Compressive failure analysis of unidirectional carbon/epoxy composite based on micro-mechanical models

Wei SUN,Zhidong GUAN,Zengshan LI,Mi ZHANG,Yongjie HUANG

School of Aeronautic Science and Engineering,Beihang University,Beijing 100083,China

Compressive failure analysis of unidirectional carbon/epoxy composite based on micro-mechanical models

Wei SUN,Zhidong GUAN,Zengshan LI*,Mi ZHANG,Yongjie HUANG

School of Aeronautic Science and Engineering,Beihang University,Beijing 100083,China

Micro-mechanical model; Unidirectional composite; Initial imperfection; Matrix plasticity; Ductile damage; Kink band

A 2D micro-mechanical model was proposed to study the compressive failure of UniDirectional(UD)carbon/epoxy composite.Considering the initial imperfection and strength distribution of the fiber,the plasticity and ductile damage of the matrix,the failure of T300/914 UD composite under longitudinal compression and in-plane combined loads was simulated by this model.Simulation results show that the longitudinal compressive failure of the UD composite is caused by the plastic yielding of the matrix in kink band,and the fiber initial imperfection is the main reason for it.Under in-plane combined loads,the stress state of the matrix in kink band is changed,which affects the longitudinal compressive failure modes and strength of UD composite.The failure envelope of σ1–τ12and σ1–σ2are obtained by the micro-mechanical model.Meanwhile,the compressive failure mechanism of the UD composite is analyzed.Numerical results agree well with the experimental data,which veri fies the validity of the micro-mechanical model.

1.Introduction

Composites are widely used in aerospace engineering industry because of their advantages,e.g.light weight,high strength and excellent fatigue resistance.With the demand of lighteningweight for the structures in aerospace engineering,the amount of the composite materials used in commercial airliners reaches more than 50%of the total weight.Accordingly,more and more primary structures made of metal are being replaced by composite structures.However,the longitudinal compressive strength of the UniDirectional(UD)composite is only 50%–60%of its tensile strength,which is a significant problem for engineering applications of composite materials.Therefore,the methods for forecasting the compressive strength of the UD composites need to be investigated by researchers and engineers.

Compressive failure of UD composites has been studied by a large number of scholars.The compression micro-buckling of the fiber was proposed by Rosen1firstly and then the initial imperfection of the fiber2,3was found to be an important factor of compressive strength in further study.Generally,the fiber initial imperfection can be caused by various factors.The micro-buckling of a single fiber during the curving process of the matrix was observed by Jochum and Grandidier.4Through a series of experimental studies,Effendi et al.5found that kink band is the main compressive failure mode of UD carbon/epoxy composites.The compressive failure mode of composite was observed in the experiment,and typical geometry features of kink band include band width w,band angle β and fiber angle α,as shown in Fig.1(a).6However,the typical kink band failure mode is difficult to be observed in the compression experiment of the UD composite.The catastrophic fracture of the CCF300/5228A UD composite is shown in Fig.1(b).7The failure mode of fiber kink band is destroyed with the drastic material failure because of the failure of UD composite accompanied by huge energy release.

In order to further study the compressive failure of UD composite,numerical simulation was applied to analyze the failure mechanism and predict compressive strength.On microscopic scale,the micro-mechanical models were employed to simulate the mechanical behavior of the fiber and matrix.Taking into account the fiber initial imperfection and the matrix plasticity,the failure of the UD composites under compressive load was studied by Hsu et al.8A micromechanical model of shear-driven fiber compressive failure was given by Gutkin et al.9and the failure envelope for the case of in-plane shear/longitudinal compression was predicted by numerical simulation.On the macroscopic scale,the compressive strength of the UD composite can be predicted by failure criterion,and a large number of failure criteria for the fiber reinforce composites have been proposed and improved.The prediction accuracy of the failure criteria was verified by Hinton et al.10Zinoviev,Puck and Tsai failure criteria,11–13etc.were recommended to be used by World-Wide Failure Exercise(WWFE)because of their high prediction accuracy.Furthermore,Jumahat et al.14proposed a combined modes model to predict the longitudinal compressive strength of UD composite,and the theoretical prediction considering the influences of fiber micro-buckling and plastic kink.Sun et al.15proposed a new unified macro-and micro-mechanics failure analysis method for composite structures in order to take the effects of composite micro-structure.

