Experimental Study on Dwell-fatigue of Titanium Alloy Ti-6AL-4V for Offshore Structures

(School of Naval Architecture and Ocean Eng,Jiangsu University of Science and Technology,Zhenjiang 212003,China)

Abstract:The fatigue peak holding load has an obvious influence on the crack growth rate of titanium alloy Ti-6Al-4V at room temperature.Therefore,the fatigue and dwell-fatigue test of titanium alloy Ti-6Al-4V under room temperature are studied in this paper,and based on the prediction model of dwell-fatigue crack growth rate,the fatigue and dwell-fatigue crack growth rate of this material are predicted as well.The results show that the stress peak holding load for 60s significantly accelerated the fatigue crack growth rate of titanium alloy Ti-6Al-4V,which is consistent with other research results of materials at home and abroad;The difference between the dwell-fatigue crack growth rate and the fatigue crack growth rate increases with the increase of stress intensity factor range.That is to say,the effect of holding load on crack growth rate increases under high stress intensity factor.The fatigue and dwell-fatigue crack growth rate of titanium alloy Ti-6Al-4V are predicted based on the prediction model that research group put forward,the predicted results are in good agreement with the experimental results.

Key words:titanium alloy;fatigue;crack growth rate;holding time

0 Introduction

The results of application and basic research at home and abroad show that Titanium alloys not only have high specific strength,local and uniform corrosion resistance in seawater,high fatigue performance and corrosion fatigue limit,but also have high fracture toughness and resistance to seawater stress corrosion cracking.It is an excellent marine material[-2].The research of α+ β titanium alloy Ti-6Al-4V is relatively mature,its dosage is more than half of all titanium alloys,ultra-low interstitial alloy Ti-6Al-4V has attracted wide attention.The U-nited States applies the Ti-6Al-4V to the horizontal tail shaft of the F-16 fighter.Titanium alloy Ti-6Al-4V is also used in the structure of pressure-resistant shell of deep-sea submersible.Japan’s ‘Deepwater 6 500’ uses the Titanium alloy Ti-6Al-4V,its depth of diving is 6 500 m.The Ti-6Al-4V titanium alloy is also used in the pressure resistant shell structure of‘Jiaolong’ in China,Its depth of diving is 7 062 m[3].The failure of these submersibles during service is mainly fatigue failure.In the course of actual work,the pressure-resistant shell structure bears in addition to floating and submerged load,the structure also bears the load of the working process under sea.That is,the fatigue problem of the pressure-resistant shell structure is actually a dwell-fatigue problem.

Many studies have shown that dwell-fatigue at room temperature has a certain effect on fatigue crack growth behavior of titanium alloy.The general fatigue crack growth rate increases with the increase of maximum stress level and holding time of load,therefore,the life of dwellfatigue structure is obviously lower than that of fatigue life.Researchers at home and abroad have given many explanations for the causes of these phenomena,for example,peak stress,holding time,microstructure,temperature and hydrogen content can affect the sensitivity of titanium alloy to dwell-fatigue.This is still an inconclusive research hotspot.Therefore,it is of great engineering significance to carry out the dwell-fatigue test of titanium alloy materials.

1 Study on prediction method of fatigue crack growth behavior

Domestic and foreign researchers have done a lot of research on fatigue life prediction of offshore structures using fatigue crack propagation theory.Many prediction models of fatigue crack growth rate are proposed.Based on the exponential power law of fatigue crack growth rate(Paris formula)put forward by Paris in 1963,some new crack growth theories are put forward in combination with experiments by McEvily.Aiming at the limitation of Paris formula,McEvily formula is proposed,which can explain more fatigue phenomena,as Eq.(1):

where ΔKeffthis the effective range of the stress intensity factor at the threshold level,ΔKeffis the effective range of the stress intensity factor,MPa

On the basis of a large number of related experiments,the McEvily crack growth prediction model based on fatigue crack growth theory can not only predict the fatigue growth behavior of long cracks,but also be applicable to the fatigue small crack propagation behavior,as Eqs.(2)-(4):

where da/dN is fatigue crack growth rate,m/cycle;KCis the plane stress fracture toughness of the material,σmaxis the maximum stress,MPa;Kmaxis the maximum stress intensity factor under cyclic fatigue loading,R is the stress ratio;Kopmaxis the maximum stress intensity factor of macroscopic long crack at crack opening level,k is the parameters of crack closure level varying with crack length;reis the material inherent defect size;σYis the yield strength of materials;Y(a)is the geometric correction coefficients related to the shape and position of cracks.

