Effects of Emulsifier on Fermentation Performance of Active Dry Wine Yeast

*

1. Hubei Key Laboratory of Yeast Function, Yichang 443003, China; 2. Angel Yeast Co. Ltd., Yichang 443003, China

Abstract [Objectives] To explore the influence of emulsifier on the fermentation performance of wine active dry yeast. [Methods] Angel active dry yeast RV002 was selected as the test strain, and the simulated grape juice was used as the fermentation medium to investigate the fermentation rate, the yeast cell number and morphology, and the physicochemical indexes of the produced wine. [Results] It was found that the viable cell rate of the active dry yeast without the emulsifier was significantly reduced, and the fermentation rate was significantly slowed down. However, the emulsifier had no significant effect on the morphology of yeast cells, the fermentation cycle, the final number of viable cells, and the quality of the produced wine. [Conclusions] The active dry wine yeast without emulsifier can reduce the formation of grape juice foam and reduce the risk of grape juice spillover.

Key words Wine, Active dry yeast, Emulsifier, Fermentation rate

1 Introduction

The application history of yeast is as long as the history of human development, and plays an important role in human social life[1]. In the wine-making industry, the wine field is the earliest, and most technologically mature industry to use active dry wine yeast extensively on a large scale. In the early 1960s, wine producing areas in Europe and the United States began to use active dry wine yeast. China has come to use active dry wine yeast since the end of 1980s. In 1997, China’s first native active dry wine yeast 1450 was introduced by China Edible Yeast Base (now Angel Yeast Co. Ltd.) in Yichang, Hubei Province, China, filling in the gap of Chinese native active dry wine yeast[2]. The commercial active dry wine yeast has the comprehensive advantages of convenient storage, fast transportation, flexible use and operation, and the yeast cells will be dehydrated and dried in the production process of the active dry wine yeast. The water content of the final active dry wine yeast is 4.0%-8.0%[3]. In the drying and dehydration process of yeast production, a variety of physical and bioengineering techniques are used to make yeast cells lose all free water and most of the bound water, and the loss of water leads to the loss of the hydration layer of the cell membrane. In order to prevent the damage of wine yeast in the drying process, the traditional process will choose to add an appropriate amount of emulsifier to protect yeast cells, so as to make the active dry wine yeast meet the corresponding product quality standards and meet the technical needs of food fermentation[4]. Through this experiment, it was verified that emulsifier could reduce the living cell rate of active dry wine yeast, and the final living cell number would meet the OIV’s requirement that the number of living cells should be more than 10 billion/g. At the beginning of fermentation, the number of living cells would be relatively reduced, but with the progress of fermentation, the final number of living cells had no significant difference, which would not affect the fermentation quality of wine. China’s wine production maintained an average annual compound growth rate of 20% from 2000 to 2010, exceeding 1 million t in 2010[5]. In industrial production, the fermentation rate of active dry wine yeast is too fast, and the grape juice foam is extremely rich, so there is a great risk of grape juice spillover. The purpose of this experiment is to explore the effects of emulsifier on the morphology of yeast cells, the number of living cells, the fermentation cycle of wine, the quality of final fermentation products and the speed of fermentation during the post-treatment of dehydration and dryness, in order to reduce the fermentation rate of active dry wine yeast in the fermentation process without affecting the fermentation cycle and the final quality of wine to prevent this risk from happening.

2 Materials and methods

2.1 Materials, reagents and instrumentsFermentation: distiller’s yeast RV002, provided by the strain bank of Biotechnology Research Institute of Angel Yeast Co., Ltd.

Reagents: molasses, emulsifier (sorbitan monostearate), yeast extract, magnesium sulfate, zinc sulfate,etc., all provided by Production Technology Center of Angel Yeast Co., Ltd.

Instruments and equipment: BK1301 biomicroscope, Nanjing Gengchen Scientific Instruments Co., Ltd.; NRY-2110 constant temperature shaker, Shanghai Nanrong Laboratory Equipment Co., Ltd.; HDS-16-5 halogen electronic moisture meter, Shanghai Fangrui Instrument Co., Ltd.; C20-2 small automatic fermentor,B.Braunof Germany; TDL-40B high speed centrifuge, Shanghai Anting Scientific Instrument Factory; J26XP high speed centrifuge, Beckman Co., Ltd.; WBF-2G small drying bed, Chongqing ENGER Technology Co., Ltd.; E-50 small granulator, Chongqing ENGER Technology Co., Ltd.

