The drift velocity equation is

From equations (4)–(6) and equations (10)–(12),the electric thrust can be calculated as follows:

The electric thrust on the particle is proportional to the electric field strengthEand the net charge.

3.Results and discussion

3.1. Effect of voltage amplitude,discharge gap,and O2 content on the discharge morphology of PDBD

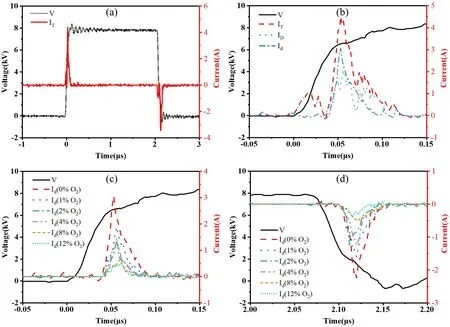

The waveforms of the applied voltage and the total current of a pulse period under a 6 mm gap at 8 kV in He PDBD are presented in figure 3(a).Two typical current pulses are observed at the rising and falling edges of the voltage pulse,similar to those reported in other literature [51].The total current (It),displacement current (ID),and discharge current(Id) at the rising edge are presented in figure 3(b),andIdis the difference betweenItandID.Figures 3(c) and (d) give the discharge currents under different O2contents at the rising and falling edges,respectively.The peak amplitude of the current at the rising edge is found to be larger than that at the falling edge with a fixed pulsed width of 2μs,which may be caused by the volume memory effects as illustrated in reference [51].In addition,this difference is decreased with the increase in O2content.Meanwhile,both the current width and the peak amplitude at the rising and falling edge decrease with the increase in O2content.

Figure 4 presents the discharge power of the pure He and He/O2mixture PDBD under different discharge gaps and applied voltages.The discharge power basically increases with the applied voltage and decreases with the increase in the discharge gap and O2content.Under a 4 mm gap at 8 kV,the discharge power decreases from~10 W to 1.5 W with 12% O2in the gas mixture,which is consistent with the trend of the discharge current.

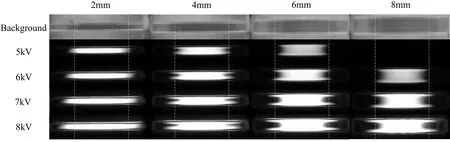

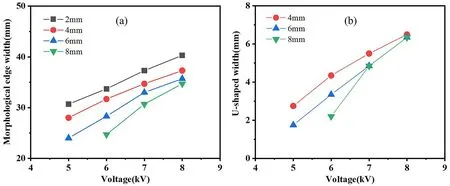

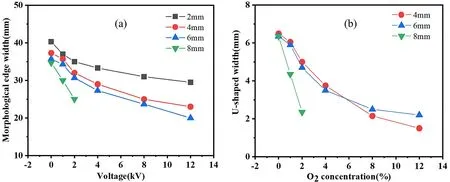

Figure 5 presents static photos of the overall discharge morphology in pure He PDBD under different discharge gaps and applied voltages.The dashed lines in figure 3 indicate the area of the copper electrode and distinguish between the inside and outside of the electrodes.For a discharge gap of 2 mm,the discharge morphology appears columnar and gradually expands outward as the voltage increases.At 8 kV,the size of the morphology is approximately 50% larger than that of the electrode.When the discharge gap exceeds 2 mm,the discharge morphology becomes narrower in the middle and wider at the top and bottom edges.The width of the main discharge column area is smaller than the width of the copper electrode. Additionally,a U-shaped structure emerges at the middle of the side edge,and its width increases with the increase in voltage amplitude.To further investigate the dimensions of the shape,the average of the diameters of the upper and lower edges of the discharge image was measured as the edge diameter,and the radius difference between the outer edge and the inner edge of the discharge was the width of the U-shaped structure.Figure 6 summarizes the width of the discharge morphology and the U-shaped structures in pure He under different discharge gaps and voltages.