Although the McEvily crack propagation rate model can explain many phenomena in fatigue tests,it can be used not only for macroscopic long cracks but also for physical small cracks.But the model can only be used in the near threshold region and ideal elastic-plastic materials.It can not reflect the phenomenon of crack instability and can not predict the loadpreserving fatigue process.The results of dwell-fatigue tests[4-5]at home and abroad show that the dwell-fatigue life of titanium alloy decreases significantly compared with the fatigue life of titanium alloy when the peak stress is introduced for a period of time.The cause of this effect is still a hot research topic,but it is generally agreed that stress and loading time have great influence on crack growth behavior of titanium alloy at room temperature according to the domestic and foreign research results.Therefore,it is no longer suitable to predict the life of titanium alloy material for pressure-resistant shell of submersible only by traditional method.In order to ensure the safety of the pressure resistant structure of the submersible,it is necessary to predict the fatigue crack propagation behavior of titanium alloy at room temperature more accurately[13].In 1980,Munz innovatively divided the load-preserving and fatigue processes into load preservation processes with peak stress peaks and pure fatigue load processes with load holding time.Therefore,there are two terms in its load-preserving fatigue crack growth rate model,one is fatigue term related to cyclic load,the other is load protection term related to peak loading time and load,as Eq.(5):

Based on the above mentioned series of prediction methods for crack propagation behavior,in order to predict the life of the hull structure of the submersible vehicle more accurately,a prediction model of loading and fatigue crack growth rate considering small crack effect is proposed[7].The prediction model divides the fatigue crack propagation process into fatigue loading process and peak load retention process,that is,the prediction model is divided into two parts:fatigue term associated with cyclic load and time-dependent load protection term.The loading time is introduced into the model,so that the influence of different loading time on the load-keeping fatigue crack growth rate can be considered.as Eqs.(6)-(8):

where A1is a material and environmentally sensitive constant of dimensions,is the modified crack length,m;m1is a constant representing the slope of the corresponding fatigue crack propagation rate curve;n1is the parameters affecting capacity of fatigue cycle part Kmax/Kmin;Kmaxis the maximum stress intensity factor under cyclic fatigue loading,Kminis the minimum stress intensity factor under cyclic fatigue loading,KCis the plane stress fracture toughness of the material,F is the crack tip elastoplastic correction factor;A2is the material and environmental constants related to the load-preserving part,MPa-mm1-m/2;m2is a constant of slope of crack growth rate curve related to load-preserving part;n2is a parameters that affect the capacity of the dwell-fatigue part Kmax/Kmin;tholdis the holding time under maximum stress.

2 Experimental study on fatigue crack growth rate

2.1 Test materials

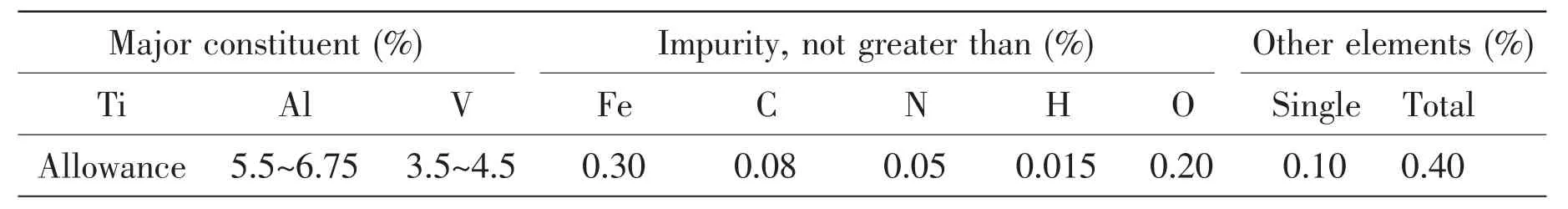

Due to the strength,plasticity,corrosion resistance and biocompatibility of titanium alloy Ti-6Al-4V are good,Ti-6Al-4V becomes the ace alloy in the titanium alloy industry.Many other types of titanium alloys can be considered as modification of titanium alloy Ti-6Al-4V.In recent years,the development of titanium alloys in China has become more and more rapid,and a set of titanium alloy system which is more suitable for the application and development of titanium alloys in China has been gradually formed.According to national standards GB/T 3620.1-2007,the standard chemical constituents of titanium alloy Ti-6Al-4V in China are listed in Tab.1.

