Effect of Milling and Parboiling Processes on Arsenic Species Distribution in Rice Grains

Maria Chiara Fontanella, Maria Martin, Daniele Tenni, Gian Maria Beone, Marco Romani

Research Paper

Effect of Milling and Parboiling Processes on Arsenic Species Distribution in Rice Grains

Maria Chiara Fontanella1, Maria Martin2, Daniele Tenni3, Gian Maria Beone1, Marco Romani3

(Department for Sustainable Food Process, Catholic University of Sacred Heart of Piacenza, Piacenza 29100, Italy; Department of Agricultural, Forest and Food Sciences, University of Torino, Torino 10095, Italy; Rice Research Center, National Rice Board, Castello d’Agogna 27030, Italy)

This study identified the role of milling and parboiling on arsenic (As) content and its species in large numbers of rice samples. Total As contents were 108± 33 μg/kg in polished rice grains(PR), 159 ± 46μg/kg in unpolished rice grains (UR), 145 ± 42μg/kg in parboiled polished rice grains (PPR) and 145 ± 44μg/kg in parboiled unpolished rice grains (PUR). The percentages of inorganic As (iAs) were 66% ± 8% in PR and from 72% to 77% in other grain categories. The polishing process reduced the As content in the rice grains, removing outer part of the UR with high amount of As, whereas the parboiling technique transferred the semimetal content within the grain. Total As and iAs contents were not significantly different in UR, PPR and PUR, homogenizing its distribution inside the grains. The results allowed to understand how different operations affect As fate and its chemical forms in grains.

rice; arsenic; inductively coupled plasma-mass spectrometer; milling; parboiling; laser ablation

Rice is the staple food in many countries, especially in Southeast Asia (FAO, 2018). Moreover, it is the main ingredient for the preparation of many food products for infants and toddlers and is strongly recommended in particular diets, such as celiac disease (Munera- Picazo et al, 2014). Rice is mainly consumed worldwide as polished rice or as polished rice flour in rice-based products. The polishing process is performed by rice industries in order to improve physical characteristics and sensory properties of rice, as well as to increase its storage stability (Monks et al, 2013). The rough rice, after harvesting, undergoes the removal of the hull and an intermediate product, called brown rice or unpolished rice, is obtained. The milling process converts the brown/unpolished rice to white/polished rice, where friction and/or abrasion eliminates the bran and the germ from the underlying endosperm. This treatment, however, also removes a large share of polyphenols and vitamins, decreasing the nutritional value of the polished rice compared with the brown rice (Babu et al, 2009). Parboiling is a hydrothermal treatment consisting of soaking, heating (wet or dry, atmospheric or in the modern methods by high pressuresteaming) and drying of the rough or brown rice (Behera and Sutar, 2018), aimed to increase the storage stability of rice with minimal changes on nutritional quality (Heinemann et al, 2006; Oli et al, 2014).

The markets of both brown and parboiled rice are presently expanding. Consumption of brown/unpolished rice, with higher nutritional content and improved texture, is increasing due to growing consumers’ interest in healthier diet (Choi et al, 2014), and the global consumption of parboiled rice was estimated around 201 million tons in 2016, with a compound annual growth rate of around 1.8% during 2009?2016.

Rice and its products are among the food that contribute most to arsenic (As) exposure, especially to inorganic As (iAs), expressed like arsenite (As3+) plus arsenate (As5+) concentrations (Cubadda et al, 2017). It is strengthened that As is a toxic element, and iAs is classified as carcinogenic to humans (group 1), while methylated forms [DiMetil arsenate (DMA5+) and MonoMetil arsenate (MMA5+)] are classified as possibly carcinogenic to humans (group 2B) by the International Agency for Research on Cancer (IARC, 2012). In rice grains, As is mostly localized at the surface, in the pericarp and aleurone layers, so that polishing results in the removal of part of the As from the grains (Meharg et al, 2008; Naito et al, 2015). Boiling rice in excess of clean water has been reported to effectively decrease As content at household level (Mwale et al, 2018), while the effect of industrial parboiling processes on As redistribution within the rice grains is still less known (Runge et al, 2019).

For these grounds, greater attention to nutrition and the consequent spread of whole-grain products, such as brown/unpolished rice, or products processed to improve nutrition levels, such as parboiled rice, tempted European Union to establish maximum levels of iAs (like sum of As3+and As5+) present in these products, 200 μg/kg for non-parboiled polished/milled rice and 250 μg/kg for parboiled rice (EU No 2015/ 1006).

The distinctiveness of this study was to determine the influence of different processes on As content (total and iAs) in the same rice grains, from unpolished rice to polished rice, with application of parboiling treatment and polishing process. This study allowed to identify the real influences of different physical and hydrothermal processes on a large number of rice samples followed to beginning to the end of the processing sections. The rice processing steps considered were milling/polishing and parboiling. In particular, the influence of the different operations was evaluated on the intermediate (unpolished and parboiled unpolished rice) and final products (polished and parboiled polished rice) of each stage.