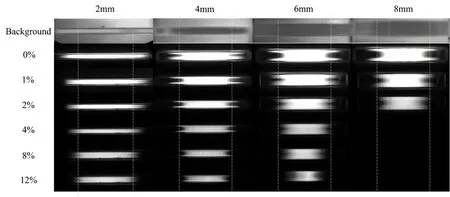

Figure 7 shows static photos of the discharge morphology in He/O2mixture at various discharge gaps and O2content,at a fixed voltage of 8 kV.The images demonstrate that the diameter of the discharge area gradually decreases as the O2content increases.Additionally,the U-shaped structure appears under all conditions when O2is added to the working gas.The widths of the discharge region and the U-shaped structure decrease with the increase in O2content and discharge gap.At an O2content of 12%,the width of the discharge region becomes smaller than the diameter of the electrode for all discharge gaps.Figure 8 summarizes the widths of the discharge morphology and the U-shaped structures in He/O2discharges under different discharge gaps and O2contents.

3.2. Analysis of particle distribution and morphology evolution of PDBD in He

The morphology captured in the photographs provides a macroscopic representation of the photons produced when excited atoms undergo the reduction process.To examine the relationship between the morphology and the distribution of particles,we have chosen specific sets of experimental and simulation results for analysis.These sets include (1) pure helium with a 2 mm gap at 5 kV and 8 kV;(2) a 6 mm gap at 8 kV in helium with varying oxygen content of 1%,2%,and 4%.It is important to note that the concentration of particles in different regions can differ significantly,sometimes by several orders of magnitude.Therefore,the density of each particle is represented logarithmically with a base of 10.

