The properties of fl ax fi ber reinforced wood fl our/high density polyethylene composites

Jingfa Zhang?Haigang Wang?Rongxian Ou?Qingwen Wang,

Introduction

Due to their increasing application,wood-plastic composites(WPC)have received signi fi cant attention from both applied science and industry.WPC is widely utilized in decking,trays,fencing,windows and playground equipment due to several advantages over wood or plastic alone(Jiang and Kamdem 2004;Markarian 2002).However,applications of WPC for structural construction are still restricted due to its weak mechanical performance resulting from the inherent incompatibility between hydrophilic wood and hydrophobic polyole fi n matrix(Wu et al.2014).This in turn results in low impact toughness and creep strain(Lai et al.2003).

In order to enhance the mechanical and physical performance of WPC,different physical processing methods(Rong et al.2001;Ou et al.2014;Ferreira et al.2014),as well as chemical modi fi cations(Wei et al.2013;Bledzki et al.2015;Dong et al.2014)have been utilized to treat wood fl our(Facca et al.2007;Aggarwal et al.2013).However,all current methods have shortcomings,such as complicated operation,high cost,or pollution,constraining their commercial development.Adding reinforcement was always an effective method to improve the mechanical properties of the resulting composites.Hybridization of wood fi ber with high-strength fi bers is suspected to significantly improve the mechanical properties of resulting composites.Reinforcing fi bers,such as carbon fi ber,glass fi ber,basalt fi ber,and synthetic fi ber are widely used(Rahmat and Hubert 2011;Zhao et al.2015;Yuan et al.2013).Adding glass fi ber has been reported to enhance fl exure properties and impact strength of WF/PE composites(Thwe and Liao 2002;Zolfaghari et al.2013;Jiang et al.2003).Incorporation of basalt fi ber produced similar results(Chen et al.2013).The addition of a small amount(2–3%)of Kevlar fi ber has been shown to simultaneously improve the strength and toughness of WF/PE composites(Ou et al.2010).In addition,carbon fi bers have been used in WPC,resulting in signi fi cant improvements of mechanical properties(Zhou et al.2014).However,all of these fi bers are derived from non-renewable resources and all of them are mixed with wood fl our or plastic prior to pelleting.

With increasing environmental consciousness,the use of natural cellulosic- fi ber (NC-Fiber) as reinforcement increased with a special emphasis on the use of hemp.Mechanical properties of different NC-Fibers(hemp,jute,kenaf and paper fi ber)indicate that they have the potential to substitute glass fi ber as a reinforcement in a speci fi c state(Wambua et al.2003;Yang et al.2015).Hemp fi ber has been widely used in a reinforced plastics matrix(Bledzki et al.2015;Corrales et al.2007).Recently,hemp has been added into WPC,resulting in improved tensile properties of wood fl our/kenaf fi ber/polypropylene hybrid composites compared to composites without kenaf fi bers(Mirbagheri et al.2007).

Flax fi ber(FF)is a natural plant fi ber with high strength due to high cellulose content(Zhang and Yu 2003).The global production of FF was 311,000 tons in 2014(Chyxx.com 2016).Most of the FF is usually used in the textile industry.Although the cost of FF is higher than wood- fl our,it is less expensive than the cost of synthetic materials and is increasingly used in WPC.

This study was designed to determine the reinforcing effects of fl ax fi bers( fl ax is widely planted in northeastern China)and the properties of the resulting WPC,while the biomass material content remained the same.Subsequent to mixture extrusion,the fi bers were mixed with the WF/PE particles to lessen the damage to the fi bers.Mechanical properties,dynamic mechanical properties,creep resistance,and rheological behavior of the composites were analyzed.Interfacial adhesion and fl ax features were characterized via scanning electron microscopy.

Materials and methods

Materials

Flax fi bers with an average diameter of 20 μm were commercially obtained and cut into lengths of 5–10 mm.The fl ax is grown in Heilongjiang province,China.HDPE pellets(5000 S)with a density of 0.954 g cm-3and a melt fl ow index of 0.7 g 10 min-1were purchased from Daqing Petrochemical Co.,Daqing,China.Wood fl our(WF)measuring 40–80 mesh wassupplied by the Harbin Yongxu Company.Poplar is used for the wood fl our and is grown in Heilongjiang.Maleic anhydride grafted polyethylene(MAPE)was supplied by the Shanghai Sunny New Technology Development Co.,Ltd.,with a MA grafting ratio of 0.9 wt%and a melt fl ow index of 2 g 10 min-1(190°C).

