A Pilot-scale Demonstration of Reverse Osmosis Unit for Treatment of Coal-bed Methane Co-produced Water and Its Modeling*

QIAN Zhi (錢智), LIU Xinchun (劉新春), YU Zhisheng (余志晟),**, ZHANG Hongxun (張洪勛) and Jü Yiwen (琚宜文) College of Resources and Environment, Graduate University of Chinese Academy of Sciences, Beijing 00049,China Earth College, Graduate University of Chinese Academy of Sciences, Beijing 00049, China

A Pilot-scale Demonstration of Reverse Osmosis Unit for Treatment of Coal-bed Methane Co-produced Water and Its Modeling*

QIAN Zhi (錢智)1, LIU Xinchun (劉新春)1, YU Zhisheng (余志晟)1,**, ZHANG Hongxun (張洪勛)1and Jü Yiwen (琚宜文)21College of Resources and Environment, Graduate University of Chinese Academy of Sciences, Beijing 100049,China2Earth College, Graduate University of Chinese Academy of Sciences, Beijing 100049, China

This study presents the first demonstration project in China for treatment of coal-bed methane (CBM)co-produced water and recycling. The work aims to provide a research and innovation base for solving the pollution problem of CBM extraction water. The reverse osmosis (RO) unit is applied to the treatment of CBM co-produced water. The results indicate that system operation is stable, the removal efficiency of the total dissolved solids (TDS)is as high as 97.98%, and Fe, Mn, and F?are almost completely removed. There is no suspended solids (SS) detected in the treated water. Furthermore, a model for the RO membrane separation process is developed to describe the quantitative relationship between key physical quantities—membrane length, flow velocity, salt concentration,driving pressure and water recovery rate, and the water recovery restriction equation based on mass balance is developed. This model provides a theoretical support for the RO system design and optimization. The TDS in the CBM co-produced water are removed to meet the “drinking water standards” and “groundwater quality standards”of China and can be used as drinking water, irrigation water, and livestock watering. In addition, the cost for treatment of CBM co-produced water is assessed, and the RO technology is an efficient and cost-effective treatment method to remove pollutants.

coal-bed methane co-produced water, high salt, pretreatment process, mass balance, reverse osmosis

1 INTRODUCTION

With the development of coal-bed methane (CBM)extraction, the treatment of water co-produced in the process is very important. With growing water shortages and rapid development of CBM industry in China, optimal use of the CBM co-produced water can not only resolve the water conflicts between mine areas and adjacent agricultural production zones, but also solve local water shortage problems.

There are abundant CBM resources in China. The CBM is composed mainly of methane, which is a high-quality fuel. Based on the calculation, 1 m3CBM can substitute 1.13 L 93#gasoline [1]. The development process for CBM is generally divided into three phases: exploration, test production and mining. Water is produced from wells in each phase and it generally takes six months or longer to be drained out. It is high-salinity water, and the total dissolved solids(TDS) in CBM co-produced water are generally 1000 mg·L?1or more. The primary concern with CBM co-produced water is the amount of Na+and its influence on the environment. Long-term irrigation of soil with the water may result in deterioration of physical and chemical properties of soil, such as soil infiltration and permeability and aggregate stability, which render soils unsuitable for plant growth and even threaten the safety of local drinking water [2-4]. Therefore, CBM co-produced water must be treated before discharge and cost-effective technologies are needed for the water to be used for beneficial purposes, such as irrigation, livestock or wildlife watering and habitats, and various industrial uses [5-7].

