Preparation and cooling performance analysis of double-layer radiative cooling hybrid coatings with TiO2/SiO2/Si3N4 micron particles

Yang-Chun Zhao(趙洋春) and Yong-Min Zhou(周勇敏)

College of Materials Science and Engineering,Nanjing Tech University,Nanjing 211816,China

Keywords: radiative cooling,coatings,thermal radiation,infrared emissivity

1.Introduction

Radiative cooling can create cooling effect without energy input, and it has been rapidly developed as a passive cooling method to alleviate the energy crisis and environmental pollution.It operates in a wavelength range from 8 μm to 13 μm (also known as the “sky window” or “atmospheric window”),[1,2]because the atmosphere around the earth is transparent to visible light, while thermal energy from surface objects is emitted into outer space in the form of infrared radiation, which is opaque to most wavelengths of infrared radiation.[3,4]

In the past decades,the radiative cooling has been studied.Its potential application for nighttime cooling has been practically demonstrated.[5–8]Materials must have good infrared(IR)emission within the atmospheric window to achieve radiative cooling at night.An SiO film covered by Granqvist forms a composite structure on an Al substrate.[6]They demonstrated a strong absorption resonance at the 10 μm based on SiO intrinsic phonon resonance,thereby realizing infrared emission.In addition to solid materials,some selective infrared emitting gases,such as ammonia(NH3),ethylene(C2H2),and ethylene oxide(C2H4O),which have high emissivity in the atmospheric window, can also be used for radiative cooling.[9,10]These results well demonstrate the capabilities of radiative cooling technology.However, the primary cooling power is usually required during the day.

For passive daytime radiative cooling(PDRC),high emissivity in the atmospheric window and high reflectivity in the solar spectrum are required.There are some studies on radiative cooling coatings.[11–17]For example,Huang and Ruan[15]proposed a method of achieving daytime radiative cooling through a double-layer coating,composed of top layer and bottom layer of acrylic resin infused with TiO2and carbon black particles, respectively.The coating can theoretically achieve more than 90% solar reflection and an average emissivity of more than 0.9 in the sky window.Peopleset al.[16]used TiO2particles of various sizes in nanocomposites to enhance solar reflectance, the results show that the selected combination of particle size and concentration can broaden the spectral scattering peak.Its radiative cooling coating could have high spectral reflectance in the solar spectrum but a lower emissivity in the atmospheric window spectrum.Researches of photonic crystals and metamaterials with radiative properties[18–24]provide new ideas for daytime radiative cooling.Ramanet al.[21]designed a planar photonic device structure, composed of seven alternating layers of hafnium oxide (HfO2) and SiO2.The structure can be cooled by about 4.9?C, below ambient temperature during the day.The three thick layers on the top mainly affect the infrared emissivity,covering the wavelength range of 8 μm–13 μm.And the four thinner bottom layers act as a one-dimensional photonic crystal, with a maximum solar reflection of 97%.Hossainet al.[22]demonstrated experimentally that anisotropic metamaterials can be tuned to have strong and strictly selective infrared emission,with a nearperfect overlap of 8 μm–13 μm.It was estimated that the projected cooling power exceeds 100 W·m-2and a cooling potential is 12?C lower than the ambient temperature.In addition to the above studies, other researches of radiative cooling have also been conducted, such as the cooling of solar cells,[25,26]decorative attractive color protective paints,[27]and windshields for maintaining cooling performance.[28]

Among the existing passive daytime radiative cooling materials, metamaterials and photonic crystal materials have excellent radiation cooling performance.However, they often require complex and expensive processing equipment, which cannot be massproduced,especially the application of energy saving in buildings has tremendous obstacles.To solve this problem,it is necessary to produce radiative cooling coatings with better radiative cooling performance that can be used on a large scale for building insulated applications.

Meanwhile,in most of the double-layer coating structures in which TiO2particles are used to reflect solar radiation, a single material is chosen for designing the emissive layer so as to achieve the radiative properties and increase the emissivity of the coatings in the atmospheric window by increasing the thickness.In practical applications,the thicker coating has disadvantages such as small usage range,high cost,and easy to crack.Therefore,in this work,we choose two inorganic materials,SiO2and Si3N4particles,to be added to the resin matrix to achieve a low-thick double-layer coating structure that can achieve a daytime radiative cooling effect through the synergistic effect of the materials.We first use the finite-difference time-domain (FDTD) algorithm to optimize particle size and film thickness in the infrared band.[29]The hybrid particles are deposited on the Al surface.Their reflectivity and emissivity are characterized.Then wed investigate the cooling power.Finally, the effect of conduction and convection on the cooling power are studied.

2.Simulation and preparation

We design a two-layer coating structure with micron particles(see Fig.1).It comprises a top layer for reflecting solar radiation and a bottom layer with emissive properties in the atmospheric transparent window.The influence of factors,such as particle size and thickness of the material, on the emissive performance will be studied in the following subsection.