Results

As distribution in rice grains

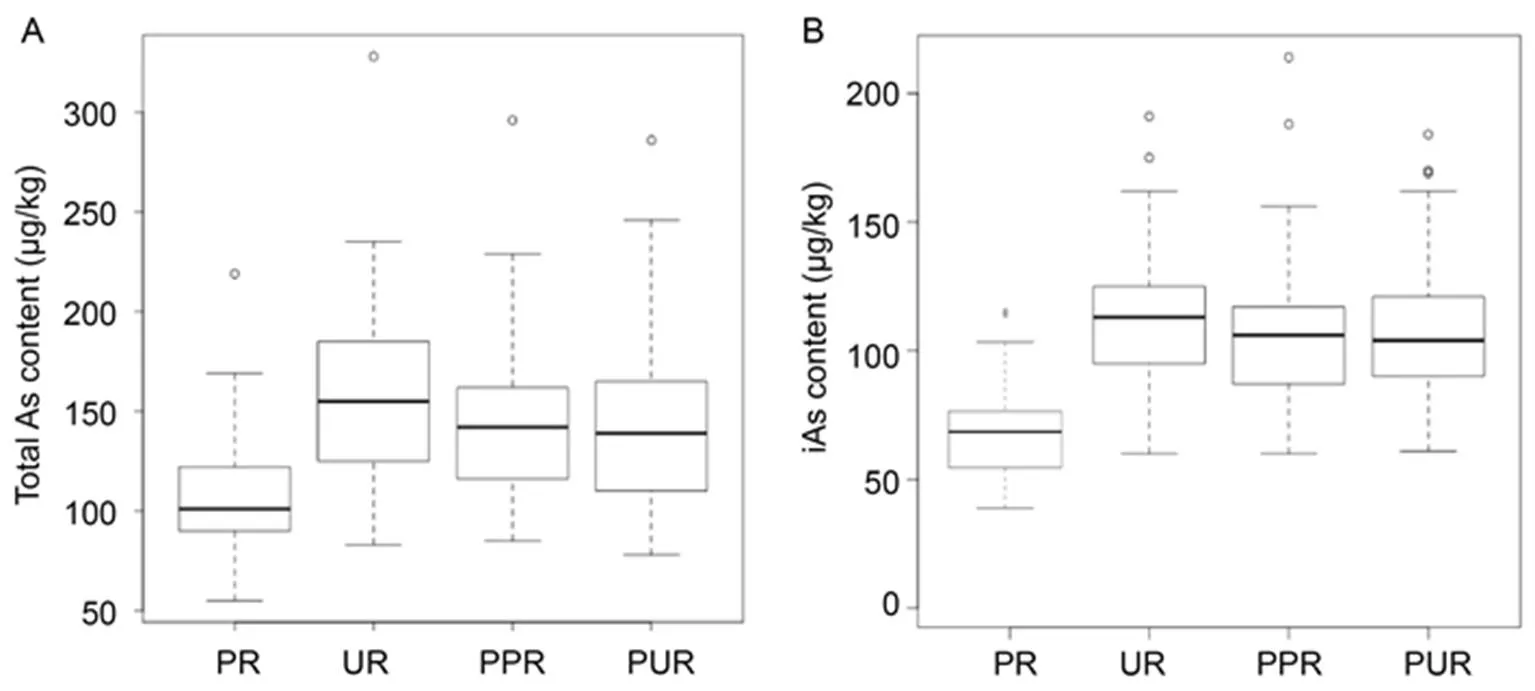

Total As content in polished rice grains (PR) (=53) was 108 ± 33 μg/kg, whereas in unpolished rice grains (UR) was 159 ± 46μg/kg (Fig. 1 and Table S1). The percentages of iAs were equal to 66% ± 8% in PR and 72% ± 8% in UR. Concentrations of arsenic species (As3+, DMA5+, MMA5+and As5+) in different rice grains are detailed in Table 1.

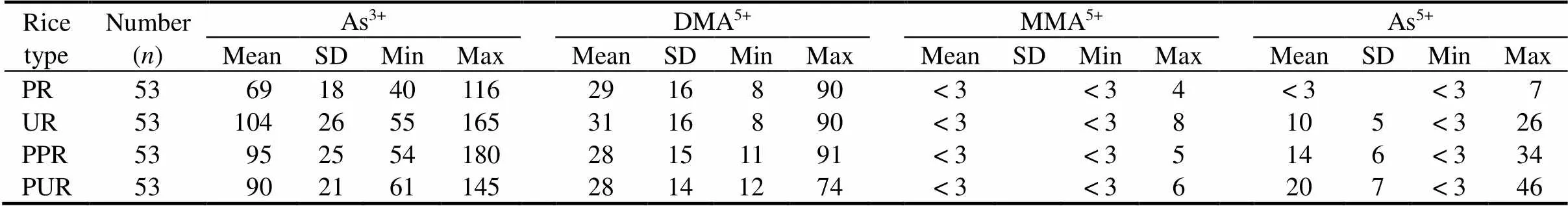

The dominant chemical form of iAs remained As3+in each type of rice processing, ranging from 92% to 99% in UR and PR, respectively. DMA5+was the major organic form of As within rice grains, with a percentage distribution over the total As content ranging from 19% to 27% in UR and PR.