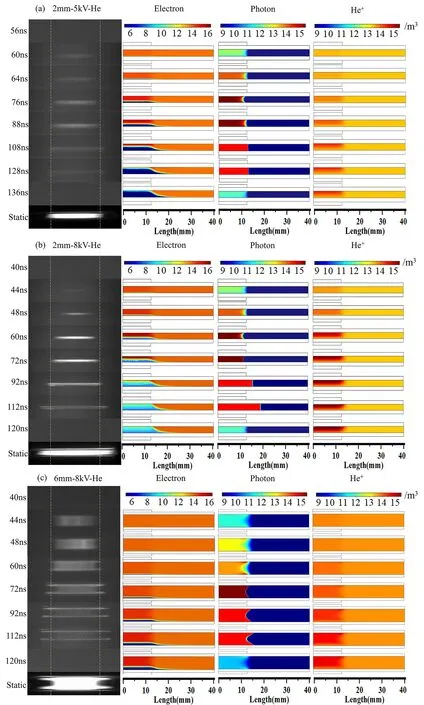

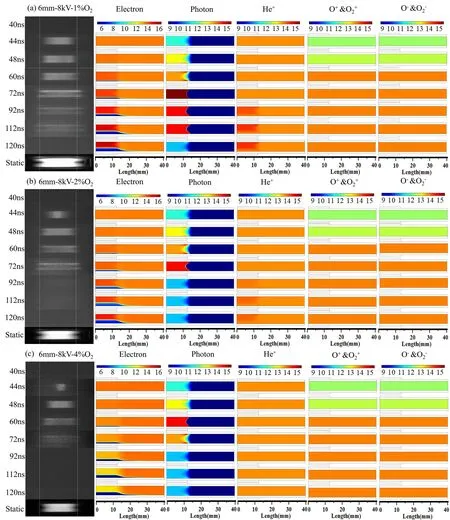

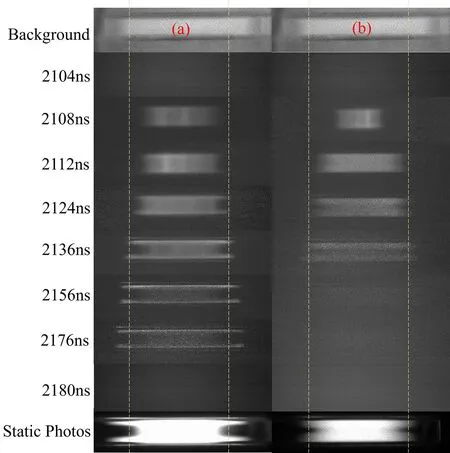

The dynamic development of PDBD was observed by capturing photos every 4 ns using an ICCD camera,and both the evolutions at the rising and falling edges of the voltage pulse were recorded.These photos allow us to study the evolution of the discharge morphology over time.Since we used a symmetrical pulse in the experiments,although the amplitude of the current pulse is slightly different in the rising and falling pulse edges due to the volume memory effects,the discharge morphology is almost the same (typical ICCD images of the discharge development at the falling edge are provided in the Appendix),so we only give the experimental and simulation results during the discharge at the rising edge here.Figure 9 presents the spatiotemporal morphology images and corresponding number densities of electrons,helium ions,and photons during the rising edge discharge at different discharge gaps and voltages in helium PDBD.Under a 2 mm discharge gap,as shown in figures 9(a) and (b),the discharge morphology gradually expands from the middle area toward the outside of the electrode as the rising edge of the pulse develops.The overall discharge morphology appears columnar.The discharge intensity initially increases and then decreases during the rising edge discharge.With the increase in voltage,the field strength in the inner region of the electrode becomes larger,resulting in more energy being injected into the electrons.This leads to an increase in electron collision ionization and subsequently an increase in the electron density.For example,the maximum electron density under 5 kV is approximately 8×1015m-3,and the maximum electron density under 8 kV is around 5×1016m-3.These electron densities are generally consistent with those obtained by Panet alunder similar conditions [52].Comparing the evolutions of particles at a fixed voltage of 8 kV under 2 mm and 6 mm discharge gaps,as shown in figures 9(b) and (c),the U-shaped structure gradually appears during the development of the rising edge discharge at around 60 ns under the 6 mm gap.The larger the discharge gap,the smaller the field strength in the inner region of the electrode,resulting in less energy being injected into the electrons and fewer electrons being produced through collision ionization.Consequently,the electron density decreases.At 72 ns,the electron density is approximately 5×1016m-3for the 2 mm gap,while it drops to around 7×1014m-3for the 6 mm gap,representing a decrease of nearly two orders of magnitude.Since helium ions are much heavier than electrons,their outward expansion is slower,and they remain confined within the electrode region.

The production of photons primarily occurs through the particle reaction e+He*→He+e.The number density of photons corresponds to the consumption of helium atoms in the excited state during this reaction.As time progresses,the region of photon aggregation continues to expand outward.The concentration of photons is positively correlated with the changes in discharge intensity spatio-temporally,and their distribution region aligns completely with the development of the discharge morphology.For instance,in the case of a 2 mm gap at 8 kV,the discharge area within the first 72 ns is primarily concentrated on the inner side of the electrode.During this period,the number density of photons gradually increases from 5×1012m-3at 8 ns to 1×1016m-3at 72 ns.After 72 ns,due to the outward expansion of electrons,electron collisions also occur on the top and bottom surfaces of the dielectric sheets.This leads to the production of excitedstate helium atoms and photons outside the electrode area.However,at this stage,the density of photons produced decreases as the overall discharge weakens,reaching 6×1014m-3at 112 ns.It is worth noting that the photon number densities at the same time point for a 5 kV,2 mm gap and an 8 kV,6 mm gap are smaller compared to the 8 kV,2 mm gap condition.This is due to the lower voltage and larger gap,which result in the reduced production of photons.

3.3. Analysis of particle distribution and morphology evolution of PDBD in He/O2 mixture

Figure 10 illustrates the spatiotemporal morphology and the corresponding number densities of electrons,helium ions,photons,and oxygen-containing ions during the rising edge discharge under different O2contents in He/O2PDBD with a fixed discharge gap of 6 mm and voltage of 8 kV.The recorded luminous duration and the total discharge area decrease with the increase in O2content,and the electron number density decreases as the O2content increases,primarily due to the electronegativity of oxygen and the electron-oxygen collision reactions,which is consistent with the trend in discharge current in figure 3(c).The reduction of discharge duration and lower transferred charge and discharge power with the increasing O2concentration were also found in references [53,54] under a N2/O2filamentary DBD system observed by H?ftet al.However,the trends of the discharge area and current peaks are opposite.These differences may be caused by the characteristics of the working gas,the discharge structure,and the discharge mode,which need systematic and comprehensive investigation in future work.

Figure 1.Sketch of the experimental setup.

Figure 2.Schematic of the 2D symmetrical model.