2.1.Materials selection

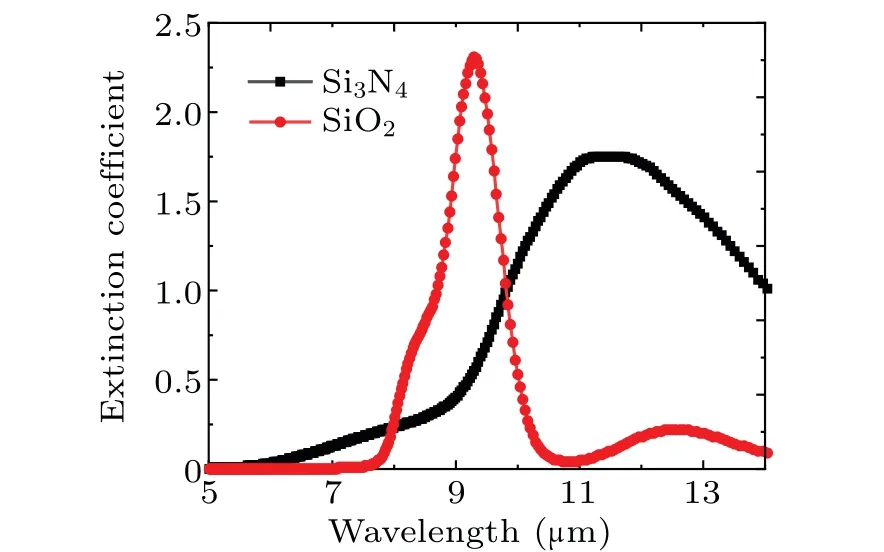

In the study of the radiative cooling coatings,the thermoplastic acrylic resin is chosen as the base material because of its high transparency,excellent weather resistance,and ability to form a film at room temperature and dry quickly.Two materials,SiO2and Si3N4,are chosen for the emitter layer.Figure 2 shows that SiO2and Si3N4have highk-values (extinction coefficients)in their corresponding wavelength regions of the atmospheric window,[30]and the highk-values indicate the rapid attenuation of electromagnetic waves that are eventually absorbed by the material.The SiO2film has highkvalues in a wavelength range of 810μm,and the Si3N4film has highkvalues in a broader region above 6μm.In the high-karea,each material exhibits high emissivity, which is caused by strong phonon polarization resonances.Mixing materials and superimposing their optical properties make it possible to achieve high emission properties throughout the sky window.

Submicron TiO2particles (anatase and rutile) have been shown to scatter sunlight strongly and act as effective solar reflectors.[31]Therefore, we use a particle radius of 0.5 μm and a volume fraction of 10%to achieve the effect of solar reflection,which have been extensively studied.[14,15]There will be no need to mention them here particularly later.

2.2.Model building

The numerical FDTD solutions software is an optical simulation and analysis software based on the FDTD algorithm for solving Maxwell’s equations in three dimensions,which has a wide range of applications in the design, analysis, and optimization of optical materials and photonic devices.A periodic structure of a specific size represents the simulation domain of a coating composed of particles.Because the volume fraction of particles is too large,it is not conducive to cast,film formation,and poor light transmission.The particle volume fraction is chosen to be 10% in the simulation.The refractive index parameters of SiO2and Si3N4arecited from Ref.[32].