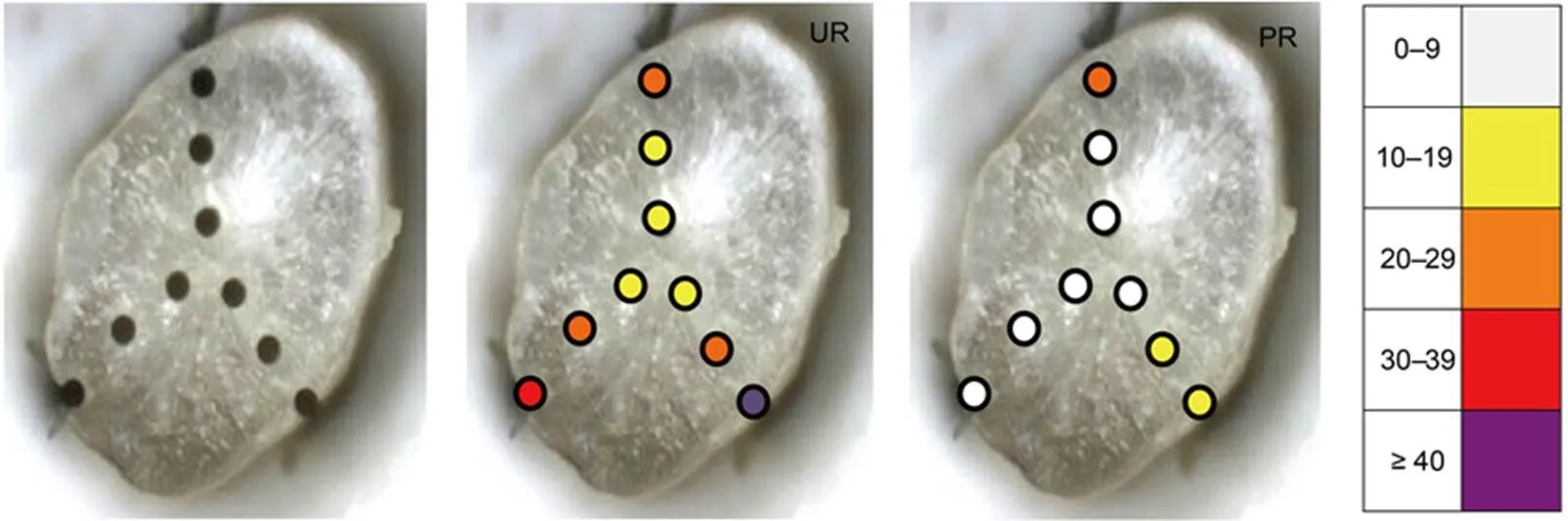

Observing the differences between different types of rice, As content (both total and iAs) was greater in UR than the correspondent PR obtained after milling process, in particular the percentage of iAs in UR was 62% ± 27% higher than that in PR, and the percentage of total As was 49% ± 18% higher in UR than in PR. The differences between rice processes were further illustrated in rice grain sections usinglaser ablation-inductively coupled plasma-mass spectrometry (LA- ICP-MS). PR had a greater distribution of spots with lower values of As ratio compared to UR (Fig. 2).

Fig. 1. Boxplot comparison of total arsenic (As, A) and inorganic arsenic (iAs, B) contents in PR (polished rice grains), UR (unpolished rice grains), PPR (parboiled polished rice grains) and PUR (parboiled unpolished rice grains).

Table 1. Contents of arsenic (As) species in rice grains with mean, standard deviation (SD), minimum (Min) and maximum (Max) divided by different treatments. μg/kg

PR, Polished rice grains; UR, Unpolished rice grains; PPR, Parboiled polished rice grains; PUR, Parboiled unpolished rice grains; As3+, Arsenite; DMA5+, DiMetil arsenate;MMA5+, MonoMetil arsenate; As5+, Arsenate.