A 2D micro-mechanical Finite Element(FE)model was proposed to analyze the compressive failure mechanism of the UD composite in this paper.The initial imperfection of the fiber,the Weibull distribution of the fiber strength,the matrix plasticity and ductile damage were taken into account.The compressive strength for UD composite was predicted,and the compressive failure mechanism was analyzed with this micro-mechanical model.Numerical results presented with the proposed model are in good agreement with the experimental data.

2.Theoretical model and numerical simulation

The compressive failure modes of UD composite are affected by various factors,such as the material properties of the matrix and fiber,the fiber geometric imperfections,the matrix defects and the interface between the fiber and matrix.Among these factors,the fiber initial imperfection and the matrix plasticity are considered as the primary ones of kink band failure.8

2.1.Matrix plastic and damage model

The matrix plasticity is considered to be one of the main reasons for the compressive failure of unidirectional composites.16,17Through the quasi-static compression tests on the resin matrix 5228A,it was found that the compression mechanical properties could be divided in to three stages:(I)elastic,(II)plastic and(III)fracture,as shown in Fig.2(a).The resin specimen for uniaxial compression test was cut into a block with a size of10 mm×10 mm×25 mm.Significant plastic deformation and brittle failure of the matrix were observed under uniaxial compression(see Fig.2(b)).Normally,the volume fraction of the matrix(vm)in UD composites is about 40%.Due to the huge difference between the modulus of the matrix and fiber,the longitudinal compressive behavior of the UD composites is shown to be linear.The failure occurs abruptly without significant stiffness reduction,which covers the decisive role of the matrix plastic on compressive failure.

Simulation of the matrix with the isotropic materials has been reported by many researchers.5,8,16Considering the large difference between the tensile and compressive plastic yield strength,the plasticity of the matrix is calculated by the linear Drucker-Prager criterion18with the FE code ABAQUS.19The initial yield surface is as

where E is the initial modulus,σ0is the yield stress level,and n is the strain hardening exponent for the stress-strain curve.Three fitting parameters of epoxy 914 matrix are E=4.0 GPa,σ0=160 MPa,n=4.0,and the compressive stressstrain curve is shown in Fig.3(a).

A ductile damage criterion21,22was used to simulate the matrix plastic damage and failure.The progressive plastic damage was calculated by equivalent plastic strainshown in Fig.3(b).σy0andare the yield stress and equivalent plastic strain at the onset of damage.is the equivalent plastic strain at failure,which corresponds to the failure of the material.When the equivalent plastic strainexceedsthe overall damage variable D is used to reduce the effective(or undamaged)stressˉσ and the material has lost its loadcarrying capacity when D=1.

The brittle failure of matrix was simulated by de fining a very small energy release rate,23and the equivalent plastic strain at failure was set as 0.5 under uniaxial compression.Failure envelope of epoxy 914 matrix under σ1–τ12was simulated by ABAQUS,as shown in Fig.4.

2.2.Weibull distribution for fiber strength

The probability of single carbon fiber strength follows the Weibull distribution24–27,and the probability of failure expression is presented as

where L is the fiber length,Lsis the reference gauge length,σfis the compressive strength,σsis the scale parameter and m is the shape parameter.As the strength of a single fiber is related to the fiber length,the macroscopic average strength is not suitable for the fiber in micro-mechanical model.In the present study,the characteristic length leof the FE model determines the value of the fiber strength.The mean compressive strength of the fiber 〈σb〉can be expressed as