Typically, technologies for treatment of highsalinity water include evaporation, ion exchange, electrodialysis and reverse osmosis [7]. The evaporation method, which is mainly used for seawater desalination, requires massive heat; also, high salinity water will cause fouling on the heat exchanger surface [7].The dissolved salts or minerals can be removed by ion-exchanger, but the pre- and post-treatment are required for high efficiency and the operation of regeneration of resin is complicated [7]. Dallbauman and Sirivedhin employed electrodialysis for treatment of high salinity water co-produced in oil-gas fields, obtaining a TDS removal efficiency of 93.4%-96.5%with a voltage 6.5 V and time of 60 min [8]. However,the membrane module needs frequent cleaning and fluctuations in water quality have a great impact on the effectiveness of the electrodialysis method. High pressure reverse osmosis (RO) processes have been the technology of choice for high-salinity water desalination in the US and many other countries [9, 10].The market share of RO desalination was 43% in 2004 and is forecasted to increase up to 61% in 2015 [11].The advantages of RO include low energy requirements, low operating temperature, small footprint,modular design, and low water production costs. Reverse osmosis with high desalination efficiency, forwhich water quality fluctuations have no negative effect on the treatment effectiveness, is a feasible technology for high-salinity water treatment [12-14].

The CBM co-produced water in Liulin County of Luliang City, Shanxi Province, China, is high-salinity water. In this work, a system with sand filtration (pretreatment) + ultrafiltration (pretreatment) + RO is employed for treatment of CBM production water in Liulin.The effects of treatment process, the system performance and the reuse feasibility are examined according to the output water quality and treatment cost.

Many mass transfer models have been developed for the flux of salt and water through RO membranes[15-19]. Song et al. [16, 17] put forward the conception of thermodynamic equilibrium that restricts the recovery of membrane and provided an alternative way for optimization of membrane design and operation conditions. In this work, based on mass balance principle,mass transfer equations for water and salt are derived,and a model depicting the relationship between salt retention, TDS concentration and water recovery is obtained. The water recovery restriction equation is developed based on mass balance. Furthermore, different operation ways of RO process are discussed and appropiate operating conditions are determined according to the theoretical model.

2 PILOT-SCALE EXPERIMENTAL

2.1 Process

The feed water was CBM field co-produced water from Liulin County of Luliang City, Shanxi Province. A process with sand filtration + UF + RO was utilized for treatment of the water with the capacity of 100 m3·d?1. First, the raw water was aerated to increase dissolved oxygen in water, and then passed through a manganese sand filter, sand filter and bag filter to remove Fe, Mn and suspended solids (SS). The water passed the UF system and then went through a security filter into the RO system. Finally, the output water from RO entered storage tanks. The process flowsheet is shown in Fig. 1, and Fig. 2 shows an on-site picture of the pilot-scale demonstration unit built in this work.

Figure 2 On-site photograph of the pilot-scale demonstration

2.2 Treatment units

2.2.1 Pretreatment

(1) Manganese sand filter

Raw water entered the manganese sand filter through the jet aeration. The manganese sand filter consists of a filter plate, with the upper plate filled with 1-2 mm manganese sand particles, which remove most of the SS, colloids, Fe, Mn and other impurities, and reduces turbidity.

(2) Sand filter

The sand filter is in form of a filter plate. Quartz sands of 0.5-1 mm and 1-2 mm in diameter are loaded from top to bottom within the sand filter, with a filtering accuracy of under 20 μm. The sand filter mainly removes SS and colloids to further reduce turbidity and ensure that the turbidity of the output water is less than 3 NTU.

(3) UF system

An X50 polypropylene hollow fiber ultra-filtration membrane is used in the UF system, with a molecular weight cutoff (MWCO) in the range of 80000-100000(membrane pore size of 0.1-0.25 μm), the treated water turbidity less than 0.3 NTU and silting density index (SDI) less than 4. The system has six sets of membranes arranged in parallel with a single membrane flux of 2-4 m3·h?1and area of 105 m2. The concentrated water from UF is totally recirculated.

2.2.2 RO system

The spiral wound RO membrane is a composite polyamide membrane (BW30-400) with a desalination rate higher than 99.5% for a single membrane, which is 1.016 m long and 0.1016 m in diameter. The height of membrane channel is 1×10?3m and membrane resistance is 8×1010Pa·s·m?1. The RO unit is operated at the pressure around 1.8 MPa. The RO membrane system consists of three membrane modules, with three membrane components arranged in series for each membrane module. Membrane modules are in a 2︰1 arrangement. The first treatment stage is composed of two membrane modules and the concentrated water produced by the first stage enters a second stage with a single membrane module. Concentrated water is generated in the second stage, while pure water generated in the first and second phases enters a storage tank.