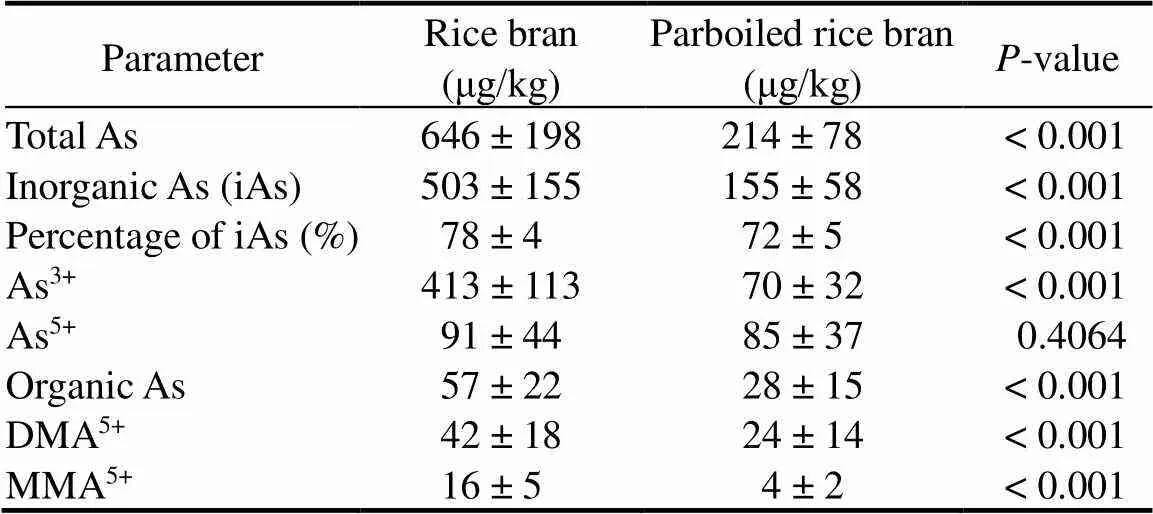

Arsenic distribution in rice bran

Rice bran from milling of unpolished and parboiled unpolished rice grains was analyzed for total As content and As species distribution (Table 2). Bran of unpolished rice had a very high content of total As, 646 ± 198 μg/kg, around 4-fold higher than that in UR and 6-fold higher than that in PR. Also, in this thin layer of grains, iAs was the prevailing form with 78% ± 4% primarily represented by As3+.

The levels of iAs and total As in the bran were positively correlated (2= 0.9673, Fig. S1). The LA data confirmed that As was more concentrated in the external part of the UR, the same area that was removed during polishing, than in the outer layer of PR.

The effects of parboiling on unpolished and polished rice were documented on the distribution of As and its forms in bran.Parboiled bran had 214 ± 78 μg/kg of total As, with a percentage of iAs around 72% ± 5% of the total As, and the content of As5+was similar to that of As3+(Table 2). A significant reduction of As3+and organic As after parboiling were observed and only As5+had no significant difference with unparboiled bran. The contents of total As and iAs, 3-fold lower in parboiled rice bran, together with comparable contents in PPR, PUR and UR reinforced the hypothesis that As was transferred from the bran to the grain by parboiling process. Also in this case, the levels of iAs and total As in parboiled bran were positively correlated (2= 0.9672, Fig. S1).

Table 2. Content of arsenic (As) species in untreated rice bran and parboiled rice bran.

As3+, Arsenite; As5+, Arsenate; DMA5+, DiMetil arsenate;MMA5+, MonoMetil arsenate. Values are expressed as Mean ± SD (=22).-values were determined by the paired-test.

Fig. 2. Sections of unpolished (UR) and polished (PR) rice grains achieved for LA-ICP-MS (Laser ablation-inductively coupled plasma-mass spectrometry).

Different colours represents the counts per second (CPS) divided into classes of75As/13C intensity ratio (×10-4).

Results of LA-ICP-MS represented an additional test, illustrating the shift of components from the superficial layer to the inner layer during parboiling. The distribution of As intensity was uniform through- out the parboiled rice grains, both unpolished and polished (Fig. S2). Small coefficient of variation (CV < 20%, data not shown) was found for these last rice types, representing homogeneous distribution of As intensities in rice grains. At the same time, we observed a significant decrease(< 0.001) of total As and iAs contents of rice bran following the parboiling process (Table 2).