Sample preparation

In order to avoid fi ber damaging during pelletizing,FF was added into the WF/PE composite subsequent to the twinscrew granulation process.This is different from most previous preparing processes of fi ber reinforced WPC and was as follows:(1)WF and FF were dried at 103°C for 24 h and then stored in a sealed container for later use;(2)WF,HDPE and MAPE were mixed using a speci fi c ratio(Table 1)in a high-speed mixer for a total of 5 min;(3)subsequently transferred to a twin-screw extruder to produce WF/PE pellet particles.The temperature of the extruder ranged from 145 to 170°C,increasing by increments of 5°C,with a rotation speed of 50 rpm;(4)particles and FF were then blended in the high-speed mixer for 20 min and then extruded,resulting in a FF/WF/PE composite sheetwith a cross sectionaldimension of 40 mm×4 mm.The processing temperature for extrusion was 160 °C during the melting period and 170 °C during the die zone.Rotation speed of the single-screw was 20 rpm.

Mechanical tests

Specimens measuring 80 mm×13 mm×4 mm were cut from the FF/WF/PE sheet and tested under three-point bending using a universal mechanical machine with a 50 KN load cell(CMT5504,The MTS(China)Co.,Ltd.),according to ASTM D790-2004.A cross head speed of 2.0 mm min-1was used and fi ve replicates used for each formulation.

Dumbbell-shaped tensile specimens measuring 165 mm×13 mm×4 mm were tested in accordance with ASTM D638-2004 using the same universal mechanical machine.A cross head speed of 5.0 mm min-1and a span length of 50 mm were used.Five parallel samples were tested.

Unnotched charpy impact testing was conducted on standard samples with nominal dimensions of 80 mm×10 mm×4 mm using an impact instrument(CJ5,Chengde Testing Machine Co.,Ltd.China)inaccordance with ISO 179-2000.There were ten parallel samples in each group.

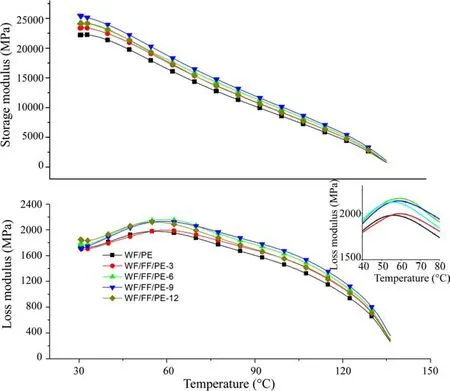

Table 1 Formulations of the composites for extruding

Dynamic mechanical analysis

Dynamic mechanical properties of the composites were analyzed via a dynamic mechanical analyzer(DMA Q800,TA Instruments,New Castle,USA).Tests were performed using the single cantilever strain controlled mode with oscillating amplitude of 50 μm and a frequency of 1 Hz.The temperature ranged from-40 to 130°C at increasing intervals of 3°C min-1.Three specimens with dimensions of 35 mm×12 mm×3 mm were tested.

Creep measurement

The 24 h creep test of the composite sample 100 mm×17 mm×4 mm was performed using a RD-100 electronic creep testing instrument(Changchun Ke Xin Experimental Instrument Co.,Ltd,China)at 23°C.The span was 64 mm and the loading force 30 N(approximately 15% of the maximum load).

Torque rheology

Rheological behavior was evaluated using the Haake torque rheometer(Polylab OS,Thermo Scienti fi c,Germany)equipped with two counter rotating rotors.WF/PE particles and FF were quickly forced into the mixing chamber when the rotors began to rotate.The test was run at 175°C and 50 rpm for a total of 10 min and with a constant degree of fi lling of 70%.Three parallel samples were tested.

Scanning electron microscopy(SEM)

Cryo-fractured surfaces were produced by breaking of the FF/WF/PE composites under liquid nitrogen conditions and subsequent sputter coating with gold.The fractured surfaces were analyzed with a scanning electron microscope(FEI QUNGTA200,USA)at an accelerating voltage of 10 kV.