Tab.1 Chemical constituents of Ti-6Al-4V

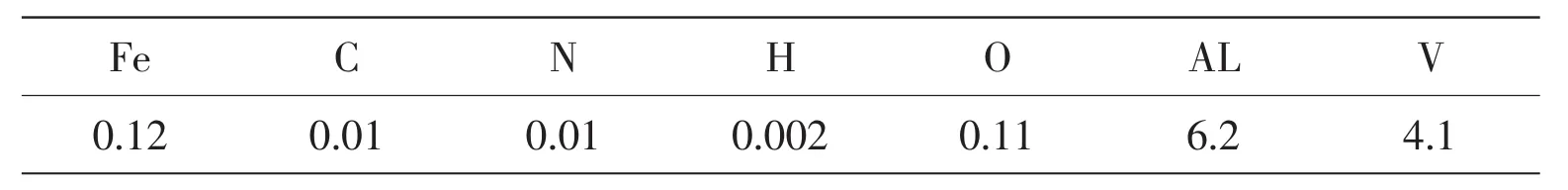

The density of titanium alloy Ti-6Al-4V is generally 4.5 g/cm3,60%of steel only;The standard yield strength of titanium alloy after Ti-6Al-4V annealing is also higher,which is 930 MPa,the ratio of fracture strength to density is about 210.Therefore,titanium alloy Ti-6Al-4V has the advantages of light material and high strength.In this paper,titanium alloy Ti-6Al-4V(TC4)forgings are used for dwell-fatigue crack growth rate test,and the chemical composition is shown in Tab.2.

Tab.2 Chemical constituents of Ti-6Al-4V(TC4)(mass fraction,%)

2.2 Fracture toughness test

In fracture mechanics,the criterion of stress intensity factor K is widely used.The socalled K criterion is that when the stress intensity factor K of the crack reaches the fracture toughness KC,the crack will be unstable and propagate.Because the fracture toughness KCis difficult to be measured,the plane strain fracture toughness KICof the material is generally replaced.

In the process of preparing and testing the plane strain fracture toughness KIC,it is necessary to preform the crack on the standard test piece first,and then to gradually increase the load during the loading process until the specimen breaks.The curve(P-V)between the load and the opening displacement of the crack nozzle should be recorded during the test.The standard specifies that the PQand KQare defined by using the intersection of the cut line and the curve that deviates from the curve tangent 5%(Conditional fracture toughness).The theoretical basis of the experiment is linear elastic fracture mechanics(LEFM).Therefore,the size and results of the specimen should meet the applicable range of LEFM.

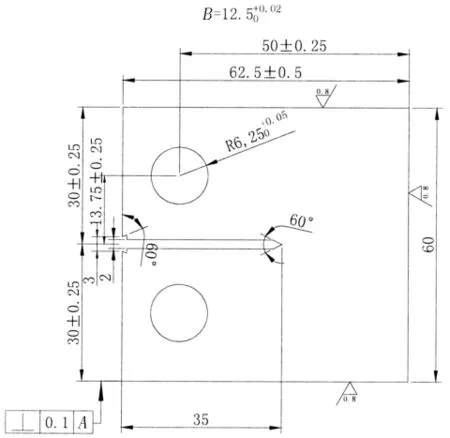

Fig.1 Tensile specimen standard

Standard compact tensile specimen(CT test sample)were machined according to the GB/T 4161-2007 Plane Strain Fracture Toughness Test Method of Metallic Materials.The specific dimensions are shown in Fig.1.W=50 mm,B=12.5 mm,H=60 mm,S=62.5 mm,force hole diameter D=12.6 mm.

The fracture toughness test samples of titanium alloy Ti-6Al-4V are 4 and the effective samples are 3.Marked A-1,A-2,A-3,respectively.Therefore,the fracture toughness of titanium alloy Ti-6Al-4V is calculated as the average of three.That is KIC≈76.5

2.3 Fatigue/dwell-fatigue crack growth rate test

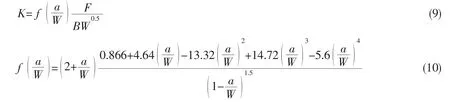

The testing of crack growth rate is generally divided into two categories:one is crack propagation in elastic range;the other is crack propagation in plastic range.The zero member with high cycle and low load belongs to the former category,while the zero member with low cycle and high load belongs to the latter class.This paper focuses on a test of fatigue and dwell-fatigue crack growth rate in elastic range.A compact tensile specimen with severe stress concentration was used in the test(CT test sample).The sample has the advantages of small volume,light weight and long crack propagation distance.Empirical formula of stress intensity factor at crack tip of CT specimenas Eqs.(9)~(10):

Before carrying out fatigue and load fatigue tests,the test specimens are uniformly prefabricated and tested.The IST 8802 type high and low temperature fatigue testing machine is adopted in the test.According to the requirements of relevant codes,the constant K method is adopted in the test.On the basis of 3-5 group pre-tests,K value is determined to be 18.6 in order to ensure the loading cycle number of precast crack is about 20 000,the best prefabrication effect can be achieved.The initial crack length is 22.5 mm,and the prefabricated crack length is 2 mm.The crack length of finished sample is 24.5 mm.