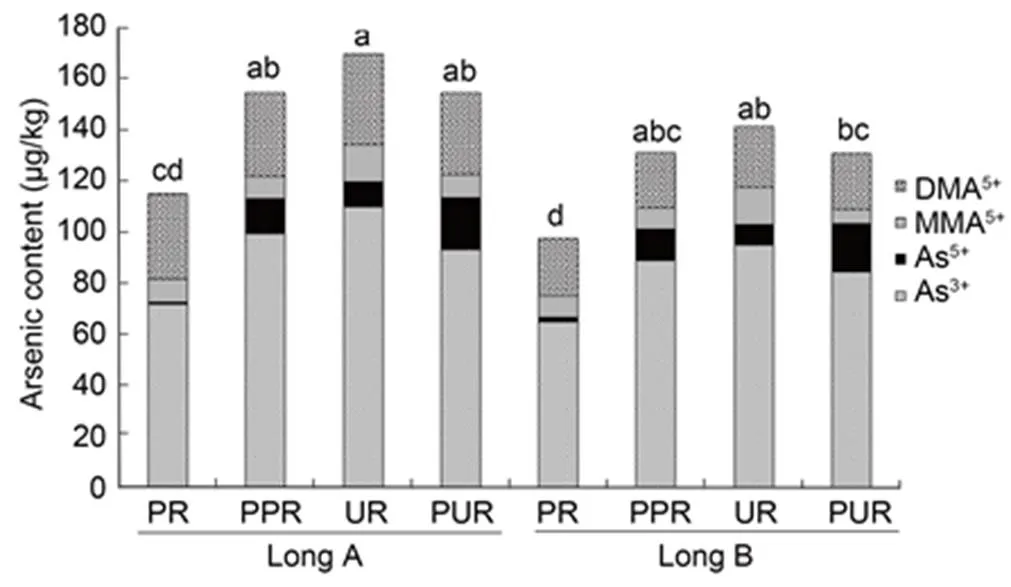

Arsenic distribution in rice grains under European classification

Following the Regulation (EU) No 1308/2013 (The European Commission, 2013), rice is classified on the basis of the length/width ratio of the grain into three groups, round, Long A (length/width ratio between 2 and 3) and Long B (length/width ratio ≥ 3). We only considered two groups, Long A and Long B. When splitting the data set in these two groups, the differences between the rice processes remained the same within the overall sample set, with the contents of total As and iAs always significantly lower in PR than in other rice treatments. Total As contents were generally slightlyhigher in Long A than those in Long B, even if there were no significant differences between the two rice groups in PR or in UR. Even after parboiling, there were no significant differences between Long A and Long B in PPR and PUR (Fig. 3 and Table S2).

Discussion

The predominance of iAs, mainly As3+on As5+and MMA5+, observed in our study on different rice grains, is in agreement with literature data (Heitkemper et al, 2001; Sanz et al, 2005; Williams et al, 2005; Guzmán Mar et al, 2009). Jorhem et al (2008), Meharg et al (2009) and Nishimura et al (2010) found a range of 56%?78% of iAs in Italian rice whereas Williams et al (2005) found 53% of iAs in Italian brown/unpolished rice. Meharg et al (2008) and Sun et al (2008) described that As content (total As and iAs) is greater in brown/ unpolished rice than the correspondent white/polished rice obtained after milling process, as observed in our samples. The high level of iAs found in unpolished rice compared to polished rice and their high difference between these types of grains proved that As is accumulated in bran and outer layer of rice (Rahman et al, 2007; Meharg et al, 2008; Smith et al, 2009). Bhattacharya at al (2010), Khan et al (2010) and Lu et al (2010) observed that the husks store much higher As than grains, and the major As species present in the husk is in inorganic forms (Lombi et al, 2009). We focused our attention on rice bran, also studied previously byMeharg et al (2008), Sun et al (2008), Lombi et al (2009),Batista et al (2011) and Narukawa et al (2014), and our results showed higher levels of total As and iAs in bran than grains. These data supported that the greatest concentrations of As are in the outer layers of rice grains (Ren et al, 2006; Rahman et al, 2007; Meharg et al, 2008). Dai et al (2014) reported high percentage of iAs (98%) in rice bran collected in local markets of three different regions of China, with 83% of As5+. Positive correlation between iAs and total As, observed in our study, was also found by Sun et al (2008). Meharg et al (2008) demonstrated that As is located at the surface of brown rice using laser ablation with the same in our detection technique.

Fig. 3. Comparison of distribution of arsenic (As) species between different rice processes divided by two rice categories, Long A and Long B.

Long A and Long B are established by the Regulation (EU) No 1308/2013. PR, Polished rice grains; PPR, Parboiled polished rice grains; UR, Unpolished rice grains; PUR, Parboiled unpolished rice grains. Means followed by the same lowercase letter were not significantly different at< 0.05 according to the Tukey’s test.

Parboiling treatment is practiced in many Asian and African countries to gelatinize the starch of rice and it can be done by different methods (Kwofie and Ngadi, 2017). The parboiling technique varies depending on the place and the scale of operation (Araullo et al, 1976), however, the basic steps are hydration of brown/unpolished rice, thermal treatment to achieve complete gelatinisation and dehydration to moisture content appropriate for milling. It is proved that this hydrothermal pre-milling treatment improves some physical and organoleptic characteristics, reducing the breakage, improving the storage and nutritional quality (Luh and Mickus, 1991). Some changes are observed in chemical compositions. Some studies indicated an enrichment of some elements in parboiled milled rice compared to milled rice (Heinemann et al, 2005), while other studies outlined scant changes or even a depletion of some components (Runge et al, 2019). Some authors supposed that inward diffusion from bran layer to endosperm during parboiling process inducing different mineral compositions between grains (Padua and Juliano, 1974). This supports the findings of Narukawa et al (2014), who described the transfer of bran components to the inner layers of rice caryopsis during the first phase of parboiling process. These results were supported by As content in parboiled bran layer. Total As and iAs contents in parboiled bran were three times lower than bran without parbolization treatment, while As values increased in PPR grains, displaying similar levels to UR grains. This shift of components from the superficial layer to the inner layer during parboiling was demonstrated by intensity distribution recorded by LA-ICP-MS.

In all rice products, the content of iAs remains always below the limits set by the European Commission (EU No 2015/1006) for foodstuffs. The rice varieties (Long A and Long B), according to the European classification, did not differ for the distribution and accumulation of As and its forms within each of the tested rice processes.