The compressive failure of the UD composite was analyzed by Berbinau et al.28The study found that the compressive failure of the fiber was dominated by compressive stress because the tensile stress caused by the fiber bending or buckling cannot reach the tensile strength of the fiber.Therefore,only the compressive failure of fiber was considered in the numerical simulation of this paper,and the maximum stress criterion was carried out in the VUSDFLD subroutine of ABAQUS.The failure expression is shown as

where σ1and Xcare the fiber compressive stress and compressive failure strength.The tensile strength distribution of T300 carbon fibers was determined by experiment,29which shows that the micro strength of fiber is much higher than their macroscopic strength.Therefore,the compressive strength of T300 fiber was set to Xc=3500 MPa5in this paper.When the fiber failure occurred(Fc=1),the fiber elastic parameters were reduced in ABAQUS subroutine.

2.3.Equivalent properties of UD composite

Fiber was considered to be isotropic in Refs.5,17,while the anisotropic material parameters of T300 fiber used by Soden et al.30were more reasonable,as shown in Table 1.However,the equivalent elastic parameters of the UD composite,E2and G12,obtained by a 3D Representative Volume Element(RVE)were significantly lower than the experimental value when the elastic parameters Ef2=15 GPa and Gf12=15 GPa were used.Therefore,a backstepping method was used to obtain the elastic parameter of the fiber based on the analysis of a RVE equivalent mechanical behavior.A RVE with fiber volume fraction of 0.6 and a hexagonal distribution was built(see Fig.5).Considering that the interface is strong enough,31the fiber/matrix interface is neglected in the RVE.It means that matrix damage will precede the interface.

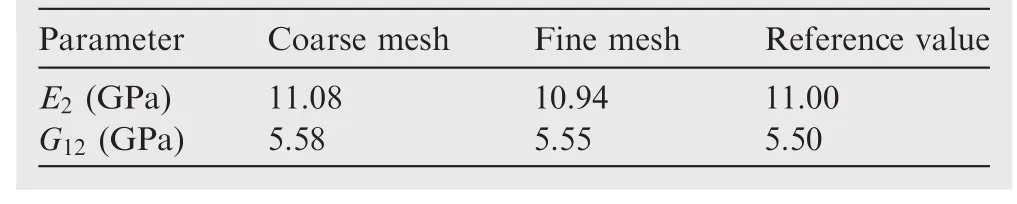

Table 2 Macroscopic elastic parameters of UD composite obtained by backstepping method.

A fine mesh and a coarse mesh with characteristic size 0.5 μm and 1.0 μm were used respectively.The fiber was meshed with solid element C3D8R and the matrix designated asC3D6.There were 25928 solid elements in the fine mesh model,and 3472 solid elements in the coarse mesh model.Periodic Boundary Conditions(PBCs)based on the control points32were used to constrain the deformation of RVE.According to the macroscopic elastic parameters E2=11 GPa and G12=5.5 GPa ofUD composite,Ef2=27.5 GPa and Gf12=75 GPa were obtained by the backstepping method.The comparison results are shown in Table 2,and the stress distributions of RVE under σ2and τ12are shown in Figs.6(a)and(b)respectively.

Table 1 T300/914 material system.

The Mises stress and equivalent plastic strain of RVE under τ12are shown in Figs.6(c)and(d).Meanwhile,the shear nonlinearity of the UD composite was simulated by the RVE.The shear yield strength is close to 75 MPa,and the yield strength obtained by the RVE with fine mesh is lower than that with coarse mesh(see Fig.7).

2.4.Initial imperfection of fiber

The compressive strength of the UD composite is very sensitive to the fiber initial geometric imperfections.5Sinusoidal imperfection of the fiber with amplitude δ and wavelength 2λ was introduced into the FE model by Hsu et al.8The initial imperfection of the fiber can be represented by the following equation:

The parameter δ is recommended for 2dfand the half wavelength takes λ=150df,where dfrepresents the fiber diameter.