2.2 Test method

2.2.1Seed yeast culture. Seed shaking culture: sucrose 100 g, yeast extract FM888 20 g, magnesium sulfate, potassium dihydrogen phosphate, volume fixed to 1 L, pH adjusted to 4.8 with dilute sulfuric acid, RV002 strain inoculated and cultured in a shaking table at a rotational speed of 180 r/min and a temperature of 30 ℃ for 24 h.

2.2.2Commercial yeast culture. Substrate sterilization: the volume of magnesium sulfate, zinc sulfate and yeast extract fixed to 9 L, pH adjusted to 4.8 with dilute sulfuric acid, sterilized at 121 ℃ for 30 min.

Inoculation: 1 L of seed shaking medium was inserted into the fermentor under aseptic condition.

Fermentation: using molasses as carbon source, ammonium sulfate as nitrogen source and ammonium dihydrogen phosphate as phosphorus source. The pH was controlled at 3.3-6.8, the speed was 300-600 r/min, the ventilation rate was controlled at 8-40 L/min, and the temperature was controlled at 29-36 ℃. After the yeast was rich in inclusion and the budding rate of the cell was less than 5%, the yeast sample was kept in the air for the next experiment[6].

2.2.3Drying of yeast[7]. Drying process: separation→washing→filtration→pressure filtration→granulation→drying.

Operation steps:

(i) Filtration of yeast cream: the emulsifier was prepared with hot water at 80-90 ℃ by adding 12.5 kg per 100 L of water. After blending, it was kept at 65-70 ℃ and the yeast cream prepared was added before filtration, 0%, 0.5%, 1% emulsifier was added, respectively, and it was ensured to be mixed well.

(ii) Plate press filtration: the water content of the yeast block after plate pressure filtration was less than 65%.

(iii) Drying: the air humidity in the drying bed was less than 6 g/kg, the inlet air temperature was controlled at 60 ℃, the material temperature was controlled at 52 ℃, and the drying time was 30 min.

2.2.4Testing of dry yeast index. The detection of protein, phosphorus pentoxide, trehalose and other trace components refers to Q/YB.J06.101-2016YeastProductionProcessAnalysisMethodofAngelYeastCo.,Ltd.

2.2.5Determination of routine physical and chemical indexes of wine samples. The determination of alcohol, residual sugar, total acid and volatile acid refers to GB/T15038-2006GeneralAnalysisofWineandFruitWine.

2.2.6Preparation of simulated grape juice. The simulated grape juice was prepared with reference to the international technical standard of OIV. The culture medium was composed of three parts: stock solution A, stock solution B and stock solution C.

Stock solution A: 240 g/L sucrose was added to 375 mL of distilled water and the final volume was fixed to 500 mL.

Stock solution B: 6 g/L tartaric acid, 3 g/L malic acid and 0.5 g of citric acid were added to 250 mL of distilled water.