In conclusion, the study showed how the polishing process, in addition to modify the physical and organoleptic characteristics of rice, decreases the content of total As compared to the raw product. This statement is demonstrated by statistically higher As content (total As and iAs) in UR than PR, with differences close to 50%. Removing the bran layer during polishing is useful to eliminate iAs, reducing the risks related to As ingestion particularly for those consumers who include relatively large amounts of rice in their diet, like babies and toddlers, or people with gluten free diet.

High pressure parboiling techniques keep the As content in the grains very close to that of raw rice even after polishing, and therefore higher than that of polished rice. The phases of the parboiling process (hydration and thermal) mobilize a large part of the As present in the rice bran, transferring it into the grain. Indeed, after parboiling, total As and iAs contents in rice bran become lower, with a significant reduction of As3+and DMA5+. However, in the rice grains subjected to the different processes, from polishing to parboiling, As3+remains the main form of iAs and DMA5+of organic As, although parboiling increases the As5+to As3+ratio.

methods

Rice sample collection and preparation

A total of 53 sample pairs of paddy rice and the corresponding parboiled paddy rice were collected directly from 6 of the main Italian rice millers with a parboiling plant. These rice samples belonged to 15 different varieties and 2 European commercial categories (Long A grain and Long B grain groups), with a different number of samples for each variety and commercial group according to its use for parboiling processes.

The samples of both paddy rice and parboiled paddy rice were dehusked with a G390/R dehuller (Colombini & Co. Srl, Abbiategrasso, Milano, Italy) to obtain 53 UR samples and 53 PUR samples. Part of husked rice samples were milled with a TM-05 grain testing mill (Satake Engineering Co., Tokyo, Japan), thus obtaining 53 PR and 53 PPR samples. A fixed milling degree was used for sample preparation in order to avoid the influence of milling process on As content among different polished rice samples. Finally, 22 sample pairs of rice bran and parboiled rice bran, coming from milling process, were analyzed. In total, 256 samples were analyzed for total As and iAs contents.

Chemical analysis

Unpolished, polished and the parboiled rice of both categories were ground with a blender. An inductively coupled plasma- mass spectrometry (ICP-MS 7700x, Agilent Technologies, USA) was applied for total As analysis in each rice sample digested by 6 mL of concentrated nitric acid (65% HNO3) and 1 mL of concentrated hydrogen peroxide H2O2(30%) (Carlo Erba, Italy).

High performance liquid chromatography (HPLC) was connected to ICP-MS (HPLC 1100 coupled with ICP-MS 7700x, both Agilent Technologies, USA) for determination of the different As species in rice samples, performed on an anion exchange column PRP-X100 (250 mm × 4.6 mm, 5 μm) fitted with a precolumn. In last case, 1.5 g of pulverized rice grains was extracted using 15 mL of 0.28 mol/L HNO3(Tenni et al, 2017).

For both analyses, rice samples were introduced in polypropylene tubes and heated in a block system (DIGIPREP, Scp Science, Quebec, Canada). After digestion, the extracts were always filtered by 0.45 μm teflon filter. The mobile phase was made by NH4H2PO4(Sigma, USA). The chromatographic conditions are explained in Table S3.

Different Certified Reference Materials (CRMs) were used to ensure the accuracy of analytical procedures for total, inorganic and other species of As in rice. The certified value of NIST 1568a rice flour is 285 ± 14 μg/kg for total As. Finally, the certified values of ERM?-BC211 rice flour are 260 ± 13 μg/kg for total As, 119 ± 13 μg/kg for DMA and 124 ± 11 μg/kg for sum of As3+and As5+. The recovery (Mean ± SE,= 5) of As species in certified materials was 103% ± 2% for total As in NIST 1568a; 104% ± 8% for total As, 115% ± 8% for DMA and 95% ± 8% for iAs in ERM?-BC211.

As3+and As5+were determined individually, but they are expressed as inorganic As.

Laser ablation

Cross sections of rice grains, treated with different transformation processes with or without parboiling technique, were prepared to assess As distribution profile with laser ablation (LA)-ICP-MS. Specific details of data collection and analysis are given in Table S4. Internal standardisation with13C was a good analytical strategy to correct drifts occurred during the signal acquisition and sampling variations as well as transport effects of the sample aerosol from the ablation chamber to ICP-MS torch.

Statistical analysis

Statistically significant differences in the bran were determined by using the paired-test (at 95% confidence level). The analysis of variance (ANOVA) and the Tukey’s range test were used to determine any significant differences in the main As species contents between groups.

Supplemental DATA

The following materials are available in the online version of this article at http://www.sciencedirect.com/journal/rice-science; http://www.ricescience.org.

Fig. S1. Correlation between total arsenic (As) and inorganic As (iAs) concentrations in bran and parboiled bran.

Fig. S2. Rice sections of parboiled unpolished (PUR) and parboiled polished (PPR) rice grains achieved by laser ablation-inductively coupled plasma-mass spectrometry.

Table S1. Contents of total arsenic (As) and inorganic As in rice grains by different treatments.

Table S2. Total and inorganic arsenic (As) distribution in rice grains divided by European classification and treatments.

Table S3. Instrumental operating conditionfor high performance liquid chromatography-inductively coupled plasma-mass spectrometry (HPLC-ICP-MS) system.