2.3 Analysis of water quality

The analysis of water quality is based on the “Drinking Water Standard Test Methods” (GB/T5750-2006),“Underground Water Standards” (GB/T14848-1993)and “Drinking Water Standards” (GB 5749-2006).

3 MODEL FOR RO SYSTEM—BALANCE EQUATIONS FOR CHEMICAL COMPONENTS

Figure 3 Schematic description of filtration channel

The RO system consists of two stages, the first stage containing 2 pressure vessels and the second stage containing 1 pressure vessel. Spiral-wound module is the predominant RO element used in the RO process.Feed water flows along the channel parallel to the central line of the module and an unwound flat sheet membrane with same channel height is employed to represent characteristics of the corresponding spiral-wound RO module as shown in Fig. 3. The following assumptions are made. Firstly, the mixing in the transverse direction of the channel is complete, u(x)is the crossflow velocity and v(x) is the permeate velocity of the membrane. Secondly, the salt retention rate for all membrane elements in the same stage is same, 98.8% for the first stage and 97.5% for the second stage. As shown in Fig. 3, the height of an infinitesimal element is H, the length is dx, and the width is dy.

Applying the mass balance principle to the infinitesimal element of CBM co-produced water on the surface of the membrane shown in Fig. 3, the relation between u(x) and v(x) can be expressed as

The mass balance equation for the water flowing in the membrane can then be obtained

The process from starting running the membrane system to reaching steady state can be described by Eq.(2). For a steady state, the density of water is not a function of time, so Eq. (2) can be simplified to

In addition, the TDS concentration distribution,c(x), along the membrane channel, which is affected by both water and salt transfer across the membrane,is very important for RO. Letting r be the membrane salt retention rate and applying the mass balance principle on the infinitesimal element for salt concentration,the balance equation can be obtained. The balance equation is applied to depict the concentration variation of components in CBM co-produced water along the filtration channel, such as H CO3?, C O32?, Cl?, C a2+,Mg2+and Na+. The attention is mainly focused on the total salt (TDS) concentration in this study.

At steady state, Eq. (4) can be rewritten as

Substituting Eq. (3) into Eq. (4) and integrating, we have

Substituting v(x) = ? H du(x) /dx into Eq. (6) and integrating, a concise relationship between c(x) and u(x)is obtained

If u(x) is known, the TDS concentration at any point in the membrane channel can be calculated. Also, v(x)can be obtained accordingly.

The recovery, R, of a RO process is often used to indicate the performance of the process. R is defined as

With Eqs. (7) and (8), the relation between water recovery rate and TDS concentration is expressed as

This simple equation based on the mass balance principle is applicable for various membranes. This expression combines c, r and R in a concise form. The salt retention rate, r, is a characteristic of the membrane.In other words, once the feed TDS concentration c0is fixed, the variation of water recovery rate is independent of other parameters and can be determined only by the value of c for a certain membrane system.

In order to acquire the velocity of water along the filtration channel, the permeate velocity model [19],based on the membrane transport theory, is introduced

where Δp is the transmembrane pressure, Δπ is the osmotic pressure and Rmis membrane resistance.Owing to the friction between the water flow and the channel wall and spacers in the membrane channel,the transmembrane pressure decreases along the membrane channel. Δp along the channel can be calculated as follows [20]

where Δp0is the initial transmembrane pressure, k is a friction coefficient, and η is the viscosity of the solution.

Empirical relationships are usually employed to determine the osmotic pressure based on a collective measurement of the total amount of salts in the water.The empirical equation of osmotic pressure usually takes the following form

The osmotic coefficient f converts salt concentration to osmotic pressure. According to the calculation,the simulated crossflow velocity and permeate velocity in both stages agree well with the operation data when the value of f is set to 61 Pa·L·mg?1.