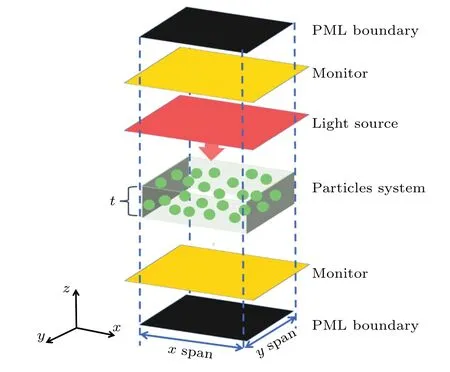

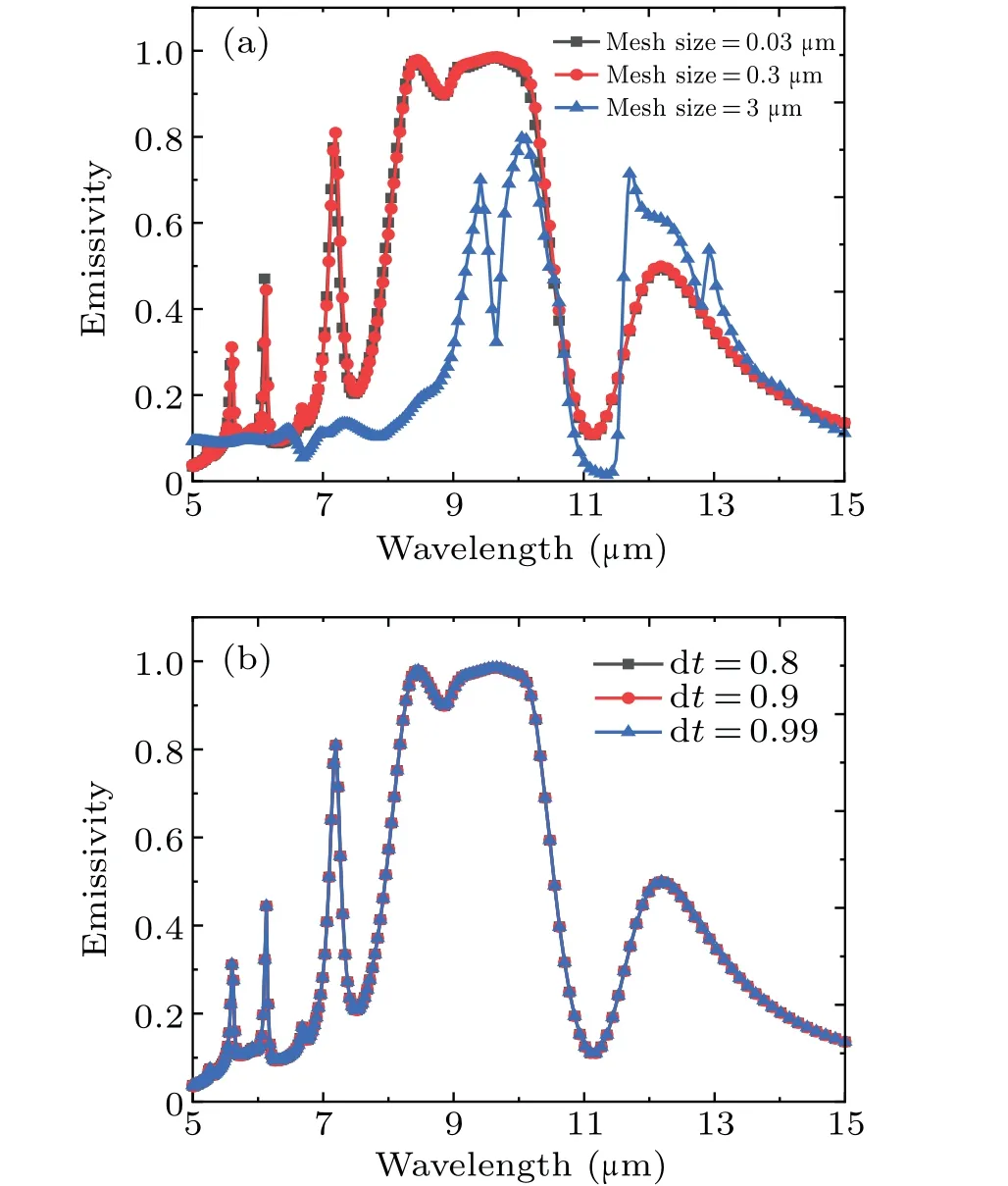

After fitting the material parameters, setting the geometric modeling and calculation area.The schematic diagram of the simulation domain can be obtained as shown in Fig.3.Thexspan andyspan are both 10 μm, and the thickness is in a range of 5μm–25μm.While thexdirection and theydirection are both set to be periodic, thezdirection is set to be in a non-periodic condition.The mesh accuracy meets the calculation requirements.Figure 4 shows the effect of the grid size and dtstability factor on the emissivity.When the SiO2is coated with 1.5-μm-radius particles and the coating thickness reaches 5 μm, it can seen that convergent results can be achieved by using a mesh size of 0.03μm.The mesh step size of 0.03 μm is chosen for the subsequent calculation.At the same time, the dtstability coefficient has little influence on the simulation results within the considered range.Considering the calculation cost,the dtstability coefficient is selected as 0.9 for calculation.Taking the light source as plane wave,its spreading area in thexdirection should be larger than the calculation area,and its propagation should be in the negative direction of thezdirection.Then the reflectivity monitor is positioned above the incident light and the transmittance monitor is placed underneath the coating.It is worth noting that the attention must be paid to selecting an appropriate distance between the monitor and the boundary.

2.3.Optimization of particle size and coating thickness

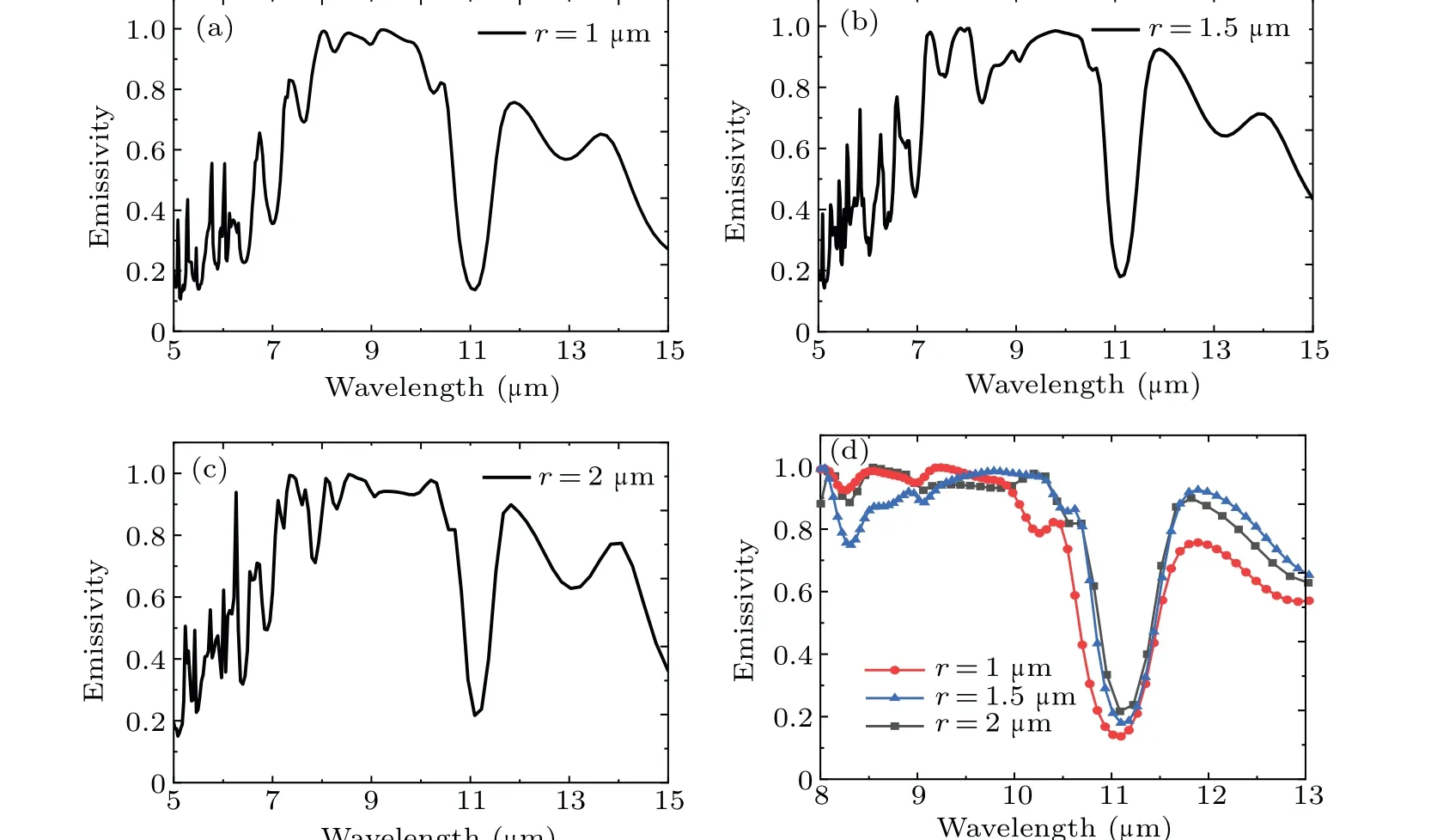

The effect of SiO2particle size on the performance of radiative cooling coating is first investigated.To study the size effect of the particles,we first set the thickness to 25μm.When the size parameter(x=2πr/λ)is approximately equal to 1,the Mie resonance peak appears.[14]In this work,the radii of SiO2particles are selected to be 1μm,1.5μm,and 2μm,respectively.The simulation results of the predicted emissivity in a range of 5μm–15μm are shown in Figs.5(a)–5(c).Figure 5(d)shows the comparison of predicted emissivity among SiO2coatings with particle radii in a range of 8μm–13μm.It can be observed that the curves of predicted emissivityversuswavelength of the coatings have similar trends in the wavelength range between 8 μm and 10.5 μm.And the particles with radius of 1.5μm have the highest emissivity in the wavelength region between 11.5 μm and 13 μm.Therefore, the particle radius is set to 1.5μm in the following studies.