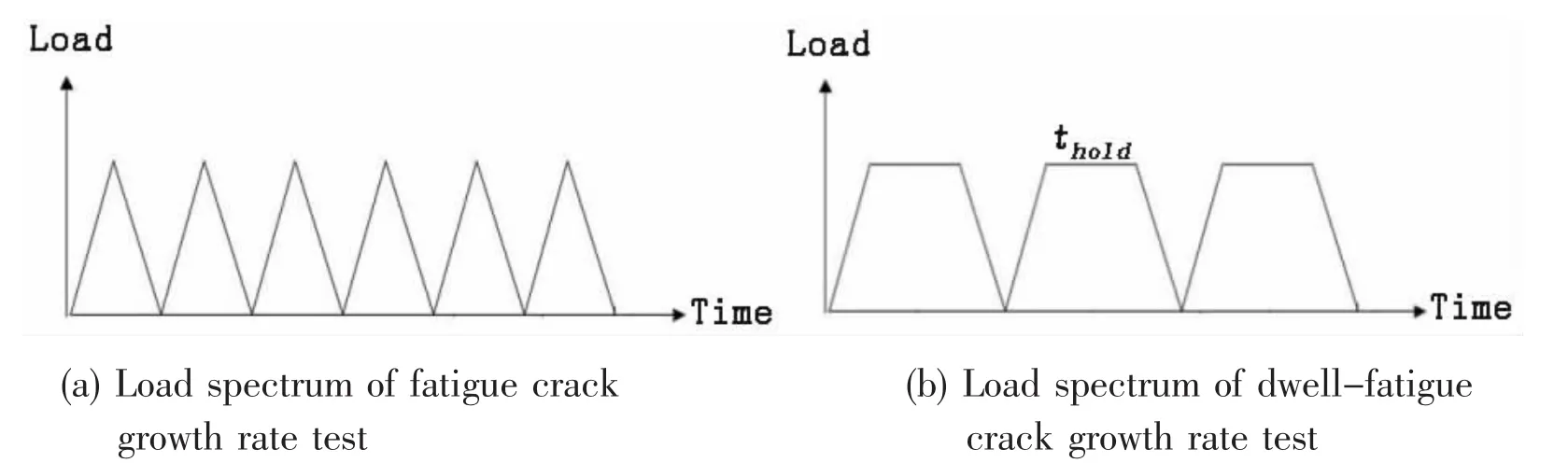

Fig.2 Loading diagram

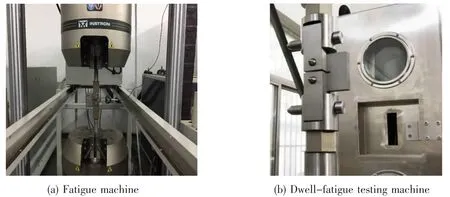

Fig.3 Connection diagram between test machine and CT specimen

IST 8802 high and low temperature fatigue testing machine is used in the fatigue crack growth rate test system.The dynamic and static load capacity of the testing machine is equal to that of the sampling rate of 10 kHz.Creep fatigue testing system is used for dwell-fatigue crack growth rate.The test process was carried out according to GB/T 6398-2000 The Fatigue Crack Growth Rate Test Method of Metal Materials[15].The load spectrum used in fatigue and dwellfatigue tests[8]is shown in Fig.2.The maximum load is set at 8 kN and the stress ratio R is 0.03.Means of connection between test equipment and CT specimens and fixtures are shown in Fig.3.The precision of testing machine and extensometer are all up to the national standard GB/T 6398-2000 The Fatigue Crack Growth Rate Test Method of Metal Materials and American standard ASTME647 Standard Test Method for Measurement of Fatigue Crack Growth Rates.

3 Results and analysis

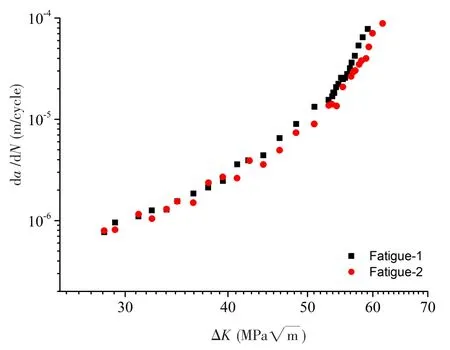

Based on the theoretical knowledge of compliance method,the length of crack propagation a is measured,and the corresponding cycle number N is determined,that is the a-N curve is obtained.By using the seven point incremental polynomial method to process the experimental data,the double logarithmic da/dN curves of fatigue and dwellfatigue crack growth rate of titanium alloy Ti-6Al-4V were made according to the treated data.The curves are shown in Figs.4-6.