2.5.Finite element model

A 2D micro-mechanical compressive model was built with T300 carbon fiber and epoxy 914 matrix.The fiber diameter df=7 μm,and the length of the FE model le= λ.Sinusoidal imperfection of fiber with amplitude δ=2dfwas introduced into the micro-mechanical model,as shown in Fig.8.

As shown in Fig.9,32 fibers were included in the model,and the volume fraction of the fibers was 0.6 which corresponds to the distance 4.67 μm of two adjacent fibers.The two ends of the FE model along the longitudinal direction were marked as fixed area and load area respectively.A displacement boundary condition was prescribed at fixed area(Ux=0,Uy=0),while a displacement load was applied at load area(Ux=u1for longitudinal load).The 2D element type of CPS4R was adopted to perform the analysis.In order to simulate the bending stiffness of fibers accurately,the transverse division number of fiber must be greater than 4,and fibers were divided into 6 grids along the transverse direction in the FE model.

The mesh of FE model along the fiber was very dense.Fine mesh with grid feature length 1.5 μm(marked as M1)was used in the middle area of the model,and the mesh size of transition region and boundary region was 3.0 μm(marked as M2)and 6.0 μm(marked as M3),respectively.There were 122880 elements for the whole FE model.Considering the large deformation and strong nonlinear behavior of the UD composite under compressive load,the ABAQUS/explicit solver was employed.The mass scaling method was used to improve the computational efficiency,and meanwhile,a smooth load step was set to eliminate the dynamic response caused by the accelerating algorithm.In order to verify the validity of the model,the convergence of the mesh was obtained by comparing the calculation results of FE models with four different grids.A variable density mesh(see Fig.9)and three invariant density meshes(M1,M2,M3)along the longitudinal direction were used with the transverse mesh density being unchanged.Simulation results show that the failure mode obtained by the FE model with M3 cannot be accepted because M3 was very rough.The kink band failure models were successfully simulated by the model with fine mesh(M1).However,the total mesh number is huge,which leads to the low computation efficiency.The calculated results of the model with variable density mesh were very close to those of the model with M1.Meanwhile,the model with a variable density mesh has high calculation efficiency,and thus the FE model with variable density mesh was used in this paper.

3.Uniaxial compression results and discussion

3.1.Elastic micro-buckling of fiber and plastic shear yield of matrix

The micro-buckling of the fiber was observed when the matrix was treated as an elastic-plastic material and the fiber failure was not considered in numerical simulation.It means that the microstructure of UD composite is instable under compressive load.Simulation results of the micro-mechanical FE model show that the fiber micro-buckling and the matrix shear yield form a kink band along the transverse section with the increase of the compressive load,as shown in Fig.10.

After the kink band formation,the maximum compressive stress of the fiber is a superposition of the bending compressive stress and the axial compressive stress due to the bending of the fiber.Computation results show that the maximum and minimum compressive stress are about 3400 and 450 MPa respectively,which means that the fiber is not broken when the initial micro-buckling occurs.However,the maximum stress of the fiber is close to the compressive strength.Moreover,when the fiber failure and the matrix plastic damage were introduced into the micro-mechanical FE model,the kink band failure mode was successfully simulated,as shown in Fig.11.

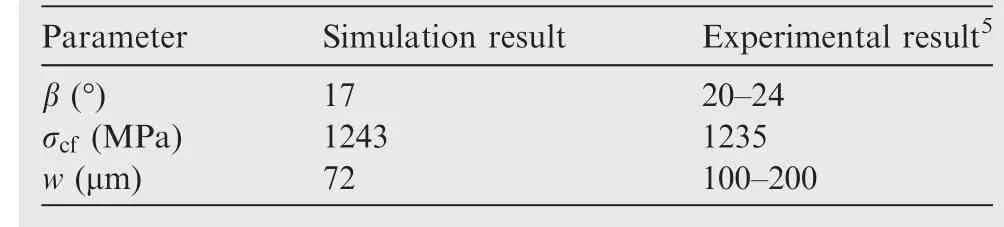

The kink band angle β and width w were 17°and 72 μm respectively,which were obtained by numerical simulation.In addition,the prediction results of compressive strength σcfis 1243 MPa.These results are consistent with the experimental results5as given in Table 3,and thus the validity of the model is verified.