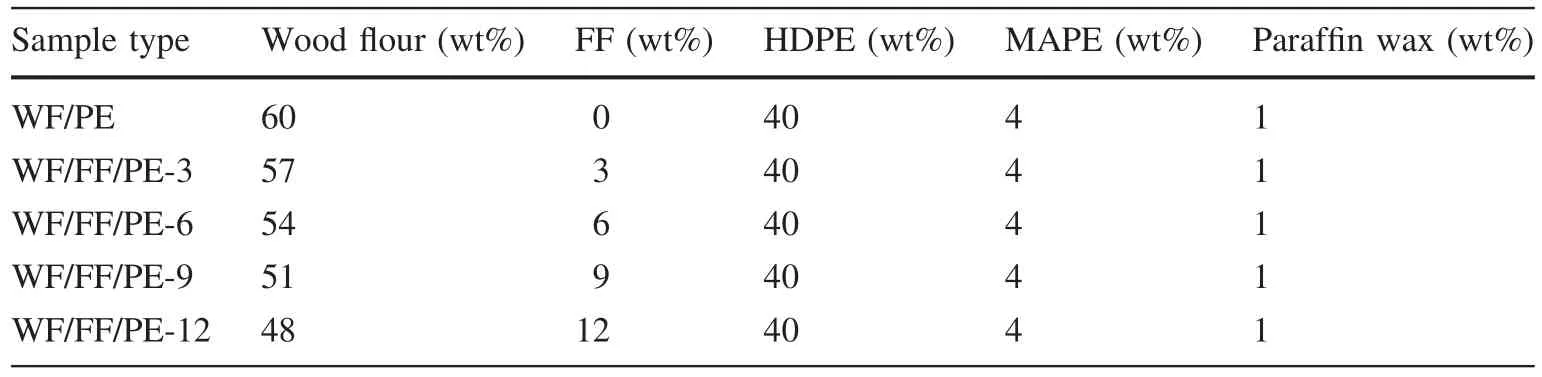

Fig.1 Effects of FF content on fl exure and tensile properties of WF/FF/PE composites:a fl exural strength and modulus,b tensile strength and modulus.The error shows the standard deviation from the average value

Results and discussion

Mechanical properties of composites

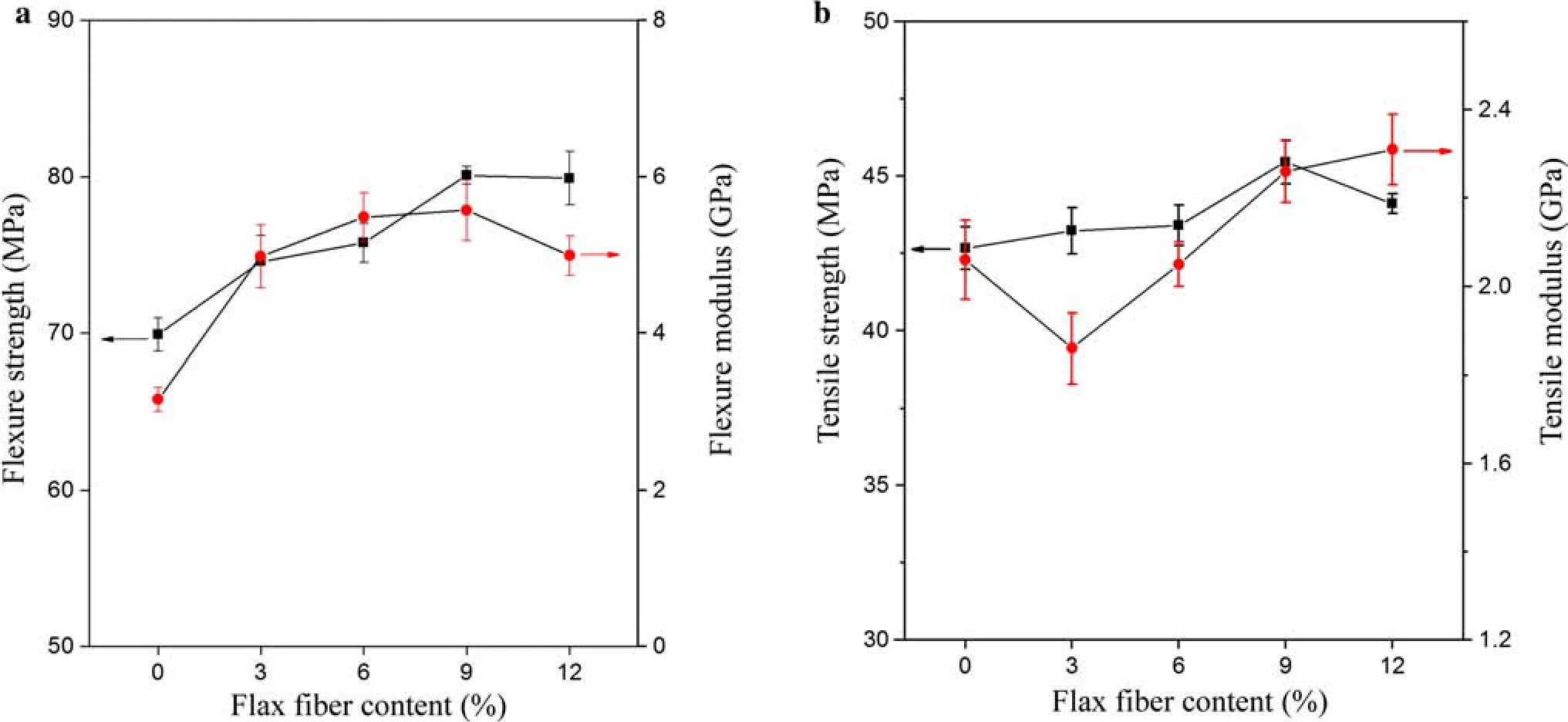

Fig.2 The un-notched impact strength of FF/WF/PE composites.Ten specimens were tested for each FF content.The error bars show the standard deviation from the average value