With Eqs. (3), (10), (11) and (12), the crossflow velocity distribution along the membrane channel can be described as

Dividing the membrane channel into n segments of equal intervals Δx, if the interval is small enough,Eq. (13) for every interval can be transformed to

where subscript i indicates segment i. Integration of Eq. (14) gives u(x). The Runge-Kutta-Fehlberg method(denoted RKF45) is employed to solve the differential equation with three initial values, ui0, ci0and Δp0.

4 RESULTS AND DISCUSSION

4.1 Chemical analysis of CBM co-produced water

The chemical components of CBM co-produced water are mainly,, Cl?, C a2+, M g2+K+, F?, etc. Hg, Cd, C r6+, As and Zn were not detected. Table 1 shows the water quality of the CBM production water in Liulin. The water from wells No.1, 2 and 3 is produced in the early stage, while that from No. 4 and 5 is produced during the intermediate stage. A single well has water production of 4-10 m3·d?1in the early stage and reaches 20 m3·d?1for normal extraction. These wells are all located in the same mining area, so the water quality is similar for the same stages. It can be seen from Table 1 that the CODMnof CBM co-produced water is low, in the range 0.5-3.6 mg·L?1, which means a low level of organic pollution.However, the water has a higher content of K+, Na+and Cl?in the range of 1613-4782 mg·L?1, which is high salt water.The percentage content of Na K+++is more than 90%. The water quality data of wells No.4 and 5 indicate that the concentrations of K+, Na+and Cl?decrease as mining time increases, but the water still needs further treatment before discharge.and Na+, etc., accompanied by a small amount of