Fig.4 Experimental results of fatigue crack growth rate of titanium alloy Ti-6Al-4V

The curve of Ti-6Al-4V fatigue crack growth rate test for titanium alloy is shown in Fig.4.It can be seen from the figure that the fatigue crack growth rate test has two sets of valid data,marked as 1#,2#,respectively.The coincidence between the two groups of test data is high.From the point of view of test,it can be considered that the test data of fatigue crack growth rate is more reliable.With the increase of the range of stress intensity factor,the growth rate of fatigue crack in both groups shows an increasing trend,and in the region with larger stress intensity factor,the increasing rate of crack growth rate is faster.Fracture occurred at the fracture toughness of 76.5.

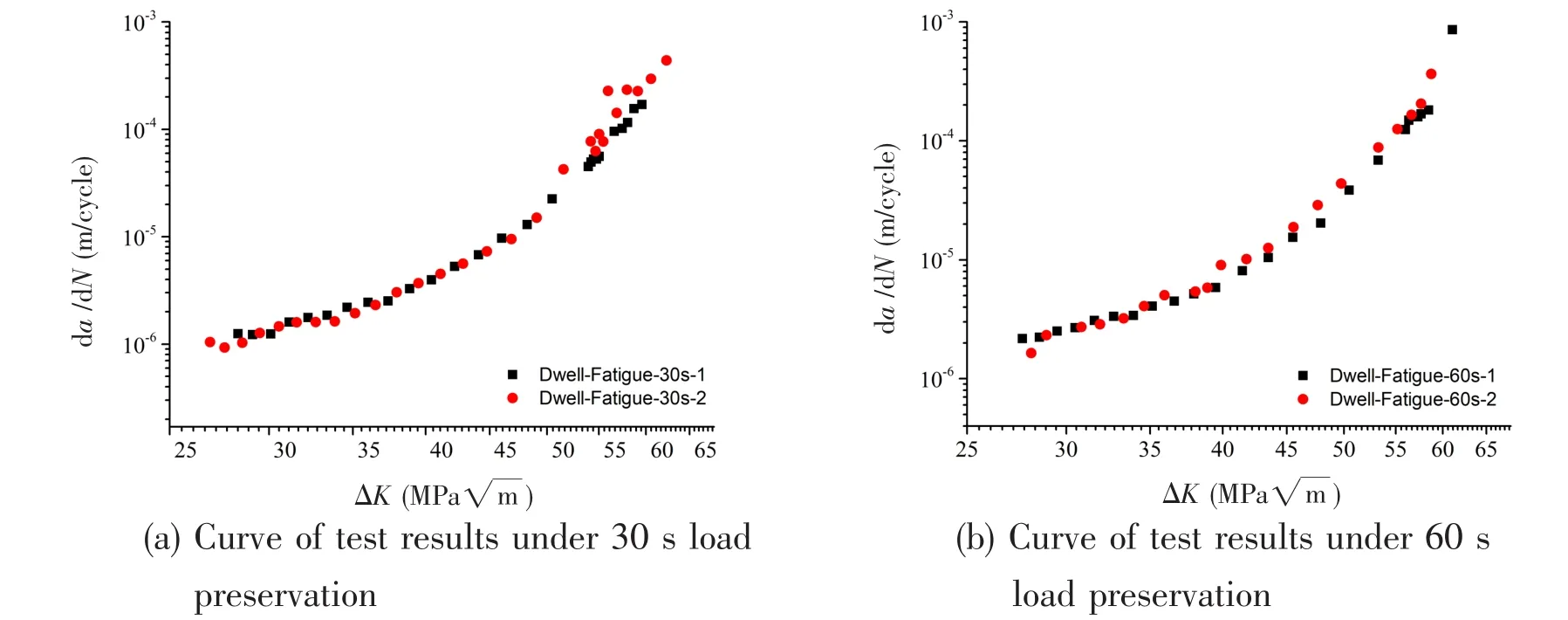

Fig.5 is the test data of dwell-fatigue test for 30 s and 60 s.There are two valid groups of data for each group,marked as 1#,2#,respectively.It can be seen from the diagram that the two groups of data have good coincidence and strong reliability.From the da/dN-ΔK logarithmic curves in the diagram,it is shown that the crack growth rate da/dN increases with the increase of the stress intensity ΔK factor range.For the crack growth rate after the loading time is introduced,the crack growth is stable in the range of stress intensity factor ΔK<45and the rate is increasing slowly.When the range of stress intensity factor ΔK reaches 76.5it is in the stage of instability and propagation,and the crack growth rate accelerates obviously in this stage.