Compared to WF/PE,the fl exural strength and modulus of WF/FF/PE-9 increased by 14.6 and 51.4%,respectively(Fig.1a).However,the results started to decrease for values above 9%FF content.Numerous small cracks would generate when the composite was subjected to external loads.With increasing force,these cracks extended until the material was damaged.However,FF crosses a crack and prevents further expansion.At material failure,FF bears the majority of the force.With further loading,increasing FF would be pulled out or off,consuming a large amount of energy.Therefore,adding FF into WF/PE composites increases the fl exural strength of WF/FF/PE.The modulus of FF was higher than that of WF(Cao et al.2014),resulting in the improvent of fl exual modulus.In addition,synergistic enhancement of physical interaction among WF,FF and PE was detected,limiting their respective deformation.The interaction hindered polyethylene molecular chain slippage.Consequently,the fl exual strength and modulus improved.However,FF may bunch up with increasing content.This was the reason for decreasing fl exural strength and modulus of FF/WF/PE-12.Increasing the content of fl ax fi ber resulted in an increase in both tensile strength and modulus of the resulting composites of 4.3 and 13.6%,respectively(Fig.1b).Compared to fl exural strength and modulus,the tensile strength showed no obvious changes.This is due to FF being too short to generate suf fi cient interfacial shear strength to bear the force.Most of the FF was arranged along the extrusion direction and therefore,the tensile force would easily extend along the interface.The improvement of tensile performance was suboptimal.

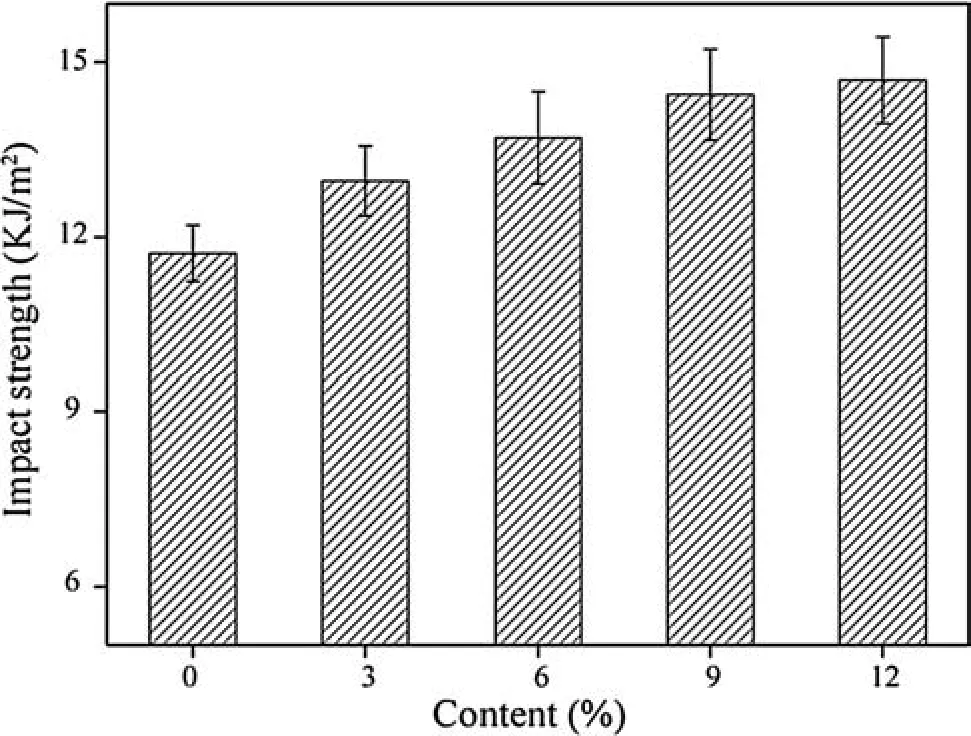

Fig.3 The Storage modulus(G′)and loss modulus(G′)of FF/WF/HDPE composites.The curve was an average of three parallel samples.WF wood fl our;FF fl ax fi ber;PE polyethylene

The unnotched impact strengths of the composites increased considerably when fl ax fi ber was added.The results of the impact strength study are depicted in Fig.2.With fl ax fi ber loading of 12 wt%,an increase of 26.5%in unnotched impact strength was obtained.

The unnotched impact strength of composites is affected by crack initiation and propagation energy.When fl ax fi ber was loaded,the impact strength improved due to the loading being transferred to the FF by the shear forces between FF and the matrix.Therefore,FF bore the impact force until the fi bers were either pulled off or out.At the same time,wood fl our and fl ax fi bers twined with each other.Based on the crazing cut and fi ber crack resistance theory(Jia et al.2007)WPC produces numerous small cracks during early damage due to external forces.FF stretched across the cracks,thus arresting developing cracks.Consequently,adding fl ax fi bersigni fi cantly improved the impact properties of WPC.