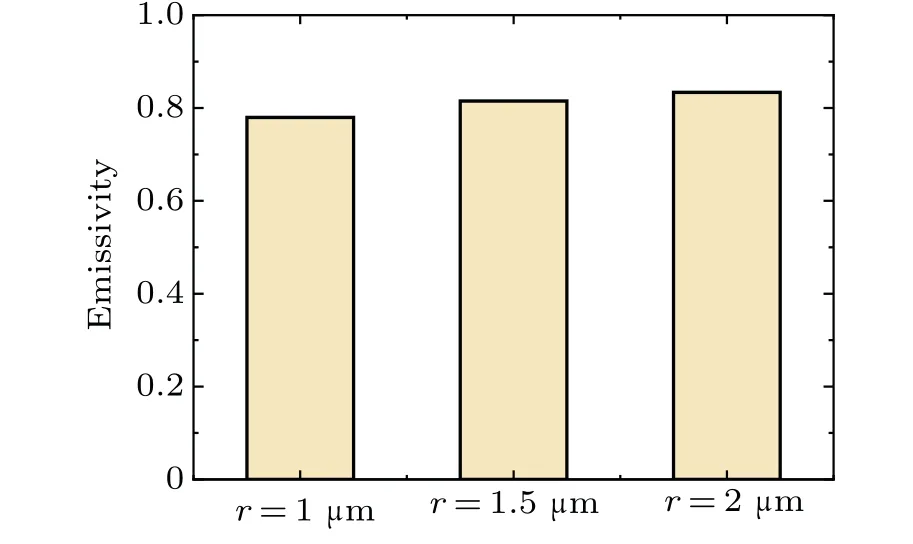

Based on the above simulation results,the average emissivity of SiO2coatings with different particle radii in a range of 8μm–13μm is calculated(see Fig.6).It can be seen from the figure that the average emissivity of disordered particles increases with the increase in particle size.The average emissivity of the coating atr=1.5μm does not differ much from that atr=2 μm.The average coating emissivity is greater than 0.8 when the particle radius is 1.5 μm.Still, the overall coating average emissivity does not reach 0.9,owing to the low coating emissivity in the particle radius range of 10.5μm–11.5μm.

The effect of thickness of densely packed particles on the coating emissivity is further investigated.And the simulation results of the predicted emissivity in the range of 5μm–15μm are shown in Figs.7(a)–7(c).Figure 7(d)shows a comparison of predicted emissivity among the SiO2coatings with different thicknesses in the range of 8 μm–13 μm.The trends of IR emissivity varying with wavelength for different thickness are almost identical.As the coating thickness increases, the emissivity in the 11.5 μm–13 μm band increases.When the thickness is 5 μm, the emissivity is low, around 0.4.However,when the thickness is above 25 μm,the emissivity of the coating is sufficiently high.

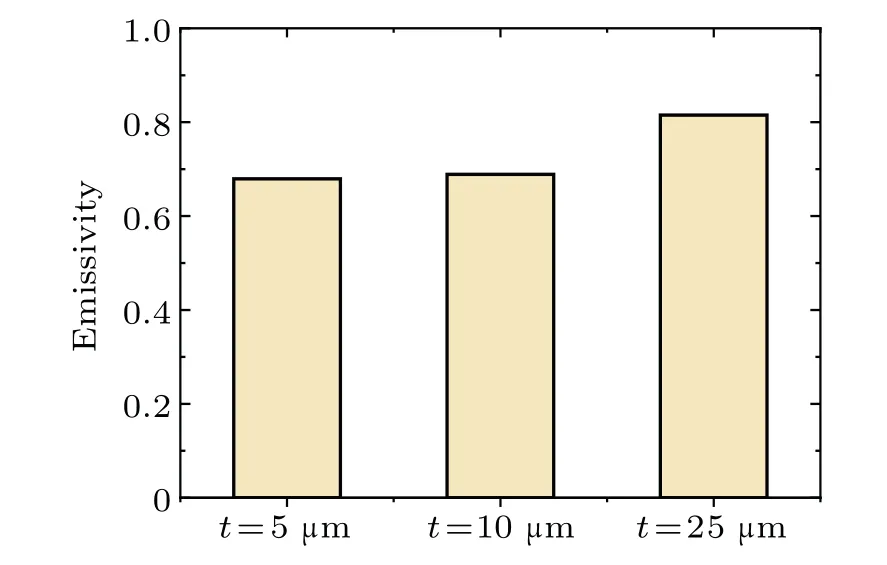

The average emissivity of SiO2coatings with different thicknesses in the range of 8 μm–13 μm is shown in Fig.8.With the increase in thickness, the average emissivity of the disordered particle system shows an increasing trend.When the film thickness is 5μm,the average IR emissivity at 8μm–13 μm is only 0.67.However, when the film thickness increases to 25μm,the average IR emissivity rises to 0.82.

At the same time,comparing the influence of coating particle radius and thickness on emissivity,the emissivity is generally lower in the range of 10.5μm–12μm.To improve the overall emissivity of the coating, the optimal particle radius and coating thickness of the SiO2coating simulation are retained, then a model witht=25 μm andr=1.5 μm is selected to study the effect of the addition of SiO2and Si3N4particles.The effect of dopant content on the coating emissivity is investigated.The existing 1.5μm-radius Si3N4particles are irregularly shaped,and to facilitate the study of their effect on the radiative properties of the coatings, spherical particles are adopted here.

The predicted emissivity values of mixed coatings with different mixing ratios of SiO2particles to Si3N4particles are shown in Fig.9.It can be found that a highly selective emissivity within the transparency atmospheric window can be achieved owing to the synergy of the optical properties of the material.The addition of Si3N4particles is beneficial to the improvement of the emissivity of the radiation coating in the wavelength region between 10.5μm and 12μm.And the average emissivity of the mixed coatings added in two mixing ratios is over 0.9 in the range of 8μm–13μm.