Figure 3.The measured voltage and current waveforms at 6 mm,8 kV.(a) A whole pulse period,(b) It,ID and Id,(c) Id under different O2 contents at rising edge of the voltage pulse,(d) Id under different O2 contents at falling edge of the voltage pulse.

Figure 4.The discharge power of PDBD under different conditions.(a) Pure He and (b) He/O2 mixture at 8 kV.

Figure 5.Photos of the discharge morphology variation with voltage amplitude and discharge gap in He PDBD.The photos are static photos taken by the ICCD camera.

Figure 6.Size variation of PDBD morphology in He versus voltage amplitude and discharge gap.(a) Average width of the discharge region and (b) average width of the U-shaped structure.

Figure 7.Photos of the discharge morphology variation with the discharge gap and O2 content in He/O2 PDBD.The photos are static photos taken by the ICCD camera.

Figure 8.Size variation of PDBD morphology in He/O2 versus O2 content and discharge gap.(a) Width of the discharge region and (b) the average width of the U-shaped structures.

Figure 9.Evolution of the discharge morphology.Logarithm results of electron density,photon density,and helium ion density of the He PDBD during the voltage-rising edge period.(a) 2 mm,5 kV,(b) 2 mm,8 kV,(c) 6 mm,8 kV.

Figure 10.Evolution of the discharge morphology;logarithm results of electron density,photon density,helium ion density,and oxygencontaining ions of the He/O2 PDBD at 8 kV,6 mm gap during the voltage-rising edge period.(a) 1% O2 content,(b) 2% O2 content,(c) 4%O2 content.

Figure 11.Logarithm results of the concentration distribution of charged particles in a 6 mm He/O2 PDBD with 4% O2 content at 72 ns.The overall distribution of (a) O+ &,(b) O- &,(c) O+ &on negative sheath layer,(d) O- & on positive sheath layer,(e) helium ion on negative sheath layer,(f) electron on positive sheath layer.

The density change of helium ions follows the same trend as electrons,resulting in a decrease in the number of helium atoms in excited states.Under 2% O2content,the electron number density is only 3.5×1014m-3.As the O2content continues to increase,the electron density within the electrode area becomes even lower than the initial value.After adding O2,the photon aggregation zone keeps diffusing outward.However,due to the electronegativity of O2and the energy consumption involved in oxygen ionization reactions,the reduction reaction of excited-state helium atoms is significantly reduced.As a result,both the number density and the presence of photons decrease.Upon comparing the simulated results with the experimental results,it is observed that in all conditions,the trend of photon intensity and the spatial and temporal distribution of the aggregation zone align with the discharge intensity and the microscopic development process of discharge morphology.

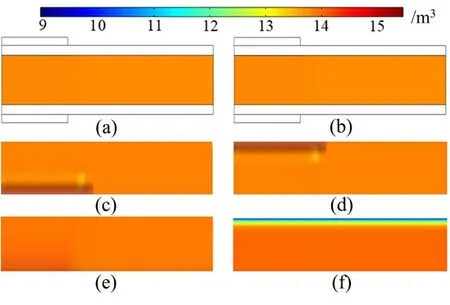

During the He/O2discharge,electrons combine with oxygen to form various oxygen ions.The simulation results reveal the formation of twoμm-level sheath layers consisting of positive and negative ions on the surfaces of the lower and upper dielectric plates,respectively.To investigate the impact of the sheath layer,the results under the condition of a 6 mm gap with 4% O2content at 72 ns are taken as an example.The overall number density distributions of O+&and O-&are shown in figures 11(a) and (b),respectively.For clearer comparison,the zoomed distribution results within 1 mm thickness around the negative and positive surfaces are presented in figures 11(c) and (d).The sheath layer has a width of approximately 27 mm,which is consistent with the width of the discharge morphology,and a thickness of around 100μm.The number density of ions within the sheath layer is approximately 1015m-3,which is one order of magnitude higher than that of the surrounding region.Figures 11(e) and (f) display the distribution of helium ions and electrons within 1 mm thickness around the negative and positive surfaces,respectively.A similar sheath layer is observed,although the number density within the sheath region is smaller,approximately two orders of magnitude lower than those of the positive and negative oxygen ions.