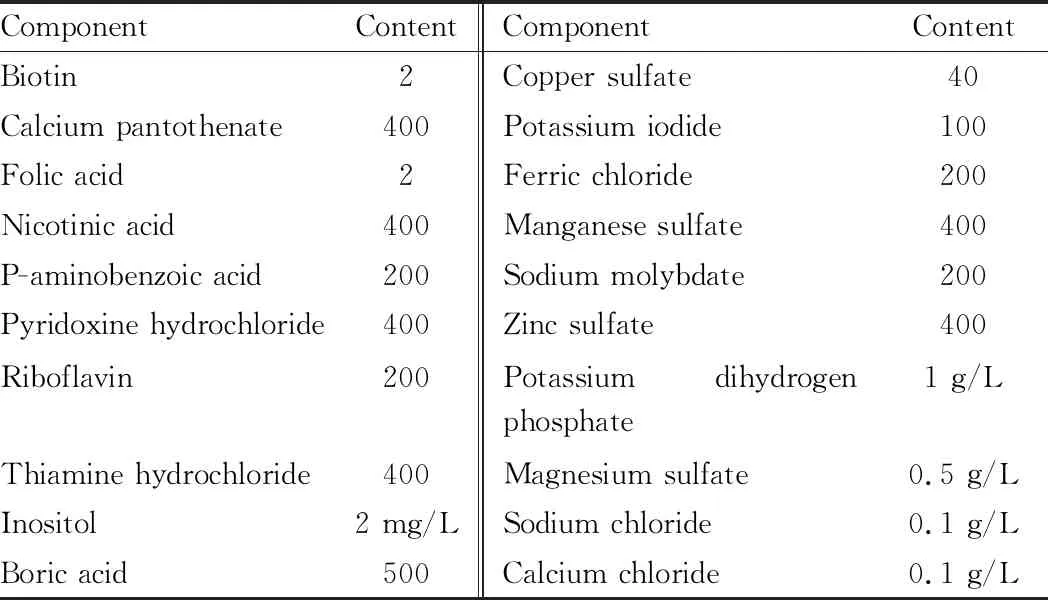

Stock solution C: 6 mg of inositol, 0.2 g of calcium chloride, 1.7 g of YNB (Table 1) and nitrogen source (1 g/L DAP, 1 g/L FM888) were added to 250 mL of distilled water.

The stock solution A, B and C were mixed and pH was adjusted to 3.5 with 4 mol/L potassium hydroxide.

Table 1 YNB medium

2.2.7Detection of fermentation performance of active dry wine yeast. Using 250 ppm inoculum, the weighed active dry wine yeast was put into a 10 mL test tube in advance. According to the conventional activation process, 1∶10 38 ℃ deionized water was added to completely dissolve the active dry wine yeast[8]. The test tube with activating solution was put into a constant temperature water bath at 38 ℃ to activate for 20 min, and then a small amount of simulated grape juice was gradually added. When the temperature difference between the yeast activation solution and the simulated grape juice was less than 10 ℃, the yeast activation solution was inoculated into a 500 mL triangle flask containing simulated grape juice. Each flask was filled with 250 mL simulated grape juice, and there were three replications for each sample[9-10].

2.2.8Observation of cell morphology in the process of fermentation. In the process of fermentation, 1 mL of fermentation broth was taken every 24 h to observe the morphology of yeast and record it by microscope, and observe the morphological changes of yeast in cell size, cell shape, budding rate, inclusion, vacuole and so on.

3 Results and analysis

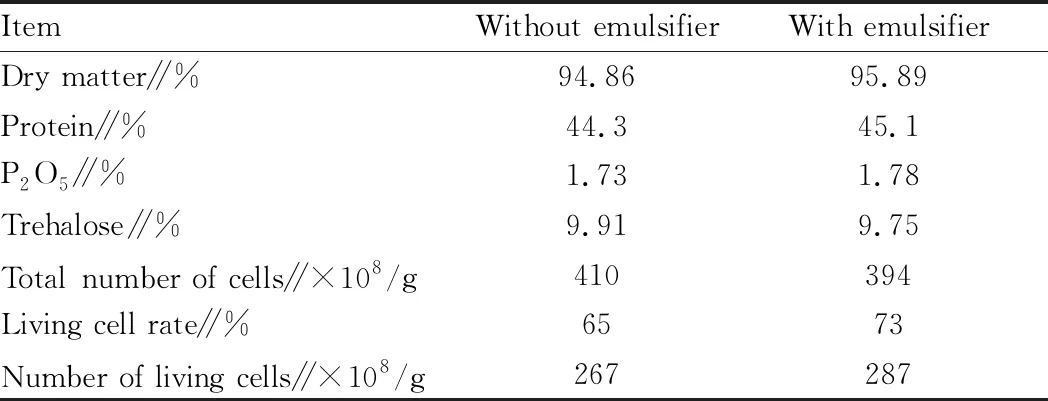

3.1 Detection of physicochemical indexes of active dry wine yeast of grape wineIt can be seen from Table 2 that the active dry wine yeast without emulsifier, with 0.5% emulsifier and with 1% emulsifier showed no significant difference in dry matter, protein, phosphorus pentoxide and trehalose. In terms of living cell rate, the living cell rate of active dry yeast without emulsifier was 11% lower than that of active dry yeast without emulsifier, and there was a significant difference. It can be seen that emulsifier had a significant effect on the living cell rate of active dry wine yeast.