Dynamic mechanical analysis

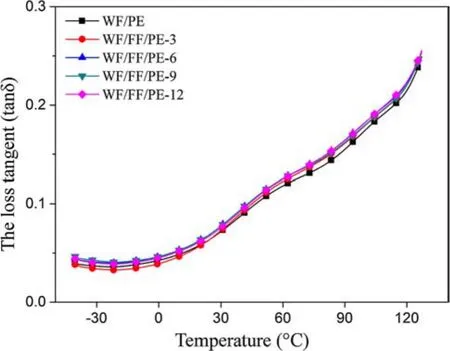

Fig.4 The loss tangent(tanδ)of FF/WF/HDPE composites.WF wood fl our;FF fl ax fi ber;PE polyethylene

The storage modulus of composites increased subsequent to adding FF(Fig.3),echoing the fl exure modulus.The storage modulus of FF/WF/PE composites decreased due to an increase in temperature and converged to a narrow range at high temperatures.The reduction of storage modulus(G′)with the temperature rise was due to matrix softening,and the G′of FF/WF/PE composites initiation of the relaxation process which is the natural character of polymers(Pothan et al.2003).The G′fi rst increased,but then decreased with increasing FF content.There are two reasons for this:on the one hand,the stiffness of FF is higher than that of WF(Cao et al.2014).Therefore,adding FF improves the modulus of composites.On the other hand,FF and WF interact and form a grid-like structure,embedded in the viscoelastic matrix(Huang and Terentjev 2012).However,as FF content increased to 12%,FF reunited,leading to a drop of the G′of FF/WF/PE.The loss modulus of the material is associated with either the viscous response or the dampening effect of the material.Figure 3 shows that the change in loss modulus(G′′)was similar to that of the storage modulus and peaked in the transition region at approximately 60°C.This relaxation peak is known as α-relaxation of HDPE,and is related to a complex multi-relaxation process associated with the molecular motion of the HDPE crystalline region.The temperature of α-relaxation increased with FF loading.However,it dropped back to initial levels when the content of FF was increased to 12 wt%.FF limited the movement of the HDPE molecules due to their three dimensional network structure(Fig.7e).However,the FF bunched up,disturbing the continuity of the matrix at relatively high contents of FF(12 wt%).

Fig.5 Creep resistance behavior of WF/FF/PE composites.WF wood fl our;FF fl ax fi ber;PE polyethylene

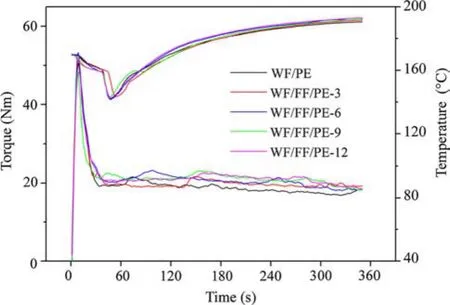

Fig.6 Effects of FF content on the mixing torque of the composites.The curve is an average of two parallel samples.WF wood fl our;FF fl ax fi ber;PE polyethylene

The tanδ,which shows differences in the viscoelastic response of the composite,is a ratio between the loss modulus and the storage modulus.In a low temperature range,the content of FF had an obvious effect on the magnitude of tanδ(Fig.4).With increasing FF content,the FF/WF/PE showed a decreased value of tanδ as compared to WF/PE composites.This indicated that the FF/WF/PE composites had more elastic character than typical curves.