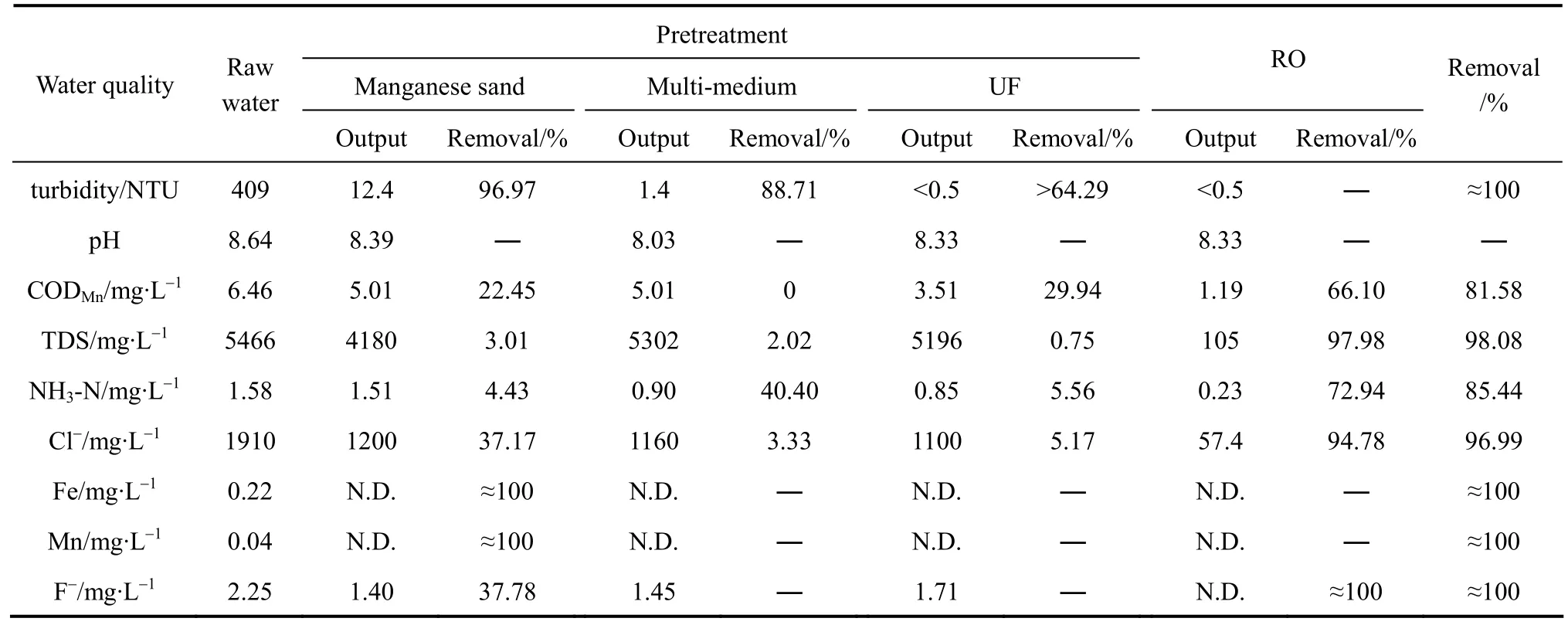

4.2 Process performance

The treatment effect for CBM co-produced water in each processing unit is shown in Table 2. For the pretreatment process, the contaminants in raw water can be removed to some extent by filtration, adsorption and chemical reaction of the manganese sand filter, sand filter and UF process. The CODMnremoval rate is 45.7%, TDS removal is 4.94%, Cl?removal is42.4% and NH3-N removal is 46.2%. The turbidity of output water from the UF is below 0.5 NTU, guaranteeing good water quality into the RO unit. The turbidity removal efficiency of the UF is high, but the salt removal rate is low, because the UF membrane is a porous one and the salt ion, which has a diameter smaller than the MWCO of the UF membranes, can not be retained. The RO membrane is a selective membrane that allows water to pass through only. RO unit can remove various contaminants effectively, especially TDS.

Table 1 Water quality of CBM co-produced water

Table 2 Treatment effects of units in term of water quality index

The RO was the core processing unit and the treatment system could remove most contaminants.The total removal rates for CODMn, NH3-N, Cl?and TDS were 81.0%, 85.4%, 97.7%, and 99.7%, respectively. The water quality meets the “Drinking Water Standards” (GB 5749-2006).

4.3 RO model simulations

4.3.1 Effects of TDS concentration of CBM co-produced water

Equation (7) gives a relationship between salt concentration c and flow velocity of feed water u in the membrane channel. The salt concentration in the concentrated water c increases with the decline of the crossflow velocity. The distribution of salt concentration c along the membrane channel can be obtained if u(x) is known, while the distribution of u along the filtration channel can be obtained if other parameters are given. Eq. (14) uses the segment Δx of membrane channel, the value of ci0for every interval Δx can be obtained from Eq. (7).

Figure 4 The variations of water recovery rate Rwith different initial salt concentration (u0=0.18 m·s?1)initial salt concentration/mg·L?1: 1—1000; 2—2000; 3—5196;4—10000

Converting the crossflow velocity into the water recovery rate using Eq. (8), Eq. (9) can be used to simulate the variation of recovery rate with salt concentration of concentrated water. The results are shown in Fig. 4. The recovery does not always increase sharply in the process and the value of R tails off and approaches a plateau when the salt concentration reaches a certain level. This result dictates that there is a limit to the recovery of the brine with a certain feed salt concentration when treated in RO membrane system, and the higher the feed salt concentration, the lower the recovery rate restriction. The critical point where the limit of recovery rate is approached, which is important for RO system design and operating condition optimization, can be found from Eq. (9) as does in Fig. 4. For example, for CBM co-produced water with a salt concentration of 5196 mg·L?1, R begins to increase extremely slowly when the salt concentration reaches 26000 mg·L?1, which means that a value of R of 79% is the threshold value for feed water with a concentration of 5196 mg·L?1; any attempt to enhance R further will result in a sharp increase in driving pressure or membrane length and is therefore neither cost-effective nor feasible. Thus R of 79% and concentrated water of 26000 mg·L?1can be regarded as the theoretical limits under the condition (with operating parameters normally below these values) when the RO system and operating conditions are being designed.