3.4. Effect of electrical thrust on discharge morphology of PDBD

When the number of electrons in the avalanche head reaches a critical valueNcr(about 108),photoionization will play a dominant role,determined as eαd≤Ncr[55],whereαis the ionization coefficient,dis the gas gap distance.In the corresponding electric field strength range in this paper,αcan be approximately calculated by the following equation [56]:

whereNis the gas molecular density,which is about 2.43×1025m-3,A=1.4×10-20m2,andB=660 Td (1 Td=10-21V m2).The calculations found that none of the values of eαdfound in this paper under the 2–8 mm gap exceeds 104,which is more than four orders lower than the critical value.That is,the discharge development in our situation is mainly dominated by collisional ionization,and the photoionization is negligible.

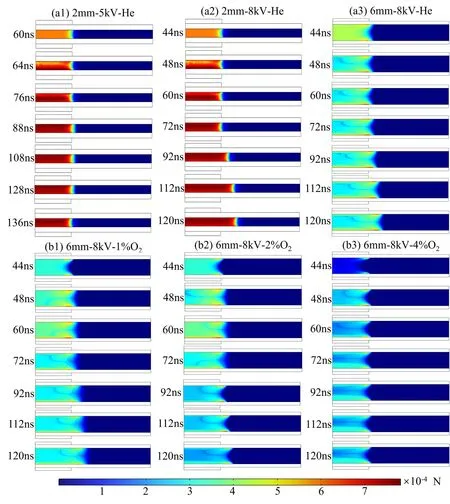

Based on the calculation formula for electric thrust,it is known that the electric thrust is directly proportional to the concentration difference between positive and negative charged particles and the electric field strength.By utilizing the known distribution of the concentration of each charged particle and the electric field,the distribution of electric thrust can be determined.Figure 12 illustrates the distribution of electric thrust under various conditions.

Figure 12.Electric thrust evolution process.(a1) 2 mm,5 kV pure helium,(a2) 2 mm,8 kV pure helium,(a3) 6 mm,8 kV pure helium,(b1)6 mm,8 kV He/O2 with 1% oxygen concentration,(b2) 6 mm,8 kV He/O2 with 2% oxygen concentration,(b3) 6 mm,8 kV He/O2 with 4%oxygen concentration.

In pure He conditions,the primary charged particles consist of helium ions and electrons only.The helium ions are primarily confined to the inner side of the electrode due to their heavier mass.The electron density,on the other hand,plays a crucial role in determining the electric thrust on the outer side of the electrode.As shown in figures 12(a1)and (a2),for a 2 mm gap,the electron density is high in all regions.Electrons in the edge or middle region will be propelled outward by the electric thrust.This results in a significant concentration difference of charged particles in the outer region,both in the middle and at the edge.Consequently,both the middle region and the edge expand outward.At a voltage of 5 kV and 120 ns,the edge size is approximately 28 mm with a maximum electric thrust of around 9.5×10-4N,while the maximum electric thrust in the middle region is approximately 8.7×10-4N,slightly smaller than at the edge.At a voltage of 8 kV and 120 ns,the edge size increases to about 39 mm with a maximum electric thrust of approximately 9.7×10-4N,and the maximum electric thrust in the middle region is around 9×10-4N.In summary,in a He PDBD with a 2 mm gap,the maximum electric thrust at the edge and in the middle region is nearly the same at the same voltage,resulting in a columnar discharge morphology.As the voltage increases,the electric field on the outer side of the electrode strengthens,leading to a more powerful electric thrust and an increase in the size of the discharge.

The electric field strength,electron density,and electric thrust in each region under the remaining gaps are smaller compared to those at the 2 mm discharge gap at the same voltage level.In the He PDBD under the 6 mm gap (figure 12(a3)),the edge size measures 32 mm at 80 ns with a maximum electric thrust of approximately 7.6×10-4N.On the other hand,the middle size is only 27 mm with a maximum electric thrust of around 3.9×10-4N,which is only about half of the electric thrust observed in the edge area.The magnitude of the electric thrust calculated above is roughly similar to that reported by Eliaset al[57].The sheath layer at the edge will result in the formation of numerous charged particle aggregations.However,the electric thrust in the middle region is not sufficient to propel a large number of charged particles toward the outer side area of the electrodes.As a result,the discharge morphology takes on a distinct U-shape in the middle region.