Table 2 Comparison of physical and chemical indexes of wine active dry yeast

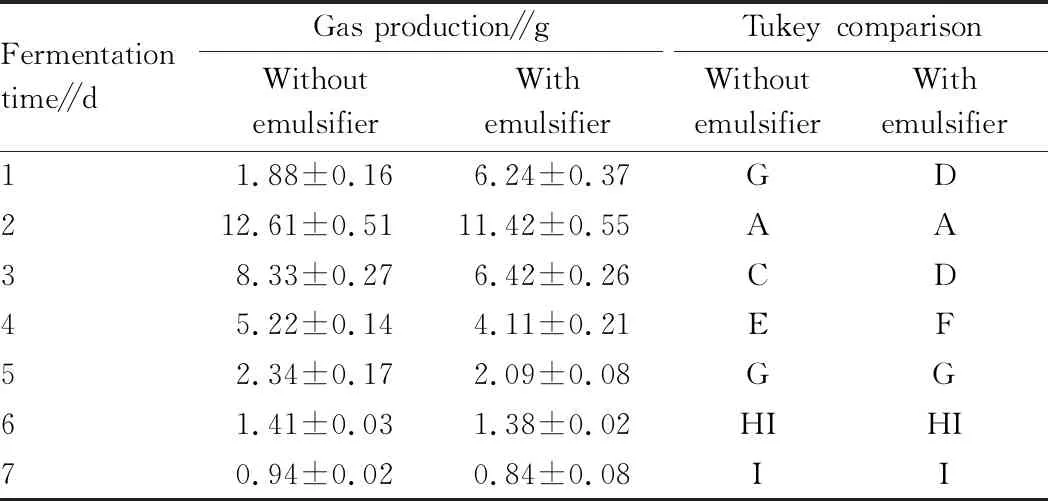

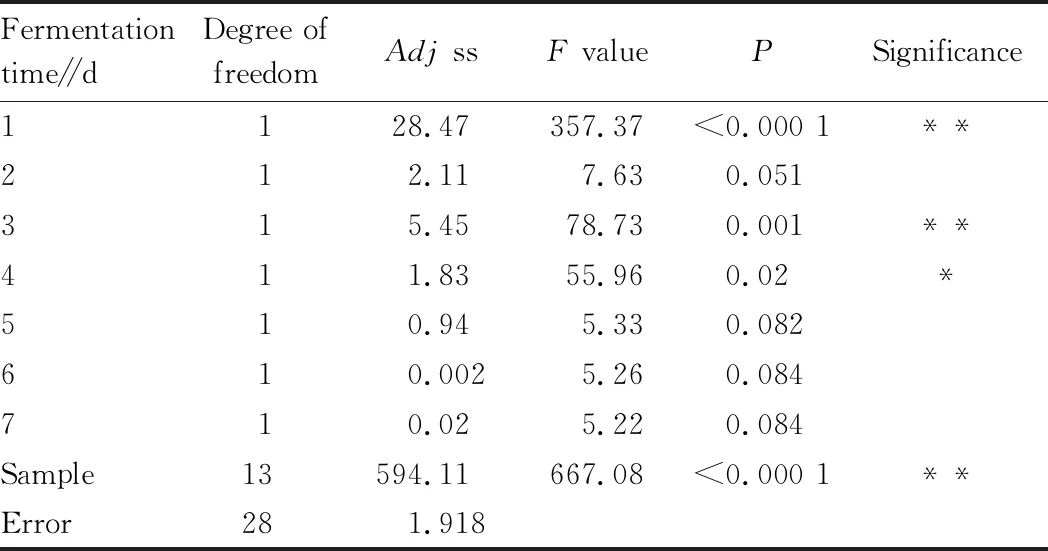

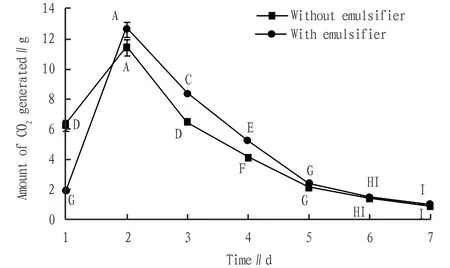

3.2 Comparison of fermentation dynamics with and without emulsifier during yeast dryingAs can be seen from Table 3-4 and Fig.1:

(i) The effect on fermentation rate: the first day weight loss of yeast with 1% emulsifier was 6.24 g, the weight loss of yeast with 0.5% emulsifier was 3.41 g, and the weight loss of yeast without emulsifier was 1.88 g. The fermentation rate would decrease with the decrease of emulsifier, and the fermentation rate of yeast without emulsifier was 30% of that with emulsifier, and the difference was extremely significant (P<0.001). It can be seen that no addition of emulsifier can significantly reduce the fermentation rate of wine yeast.

(ii) The effect on fermentation peak: the fermentation of wine yeast reached the peak on the second day, in which the weight loss of yeast without emulsifier was 12.6 g, the weight loss of yeast with 0.5% emulsifier was 12.26 g, and the weight loss of yeast with 1% emulsifier was 11.4 g. There was no significant difference among them (P>0.05). It can be seen that no addition of emulsifier would not affect the peak performance of wine yeast in the fermentation process.

(iii) The effect on fermentation time: the yeast with 1% emulsifier, 0.5% emulsifier and yeast without emulsifier all completed fermentation in 7 d (the fermentation was judged to be completed by daily weight loss of less than 1 g/L). It can be seen that emulsifier had no effect on the fermentation cycle of active wine yeast.

In summary, the fermentation rate of active dry yeast without emulsifier was significantly slow, but it had no significant effect on the fermentation peak value and no effect on the fermentation cycle.

Table 3 Daily weight loss during fermentation

Table 4 ANOVA using minitab regression model

Fig.1 Comparison of daily weight loss in fermentation

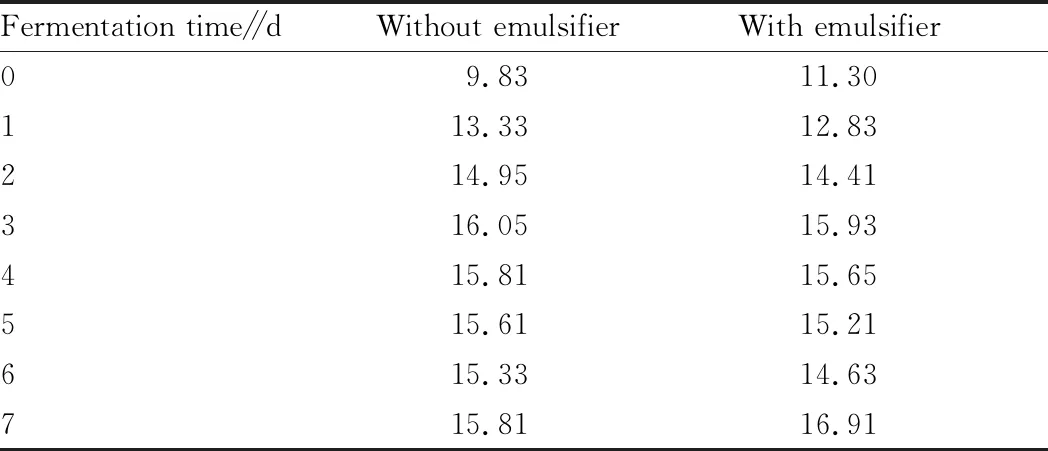

3.3 The number of yeast cells during fermentationIt can be seen from Table 5 that on the first day, the difference in the number of living cells between yeast without emulsifier and yeast with emulsifier was 14%, and the difference was significant (P<0.05). However, from the second day to the end of fermentation, the number of living cells of yeast tended to be consistent, and thePvalue calculated by minitab was 0.985, with no significant difference, which was consistent with that verified in fermentation application.