3.2.Matrix plastic response

With the increase of the axial compressive load,the compressive stress σ1of the matrix in kink band goes up linearly.However,the shear stress τ12induced by the initial imperfection of the fibers increases nonlinearly(see Fig.12(a)).The high shear stress leads to the matrix yield,and then the matrix plastic expansion forms a shear yield band in the transverse direction,as shown in Fig.13.

The variation of the equivalent plastic strain of the matrix in kink band with the axial compressive load is shown in Fig.12(b).The signi ficant growth of the matrix plastic strain near the compressive failure load shows that the plastic expansion of the matrix is important for the compressive failure of UD composite.

3.3.Compressive failure modes

As shown in Fig.14(a),simulation results show the formation of the typical failure mode of kink band,and the broken fibers on the two transverse sections of matrix yield band.The matrix plastic damage appeared in the kink band area while the maximum damage appeared near the fiber breaking point(see Fig.14(b)).The matrix damage parameter DUCTCRT reached 1.0 in the local area,and then the failure matrix was removed from the FE model.

Table3 Compressive failure simulation results of UD composite.

Due to the influence of the boundary effect,a small amount of fibers near the free edge did not break.The simulation results are in good agreement with the experimental results33,as shown in Fig.15.It means that boundary conditions have a significant effect on the simulation results of compressive failure mode.

4.Effect of in-plane loads on compressive failure

Kink band is the main failure mode of the UD composite under uniaxial compression,and it is dominated by the matrix plastic.In this section,the compressive failure of the UD composite under combined loads was simulated.In-plane shear load and transverse load were introduced into the compressive failure FE models,as shown in Fig.16.The failure envelopes were simulated by the micro-mechanical models under combined loads,and the effect of combined loads on the failure mode was analyzed.

4.1.Effect of in-plane shear load on compressive failure

As shown in Fig.17,the in-plane shear load leads to the failure of UD composite prematurely,and the compressive strength decreases with the increase of the shear load.When the shear load reached 35 MPa(about half of the shear strength X12),the kink failure of the fiber was inhibited(see Fig.17(c)).The fiber will not break and the main failure mode converts from fiber kink to inter- fiber matrix cracking.Meanwhile,the area of matrix cracking goes up with the increase of inplane shear load,as shown in Figs.17(c)and(d).

It is worth pointing out that the failure mode of UD composite under σ1and τ12is dominated by the matrix plastic yield,and thus results in the different failure modes corresponding to a smooth failure envelope,as shown in Fig.17(e).As we can see,the compressive strength decreases linearly with the increase of in-plane shear load.

4.2.Effect of transverse stress on compressive failure mode

Numerical simulation results demonstrate that the transverse compressive load does not change the kink band failure mode of UD composite(see Figs.18(a)and(b)).However,the failure mode of fiber kink will be changed by inter- fiber matrix cracking under transverse tensile load(see Fig.18(c)).As shown in Fig.18(d),the fiber break will be suppressed in the case of the larger transverse tensile load.

In Fig.18(e),the compressive strength of UD composite obviously decreases under the transverse tensile load.However,the strength will increase firstly and then decrease quickly with the increase of transverse compressive load.A smooth failure envelope under σ1–σ2plane was calculated,and the results show that the compressive strength of UD composite is higher under moderate transverse compressive stress.

As shown in Fig.19(a),the failure envelope of σ1–τ12simulated by the micro-mechanical models in this paper is agreeable to the predicted result of linear LaRC05 criterion.34Meanwhile,the failure envelope of σ1–σ2predicted in the present study can be fitted with a parabola(see Fig.19(b)),and the variation tendency of the σ1–σ2failure envelope is consistent with the three-dimensional failure criteria based on physical failure mode.35

5.Results and discussion

The compressive failure of T300/914 UD composite is mainly controlled by the matrix plastic yield.The coordinated deformation of fibers induced by the initial imperfection leads to the shear stress of the matrix under uniaxial compressive load.The shear yield of the matrix in kink band plays an important role in the failure of the UD composite.