For an 8 kV discharge with O2addition under a 6 mm gap,there are four additional charged particles present: O+,O-,,and,in addition to the helium ions and electrons.As depicted in figures 10,11 and 12(b1)–(b3),it is evident that there is a significant variation in ion concentration only on the surface of the positive and negative dielectric plates,resulting in a noticeable electric thrust at the outer edge of the electrode.The difference in number density between electrons and helium ions in the sheath region is much smaller compared to that of oxygen-containing ions.Therefore,the primary factor contributing to the electric thrust along the outer edge of the electrode surface is the oxygencontaining ions.However,increasing the O2content will weaken the motion of electrons and subsequently reduce the concentration of charged particles,leading to a decrease in electric thrust.For instance,the concentration of net negative ions at 4% O2content is only 70% of that observed under the same gap and voltage level in He PDBD.The edge size measures approximately 26.2 mm with a maximum electric thrust of around 5.4×10-4N,while the middle size is approximately 20.8 mm with a maximum electric thrust of around 2.5×10-4N.The electric thrust at the edge and in the middle is only 70% of that observed under the He PDBD condition.

The simulation results indicate that the formation of the PDBD morphology is strongly influenced by the movement of charged particles driven by the electric thrust.In the case of He PDBD,the charged particles that significantly impact the overall discharge morphology are electrons and helium ions.On the other hand,in He-O2PDBD,the charged particles that predominantly contribute to the development of the morphology at the outer edge of the electrodes are primarily oxygen-containing ions.

4.Conclusion

In this study,we conducted a systematic investigation into the development of discharge morphology and the possible mechanism of the U-shaped formation in PDBD.We performed experimental comparisons of morphological changes at different voltages,gas gaps,and O2content.The evolution of the discharge morphology was then compared with the trends observed in charged particles,excited state atoms,electric thrust,and other parameters using 2D simulations.Our findings revealed that the morphological changes in PDBD are closely correlated with the applied voltage,discharge gap,and gas composition.Under a 2 mm gap,the discharge exhibited a cylindrical shape in He PDBD.However,under larger gaps or with O2addition,a U-shaped structure began to appear at the middle edge of the discharge region.The width of the discharge and the U-shaped structure increased with the increase of the voltage amplitude and decreased with higher O2content.

The simulation results provided insights into the aggregation region and density of photons generated during the reduction of excited atoms,which were found to agree with the microscopic development of the discharge shape and intensity.Furthermore,the calculation of electric thrust demonstrated that it played a major role in driving the morphological changes.In He PDBD with a small 2 mm gap,the electric thrust in the middle region and at the outer edge of the electrodes was nearly identical,resulting in an overall column shape of the discharge region.However,as the discharge gap and O2content increased,the electric thrust in the middle region near the outer edge of the electrode became smaller compared to that along the outward electrode.This led to the formation of a U-shaped structure.In pure He PDBD,the formation of the discharge shape was primarily influenced by electrons and helium ions.In He/O2PDBD,the presence of oxygen-containing ions in the sheaths (O+,,O-,and) played a significant role in the formation of electric thrust along the outer side of the electrode.

Acknowledgments

The authors are grateful for financial support from the Interdisciplinary Fund of the Wuhan National High Magnetic Field Center (No.WHMFC202101).

Appendix

Figure A1.Evolution of the discharge morphology of the He PDBD during the falling edge period of the voltage pulse.(a) 6 mm,8 kV,He,(b) 6 mm,8 kV,2% O2.

Plasma Science and Technology2024年4期

Plasma Science and Technology2024年4期

- Plasma Science and Technology的其它文章

- Experimental results of a magnetic field modification to the radio frequency driver of a negative ion source

- A fringe jump counting method for the phase measurement in the HCN laser interferometer on EAST and its FPGA-based implementation

- Simulation of liquid cone formation on the tip apex of indium field emission electric propulsion thrusters

- Novel method for identifying the stages of discharge underwater based on impedance change characteristic

- Performance of pulsed plasma thruster at low discharge energy

- Dynamic propagation velocity of a positive streamer in a 3 m air gap under lightning impulse voltage