Table 5 Changes in the number of cells during fermentation (×107/mL)

It can be seen from the microscope that the first day of fermentation was the main budding time of yeast, and then the budding rate of yeast was low or even not observed, and the trend of budding rate is consistent with that of the number of living cells of yeast. The higher the budding rate, the greater the number of cells. On the seventh day of fermentation, it was observed that the mortality rates of yeast without emulsifier and with emulsifier were 14.73% and 15.57%, respectively. In the process of fermentation, there was no significant difference in the shape of yeast without emulsifier and with emulsifier. In the process of fermentation, the yeast showed almost round shape and uneven size, and the final number of cells was almost the same. It can be seen that no addition of emulsifier in the process of yeast drying had no significant effect on the morphology and the final number of living cells of yeast in the process of fermentation.

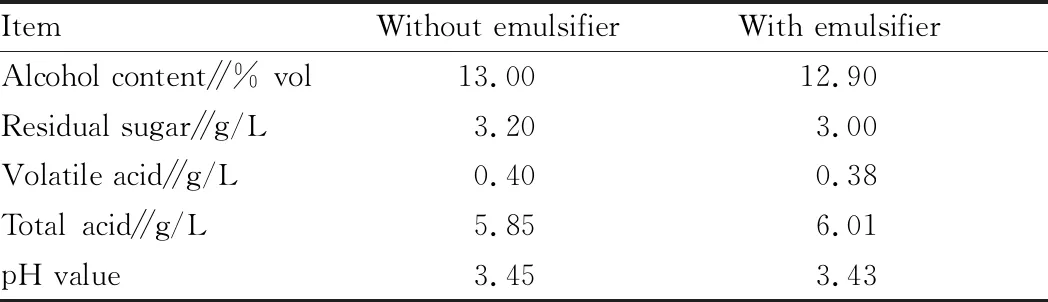

3.4 Conventional physical and chemical detection of simulated wine after fermentationAs can be seen from Table 6, through the conventional physical and chemical detection of simulated grape juice, it was found that the residual sugar content of both was less than 5 g/L[12], and both of them could complete fermentation. There was no significant difference in alcohol content, volatile acid, total acid and pH of simulated grape juice.

There was no significant difference in the physical and chemical indexes of the final wine between the simulated juice fermented by yeast without emulsifier and the simulated juice fermented by yeast with emulsifier, and the sensory group evaluated that there was no significant difference between them. It can be seen that the active dry yeast without emulsifier will not affect the quality of wine.

Table 6 Conventional physical and chemical index of wine

4 Conclusions

In this experiment, the number of living cells of active dry wine yeast decreased without adding emulsifier, but the number of living cells tended to be consistent from the second day after the start of fermentation to the end of fermentation, but there was no significant difference in the number of living cells. It will not affect the shape of wine yeast in the fermentation process, the final number of living cells, the fermentation cycle of wine, the physicochemical index of simulated wine juice, and there was no significant difference in the quality of simulated grape juice evaluated by sensory group.

The fermentation rate of active dry wine yeast without emulsifier was 30% of that with emulsifier. The active dry wine yeast without emulsifier can significantly reduce the fermentation rate of wine yeast. In this way, it can reduce the fermentation rate on the first day of wine production, reduce the formation of grape juice foam and reduce the risk of grape juice spillover.

Asian Agricultural Research2022年3期

Asian Agricultural Research2022年3期

- Asian Agricultural Research的其它文章

- Discussion on Soil Sampling Technology Based on the Experience of Yuanzegou Small Watershed

- Development Model of Daren Village Pastoral Complex in Ningbo in the Context of Rural Revitalization Strategy

- Development Status and Countermeasures of Potato Industry in Zaozhuang City

- Evaluation Model of Rural Drinking Water Project Based on Entropy Weight and Fuzzy Comprehensive Evaluation Method

- Key Technology for Virus-free Seed Potatoes Pre-elite Breeding

- Current Situations, Evolution Trend, and Improvement Measures of Soil Organic Matter in Cultivated Land of Northeast China