As shown in Fig.20(a),the initial imperfection of the fiber induces the matrix shear stress(τi)under σ1,and the expansion of the matrix plastic region forms a yield band along the transverse direction under σ1and τi.Simulation results show that the matrix yield band leads to the micro-buckling of the fibers because the supporting effect of the matrix on the fibers is weakened,and the maximum compressive stress of the fiber greatly increases at the edge of matrix yield band.Once the plastic yield band of matrix forms,the fibers fracture immediately.It means that the compressive failure of UD composite is not controlled by the fiber failure and this is the main reason for the low compressive strength of UD composite.Based on the compressive failure mechanism obtained by the micromechanical FE model,we can draw the conclusion that the compressive strength of UD composites cannot be improved by unilaterally increasing the compressive strength of the fiber.

Fiber breakage and matrix cracks are the two microscopic failure modes of UD composite under combined loads,as shown in Fig.17(a)–(d)and Fig.18(a)–(d).Under uniaxial compressive load,the plastic extension of the matrix is limited to a local area( fiber kink band or matrix yield band)because the matrix shear stress τiinduced by the fiber initial dislocation is concentrated in the fiber kink band and the stress level of the matrix is low outside the matrix yield band.Matrix yield band forms first,then fiber buckling occurs and finally fiber breaks without inter- fiber matrix crack.Under combined loads,especially the transverse tensile load and in-plane shear load,the plastic extension of the matrix is not limited to a local area.When these loads are relatively high,inter- fiber matrix cracking precedes the fiber buckling and fracture.The matrix cracks lead to the debonding of the fibers and the axial load on the fibers is unloaded due to the fiber micro-buckling.

On the basis of plasticity theory,the yield of the matrix is independent of the hydrostatic stress.Under combined loads,high stress deviator makes the matrix plastic yield easily.Generally,the stress deviator of the matrix in kink band increases with the rise of transverse tensile load and in-plane shear load.However,the stress deviator decreases firstly and then increases with the enhancement of transverse compressive load when σ1< 0.For the Drucker-Prager plastic model used in this paper,point A corresponds to the ultimate yield of matrix under uniaxial compression(σ2=0)on the ultimate yield surface of σ1–σ2,as shown in Fig.20(b).Point B corresponds to the ultimate yield of matrix under combined compression(σ2< 0).From point A to point B,the stress state of the matrix changes from one plastic state to another,which indicates that the compressive strength of the matrix is improved.Based on the above analysis and discussion,the following conclusions can be obtained:(A)transverse shear and tensile load can accelerate the yield of the matrix and significantly reduce the compressive strength;(B)transverse compressive load can alleviate the plastic yield of the matrix,and the maximum compressive strength can be obtained when|σ2|is moderate.

6.Conclusions

In this paper,a micro-mechanical model for compressive failure of the UD composite was established.Considering the initial imperfection of fiber,the Weibull distribution of the fiber strength and the plastic damage of the matrix,the compressive failure mechanism of the UD composite was analyzed by this model.The numerical results are in good agreement with the experimental data,and the following conclusions can be drawn:

(1)The compressive strength and failure mode of the UD composite are influenced mainly by the stress state of the matrix in kink band.The fiber initial imperfection and matrix plasticity,instead of the fiber failure,are the two main factors to affect the compressive strength.The compressive strength of the UD composites cannot be improved by unilaterally increasing the fiber compressive strength.

(2)In-plane loads have a great influence on the compressive failure of the UD composite,while in-plane shear load and transverse tensile load will induce the formation and propagation of matrix plastic yield band,which accelerate the compressive failure of the UD composite.