Table S4. Operational parameters for inductively coupled plasma-mass (ICP-MS) and laser ablation (LA)-ICP-MS determinations.

Araullo E V, de Padua D B, Graham M. 1976. Rice: Postharvest TechnologyOttawa, Canda: International Development Research Centre.

Babu P D, Subhasree R S, Bhakyaraj R, Vidhyalakshmi R. 2009. Brown rice: Beyond the color reviving a lost health food: A review., 2(2): 67?72.

Batista B L, Souza J M O, de Souza S S, Barbosa Jr F. 2011. Speciation of arsenic in rice and estimation of daily intake of different arsenic species by Brazilians through rice consumption., 191: 342–348.

Bhattacharya P, Samal A C, Majumdar J, Santra S C. 2010. Accumulation of arsenic and its distribution in rice plant (L.) in Gangetic West Bengal, India., 8(1): 63–70.

Behera G, Sutar P P. 2018. A comprehensive review of mathematical modeling of paddy parboiling and drying: Effects of modern techniques on process kinetics and rice quality., 75: 206–230.

Choi S H, Kim J S, Lee J Y, Jeon J S, Kim J W, Russo R E, Gonzalez J, Yoo J H, Kim K S, Jung Yang S, Park K S. 2014. Analysis of arsenic in rice grains using ICP-MS and fs LA-ICP-MS., 29(7): 1233–1237.

Cubadda F, Jackson B P, Cottingham K L, van Horne Y O, Kurzius-Spencer M. 2017. Human exposure to dietary inorganic arsenic and other arsenic species: State of knowledge, gaps and uncertainties., 579: 1228–1239.

Dai S, Yang H U I, Mao X F, Qiu J, Liu Q J, Wang F H, Wang M I N. 2014. Evaluation of arsenate content of rice and rice bran purchased from local markets in the People’s Republic of China., 77(4): 665–669.

FAO (Food and Agriculture Organization). 2018. World Food and Agriculture: Statistical Pocketbook 2018. Rome: Food and Agriculture Organization.

Guzmán Mar J L, Hinojosa Reyes L, Mizanur Rahman G M, Kingston H M S. 2009. Simultaneous extraction of arsenic and selenium species from rice products by microwave-assisted enzymatic extraction and analysis by ion chromatography- inductively coupled plasma-mass spectrometry., 57(8): 3005–3013.

Heinemann R J B, Fagundes P L, Pinto E A, Penteado M V C, Lanfer-Marquez U M. 2005. Comparative study of nutrient composition of commercial brown, parboiled and milled rice from Brazil., 18(4): 287–296.

Heinemann R J B, Behrens J H, Lanfer-Marquez U M. 2006. A study on the acceptability and consumer attitude towards parboiled rice., 41(6): 627–634.

Heitkemper D T, Vela N P, Stewart K R, Westphal C S. 2001. Determination of total and speciated arsenic in rice by ion chromatography and inductively coupled plasma mass spectrometry., 16(4): 299–306.

IARC (International Agency for Research on Cancer). 2012. A Review of Human Carcinogens: Arsenic, Metals, Fibres, and Dusts. Lyon: World Health Organization Press.

Jorhem L, ?strand C, Sundstr?m B, Baxter M. Stokes P, Lewis J, Grawé K P. 2008. Elements in rice from the Swedish market: 1. Cadmium, lead and arsenic (total and inorganic)., 25(3): 284–292.

Khan M A, Islam M R, Panaullah G M, Duxbury J M, Jahiruddin M, Loeppert R H. 2010. Accumulation of arsenic in soil and rice under wetland condition in Bangladesh., 333(1): 263–274.

Kwofie E M, Ngadi M. 2017. A review of rice parboiling systems, energy supply, and consumption., 72: 465–472.

Lombi E, Scheckel K G, Pallon J, Carey A M, Zhu Y G, Meharg A A. 2009. Speciation and distribution of arsenic and localization of nutrients in rice grains., 184(1): 193–201.

Lu Y, Dong F, Deacon C, Chen H J, Raab A, Meharg A A. 2010. Arsenic accumulation and phosphorus status in two rice (L.) cultivars surveyed from fields in South China., 158(5): 1536–1541.

Luh B S, Mickus R R. 1991. Parboiled rice.: Luh B S. Rice: Volume I. Production/Volume II. Utilization. Boston, USA: Springer: 470–507.

Meharg A A, Lombi E, Williams P N, Scheckel K G, Feldmann J, Raab A, Islam R. 2008. Speciation and localization of arsenic in white and brown rice grains., 42(4): 1051–1057.

Meharg A A, Williams P N, Adomako E, Lawgali Y Y, Deacon C, Villada A, Cambell R C J, Sun G, Zhu Y G, Feldmann J, Raab A, Zhao F J, Islam R, Hossain S, Yanai J. 2009. Geographical variation in total and inorganic arsenic content of polished (white) rice., 43(5): 1612–1617.