2.4.Fabrication

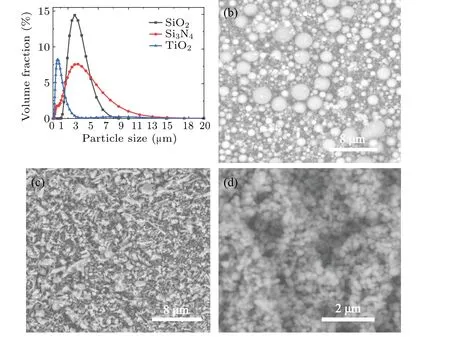

Based on the results of theoretical simulations,the rutile TiO2(1μm),SiO2(3μm),and Si3N4(3μm)particles are selected to prepare coatings for the experiments.Figure 10 provides the particle size distributions and morphological characterizations of raw material.The results show that the SiO2and TiO2particles are relatively regular spherical particles with smooth surfaces,while the Si3N4particles are irregularly shaped.

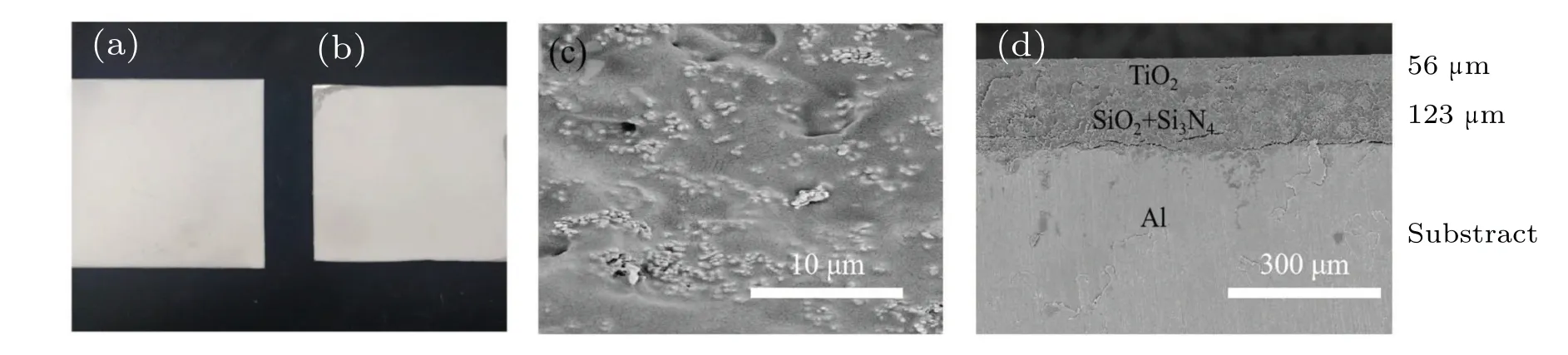

In the first step of the coating preparation,the acrylic resin is mixed with N,N-dimethylformamide(DMF)solvent to prepare the solution.The volume ratio between solute and solvent is about 1:3.The solution is then stirred with a magnetic stirrer for 30 min until the solute is completely dissolved and SiO2and Si3N4microparticles with different ratios are added.Then the solution is stirred for 1 h to obtain uniform suspensions,during which an anti-settling and leveling agent are added to improve the coating performance.The prepared dispersion solution is dropped onto the Al substrate,and the mixed coatings embedded with SiO2and Si3N4microparticles are applied using a wire rod applicator by controlling the rotational speed.Then the deposited film layer is dried at room temperature for 1 h.To prepare a two-layer coating,a second layer of the dispersion solution is placed at the top in the same way and dried at room temperature.To ease fabrication, a hybrid coating with a thickness of 120 μm is prepared here by scratch coating.The photograph of the double-layer coatings painted on an Al substrate, surface, and cross-sectional SEM images for coating prepared by 1:1 ratio are shown in Fig.11.The total thickness of the double layer coating is about 179μm.

3.Results and discussion

3.1.Radiation properties of coatings

The reflectance of the coatings in the solar spectral region (0.3 μm–2.5 μm) is measured by using a UV–Vis–NIR spectrophotometer(UV-3600i Plus, Shimadzu, Japan)and an integrating sphere.Specular reflectance in a wavelength band of 2.5 μm–15 μm is measured by using a Fourier transform infrared spectrometer(Nicolet IS-50,Thermal Sciences).Because the measured coating is opaque, the absorptivity of the coating can be calculated byA=1-R.In the formula,Ais the spectral absorptance,Ris the reflectance.And the emissivity of the coating can be further obtained according to Kirchhoff’s thermal radiation law.[14]

The measured spectral emissivity values of 120-μm-thick hybrid coatings with different mixing ratios on Al substrates are shown in Fig.12(a).Layers mixed with SiO2and Si3N4have high reflectivity in the solar radiation region (0.3 μm–2.5 μm) and high emissivity in the infrared area (2.5 μm–15 μm).The high reflectivity values of the two coatings in the wavelength band of 0.3μm–2.5μm are mainly due to the strong scattering effect of the TiO2particles, and gradually disappear with the increase of the wavelength.While the mixture coating with a 1:1 ratio on the Al substrate has higher emissivity in the wavelength band of 0.3 μm–2.5 μm due to the relatively low band gap energy of Si3N4and the increase in its content, which affects solar reflection.[28]The spectral emissivity of the double-layer coating depends mainly on the underlying emissive layer.Owing to the superposition of the high-kregion of SiO2and Si3N4, high emissivity is achieved for the entire atmospheric transparency window,which is consistent with the theoretical simulation result.The emissivity spectra of the two double-layers are similar, and the hybrid coating with a 1:1 ratio added has better emission performance in the wavelength range of 8μm–13μm.This may be because Si3N4films have highkvalues in the wavelength range above 6μm.An increase in Si3N4content,caused by strong phononpolarization resonance effects increases the emissivity of the coating.The reflectance of the coating prepared at a 1:1 ratio exceeds 0.9 at 0.4μm–1.6μm,and the average reflectance in the solar spectrum reaches 87.6%.The average emissivity of 2.5μm–15μm is 92%.