(3)Due to the inhibition of the matrix plastic yielding in kink band,the compressive strength of the UD composite can be improved with the increase of the transverse compression load appropriately.The simulation result shows that the maximum strength is approximately 15%higher than the uniaxial compressive strength.

(4)The compressive failure modes of the UD composite can be effectively simulated by the micro-mechanical model proposed in this paper,and it can be used to analyze the microscopic failure mechanism and verify the failure theory.

1.Rosen BW.Mechanics of composite strengthening.Washington,D.C.:NASA;1964.Report No.:NASw-817.

2.Paluch B.Analyse des Imperfections Ge′ome′triques affectant les fibres dans un mate′riau composite a`renfort unidirectionnel.La Recherche Ae′ronautique 1994;6:431–48.

3.Clarke AR,Archenhold G,Davidson NC.A novel technique for determining the 3D spatial distribution of glass fibres in polymer composites.Comp Sci Technol 1995;55(1):75–91.

4.Jochum CH,Grandidier JC.Microbuckling elastic modelling approach of a single carbon fibre embedded in an epoxy matrix.Comp Sci Technol 2004;64(16):2441–9.

5.Effendi RR,Barrau JJ,Guedra-Degeorges D.Failure mechanism analysis under compression loading of unidirectional carbon/epoxy composites using micromechanical modelling.Compos Struct 1995;31(31):87–98.

6.Gutkin R,Pinho ST,Robinson P,Curtis PT.On the transition from shear-driven fibre compressive failure to fibre kinking in notched CFRP laminates under longitudinal compression.Compos Sci Technol 2010;70(8):1223–31.

7.Han G,Guan Z,Li X,Zhang W,Du S.Microscopic progressive damage simulation of unidirectional composite based on the elastic-plastic theory.J Reinf Plast Comp 2015;34(3):232–47.

8.Hsu SY,Vogler TJ,Kyriakides S.Compressive strength predictions for fiber composites.J Appl Mech 1998;65(1):7–16.

9.Gutkin R,Pinho ST,Robinson P,Curtis PT.Micro-mechanical modelling of shear-driven fibre compressive failure and of fibre kinking for failure envelope generation in CFRP laminates.Comp Sci Technol 2010;70(8):1214–22.

10.Hinton MJ,Kaddour AS,Soden PD.A comparison of the predictive capabilities of current failure theories for composite laminates,judged against experimental evidence.Compos Sci Technol 2002;62(12–13):1725–97.

11.Zinoviev PA,Lebedeva OV,Tairova LP.A coupled analysis of experimental and theoretical results on the deformation and failure of composite laminates under a state of plane stress.Compos Sci Technol 2002;62(12–13):1711–23.

12.Puck A,Schürmann H.Failure analysis of FRP laminates by means of physically based phenomenological models.Compos Sci Technol 1998;58(7):1045–67.

13.Tsai SW,Wu EM.A general theory of strength for anisotropic materials.J Compos Mater 1971;5(1):58–80.

14.Jumahat A,Soutis C,Jones FR,Hodzic A.Fracture mechanisms and failure analysis of carbon fibre/toughened epoxy composites subjected to compressive loading.ComposStruct2010;92(2):295–305.

15.Sun ZG,Zhao L,Chen L,Song YD.Research on failure criterion of composite based on uni fied macro-and micro-mechanical model.Chin J Aeronautics 2013;26(1):122–9.

16.Nezamabadi S,Potier-Ferry M,Zahrouni H,Yvonnet J.Compressive failure of composites:a computational homogenization approach.Compos Struct 2015;127:60–8.

17.Christensen RM.Compressive failure of composites using a matrix-controlled failure criterion with the kink band mechanism.Mech Mater 2000;32(9):505–9.

18.Hsu SY,Vogler TJ,Kyriakides S.Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear.Part II:Modeling.Int J Plast 1999;15(8):807–36.

19.Dassault Systems.ABAQUS 6.12 documentation.Pairs:Dassault Systemes;2012.