4.3.2 Effects of membrane length

According to Eq. (13), the flow velocity u(x)along the filtration channel can be simulated. The RO system consists of two stages with the 1st stage containing 2 pressure vessels and 1 vessel for the 2nd stage as shown in Fig. 5. Each pressure vessel consists of 3 composite polyamide membrane elements. With the velocity distribution, the recovery rate can be calculated. It is interesting to note that it is impossible to enhance water recovery endlessly by increasing the length of membrane. In order to clearly describe the relationship between treatment effects and membrane length, the variations of recovery rate with the channel length in the two stages are combined in Fig. 6. Due to the difference in salt concentration, the slope of recovery rate in the 1st stage is higher than that in the 2nd stage. The variations in recovery become marginal when the membrane length exceeds 6 m. The membrane length used in the pilot-scale RO system for this study is 6 m, so a recovery rate of 71.2% can be predicted from the simulation.

Figure 5 The sketch of arrangement of membrane components with two stages

Figure 6 The variation of recovery rate with the length of membrane for two stage operation (u0=0.18 m·s?1, c0 5196 mg·L?1, Δp=1.8 MPa, Rm=8×1010 Pa·s·m?1)

The pilot-scale RO test system, with L13 m in the first stage, L2=3 m in the second stage, u00.18 m·s?1, c0=5196 mg·L?1, and Δp=1.8 MPa, gave a water recovery rate of 70%, which is in good agreement with the predicted value, indicating that the model developed in this study describes the performance of spiral wound RO membrane system.

Figure 7 Arrangement of membrane components in one stage operation

Figure 8 The variation of recovery rate with the length of membrane for one stage operation (u0=0.18 m·s?1,c0 5196 mg·L?1, Δp 1.8 MPa, Rm=8×1010 Pa·s·m?1)

A RO system consisting of one stage with 3 pressure vessels, as shown in Fig. 7, is also simulated,to compare with the two stage operation. With the flow velocity distribution simulated, the water recovery rate can be calculated. The variation of recovery with channel length is shown in Fig. 8, suggesting that the membrane length should not exceed 4 m for the one stage membrane arrangement. According to the calculation, the recovery rate for the one stage operation is 71.2% for L 3 m, u00.18 m·s?1, c0=5196 mg·L?1and Δp 1.8 MPa, which is the same as that with the two stage operation. It can be concluded that both one stage and two stage arrangements are equivalent if there is no the interstage booster pump between 1st stage and 2nd stage in the two stage operation.

4.3.3 Effects of driving pressure

The variation of recovery with driving pressure for the two stage operation is plotted in Fig. 9. The recovery increases with pressure but increase little when the pressure is higher than 1.8 MPa. A recovery rate of 78% can be observed as the restriction to the treatment process under the condition, as shown in Fig. 4. Also,the required working pressure to attain a specified recovery can be determined. Pilot-scale tests were performed under different driving pressures and the results are plotted as symbols in Fig. 9. The theoretical recoveries agree very well with the experimental data.Thus the model of RO system developed in this work is validated and can be used for the design of RO unit.

4.3.4 Effects of membrane resistance

Figure 9 The dependency of water recovery rate on driving pressure in two stage treatment process (u0=0.18 m·s?1,c0=5196 mg·L?1, L=6 m, Rm=8×1010 Pa·s·m?1)predicted value; □ experimental value

Equation (13) can be used to simulate the variation of water recovery with the membrane resistance.The resistance will increase because of membrane fouling, and the water recovery rate will decrease accordingly. However, as shown in Fig. 10, the recovery is unchanged with the increase of resistance until a certain value is reached, which indicates that the recovery is independent of resistance during the initial period of membrane fouling. The reason for this result is the high driving pressure. Fig. 9 shows that the recovery increases little when the pressure exceeds 1.8 MPa. For the driving pressure of 2.0 MPa, these excessive pressures can compensate for the increase of membrane resistance caused by membrane fouling, so the recovery can maintain a certain level until the membrane fouling is severe. The simulation results suggest that a high system driving pressure will result in bad membrane fouling that can not be detected earlier. For avoiding severe membrane fouling, the pressure of 1.8 MPa is appropriate from Fig. 9. Based on the discussion, the RO process will be high efficient and durable at 1.8 MPa pressure and 6 m membrane length, with 70% water recovery under the condition.