Fig.5 Experimental results of Ti-6Al-4V dwell-fatigue crack growth rate for titanium alloys

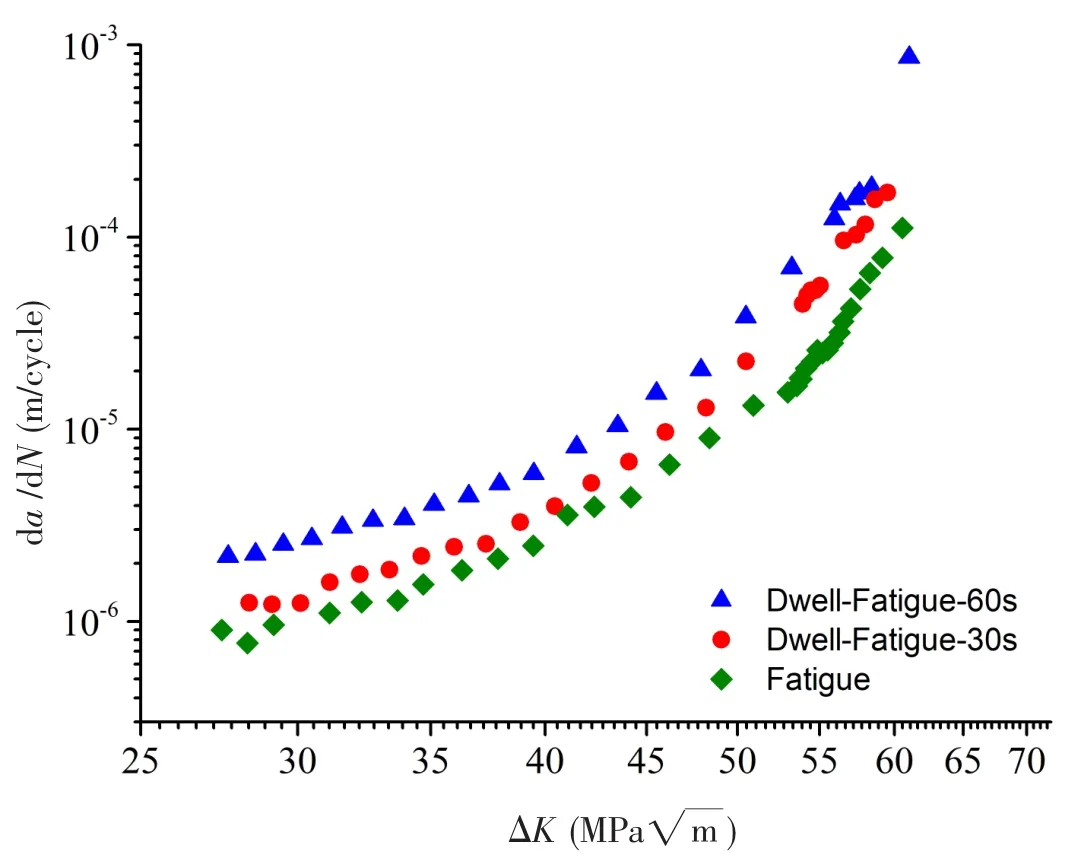

Fig.6 Summary of fatigue and dwell-fatigue crack growth rate of titanium alloy Ti-6Al-4V

In order to compare and analyze the effect of different holding time on fatigue crack growth rate of titanium alloy Ti-6Al-4V,the double logarithmic curves da/dN-ΔK of Ti-6Al-4V fatigue and dwell-fatigue crack growth rate of titanium alloy under holding time of 30 s and 60 s are given in Fig.6.It is found from Fig.6 that the holding time has a significant effect on the fatigue crack growth rate of titanium alloy Ti-6Al-4V.The dwell-fatigue crack growth rate at 30 s and 60 s is higher than that of fatigue crack propagation.When holding time is introduced,with the increasing of holding time,the dwell-fatigue crack growth rate increases linearly in the same stress intensity factor range.With the increase of the range of stress intensity factor,the difference between fatigue and dwell-fatigue crack growth rate under holding time increases gradually.It is found that the material has lower resistance to dwell-fatigue crack propagation.That is,under the same stress intensity factor ΔK,the fatigue crack growth rate of the holding time 30 s and 60 s is higher than that of the fatigue crack growth rate.In the whole stress intensity factor range,the dwell-fatigue crack growth rate is about 4-5 times higher than that of fatigue crack growth rate.Therefore,this experiment can reflect the effect of dwell-fatigue on fatigue crack growth rate.