The comparison between simulated emissivity and measured emissivity of the 120-μm-thick radiative cooling coating prepared at 1:1 addition in a wavelength range of 5μm–15μm is shown in Fig.12(b).The results show that the average emissivity of the coatings in the range of 5 μm–8 μm increases from 0.82 to 0.92 as the thickness increases.And the simulation results fluctuate within a specific range compared with the measured emissivity in the 8μm–15μm band,which may be attributed to the fact that the simulations are performed with a certain accuracy and that the raw material may also have errors due to incomplete dissolution during the actual sample preparation.

3.2.Theoretical cooling performance

When the radiative cooling material is exposed to a clear sky, it will spontaneously radiate heat outward radiation, but also absorbs thermal radiation from the sun,atmospheric thermal radiation, and its non-radiative heat transfer.Assuming that the ambient temperature isTamband the surface temperature of the radiative cooling material isT, the cooling power per unit surface areaPcool(T)can be expressed as[33]

wherePradis the power emitted from the surface of the radiative cooling materials,Patmis the power absorbed from the atmospheric projected radiation,Psunis the power absorbed by solar thermal radiation,andPnonradis the absorbed power due to heat conduction and convection, all in units of W·m-2.It can be calculated from the following equation:[16]

whereEbλ(T,λ) is the monochromatic emissive power of the surface at temperatureTand wavelengthλ,ε(λ) denotes the spectral emissivity of the coating at wavelengthλ.εatm(λ,θ)represents the atmospheric emissivity,and its value isεatm(λ,θ) =1-t(λ,0)1/cosθ,t(λ,0) refers to the atmospheric transmittance in the zenith direction,EAM1.5(λ)is the solar radiance,and the integral over a range of 0.3μm–2.5μm is about 900 W·m-2,andhcis the non-radiative heat transfer coefficient.

From the viewpoint of emissivity,passive radiative coolers can be divided into selective emitter and broadband emitter.Their difference lies in the fact that the broadband emitter has an infrared emissivity of 1 in all but for the range of 0.3μm–2.5 μm.For the broadband emitter, when the temperature of the radiative cooler is lower than the atmospheric temperature,the power absorbed from the atmosphere increases, which is not conducive to achieving radiative cooling.When the surface temperature is higher than a certain value,280 K,which is cited from Ref.[15],the increase in emission is better than the increase in absorption,and the broadband emitter has a better cooling capacity.[15,34,35]In practical applications, the building surface temperature is higher than the atmospheric temperature under direct daytime sunlight conditions.The material temperature for radiative cooling over the building surface is usually set to be higher than the atmospheric temperature.

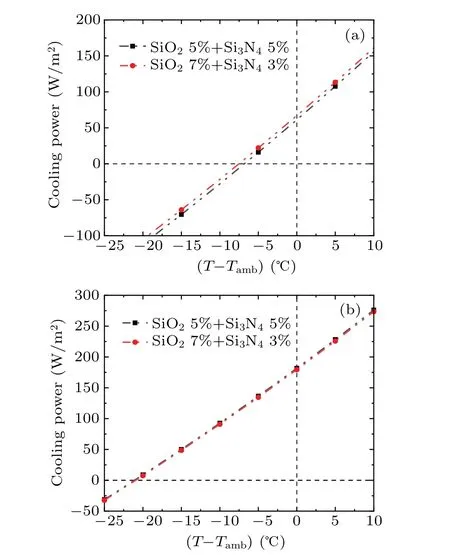

To analyze the radiative cooling performance of our bilayer hybrid coating, we perform theoretical calculations at different values of surface temperatureT.First,we assum that the ambient temperature is 300 K.Second, the heat convection caused by temperature difference and the energy transfer triggered off by heat conduction cannot be ignored.Generally,the non-radiative heat transfer coefficient ranges from 0 to 12 W·m-2·K-1.Here,hc=4 W·m-2·K-1is selected in cooling power calculation.At the same time, it is compared with the cooling power without non-radiative heat transfer.The calculated relationship between cooling power and the temperature difference is shown in Fig.13.

Figure 13(a)shows the radiative cooling power at different temperature differences of coatings during the day.Under direct sunlight (AM1.5), a hybrid coating with a 7:3 ratio addition of SiO2and Si3N4can theoretically achieve a cooling power of 67 W·m-2when the surface temperature is the same as the ambient temperature.And the hybrid coating with a 1:1 ratio addition can achieve a cooling power of 61 W·m-2.Both layers can theoretically achieve a cooling capacity of about 8?C below the ambient temperature(whenhc=4 W·m-2·K-1).Furthermore, if the non-radiative heat transfer is neglected,the hybrid coating with 7:3 addition can theoretically achieve about 15?C below the ambient temperature.

Figure 13(b)shows the radiative cooling performances of the coatings during the night at different surface temperatures.When the surface temperature is the same as the ambient temperature, the hybrid coating added at a 1:1 ratio addition has a larger cooling power (about 180 W·m-2), and both coatings achieve similar stagnation temperatures, which are theoretically about 21?C below the ambient temperature (whenhc=4 W·m-2·K-1).In addition,if non-radiative heat transfer is neglected, the mixed coatings with different ratios all can reach approximately 40?C below the ambient temperature.

The cooling performance of the coatings are further investigated by considering conduction and convection heat exchange.We consider three different values of nonradiative heat transfer coefficienthcof 0, 6 W·m-2·K-1,and 12 W·m-2·K-1, in whichhc= 6 W·m-2·K-1and 12 W·m-2·K-1denote wind speeds of 1 m/s and 3 m/s,respectively.[36]Figure 14 shows the relationships between cooling power and surface temperature of the hybrid coating added with a ratio of 1:1 at different non-radiative heat transfer coefficients.

As shown in Fig.14, the coating has the same cooling power for different non-radiative heat transfer coefficients when the coating surface temperature is the same as the ambient temperature.Owing to the neglect of solar thermal radiation at night, the corresponding radiative cooling flux increases.When the surface temperature of the coating is higher than the ambient temperature, the net radiative cooling flux of the composite coating keeps increasing because the temperature difference causes the coating to dissipate heat to the outside.When the surface temperature of the coating is lower than the ambient temperature, the net radiative cooling flux of the coating becomes smaller and smaller because the temperature difference causes the coating to absorb external heat.When the value of the radiative cooling flux decreases to 0,the surface temperature of the coating reaches its minimum value.During the daytime,the minimum surface temperatures of the coating are 287 K(hc=0),294.5 K(hc=6 W·m-2·K-1),and 296 K (hc=12 W·m-2·K-1) for different non-radiative heat transfer coefficients,respectively.