Figure 10 The variations of water recovery rate with the membrane resistance in the two stage process (u0 0.18 m·s?1, c0=5196 mg·L?1, Δp=2.0 MPa)

4.4 Feasibility study for treated water reuse

Under the operating condition of 1.8 MPa pressure and 6 m membrane length the quality of the RO system output water meets the “Drinking Water Standards” (GB 5749-2006), so it can be used as domestic water as well as those for local road cleaning, watering plants, etc., in order to be fully utilized.

Table 3 compares the experimental results with water quality standards. Most of the indicators for the treated water meet the national first class standard for underground water, except for chloride and ammonianitrogen. The concentration of chlorine compounds is slightly higher than the national first class standard,and the level of ammonia-nitrogen is slightly higher than the national third class standard, but still meets the drinking water standards. Thus CBM co-produced water can meet domestic drinking water standards after the water treatment process.

Table 3 Quality of output water and comparison with standards

4.5 Operating cost estimation

The operating costs of such a treatment system are shown in Table 4, including electricity bills, chemicalcosts, pharmacy, labor costs and replacement and depreciation charges. The water treatment capacity is 100 m3·d?1and the output water is 70 m3·d?1. The treatment cost for one ton of output water is assessed to be 2.58 CNY. A promising future for civilian use of CBM co-produced water can be expected from the Table 4.

Table 4 Estimated operating costs

5 CONCLUSIONS

CBM fields produce large amount of high salinity water, which can feasibly be treated on a largescale using an RO system. The pilot-scale test results indicate that the RO system runs smoothly and has a good treatment effect for CBM co-produced water.

With a model for the RO membrane separation process developed, the predicted values are in good agreement with experimental values. This model provides a theoretical support for the RO system design and operation condition optimization.

Through the pretreatment and RO system, turbidity,Mn, Fe and F?almost were almost completely removed.CODMnremoval efficiency was 81.6%, while 85.4%for NH3-N, 97.0% for Cl?and 97.6% for TDS. After the treatment, the output water meets the “Drinking Water Standards” (GB 5749-2006) in China, so it can be used for domestic water and thus be fully utilized.

NOMENCLATURE

c concentration of TDS in solution, mg·L?1

H height of membrane channel, m

k friction coefficient

L membrane length, m

Δp transmembrane pressure, Pa

R water recovery rate, %

Rmmembrane resistance, Pa·s·m?1

r salt retention rate, %

t time, s

u crossflow velocity along the membrane channel, m·s?1

v permeate flux along the membrane channel, m·s?1

η viscosity, Pa·s

Δπ osmotic pressure across the membrane, Pa

ρH2Odensity of CBM co-produced water

1 Zhao, W., Guo, Z,G., Niu, W.P., “The exploitation and utilization of coal-bed methane in Jincheng”, Energy Technol. Manage., 5, 125-127(2011).

2 King, L.A., Wheaton, J., Vance, G.F., Ganjegunte, G.K., “Water issues associated with coal-bed methane (natural gas) in the Powder River Basin of Wyoming and Montana”, Reclamation Matters, 2,7-12 (2004).

3 Vance, G.F., King, L.A., Ganjegunte, G.K., “Coal-bed methane co-produced water: management options”, Reflections, June, 31-34(2004).

4 Ganjegunte, G.K., Vance, G.F., King, L.A., “Soil chemical changes resulting from irrigation with water co-produced with coal-bed natural gas”, J. Envi. Quali., 34 (6), 2217-2227 (2005).

5 Vance, G.F., Zhao, H., Ganjegunte, G., Urynowicz, M.A., Gregory,R.W., “Reduction in coal-bed methane (CBM) water sodicity using zeolites”, In: 30 Years of SMCRA and Beyond, American Society of Mining and Reclamation Proceedings, Lexington, KY, 837-844(2007).

6 Veil, J., Puder, M.G., Elcock, D., Redweik, R.J.J., “A white paper describing produced water from production of crude oil, natural gas and coal bed methane”, Argonne National Laboratory, 49-54 (2004).