4 Reliability verification of prediction model for dwell-fatigue crack growth behavior

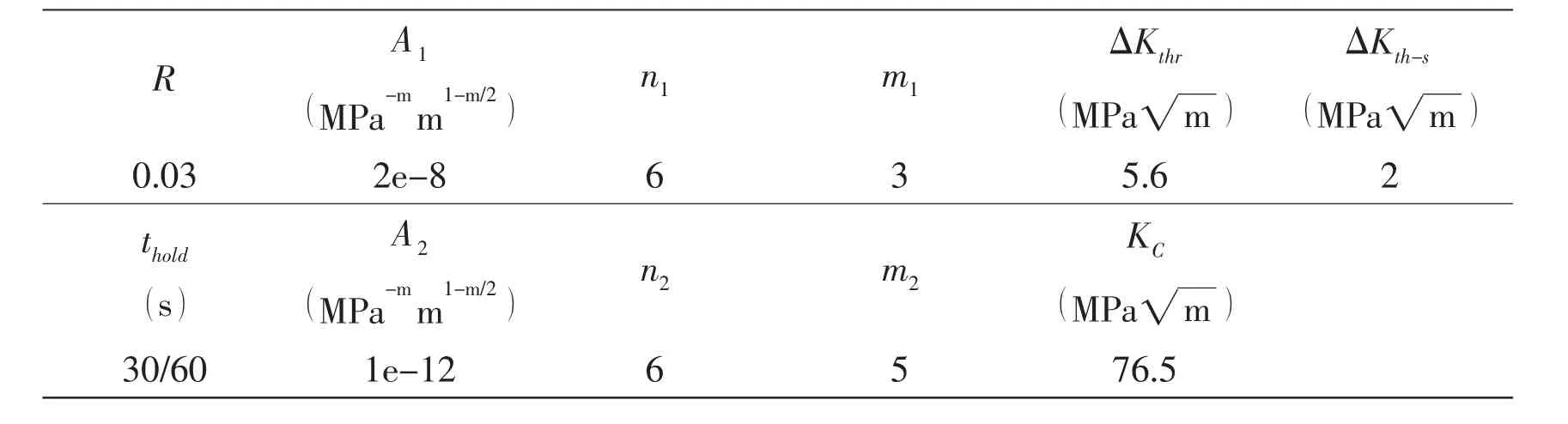

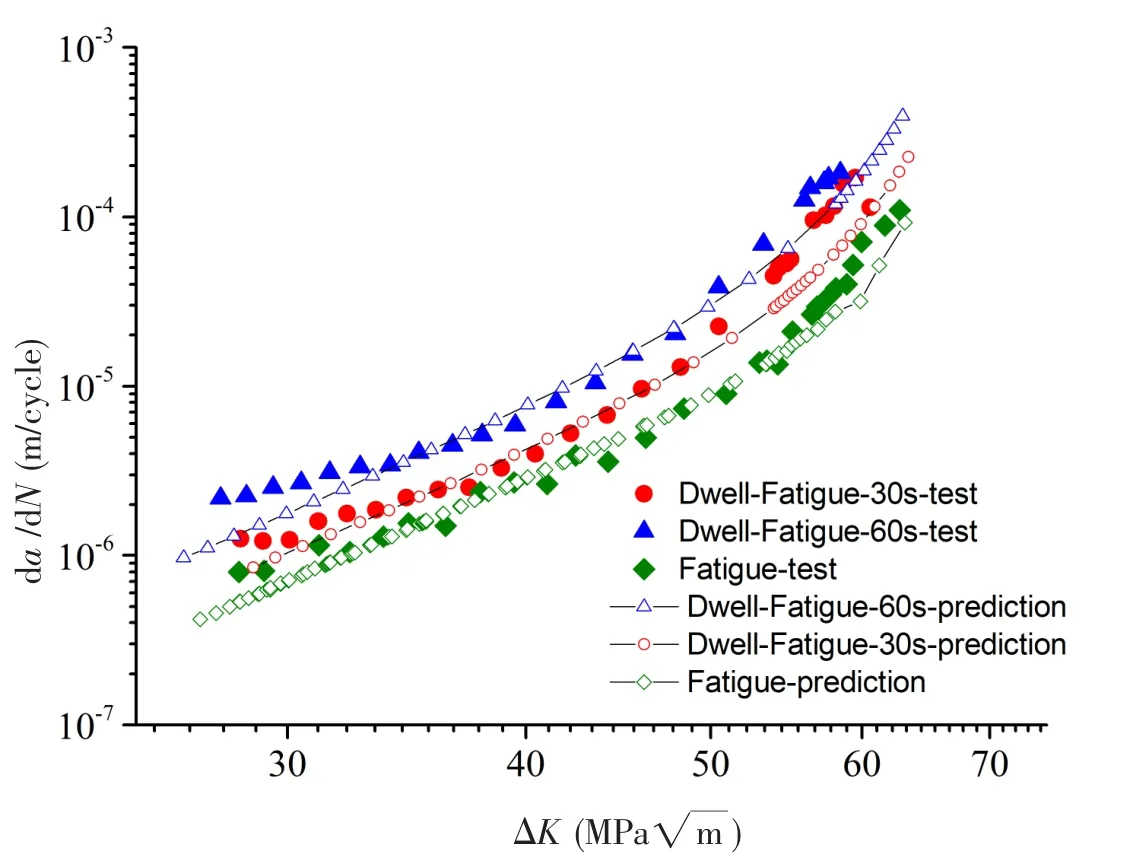

The fatigue crack growth rate test of titanium alloy Ti-6Al-4V under different holding time is predicted by using the dwell-fatigue crack growth rate prediction model mentioned above,and the predicted crack growth rate is compared with the experimental results.The corresponding prediction model parameters[16]are shown in Tab.3.The double logarithmic curves da/dN-ΔK of forecast result and test result based on forecast model,as shown in Fig.7.