3.3.Experimental results of cooling performance

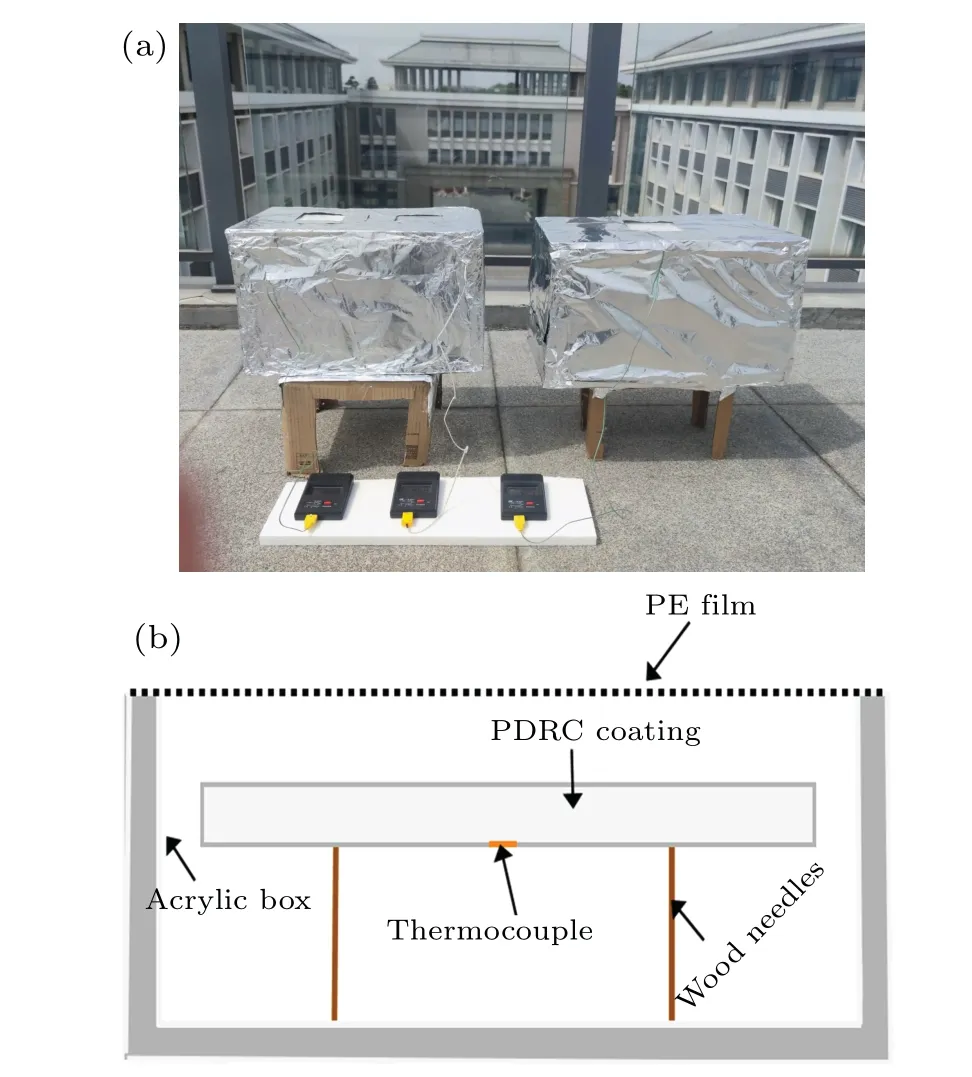

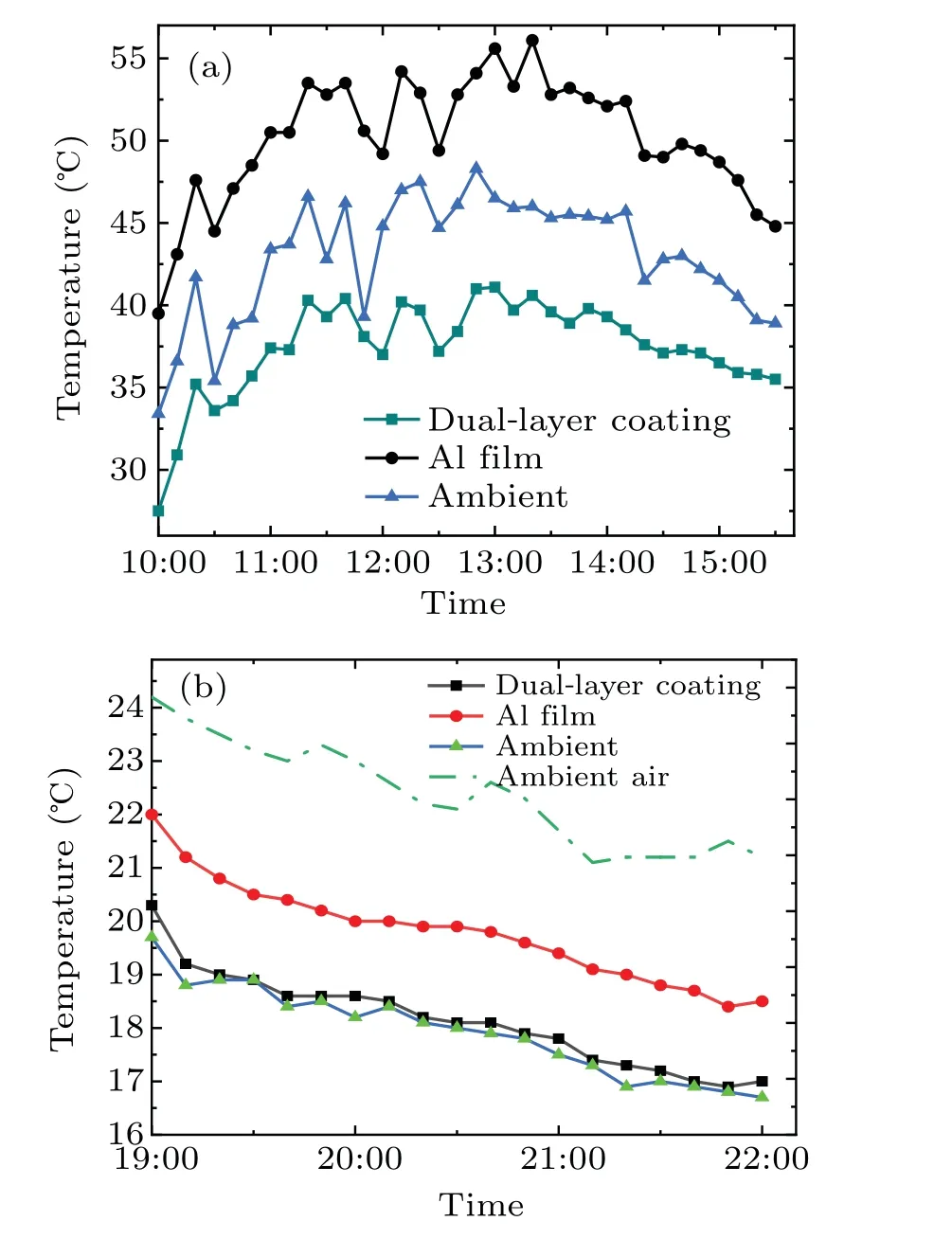

To obtain the actual cooling effect of coatings,a 120-μmthick hybrid coating with a particle size of 3μm is prepared.And a volume fraction of both SiO2and Si3N4of 5% is selected here for the radiative cooling experiments on the roof in Nanjing,the uncoated Al film and the ambient temperature are also selected as the control experimental factors.The experimental setup and its internal schematic are shown in Fig.15.Polystyrene foam box is used for isolating the heat exchange between the coating and the outside environment.A PE film is used on the top to ensure that the energy emitted by the layer can enter into outer space while reducing the air convection effect.Wood needles support the coating to prevent the floor for heating.And for daytime radiative cooling experiments,the surface is covered with aluminum foil to reduce solar radiation.The temperature of the inner surface of the coating is measured by using a thermocouple,while the ambient temperature is calculated by using a device with no PDRC coating placed on it.[37]

We conducte daytime outdoor experiments from 10:00 a.m.to 15:30 on April 15,2023 when the humidity was 38%.The test results are shown in Fig.16(a).The results show that the temperature of the double-layer radiative cooling coating is always lower than the ambient temperature under direct sunlight,reaching an average of 5?C below the ambient temperature and about 12?C below the temperature of the Al film.Although the aluminum film can reflect part of the sunlight,the temperature of the aluminum film is about 7?C higher than the ambient temperature.It is important to note that our temperature measurement points are located inside the PE film-sealed cavity, which produces a greenhouse effect during daytime measurements.[37]Hence,the temperature inside the box is higher than the outdoor atmospheric temperature.Also, weather conditions (wind speed, humidity, and cloudiness)significantly affect outdoor test results.[34]The increase in cloud cover during daytime measurements can lead to significant fluctuations in test temperature.

The night cooling experiment was measured from 19:00 to 22:00,with an average wind speed of 1.4 m/s and humidity of 52%.The test results are shown in Fig.16(b).As can be seen from the figure,both the Al film temperature and the ambient temperature measured inside the sealed cavity of the PE film are lower than the ambient air temperature measured outside the device at night.The double radiative cooling coating has no cooling effect compared with the ambient temperature measured inside the sealed PE film cavity, indicating that the broadband radiative cooler is more suitable for environments where the temperature is higher than the atmospheric temperature.However,its temperature can be about 1.6?C below the temperature of the Al film,and it can be cooled by about 4?C compared to the ambient air temperature measured outside the experimental setup.