Monks J L F, Vanier N L, Casaril J, Berto R M, de Oliveira M, Gomes C B, Carvalho M P, Dias A R G, Elias M C. 2013. Effects of milling on proximate composition, folic acid, fatty acids and technological properties of rice., 30(2): 73–79.

Munera-Picazo S, Burló F, Carbonell-Barrachina á A. 2014. Arsenic speciation in rice-based food for adults with celiac disease., 31(8): 1358–1366.

Mwale T, Rahman M M, Mondal D. 2018. Risk and benefit of different cooking methods on essential elements and arsenic in rice., 15(6): 1056.

Naito S, Matsumoto E, Shindoh K, Nishimura T. 2015. Effects of polishing, cooking, and storing on total arsenic and arsenic species concentrations in rice cultivated in Japan., 168: 294–301.

Narukawa T, Matsumoto E, Nishimura T, Hioki A. 2014. Determination of sixteen elements and arsenic species in brown, polished and milled rice., 30(2): 245–250.

Nishimura T, Hamano-Nagaoka M, Sakakibara N, Abe T, Maekawa Y, Maitani T. 2010. Determination method for total arsenic and partial-digestion method with nitric acid for inorganic arsenic speciation in several varieties of rice., 51(4): 178–181.

Oli P, Ward R, Adhikari B, Torley P. 2014. Parboiled rice: Understanding from a materials science approach., 124: 173–183.

Padua A B, Juliano B O. 1974. Effect of parboiling on thiamin, protein and fat of rice., 25(6): 697–701.

Rahman M A, Hasegawa H, Rahman M M, Rahman M A, Miah M A M. 2007. Accumulation of arsenic in tissues of rice plant (L.) and its distribution in fractions of rice grain., 69(6): 942–948.

Ren X L, Liu Q L, Wu D X, Shu Q Y. 2006. Variations in concentration and distribution of health-related elements affected by environmental and genotypic differences in rice grains., 13: 170?l78.

Runge J, Heringer O A, Ribeiro J S, Biazati L B. 2019. Multi- element rice grain s analysis by ICP-OES and classification by processing types., 271: 419?424.

Sanz E, Mu?oz-Olivas R. Cámara C. 2005. A rapid and novel alternative to conventional sample treatment for arsenic speciation in rice using enzymatic ultrasonic probe., 535(1/2): 227–235.

Smith E, Kempson I, Juhasz A L, Weber J, Skinner W M, Gr?fe M. 2009. Localization and speciation of arsenic and trace elements in rice tissues., 76(4): 529–535.

Sun G X, Williams P N, Carey A M, Zhu Y G, Deacon C, Raab A. Feldmann J, Islam R M, Meharg A A. 2008. Inorganic arsenic in rice bran and its products are an order of magnitude higher than in bulk grain., 42(19): 7542–7546.

Tenni D, Martin M, Barberis E, Beone G M, Miniotti E, Sodano M, Zanzo E, Fontanella M C, Romani M. 2017. Total As and As speciation in Italian rice as related to producing areas and paddy soils properties., 65(17): 3443–3452.

The European Commission. 2013. Regulation (EU) No 1308/2013 of the European Parliament and of the Council of 17 December 2013 establishing a common organisation of the markets in agricultural products and repealing Council Regulations (EEC) No 922/72, EEC No 234/79, EC No 1037/2001 and EC No 1234/2007. https://eur-lex.europa.eu/legal-content/EN/ TXT/?uri=CELEX%3A32013R1308

The European Commission. 2015.Commission regulation (EU) 2015/1006 of 25 June 2015 amending regulation (EC) No. 1881/2006 as regards maximum levels of inorganic arsenic in foodstuff. http://eur-lex.europa.eu/legal-content/EN/TXT/ PDF/?uri=CELEX:32015R1006&from=EN.

Williams P N, Price A H, Raab A, Hossain S A, Feldmann J, Meharg A A. 2005. Variation in arsenic speciation and concentration in paddy rice related to dietary exposure., 39(15): 5531–5540.

1 May 2020;

23 June 2020

Copyright ? 2021, China National Rice Research Institute. Hosting by Elsevier B V

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/)

Peer review under responsibility of China National Rice Research Institute

http://dx.doi.org/10.1016/j.rsci.2021.05.010

Maria Chiara Fontanella(mariachiara.fontanella@unicatt.it)

(Managing Editor: Wu Yawen)

- Rice Science的其它文章

- Genome-Wide Association Study of Nitrogen Use Efficiency and Agronomic Traits in Upland Rice

- Development of Chromosome Segment Substitution Lines and Genetic Dissection of Grain Size Related Locus in Rice

- Water Management for Improvement of Rice Yield, Appearance Quality and Palatability with High Temperature During Ripening Period

- iTRAQ-Based Proteomics Investigation of Critical Response Proteins in Embryo and Coleoptile During Rice Anaerobic Germination

- A New Approach to Select Doubled Haploid Rice Lines under Salinity Stress Using Indirect Selection Index

- OsbZIP09, a Unique OsbZIP Transcription Factor of Rice, Promotes Rather Than Suppresses Seed Germination by Attenuating Abscisic Acid Pathway