20.Ramberg W,Osgood WR.Description of stress-strain curves by three parameters.Washington,D.C.:NACA;1943.Report No.:NACA-TN-902

21.Hooputra H,Gese H,Dell H,Werner H.A comprehensive failure model for crashworthiness simulation of aluminium extrusions.Int J Crashworthiness 2004;9(5):449–64.

22.Bai YL,Wierzbicki T.A new model of metal plasticity and fracture with pressure and lode dependence.Int J Plast 2008;24(6):1071–96.

23.Yang L,Yan Y,Liu YJ,Ran ZG.Microscopic failure mechanisms of fiber-reinforced polymer composites under transverse tension and compression.Compos Sci Technol 2012;72(15):1818–25.

24.Nakatani M,Shioya M,Yamashita J.Axial compressive fracture of carbon fibers.Carbon 1999;37(4):601–8.

25.Swolfs Y,McMeeking RM,Verpoest I,Gorbatikh L.Matrix cracks around fibre breaks and their effect on stress redistribution and failure development in unidirectional composites.Compos Sci Technol 2015;108:16–22.

26.Ueda M,Saito W,Imahori R,Kanazawa D,Jeong TK.Longitudinal direct compression test of a single carbon fiber in a scanning electron microscope.Composites Part A 2014;67:96–101.

27.Shioya M,Nakatani M.Compressive strengths of single carbon fibresand compositestrands.Comp SciTechnol2000;60(2):219–29.

28.Berbinau P,Soutis C,Guz IA.Compressive failure of 0 unidirectional Carbon-Fibre-Reinforced Plastic(CFRP)laminates by fibre microbuckling.Comp Sci Technol 1999;59(9):1451–5.

29.R’Mili M,Bouchaour T,Merle P.Estimation of Weibull parameters from loose-bundle tests.Comp Sci Technol 1996;56(7):831–4.

30.Soden PD,Hinton MJ,Kaddour AS.Lamina Properties.Lay-up con figurations and loading conditions for a range of fibrereinforced composite laminates.Comp Sci Technol 1998;58(7):1011–22.

31.Piggot MR.Why the fibre/polymer interface can appear to be stronger then the polymer matrix.Comp Sci Technol 1997;57(8):853–7.

32.Xia ZH,Zhang YF,Ellyin F.A unified periodical boundary conditions for representative volume elements of composites and applications.Int J Solids Struct 2003;40(8):1907–21.

33.Svensson D,Alfredsson KS,Stigh U,Jansson NE.Measurement of cohesive law for kink-band formation in unidirectional composite.Eng Fract Mech 2016;151:1–10.

34.Pinho ST,Darvizeh R,Robinson P,Schuecker C,Camanho PP.Material and structural response of polymer-matrix fibre-reinforced composites.J Compos Mater 2012;46(19-20):2313–41.

35.Catalanotti G,Camanho PP,Marques AT.Three-dimensional failure criteria for fiber-reinforced laminates.Compos Struct 2013;95(1):63–79.

24 November 2016;revised 24 February 2017;accepted 1 August 2017

Available online 14 October 2017

?2017 Production and hosting by Elsevier Ltd.on behalf of Chinese Society of Aeronautics and Astronautics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

*Corresponding author.

E-mail address:lizengshan@buaa.edu.cn(Z.LI).

Peer review under responsibility of Editorial Committee of CJA.

CHINESE JOURNAL OF AERONAUTICS2017年6期

CHINESE JOURNAL OF AERONAUTICS2017年6期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Hybrid task priority-based motion control of a redundant free- floating space robot

- An optimal method of posture adjustment in aircraft fuselage joining assembly with engineering constraints

- Effects of pore structure and distribution on strength of porous Cu-Sn-Ti alumina composites

- Three-dimensional adaptive finite-time guidance law for intercepting maneuvering targets

- Helicopter blades running elevation measurement using omnidirectional vision

- Evasion and pursuit guidance law against defended target