7 Ahmadun, F.R., Pendashteha, A., “Review of technologies for oil and gas produced water treatment”, J. Haz. Materi., 170, 530-551(2009).

8 Dallbauman, L., Sirivedhin, T., “Reclaiming produced water for beneficial use: salt removal by electrodialysis”, J. Membr. Sci., 243,335-343 (2004).

9 Hyung, H., Kim, J.H., “A mechanistic study on boron rejection by sea water reverse osmosis membranes”, J. Membr. Sci., 286,269-278 (2006).

10 Atkinson, S., “Japan’s largest sea-water desalination plant uses Nitto Denko membranes”, Membr. Technol., 2005 (4), 10-11 (2005).

11 Allison, P., Gasson, C., Intelligence, G.W., “Desalination markets 2005–2015: A global assessment and forecast”, Oxford, UK, Media Analytics (2004).

12 Tao, F.T., Curtice, S., Hobbs, R.D., Sides, J.L., Wieser, J.D., Dyke,C.A., Tuohey, D., Pilger, P.F., “Reverse osmosis process successfully converts oil field brine into freshwater”, Oil Gas J., 91, 88-91(1993).

13 Murray-Gulde, C., Heatley, J.E., Karanfil, T., Rodgers Jr., J.H.,Myers, J.E., “Performance of a hybrid reverse osmosis-constructed wetland treatment system for brackish oil field produced water”,Water Res., 37 (3), 705-713 (2003).

14 Bradley, R., “Pilot testing high efficiency reverse osmosis on gas well produced water”, In: Proceedings of the International Water Conference (61st Annual Meeting), Pittsburg, PA (2000).

15 Oh, H.J., Hwang, T.M., Lee, S., “A simplified simulation model of RO systems for seawater desalination”, Desalination, 238, 128-139(2009).

16 Tay, K.G., Song, L., “A more effective method for fouling characterization in a full-scale reverse osmosis process”, Desalination, 177,95-107 (2005).

17 Song, L., Hu, J.Y., Ong, S.L., Ng, W.J., Elimelech, M., Wilf, M.,“Performance limitation of the full-scale reverse osmosis process”, J.Membr. Sci., 214, 239-244 (2003).

18 A1-Bastaki, N.M., Abbas, A., “Predicting the performance of RO membranes”, Desalination, 132, 181-187 (2000).

19 AI-Bastaki, N.M., Abbas, A., “Modeling an industrial reverse osmosis unit”, Desalination, 126, 33-39 (1999).

20 Bouchard, C.R., Carreau, P.J., Matsuura, T., Sourirajan, S., ‘Modeling of ultrafiltration: predictions of concentration polarization effects”, J. Membr. Sci., 97, 215-229 (1994).

2012-01-06, accepted 2012-02-21.

* Supported by the National Basic Research Program of China (2011ZX05060-005; 2009ZX05039-003), the National Natural Science Foundation of China (21106176), the President Fund of GUCAS (Y15101JY00) and the National Science Foundation for Post-doctoral Scientists of China (20110490627).

** To whom correspondence should be addressed. E-mail: yuzs@gucas.ac.cn

Chinese Journal of Chemical Engineering2012年2期

Chinese Journal of Chemical Engineering2012年2期

- Chinese Journal of Chemical Engineering的其它文章

- Optimization for Production of Intracellular Polysaccharide from Cordyceps ophioglossoides L2 in Submerged Culture and Its Antioxidant Activities in vitro*

- ECT Image Analysis Methods for Shear Zone Measurements during Silo Discharging Process*

- Temperature-triggered Protein Adsorption and Desorption on Temperature-responsive PNIPAAm-grafted-silica: Molecular Dynamics Simulation and Experimental Validation*

- Adsorptive Thermodynamic Properties and Kinetics of trans-1,2-Cyclohexandiol onto AB-8 Resin

- Tracking Submicron Particles in Microchannel Flow by Microscopic Holography*

- Oxidation of p/o-Cresols to p/o-Hydroxybenzaldehydes Catalyzed by Metalloporphyrins with Molecular Oxygen*