Our prepared coatings are compared with other coatings in order to evaluate the cooling performance of our coatings.A comparison of our coating is made with a double-layer radiative cooling coating (ε=0.90) containing TiO2particles and SiO2particles cited from Ref.[14], showing that the hybrid coating with a 1:1 ratio addition of SiO2and Si3N4can increase the average emissivity of the“atmospheric window”spectrum by 2.2%.And it is beneficial to the theoretical cooling of 3?C during the day whenh=4 W·m-2·K-1.Another comparison of our coating is conducted with the single-layer radiative cooling coating (ε=0.86) cited from Ref.[17], indicating that adding a 1:1 ratio of hybrid coating can increase the average emissivity of the“atmospheric window”spectrum by 6.9%.

4.Conclusions

In summary,a cost-effective double-layer coating embedded with TiO2, SiO2, and Si3N4micro particles in acrylic resin, which can improve cooling performance, are proposed in this work.The simulation results show that the particle size of 3 μm can give the best cooling performance and the coating thickness should be above 25 μm for SiO2coating.Meanwhile,the addition of Si3N4particles is beneficial to the improvement of the emissivity of the radiation coating.The coatings prepared by mixing different ratios of SiO2to Si3N4all have good PDRC optical properties.On an Al substrate,the overall reflectance of the mixed coating added with a ratio of 1:1 in the solar spectrum reaches 87.6%and the emittance is 92% in the atmospheric transparency window.Under dry air condition and assuming non-radiative heat transfer coefficienthc=4 W·m-2·K-1, the cooling power values of these coatings are calculated with the measured spectral emissivity.Both coatings can be theoretically cooled by about 8?C during the daytime and about 21?C at nighttime.The achieved equilibrium temperature is lower than the ambient temperature,indicating that even after considering the significant conduction and convective heat exchange, the cooling effect still exists.Daytime outdoor experiments show that the radiative cooling coating temperature is lower than the ambient temperature and that the coating has a cooling effect.

- Chinese Physics B的其它文章

- The application of quantum coherence as a resource

- Special breathing structures induced by bright solitons collision in a binary dipolar Bose–Einstein condensates

- Effect of short-term plasticity on working memory

- Directional-to-random transition of cell cluster migration

- Effect of mono-/divalent metal ions on the conductivity characteristics of DNA solutions transferring through a microfluidic channel

- Off-diagonal approach to the exact solution of quantum integrable systems