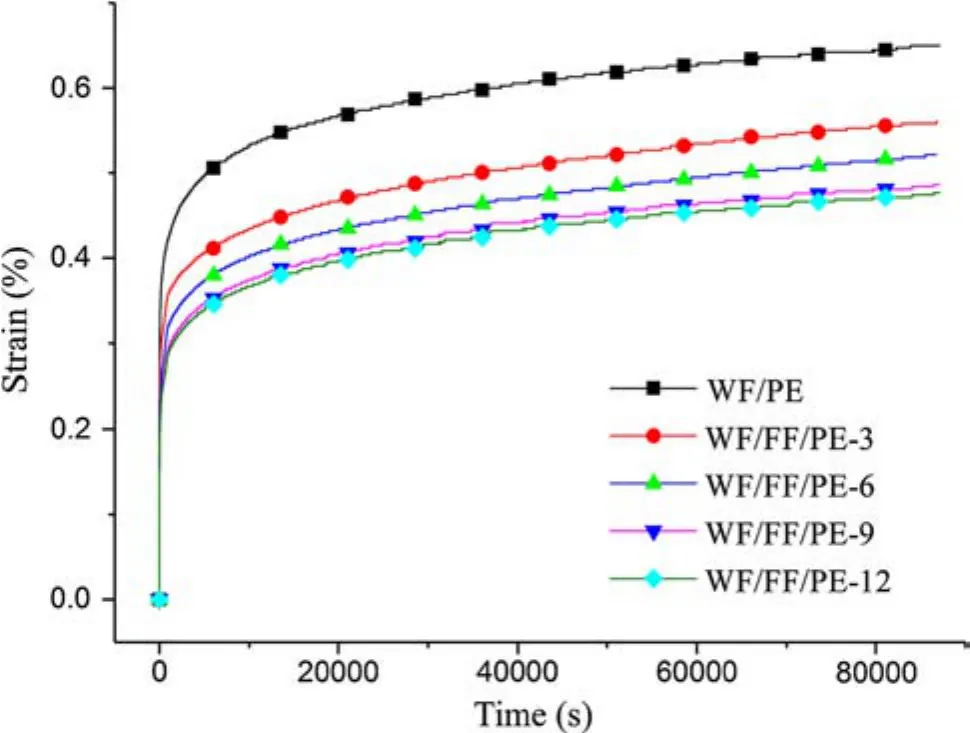

Creep measurement

Adding FF improved creep resistance(Fig.5)and with increasing content,the value gradually decreased.This indicates that a small amount of FF could improve creep resistance and a content of 9%FF was found to be optimal,resulting in effective creep reduction.Further increases of FF content may cause poor dispersion of FF within the matrix,a negative factor for properties such as creep value and tensile strength.Wang et al.(2015)reported that with increasing size of wood fi bers,the creep strain was reduced.This phenomenon was attributed to the large fi ber aspect ratio which can lead to improved creep resistance.Compared to WF,there were more friction forces between FF and plastic due to the larger surface area of a single FF fi ber compared to a WF particle.In addition,the interaction between FF,WF,and HDPE was enhanced with increasing FF content,restraining matrix deformation.

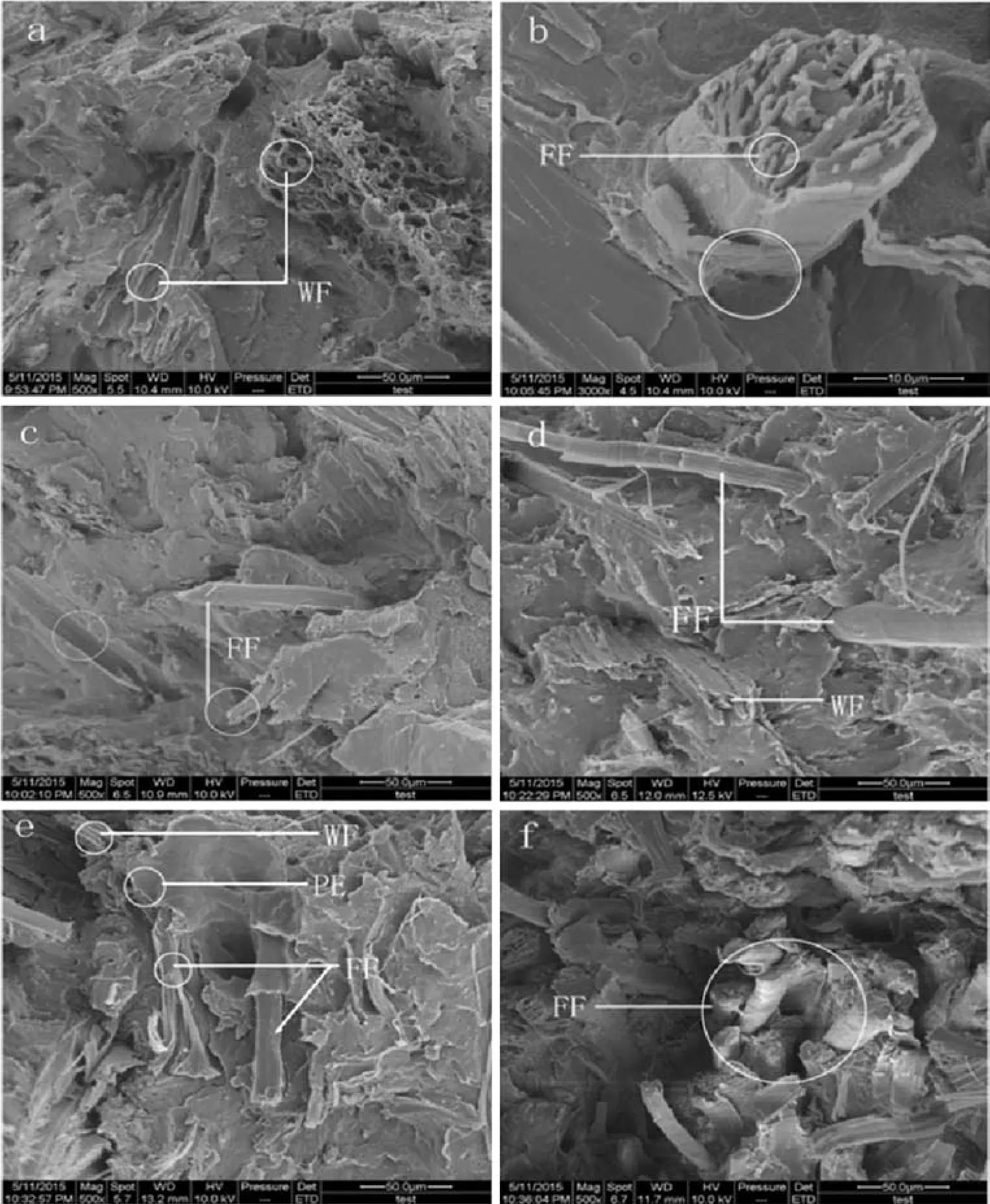

Fig.7 The SEM micrographs of the fractured surfaces of WPCs(a),FF/FF/PE-3(b and c),FF/FF/PE-6(d),FF/FF/PE-9(e),and FF/FF/PE-12(f)