Tab.3 Model parameters

Fig.7 Comparison of fatigue and dwell-fatigue crack growth rates of titanium alloy Ti-6Al-4V under different holding times

It can be seen from Fig.7 that the prediction results of Ti-6AL-4V dwell-fatigue of titanium alloy by using the dwell-fatigue crack growth rate prediction model are in good agreement with the corresponding experimental results,and the experimental values are all distributed in the predicted values.With the increase of the stress intensity factor range,the fatigue crack growth rate also increases.When the range of stress intensity factor exceeds 50the prediction results of fatigue crack growth rate are in good agreement with the experimental results.When the stress intensity factor is larger than 50the experimental results are slightly different from the predicted ones.The reason may be that the crack growth rate is in the stage of unstable growth in the middle and late stage of the experiment,and the crack growth rate fluctuates slightly,which leads to a slight deviation from the predicted results.

With the increase of holding time,the dwell-fatigue crack propagation rate of the material increases obviously.The test results and forecast results at 60 s are higher than those when holding time is 30 s.Compared with the results of two groups of dwell-fatigue prediction,the difference between the predicted values of 60 s and 30 s is about 1.5 to 2 times.Under the same stress intensity factor range,the difference between the experimental values of 60 s and 30 s of dwell-fatigue is about 1.7 to 2.5 times.In general,the prediction formula can be used to predict the dwell-fatigue crack growth rate of Ti-6Al-4V.

5 Conclusions

The fatigue problem of pressure-resistant shell structure is a hot topic in recent years.In this paper,the fatigue and dwell-fatigue crack propagation rate of titanium alloy Ti-6Al-4V has been studied experimentally and predicted.The fatigue of titanium alloy Ti-6Al-4V and the holding time of 30 s and 60 s were studied.The data are classified,calculated and analyzed after the test.And the forecasting model was put forward by our research group.The prediction value of the model is compared with the test value.The following conclusions are obtained:

(1)The fatigue and dwell-fatigue of titanium alloy Ti-6Al-4V materials were studied.The holding time of dwell-fatigue was 30 s and 60 s,respectively.According to the experimental results,with the increase of the stress intensity factor range,the fatigue and dwell-fatigue crack growth rate increased in the same trend,and in the region with larger stress intensity factor,the increasing rate of crack growth rate is faster.Fracture occurred at the fracture toughness of 76.5;

(2)The crack propagation rate curves of fatigue and dwell-fatigue were compared and analyzed.It is known that the dwell-fatigue crack growth rate is higher than the fatigue crack growth rate under the same stress intensity factor ΔK,in the whole stress intensity factor range,the dwell-fatigue crack growth rate is about 4-5 times higher than that of fatigue crack growth rate.With the increase of holding time,the crack growth rate increases obviously.The results show that the dwell has a significant effect on the fatigue crack growth rate of titanium alloy Ti-6Al-4V;

(3)Based on the prediction model of dwell-fatigue crack propagation proposed by our group,the dwell-fatigue crack propagation behavior of titanium alloy Ti-6Al-4V was predicted and compared with the experimental results.It is found that with the increase of holding time,the Ti-6Al-4V dwell effect of titanium alloy is obvious.The predicted crack growth rate of titanium alloy Ti-6Al-4V is in good agreement with the experimental data,which indicates that the prediction model has a good ability to predict the dwell-fatigue crack growth behavior of titanium alloy Ti-6Al-4V.Therefore,the dwell-fatigue crack growth rate prediction model proposed in this paper,considering the dwell effect,has a strong ability to predict the crack growth rate of titanium alloy Ti-6Al-4V under dwell-fatigue condition.It provides a theoretical basis for studying the fatigue life prediction of marine structures under cyclic dwell-loading.

- 船舶力學(xué)的其它文章

- Frequency-domain Response Analysis of Adjacent Multiple Floaters with Flexible Connections

- Study on the Hydroelastic Response of Very Large Floating Structures Near Islands and Reefs

- Hydroelasticity of a Barge with Varying Bathymetry

- Study on the Performance of Spherical Tail Bearing based on Finite Element Method

- Dynamic Property and Motion Simulation of Atmospheric Diving Suit

- Investigation on Higher-Order Responses of Vortex-Induced Vibration for a Mounted Cylinder