Rheological properties during processing

The balance torque and temperature of the composite melts increased with increasing FF content(Fig.6).This may be attributed to the interaction among FF,WF,and HDPE inhibiting the thermal mobility of the HDPE chains.Moreover,adding FF increased the internal friction of the composites and improved shear heat.This led to a rise in melt temperature.

Micrographic analysis of fracture surface

Most wood particles in the HDPE matrix were well-bonded as a result of coupling.However,the interface was noticeable(Fig.7a).Furthermore,the interface between FF and HDPE was similar to that of the WF/PE composites(Fig.7b).Figure 7c indicates that fi ber pullout was the dominant mode of failure for the WF/FF/PE composites.In a general way,the failure modes of fi ber-reinforced polymers included interface de-bonding, fi ber fracture, fi brillation,and buckling under different test conditions(Yue and Padmanabhab 1999).

With increasing FF content,the complicated con fi guration ofFF becomesincreasingly bene fi cialto the mechanical interlocking among FF,wood- fl our,and the resin matrix forming a three-dimensional network structure(Fig.7e).This can lead to a more ef fi cient stress transfer between the FF and matrix,thereby producing a composite with superior strength and toughness as compared to that of WPCs.Figure 7f shows FF agglomeration present in the composite when the content was as high as 12%.This furtherdestroyed the continuity ofthe matrix and decreased the fl exural and tensile strength(Fig.1).

Conclusions

The incorporation of FF as a reinforcement material plays a vital role in WF/PE composites,improving mechanical properties and dynamic modulus without changing the content of biomass fi bers.This has mainly been attributed to the high strength of the fl ax fi ber and its excellent compatibility with both wood- fl our and HDPE matrix.Adding fl ax fi bers can improve toughness and creep resistance of WPC.However,the processing performance of WF/FF/PE declined.

Aggarwal PK,Chauhan S,Raghu N,Karmarkar S,Shashidhar GM(2013)Mechanical properties of bio- fi bers reinforced high density polyethylene composites:effect of coupling agents and bio- fi llers.J Reinf Plast Compos 32:1722–1732

Bledzki AK,Mamun AA,Jaszkiewicz A,Erdmann K(2015)Polypropylene biocomposites reinforced with softwood,abaca,jute,and kenaf fi bers.Ind Crop Prod 70:91–99

Cao Y,Wang WH,Wang QW(2014)Application of mechanical model for natural fi bre reinforced polymer composites.Mater Res Innov 18:354–357

Chen JX,Wang Y,Gu CL,Liu JX,Liu YF,Li M,Lu Y(2013)Enhancement of the mechanical properties of basalt fi ber-woodplastic composites via maleic anhydride grafted high-density polyethylene(mape)addition.Materials 6:2483–2487

CNII(2016)The analysis of the regional distribution and production of fl ax fi ber and fi ber bundle in the world in 2014,China.http://www.chyxx.com/industry/201602/388177.html

Corrales F,Vilaseca F,Llop M,Girones J,Mendez JA,Mutje P(2007)Chemical modi fi cation of jute fi bers for the production of green-composites.J Hazard Mater 144:730–735

Dong AX,Yu YY,Yuan JG,Wang Q,Fan XR(2014)Hydrophobic modi fi cation of jute fi ber used for composite reinforcement via laccase-mediated grafting.Appl Surf Sci 301:418–427

Facca AG,Kortschot MT,Yan N(2007)Predicting the tensile strength of natural fi bre reinforced thermoplastics.Compos Sci Technol 67:2454–2466

Ferreira MS,Sartori MN,Oliveira RR,Guven O,Moura EA(2014)Short vegetal- fi ber reinforced HDPE—A study of electron-beam radiation treatment effects on mechanical and morphological properties.Appl Surf Sci 310:325–330

Huang YY,Terentjev EM(2012)Dispersion of carbon nanotubes:mixing,sonication,stabilization,and composite properties.Polymers 4:275–295

Jia Z,Jiang B,Cheng GX,Yang XB(2007)Research progress of fi bers reinforced cement based composites.Mater Adminicle 8:65–68

Jiang HH,Kamdem DP(2004)Development of poly(vinyl chloride)/wood composites.A literature review.J Vinyl Addit Technol 10:59–69

Jiang HH,Pascal Kamdem D,Bezubic B,Ruede P(2003)Mechanical properties of poly(vinyl chloride)/wood fl our/glass fi ber hybrid composites.J Vinyl Addit Technol 9:138–145

Lai SM,Yeh FC,Wang Y,Chan HC,Shen HF(2003)Comparative study of maleated polyole fi ns as compatibilizers for polyethylene/wood fl our composites.J Appl Polym Sci 87:487–496

Markarian J(2002)Additive developments aid growth in woodplastic composites.Plast Addit Compd 4:18–21

Mirbagheri J,Tajvidi M,Hermanson JC,Ghasemi I(2007)ensile properties of wood fl our/kenaf fi ber polypropylene hybrid composites.J Appl Polym Sci 105:3054–3059

Ou RX,Zhao H,Sui SJ,Song YM,Wang QW(2010)Reinforcing effects of kevlar fi ber on the mechanical properties of woodfl our/high-density-polyethylene composites.Compos A Appl Sci Manuf 41:1272–1278

Ou RX,Xie YJ,Wang QW,Sui SJ,Wolcott MP(2014)Effects of ionic liquid on the rheological properties of wood fl our/high density polyethylene composites.Compos Part a Appl Sci Manuf 61:134–140

Pothan LA,Oommen Z,Thomas S(2003)Dynamic mechanical analysis of banana fi ber reinforced polyester composites.Compos Sci Technol 63:283–293

Rahmat M,Hubert P(2011)Carbon nanotube–polymer interactions in nanocomposites:a review.Compos Sci Technol 72:72–84

Rong MZ,Zhang MQ,Liu Y,Yang GC,Zeng HM(2001)The effect of fi ber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites.Compos SciTechnol 61:1437–1447

Thwe MM,Liao K(2002)Effects of environmental aging on the mechanical properties of bamboo–glass fi ber reinforced polymer matrix hybrid composites.Compos A Appl Sci Manuf 33:43–52

Wambua P,Ivens J,Verpoest I(2003)Natural fi bres:can they replace glassin fi bre reinforced plastics.ComposSciTechnol 63:1259–1264

Wang WH,Huang HB,Du HH,Wang H(2015)Effects of fi ber size on short-term creep behavior of wood fi ber/HDPE composites.Polym Eng Sci 55:693–700

Wei LQ,McDonald AG,Freitag C,Morrell JJ(2013)Effects of wood fi ber esteri fi cation on properties,weatherability and biodurability of wood plastic composites.Polym Degrad Stab 98:1348–1361

Wu QL,Chi K,Wu YQ,Lee S(2014)Mechanical,thermal expansion,and fl ammability properties of co-extruded wood polymer composites with basalt fi ber reinforced shells.Mater Des 60:334–342

Yang XH,Zhang XQ,Wang WH,Huang HB,Sui SJ(2015)Properties of paper mill sludge–wood fi ber–HDPE composites after exposure to xenon-arc weathering.J For Res 26(2):509–515

Yuan FP,Ou RX,Xi?e YJ,Wang QW(2013)Reinforcing effects of modi fi ed Kevlar fi ber on the mechanical properties of wood fl our/polypropylene composites.J For Res 24:149–153

Yue CY,Padmanabhab K(1999)Interfacial studies on surface modi fi ed kevlar fi bre/epoxy matrix composites.Compos B Eng 30:205–217

Zhang YM,Yu WD(2003)Study on the physical and chemical properties of fl ax fi bers.Plant Fiber Prod 25:130–134

Zhao ZZ,Chen X,Wang X(2015)Deformation behavior of woven glass/epoxy composite substrate under thermo-mechanical loading.Mater Des 82:130–135

Zhou ZF,Xu M,Yang ZZ,Li XX,Shao DW(2014)Effect of maleic anhydride grafted polyethylene on the properties of chopped carbon fi ber/wood plastic composites.J Reinf Plast Compos 33:1216–1225

Zolfaghari A,Behravesh AH,Adli A(2013)Continuous glass fi ber reinforced wood plastic composite in extrusion process:mechanical properties.Mater Des 51:701–708

Journal of Forestry Research2018年2期

Journal of Forestry Research2018年2期

- Journal of Forestry Research的其它文章

- Measurement of lumber moisture content based on PCA and GSSVM

- Characterization of mean stem density, fi bre length and lignin from two Acacia species and their hybrid

- Theoretical modeling of the effects of temperature and moisture content on the acoustic velocity of Pinus resinosa wood

- Risks involved in fecal DNA-based genotyping of microsatellite loci in the Amur tiger Panthera tigris altaica:a pilot study

- Genecological zones and selection criteria for natural forest populations for conservation:the case of Boswellia papyrifera in Ethiopia

- Expansion of traditional land-use and deforestation:a case study of an adat forest in the Kandilo Subwatershed,East Kalimantan,Indonesia